How to Optimize GDI Engine Efficiency at High RPM

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Engine Evolution and Efficiency Targets

Gasoline Direct Injection (GDI) technology has evolved significantly since its commercial introduction in the late 1990s. The journey began with first-generation systems focused primarily on fuel economy improvements through stratified charge combustion at part load conditions. These early systems achieved modest efficiency gains but struggled with emissions control and combustion stability at higher engine speeds.

The second evolutionary phase, emerging in the mid-2000s, introduced multi-pulse injection capabilities and improved injector designs that enhanced fuel atomization. This period marked a critical transition as manufacturers began optimizing GDI systems specifically for performance applications, recognizing the technology's potential beyond mere fuel economy.

By the 2010s, GDI technology entered its third evolutionary phase with sophisticated electronic control systems, advanced injector designs featuring multiple orifices, and integration with other technologies such as variable valve timing and turbocharging. This combination unlocked significant performance potential while maintaining efficiency advantages, particularly in downsized turbocharged applications.

Current state-of-the-art GDI systems represent the fourth evolutionary phase, featuring ultra-high pressure injection (exceeding 350 bar), precision-engineered spray patterns, and intelligent combustion management systems. These advancements have progressively addressed historical challenges of GDI operation at high RPM, including fuel atomization quality, mixture homogeneity, and combustion stability.

The efficiency targets for modern GDI engines operating at high RPM focus on several key metrics. Primary among these is thermal efficiency, with current production engines achieving peak values of 38-41% and research targets pushing toward 45% through optimized combustion chamber design and reduced heat rejection. Volumetric efficiency targets exceed 95% at high RPM through advanced intake design and variable valve timing systems.

Specific fuel consumption reduction targets at high RPM operation (above 5000 RPM) aim for 8-12% improvement compared to port fuel injection systems, while maintaining power density advantages of 10-15%. Emissions compliance remains a critical target, with particular focus on particulate matter reduction at high-load, high-RPM operation without compromising performance.

The technology roadmap projects continued advancement toward 400+ bar injection pressures, further refinement of spray patterns for high-speed operation, and integration with electrification technologies. The ultimate goal is to achieve robust, clean combustion at engine speeds exceeding 7500 RPM while maintaining thermal efficiency values within 90% of peak efficiency points, representing a significant challenge that drives current research and development efforts.

The second evolutionary phase, emerging in the mid-2000s, introduced multi-pulse injection capabilities and improved injector designs that enhanced fuel atomization. This period marked a critical transition as manufacturers began optimizing GDI systems specifically for performance applications, recognizing the technology's potential beyond mere fuel economy.

By the 2010s, GDI technology entered its third evolutionary phase with sophisticated electronic control systems, advanced injector designs featuring multiple orifices, and integration with other technologies such as variable valve timing and turbocharging. This combination unlocked significant performance potential while maintaining efficiency advantages, particularly in downsized turbocharged applications.

Current state-of-the-art GDI systems represent the fourth evolutionary phase, featuring ultra-high pressure injection (exceeding 350 bar), precision-engineered spray patterns, and intelligent combustion management systems. These advancements have progressively addressed historical challenges of GDI operation at high RPM, including fuel atomization quality, mixture homogeneity, and combustion stability.

The efficiency targets for modern GDI engines operating at high RPM focus on several key metrics. Primary among these is thermal efficiency, with current production engines achieving peak values of 38-41% and research targets pushing toward 45% through optimized combustion chamber design and reduced heat rejection. Volumetric efficiency targets exceed 95% at high RPM through advanced intake design and variable valve timing systems.

Specific fuel consumption reduction targets at high RPM operation (above 5000 RPM) aim for 8-12% improvement compared to port fuel injection systems, while maintaining power density advantages of 10-15%. Emissions compliance remains a critical target, with particular focus on particulate matter reduction at high-load, high-RPM operation without compromising performance.

The technology roadmap projects continued advancement toward 400+ bar injection pressures, further refinement of spray patterns for high-speed operation, and integration with electrification technologies. The ultimate goal is to achieve robust, clean combustion at engine speeds exceeding 7500 RPM while maintaining thermal efficiency values within 90% of peak efficiency points, representing a significant challenge that drives current research and development efforts.

