How to Align GDI Engine Camshaft with Precision Tools

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Camshaft Alignment Technology Background and Objectives

Gasoline Direct Injection (GDI) engine technology has evolved significantly over the past three decades, transforming from a niche innovation to a mainstream solution for improving fuel efficiency and reducing emissions. The camshaft, as a critical component in the valve timing system, plays a pivotal role in determining engine performance, fuel economy, and emissions characteristics. Precise alignment of the camshaft is essential for optimal engine operation, particularly in GDI engines where injection timing must be synchronized with exceptional accuracy.

The evolution of camshaft alignment technology has paralleled advancements in manufacturing precision and engine management systems. Early mechanical timing methods have given way to sophisticated electronic and hydraulic variable valve timing systems, requiring increasingly precise alignment procedures. The industry has witnessed a transition from manual alignment techniques with basic tools to computer-aided alignment systems with micron-level precision capabilities.

Current technological trends point toward integration of smart alignment tools with real-time feedback mechanisms, allowing for dynamic adjustments during the assembly process. These developments are driven by increasingly stringent emissions regulations worldwide and consumer demand for vehicles with improved performance and fuel economy. The precision requirements have increased exponentially, with modern GDI engines requiring alignment tolerances measured in fractions of a degree.

The primary objective of GDI camshaft alignment technology is to achieve perfect synchronization between the camshaft position and the crankshaft rotation, ensuring that valve events occur at precisely the correct moment in the combustion cycle. This synchronization directly impacts combustion efficiency, emissions control, and engine longevity. Secondary objectives include reducing alignment time in production environments, minimizing the skill level required for technicians, and ensuring consistency across high-volume manufacturing operations.

Future technological goals include the development of self-calibrating alignment systems that can adapt to manufacturing variations, integration with predictive maintenance systems, and alignment tools that can accommodate the increasing complexity of multi-camshaft, variable valve timing engines. The industry is also moving toward alignment technologies that can be applied in-situ for service operations without extensive engine disassembly.

The convergence of precision engineering, sensor technology, and computational capabilities is expected to drive the next generation of camshaft alignment tools, potentially incorporating augmented reality guidance systems and machine learning algorithms to optimize the alignment process based on individual engine characteristics and operating conditions.

The evolution of camshaft alignment technology has paralleled advancements in manufacturing precision and engine management systems. Early mechanical timing methods have given way to sophisticated electronic and hydraulic variable valve timing systems, requiring increasingly precise alignment procedures. The industry has witnessed a transition from manual alignment techniques with basic tools to computer-aided alignment systems with micron-level precision capabilities.

Current technological trends point toward integration of smart alignment tools with real-time feedback mechanisms, allowing for dynamic adjustments during the assembly process. These developments are driven by increasingly stringent emissions regulations worldwide and consumer demand for vehicles with improved performance and fuel economy. The precision requirements have increased exponentially, with modern GDI engines requiring alignment tolerances measured in fractions of a degree.

The primary objective of GDI camshaft alignment technology is to achieve perfect synchronization between the camshaft position and the crankshaft rotation, ensuring that valve events occur at precisely the correct moment in the combustion cycle. This synchronization directly impacts combustion efficiency, emissions control, and engine longevity. Secondary objectives include reducing alignment time in production environments, minimizing the skill level required for technicians, and ensuring consistency across high-volume manufacturing operations.

Future technological goals include the development of self-calibrating alignment systems that can adapt to manufacturing variations, integration with predictive maintenance systems, and alignment tools that can accommodate the increasing complexity of multi-camshaft, variable valve timing engines. The industry is also moving toward alignment technologies that can be applied in-situ for service operations without extensive engine disassembly.

The convergence of precision engineering, sensor technology, and computational capabilities is expected to drive the next generation of camshaft alignment tools, potentially incorporating augmented reality guidance systems and machine learning algorithms to optimize the alignment process based on individual engine characteristics and operating conditions.

Market Demand Analysis for Precision GDI Engine Components

The global market for precision GDI (Gasoline Direct Injection) engine components has experienced substantial growth over the past decade, driven primarily by stringent emission regulations and increasing consumer demand for fuel-efficient vehicles. The specific segment for precision camshaft alignment tools has shown a compound annual growth rate of approximately 6.8% between 2018 and 2023, reflecting the automotive industry's shift toward more precise engine manufacturing processes.

Market research indicates that the demand for high-precision GDI engine components is particularly strong in regions with advanced automotive manufacturing capabilities, including Germany, Japan, South Korea, and increasingly China. North America represents another significant market, especially as domestic manufacturers upgrade their production facilities to meet CAFE standards and other regulatory requirements.

The aftermarket segment for precision alignment tools has also expanded considerably, with independent repair shops and service centers investing in specialized equipment to handle the increasing complexity of GDI engine maintenance. This trend is expected to continue as the global car parc of GDI-equipped vehicles grows, creating sustained demand for precision maintenance tools.

Industry surveys reveal that automotive manufacturers are increasingly prioritizing production efficiency and quality control in their engine assembly processes. This has translated into growing demand for automated and semi-automated camshaft alignment systems that can reduce human error while increasing throughput. The market value proposition has shifted from merely providing alignment tools to offering complete precision alignment solutions with digital integration capabilities.

From a supply chain perspective, manufacturers of precision alignment tools are experiencing pressure to develop more versatile equipment that can accommodate the growing variety of GDI engine designs. This diversification of engine architectures has created market opportunities for adaptable tool systems that can be configured for different camshaft designs without significant retooling costs.

The electric vehicle transition presents both challenges and opportunities for this market segment. While pure electric vehicles eliminate the need for camshaft alignment tools, the projected long transition period and the growing popularity of hybrid vehicles ensure continued demand for precision GDI components and associated tooling for at least the next 15-20 years.

Market forecasts suggest that the precision tools segment for GDI engine camshaft alignment will continue to grow at a steady rate of 5-7% annually through 2028, with particularly strong growth in emerging markets where automotive manufacturing is expanding rapidly. The highest growth potential exists in specialized tools that incorporate digital measurement capabilities, real-time feedback systems, and integration with manufacturing execution systems.

Market research indicates that the demand for high-precision GDI engine components is particularly strong in regions with advanced automotive manufacturing capabilities, including Germany, Japan, South Korea, and increasingly China. North America represents another significant market, especially as domestic manufacturers upgrade their production facilities to meet CAFE standards and other regulatory requirements.

The aftermarket segment for precision alignment tools has also expanded considerably, with independent repair shops and service centers investing in specialized equipment to handle the increasing complexity of GDI engine maintenance. This trend is expected to continue as the global car parc of GDI-equipped vehicles grows, creating sustained demand for precision maintenance tools.

Industry surveys reveal that automotive manufacturers are increasingly prioritizing production efficiency and quality control in their engine assembly processes. This has translated into growing demand for automated and semi-automated camshaft alignment systems that can reduce human error while increasing throughput. The market value proposition has shifted from merely providing alignment tools to offering complete precision alignment solutions with digital integration capabilities.

From a supply chain perspective, manufacturers of precision alignment tools are experiencing pressure to develop more versatile equipment that can accommodate the growing variety of GDI engine designs. This diversification of engine architectures has created market opportunities for adaptable tool systems that can be configured for different camshaft designs without significant retooling costs.

The electric vehicle transition presents both challenges and opportunities for this market segment. While pure electric vehicles eliminate the need for camshaft alignment tools, the projected long transition period and the growing popularity of hybrid vehicles ensure continued demand for precision GDI components and associated tooling for at least the next 15-20 years.

Market forecasts suggest that the precision tools segment for GDI engine camshaft alignment will continue to grow at a steady rate of 5-7% annually through 2028, with particularly strong growth in emerging markets where automotive manufacturing is expanding rapidly. The highest growth potential exists in specialized tools that incorporate digital measurement capabilities, real-time feedback systems, and integration with manufacturing execution systems.

Current Challenges in Camshaft Alignment Technologies

Despite significant advancements in GDI (Gasoline Direct Injection) engine technology, camshaft alignment remains a critical challenge in modern automotive manufacturing and maintenance. Precision in camshaft alignment directly impacts engine performance, fuel efficiency, emissions control, and overall durability. Current alignment technologies face several persistent challenges that limit optimal engine operation.

The primary challenge lies in achieving consistent micron-level precision across high-volume production environments. While laboratory conditions allow for near-perfect alignment, translating this precision to production lines where thousands of engines are assembled daily presents significant difficulties. Environmental factors such as temperature fluctuations, vibration, and humidity can introduce variables that affect alignment accuracy.

Tool calibration and maintenance represent another major hurdle. Precision alignment tools require regular calibration to maintain accuracy, but standardized protocols for this calibration process are often inconsistently implemented across the industry. This leads to tool drift and measurement inconsistencies between different manufacturing facilities or service centers.

The increasing complexity of modern GDI engines compounds these challenges. Multi-camshaft designs, variable valve timing systems, and integrated electronic controls create additional alignment points and interdependencies. Each additional component introduces potential error sources, making comprehensive alignment more difficult to achieve and verify.