Market Demand for High-RPM Efficient Engines

The global automotive market is witnessing a significant shift towards high-performance engines with optimized efficiency at high RPM ranges. This trend is driven by multiple factors, including stricter emission regulations, consumer demand for better fuel economy without sacrificing performance, and the competitive nature of the automotive industry. The market for high-RPM efficient engines has grown substantially over the past decade, with particular emphasis on GDI (Gasoline Direct Injection) technology.

Consumer preferences have evolved considerably, with a growing segment of buyers seeking vehicles that deliver both exhilarating performance and reasonable fuel economy. This dual demand has created a robust market for engines that can maintain efficiency even when operating at high RPM ranges. Sports cars, performance sedans, and even some SUVs now feature engines designed to operate efficiently at elevated RPMs, expanding the potential market for this technology.

Regulatory pressures represent another major market driver. Governments worldwide have implemented increasingly stringent emissions standards and fuel economy requirements. The European Union's Euro 7 standards, the United States' Corporate Average Fuel Economy (CAFE) regulations, and China's dual-credit policy all push manufacturers to develop engines that can deliver more power while consuming less fuel and producing fewer emissions.

Racing and motorsport applications continue to serve as both a development platform and a marketing showcase for high-RPM efficient engines. Technologies developed for Formula 1, WRC, and other racing series often trickle down to production vehicles, creating consumer awareness and demand for similar performance characteristics in everyday vehicles.

The premium and luxury vehicle segments represent the largest current market for high-RPM efficient engines. Brands like BMW, Mercedes-Benz, Audi, and Porsche have invested heavily in GDI technology that maintains efficiency at high RPMs. However, the technology is gradually penetrating mid-range vehicle segments as production costs decrease and consumer expectations rise.

Market research indicates that the global market for high-performance, fuel-efficient engines is expected to grow at a compound annual growth rate of 5.8% through 2028. GDI engines specifically are projected to account for over 50% of all gasoline engines produced globally by 2025, representing a substantial market opportunity for optimized high-RPM solutions.

Regional variations in market demand are notable, with North American and European consumers showing stronger preference for high-performance characteristics, while Asian markets often prioritize fuel efficiency. However, the convergence of these demands is creating a global market for engines that excel in both areas, particularly at high RPM operation where traditional engines typically suffer efficiency losses.

Consumer preferences have evolved considerably, with a growing segment of buyers seeking vehicles that deliver both exhilarating performance and reasonable fuel economy. This dual demand has created a robust market for engines that can maintain efficiency even when operating at high RPM ranges. Sports cars, performance sedans, and even some SUVs now feature engines designed to operate efficiently at elevated RPMs, expanding the potential market for this technology.

Regulatory pressures represent another major market driver. Governments worldwide have implemented increasingly stringent emissions standards and fuel economy requirements. The European Union's Euro 7 standards, the United States' Corporate Average Fuel Economy (CAFE) regulations, and China's dual-credit policy all push manufacturers to develop engines that can deliver more power while consuming less fuel and producing fewer emissions.

Racing and motorsport applications continue to serve as both a development platform and a marketing showcase for high-RPM efficient engines. Technologies developed for Formula 1, WRC, and other racing series often trickle down to production vehicles, creating consumer awareness and demand for similar performance characteristics in everyday vehicles.

The premium and luxury vehicle segments represent the largest current market for high-RPM efficient engines. Brands like BMW, Mercedes-Benz, Audi, and Porsche have invested heavily in GDI technology that maintains efficiency at high RPMs. However, the technology is gradually penetrating mid-range vehicle segments as production costs decrease and consumer expectations rise.

Market research indicates that the global market for high-performance, fuel-efficient engines is expected to grow at a compound annual growth rate of 5.8% through 2028. GDI engines specifically are projected to account for over 50% of all gasoline engines produced globally by 2025, representing a substantial market opportunity for optimized high-RPM solutions.

Regional variations in market demand are notable, with North American and European consumers showing stronger preference for high-performance characteristics, while Asian markets often prioritize fuel efficiency. However, the convergence of these demands is creating a global market for engines that excel in both areas, particularly at high RPM operation where traditional engines typically suffer efficiency losses.

High-RPM GDI Challenges and Limitations

Gasoline Direct Injection (GDI) engines face significant challenges when operating at high RPM ranges, primarily due to the reduced time window available for fuel injection and combustion processes. At engine speeds exceeding 5,000 RPM, the injection-to-combustion window can shrink to less than 10 milliseconds, creating a fundamental timing constraint that affects multiple engine systems.

The fuel delivery system encounters substantial limitations at high RPM. Conventional GDI injectors struggle to maintain precise spray patterns and atomization quality when injection duration is compressed. This often results in incomplete atomization, leading to uneven air-fuel mixtures and potential wall wetting issues where fuel adheres to cylinder walls rather than vaporizing properly.

Combustion stability becomes increasingly problematic as RPM increases. The shortened time available for mixture formation means that achieving homogeneous charge distribution becomes exceptionally difficult. This creates localized rich and lean zones within the combustion chamber, contributing to increased cycle-to-cycle variations and combustion instability that manifests as power fluctuations and reduced thermal efficiency.

Thermal management presents another critical challenge. High-RPM operation generates significantly more heat, particularly around injector tips and valve seats. Excessive thermal loading can lead to carbon deposit formation on injectors, altering spray patterns and reducing volumetric efficiency over time. These deposits are particularly problematic in GDI systems compared to port injection alternatives.

Mechanical limitations also become apparent at elevated engine speeds. Valve train dynamics, including valve float and harmonics, can disrupt the precisely timed injection events necessary for optimal GDI performance. Additionally, increased mechanical friction at high RPM directly counteracts efficiency gains, creating a diminishing returns scenario where power increases come at a disproportionate fuel economy cost.

Emissions control represents a substantial challenge at high RPM operation. The less-than-ideal combustion conditions often lead to increased particulate matter formation, a known weakness of GDI systems. NOx emissions also tend to spike due to higher combustion temperatures, creating a difficult emissions compliance scenario without additional aftertreatment systems.

From a control systems perspective, the ECU faces significant computational challenges when managing high-speed operation. The processing demands for real-time adjustment of injection timing, duration, and pressure increase exponentially with engine speed. Many production ECUs lack the processing power to implement truly optimal fuel strategies at the upper RPM range, instead defaulting to more conservative maps that prioritize reliability over maximum efficiency.

The fuel delivery system encounters substantial limitations at high RPM. Conventional GDI injectors struggle to maintain precise spray patterns and atomization quality when injection duration is compressed. This often results in incomplete atomization, leading to uneven air-fuel mixtures and potential wall wetting issues where fuel adheres to cylinder walls rather than vaporizing properly.

Combustion stability becomes increasingly problematic as RPM increases. The shortened time available for mixture formation means that achieving homogeneous charge distribution becomes exceptionally difficult. This creates localized rich and lean zones within the combustion chamber, contributing to increased cycle-to-cycle variations and combustion instability that manifests as power fluctuations and reduced thermal efficiency.

Thermal management presents another critical challenge. High-RPM operation generates significantly more heat, particularly around injector tips and valve seats. Excessive thermal loading can lead to carbon deposit formation on injectors, altering spray patterns and reducing volumetric efficiency over time. These deposits are particularly problematic in GDI systems compared to port injection alternatives.

Mechanical limitations also become apparent at elevated engine speeds. Valve train dynamics, including valve float and harmonics, can disrupt the precisely timed injection events necessary for optimal GDI performance. Additionally, increased mechanical friction at high RPM directly counteracts efficiency gains, creating a diminishing returns scenario where power increases come at a disproportionate fuel economy cost.

Emissions control represents a substantial challenge at high RPM operation. The less-than-ideal combustion conditions often lead to increased particulate matter formation, a known weakness of GDI systems. NOx emissions also tend to spike due to higher combustion temperatures, creating a difficult emissions compliance scenario without additional aftertreatment systems.

From a control systems perspective, the ECU faces significant computational challenges when managing high-speed operation. The processing demands for real-time adjustment of injection timing, duration, and pressure increase exponentially with engine speed. Many production ECUs lack the processing power to implement truly optimal fuel strategies at the upper RPM range, instead defaulting to more conservative maps that prioritize reliability over maximum efficiency.

Current High-RPM Optimization Techniques

01 Fuel injection optimization for GDI engines

Optimizing fuel injection parameters in Gasoline Direct Injection (GDI) engines can significantly improve efficiency. This includes precise control of injection timing, pressure, and spray pattern to ensure optimal air-fuel mixture formation. Advanced injection strategies such as multiple injections per cycle and variable injection pressure systems help reduce fuel consumption while maintaining or improving power output.- Fuel injection optimization for GDI engines: Gasoline Direct Injection (GDI) engine efficiency can be improved through optimized fuel injection strategies. This includes precise control of injection timing, pressure, and spray patterns to ensure optimal air-fuel mixture formation. Advanced injection systems can deliver multiple injections per cycle, allowing for better combustion control and reduced emissions while improving thermal efficiency. These optimization techniques help achieve more complete combustion and better fuel utilization.

- Combustion chamber design improvements: Innovative combustion chamber designs significantly impact GDI engine efficiency. Optimized piston crown shapes, cylinder head configurations, and valve positioning can enhance air-fuel mixing and combustion dynamics. These design improvements promote better flame propagation, reduce knocking tendencies, and minimize heat losses. Advanced combustion chamber geometries also help in creating controlled turbulence that improves fuel atomization and combustion stability across various engine operating conditions.

- Thermal management systems for efficiency: Effective thermal management systems play a crucial role in enhancing GDI engine efficiency. These systems regulate engine temperature to optimize combustion conditions and reduce friction losses. Advanced cooling strategies, including split cooling circuits, precision temperature control, and heat recovery systems, help maintain ideal operating temperatures. Improved thermal management also enables faster warm-up periods, reduces cold-start emissions, and extends engine component lifespan while contributing to overall fuel economy improvements.

- Variable valve timing and lift technologies: Variable valve timing and lift technologies significantly enhance GDI engine efficiency by optimizing air intake and exhaust flow across different operating conditions. These systems allow for precise control of valve events, enabling better volumetric efficiency, reduced pumping losses, and improved combustion stability. Advanced valve control mechanisms can implement strategies like Atkinson cycle operation at part loads while switching to conventional cycles for full power, providing flexibility that maximizes efficiency throughout the engine's operating range.

- Integration of turbocharging with GDI systems: Combining turbocharging technology with GDI systems creates synergistic efficiency benefits. This integration enables engine downsizing while maintaining or improving power output, resulting in reduced friction losses and weight. Turbocharging increases air density in the combustion chamber, allowing for more efficient fuel utilization and better thermal efficiency. Advanced control strategies for these combined systems can mitigate traditional turbocharging challenges like lag and heat management, while maximizing the benefits of direct injection for improved overall engine performance.

02 Combustion chamber design improvements

Innovative combustion chamber designs enhance GDI engine efficiency by optimizing air-fuel mixture distribution and flame propagation. These designs include modified piston crown shapes, optimized intake port configurations, and strategic placement of the injector and spark plug. Such improvements promote better combustion stability, reduced knock tendency, and more complete fuel burning, resulting in higher thermal efficiency.Expand Specific Solutions03 Advanced thermal management systems

Thermal management systems specifically designed for GDI engines help maintain optimal operating temperatures, reducing friction losses and improving combustion efficiency. These systems include variable coolant flow control, strategic cooling channel placement, exhaust heat recovery mechanisms, and thermal barrier coatings. Effective thermal management ensures faster warm-up times and prevents overheating during high-load conditions.Expand Specific Solutions04 Integration of turbocharging and downsizing

Combining GDI technology with turbocharging and engine downsizing creates significant efficiency gains. This approach allows smaller displacement engines to deliver equivalent power to larger engines while consuming less fuel. Advanced turbocharger designs with reduced lag, variable geometry, and electric assistance complement GDI systems by ensuring optimal air supply across the entire operating range, enhancing both efficiency and performance.Expand Specific Solutions05 Electronic control and monitoring systems

Sophisticated electronic control systems optimize GDI engine operation through real-time monitoring and adjustment of multiple parameters. These systems employ advanced sensors, predictive algorithms, and adaptive control strategies to continuously fine-tune combustion processes. Machine learning and artificial intelligence technologies enable the engine to adapt to changing conditions, driver behavior, and fuel quality variations, maximizing efficiency across all operating conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The GDI (Gasoline Direct Injection) engine efficiency optimization at high RPM market is currently in a growth phase, with increasing demand for fuel-efficient, high-performance engines. The global market size for GDI technology is expanding rapidly, projected to reach significant volumes as emission regulations tighten worldwide. Leading automotive manufacturers like Ford, Mercedes-Benz, and Hyundai-Kia have achieved varying levels of technical maturity in this space. Research institutions such as MIT and Southwest Research Institute are advancing fundamental innovations, while specialized companies like Tula Technology focus on software-based optimization solutions. Oil companies including ExxonMobil, Chevron, and Lubrizol are developing complementary fuel and lubricant technologies to enhance GDI performance. The competitive landscape shows a mix of established OEMs and emerging technology providers collaborating to overcome challenges like carbon deposits and thermal management at high engine speeds.

Ford Global Technologies LLC

Technical Solution: Ford has developed advanced dual-injection systems that combine port and direct injection to optimize fuel delivery at high RPM. Their EcoBoost technology incorporates variable cam timing, advanced turbocharging, and precise electronic control systems to maintain optimal air-fuel ratios during high-speed operation. Ford's latest GDI engines feature redesigned intake ports with enhanced tumble and swirl characteristics to improve fuel atomization and combustion efficiency at elevated engine speeds. They've also implemented innovative cooling strategies targeting the cylinder head and piston crown to prevent knock and allow higher compression ratios even at high RPM operation. Ford's proprietary combustion chamber designs minimize surface-to-volume ratios and strategically position fuel injectors to optimize spray patterns specifically for high-speed operation conditions.

Strengths: Exceptional balance between performance and efficiency through dual-injection technology; advanced thermal management systems effectively control temperatures at high RPM; sophisticated electronic control systems provide precise adaptation to changing conditions. Weaknesses: Higher system complexity increases manufacturing costs; requires premium fuel for optimal high-RPM performance; potential carbon buildup issues in some implementations requiring additional maintenance.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has pioneered the Continuously Variable Valve Duration (CVVD) technology specifically to address GDI efficiency at high RPM. This innovative system independently controls valve opening duration, allowing the engine to optimize both power and efficiency across all operating conditions. At high RPM, the CVVD system can reduce the valve opening duration to improve combustion stability while maintaining optimal intake charge. Hyundai's SmartStream engines incorporate high-pressure direct injection (up to 350 bar) with multi-hole injectors strategically positioned for optimal spray patterns during high-speed operation. Their integrated thermal management system features split cooling circuits that can independently control cylinder head and block temperatures, crucial for maintaining efficiency at elevated RPM. Additionally, Hyundai has implemented advanced piston designs with cooling galleries and thermal barrier coatings to manage combustion temperatures and reduce knock tendency at high engine speeds.

Strengths: CVVD technology provides unprecedented control over valve events specifically optimized for different RPM ranges; integrated thermal management system effectively controls temperatures under high-load conditions; advanced electronic control unit provides sophisticated adaptive strategies. Weaknesses: Higher manufacturing complexity and cost compared to conventional systems; requires more sophisticated maintenance procedures; potential reliability concerns with the complex valve control mechanisms over extended vehicle life.

Key Patents in GDI High-RPM Performance

Gasoline Direct Injection Engine

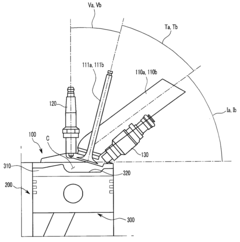

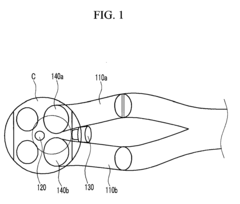

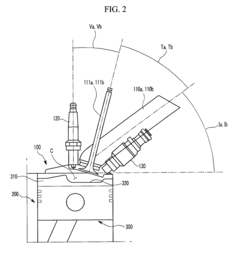

PatentInactiveUS20100108013A1

Innovation

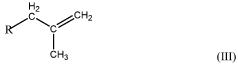

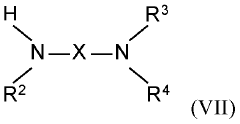

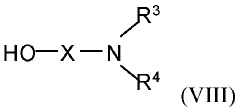

- The engine design includes specific angle configurations between the piston, intake manifold, intake valve, and injector, such as acute valve, tumble, and incidence angles, along with a cavity on the piston to optimize fuel and air mixing, reducing interference and promoting effective tumble and swirl generation.

Fuel additives and formulations for improving performance of gasoline direct injection engines

PatentWO2022140533A1

Innovation

- A novel fuel additive composition comprising an acylated detergent, a Mannich detergent, and a polyether/polyetheramine, which reduces carbonaceous deposits in both PFI and GDI engines by preventing or removing deposits, thereby improving engine performance and reducing emissions.

Emissions Regulations Impact on GDI Development

Emissions regulations have become a primary driver for Gasoline Direct Injection (GDI) engine development, creating both challenges and opportunities for high-RPM efficiency optimization. The global regulatory landscape has evolved significantly over the past decade, with Euro 7, China 6b, and US Tier 3 standards imposing increasingly stringent limits on particulate matter (PM), NOx, and CO2 emissions. These regulations have fundamentally altered the design parameters and optimization strategies for GDI engines.

The introduction of Real Driving Emissions (RDE) testing protocols has particularly impacted high-RPM efficiency considerations, as manufacturers must now ensure compliance across the entire operating range rather than just optimizing for standardized test cycles. This has necessitated more sophisticated combustion control strategies and after-treatment systems capable of maintaining efficiency during high-load, high-RPM operation.

Particulate number (PN) limits have become especially challenging for GDI engines at high RPM, where fuel atomization and mixing time are compromised by reduced cycle duration. The regulatory focus on particulates has driven innovations in injector design, with multi-hole injectors operating at pressures exceeding 350 bar becoming standard to achieve the finer atomization necessary for reduced particulate formation during high-speed operation.

CO2 fleet targets have simultaneously pushed manufacturers toward downsized, turbocharged GDI engines that operate at higher specific loads. This trend creates a technical contradiction: the need to extract maximum power density while maintaining thermal efficiency and emissions compliance at elevated RPM ranges. The regulatory pressure has accelerated the adoption of variable valve timing, cooled EGR, and integrated exhaust manifolds as standard features rather than premium options.

Regional regulatory differences have created additional complexity in GDI optimization strategies. European standards emphasize CO2 reduction, while US regulations maintain stricter NOx limits, and Asian markets increasingly focus on particulate emissions in urban environments. This has led to region-specific calibration strategies for high-RPM operation, complicating global platform development.

Looking forward, upcoming regulations are expected to further tighten emissions limits while introducing lifecycle carbon assessments. This regulatory trajectory suggests that future GDI optimization efforts must increasingly consider the entire emissions profile across all operating conditions, with particular attention to transient operation and cold-start emissions even at high engine speeds. The regulatory push toward electrification also means that GDI engines must be optimized for hybrid applications, where high-RPM efficiency becomes critical during high-power demand scenarios.

The introduction of Real Driving Emissions (RDE) testing protocols has particularly impacted high-RPM efficiency considerations, as manufacturers must now ensure compliance across the entire operating range rather than just optimizing for standardized test cycles. This has necessitated more sophisticated combustion control strategies and after-treatment systems capable of maintaining efficiency during high-load, high-RPM operation.

Particulate number (PN) limits have become especially challenging for GDI engines at high RPM, where fuel atomization and mixing time are compromised by reduced cycle duration. The regulatory focus on particulates has driven innovations in injector design, with multi-hole injectors operating at pressures exceeding 350 bar becoming standard to achieve the finer atomization necessary for reduced particulate formation during high-speed operation.

CO2 fleet targets have simultaneously pushed manufacturers toward downsized, turbocharged GDI engines that operate at higher specific loads. This trend creates a technical contradiction: the need to extract maximum power density while maintaining thermal efficiency and emissions compliance at elevated RPM ranges. The regulatory pressure has accelerated the adoption of variable valve timing, cooled EGR, and integrated exhaust manifolds as standard features rather than premium options.

Regional regulatory differences have created additional complexity in GDI optimization strategies. European standards emphasize CO2 reduction, while US regulations maintain stricter NOx limits, and Asian markets increasingly focus on particulate emissions in urban environments. This has led to region-specific calibration strategies for high-RPM operation, complicating global platform development.

Looking forward, upcoming regulations are expected to further tighten emissions limits while introducing lifecycle carbon assessments. This regulatory trajectory suggests that future GDI optimization efforts must increasingly consider the entire emissions profile across all operating conditions, with particular attention to transient operation and cold-start emissions even at high engine speeds. The regulatory push toward electrification also means that GDI engines must be optimized for hybrid applications, where high-RPM efficiency becomes critical during high-power demand scenarios.

Materials Science Advancements for GDI Components

Materials science innovations have become a critical frontier in advancing GDI (Gasoline Direct Injection) engine performance at high RPM operations. Recent developments in coating technologies have yielded significant improvements in component durability and efficiency. Diamond-like carbon (DLC) coatings applied to fuel injectors have demonstrated superior wear resistance while maintaining precise spray patterns even under extreme thermal conditions experienced at high engine speeds. These coatings reduce carbon buildup on injector tips, ensuring consistent atomization quality throughout the engine's operational lifetime.

Ceramic thermal barrier coatings represent another breakthrough, particularly for combustion chamber components. When applied to piston crowns and cylinder heads, these materials can withstand temperatures exceeding 2000°C while providing thermal insulation properties that reduce heat rejection to the cooling system. This thermal management capability becomes increasingly valuable at high RPM when combustion temperatures peak, allowing for more efficient energy conversion and reduced cooling system demands.

Advanced nickel-silicon alloys have emerged as superior materials for high-pressure fuel pumps in GDI systems. These alloys exhibit exceptional resistance to cavitation damage—a phenomenon that intensifies at elevated engine speeds due to increased fuel flow rates. Research indicates that pumps manufactured with these materials maintain volumetric efficiency above 95% even after 5,000 hours of operation under high-load conditions, compared to conventional materials that show degradation after 3,000 hours.

Nano-composite materials incorporating silicon carbide particles within aluminum matrices have revolutionized piston design for high-performance GDI engines. These materials offer a 30% improvement in thermal conductivity while maintaining mechanical strength at elevated temperatures. The enhanced thermal properties enable more aggressive ignition timing strategies at high RPM without risking pre-ignition or knock, directly contributing to efficiency gains of 2-3% in the upper RPM range.

Surface texturing technologies, particularly laser-etched micropatterns on cylinder walls, have demonstrated remarkable friction reduction properties. These precisely engineered surface topographies create optimized oil retention patterns that maintain lubrication film integrity even under the increased lateral forces experienced during high-RPM operation. Testing has shown friction coefficient reductions of up to 15% compared to conventional honing patterns, translating to measurable power gains and efficiency improvements specifically in the upper RPM ranges where frictional losses typically escalate.

Ceramic thermal barrier coatings represent another breakthrough, particularly for combustion chamber components. When applied to piston crowns and cylinder heads, these materials can withstand temperatures exceeding 2000°C while providing thermal insulation properties that reduce heat rejection to the cooling system. This thermal management capability becomes increasingly valuable at high RPM when combustion temperatures peak, allowing for more efficient energy conversion and reduced cooling system demands.

Advanced nickel-silicon alloys have emerged as superior materials for high-pressure fuel pumps in GDI systems. These alloys exhibit exceptional resistance to cavitation damage—a phenomenon that intensifies at elevated engine speeds due to increased fuel flow rates. Research indicates that pumps manufactured with these materials maintain volumetric efficiency above 95% even after 5,000 hours of operation under high-load conditions, compared to conventional materials that show degradation after 3,000 hours.

Nano-composite materials incorporating silicon carbide particles within aluminum matrices have revolutionized piston design for high-performance GDI engines. These materials offer a 30% improvement in thermal conductivity while maintaining mechanical strength at elevated temperatures. The enhanced thermal properties enable more aggressive ignition timing strategies at high RPM without risking pre-ignition or knock, directly contributing to efficiency gains of 2-3% in the upper RPM range.

Surface texturing technologies, particularly laser-etched micropatterns on cylinder walls, have demonstrated remarkable friction reduction properties. These precisely engineered surface topographies create optimized oil retention patterns that maintain lubrication film integrity even under the increased lateral forces experienced during high-RPM operation. Testing has shown friction coefficient reductions of up to 15% compared to conventional honing patterns, translating to measurable power gains and efficiency improvements specifically in the upper RPM ranges where frictional losses typically escalate.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!