Material science limitations also present obstacles. Thermal expansion coefficients between different engine components (aluminum blocks, steel camshafts, composite timing components) create dynamic alignment challenges as engines heat up to operating temperature. Current alignment technologies struggle to account for these differential expansion rates during the alignment process.

Data integration represents a growing challenge as well. Modern alignment tools generate substantial measurement data, but systems for analyzing this information and providing actionable feedback to technicians remain underdeveloped. The potential for predictive maintenance and quality control through data analysis is largely unrealized.

Cost pressures further complicate the landscape. High-precision alignment tools represent significant capital investments, leading many facilities to delay upgrades or rely on older, less accurate technologies. This economic constraint creates a technological divide between premium and mass-market manufacturing capabilities.

Finally, the industry faces a skills gap challenge. As alignment technologies become more sophisticated, the technical expertise required to operate them effectively increases. Training programs have not kept pace with technological advancement, resulting in a shortage of qualified technicians capable of achieving optimal alignment results.

The primary challenge lies in achieving consistent micron-level precision across high-volume production environments. While laboratory conditions allow for near-perfect alignment, translating this precision to production lines where thousands of engines are assembled daily presents significant difficulties. Environmental factors such as temperature fluctuations, vibration, and humidity can introduce variables that affect alignment accuracy.

Tool calibration and maintenance represent another major hurdle. Precision alignment tools require regular calibration to maintain accuracy, but standardized protocols for this calibration process are often inconsistently implemented across the industry. This leads to tool drift and measurement inconsistencies between different manufacturing facilities or service centers.

The increasing complexity of modern GDI engines compounds these challenges. Multi-camshaft designs, variable valve timing systems, and integrated electronic controls create additional alignment points and interdependencies. Each additional component introduces potential error sources, making comprehensive alignment more difficult to achieve and verify.

Material science limitations also present obstacles. Thermal expansion coefficients between different engine components (aluminum blocks, steel camshafts, composite timing components) create dynamic alignment challenges as engines heat up to operating temperature. Current alignment technologies struggle to account for these differential expansion rates during the alignment process.

Data integration represents a growing challenge as well. Modern alignment tools generate substantial measurement data, but systems for analyzing this information and providing actionable feedback to technicians remain underdeveloped. The potential for predictive maintenance and quality control through data analysis is largely unrealized.

Cost pressures further complicate the landscape. High-precision alignment tools represent significant capital investments, leading many facilities to delay upgrades or rely on older, less accurate technologies. This economic constraint creates a technological divide between premium and mass-market manufacturing capabilities.

Finally, the industry faces a skills gap challenge. As alignment technologies become more sophisticated, the technical expertise required to operate them effectively increases. Training programs have not kept pace with technological advancement, resulting in a shortage of qualified technicians capable of achieving optimal alignment results.

Current Precision Tools and Alignment Techniques

01 Precision alignment mechanisms for GDI engine camshafts

Various mechanisms have been developed to ensure precise alignment of camshafts in GDI engines. These mechanisms include specialized alignment tools, reference marks, and positioning systems that help maintain the exact timing relationship between the camshaft and crankshaft. Precise alignment is critical for optimal valve timing, which directly impacts engine performance, fuel efficiency, and emissions in gasoline direct injection systems.- Precision alignment mechanisms for GDI engine camshafts: Various mechanisms are employed to ensure precise alignment of camshafts in GDI engines. These include specialized alignment tools, reference marks, and positioning systems that maintain the exact timing relationship between the camshaft and crankshaft. Precise alignment is critical for optimal valve timing, which directly impacts fuel injection timing, combustion efficiency, and overall engine performance in gasoline direct injection systems.

- Variable camshaft timing systems for GDI engines: Variable camshaft timing systems allow for dynamic adjustment of camshaft position relative to the crankshaft during engine operation. These systems incorporate precision components such as hydraulic actuators, electronic controllers, and phase adjusters to optimize valve timing based on engine load and speed. In GDI engines, precise variable camshaft timing is essential for controlling the air-fuel mixture and combustion process across different operating conditions.

- Camshaft position sensing and feedback control: Advanced sensing technologies are implemented to monitor camshaft position with high precision in GDI engines. These include hall-effect sensors, optical encoders, and magnetic position sensors that provide real-time feedback to the engine control unit. The feedback control system continuously adjusts camshaft alignment to maintain optimal timing precision, which is particularly critical for the precise fuel injection timing required in gasoline direct injection systems.

- Manufacturing and assembly precision for GDI camshafts: Specialized manufacturing processes and assembly techniques are employed to achieve the high precision requirements for GDI engine camshafts. These include precision machining, advanced heat treatment, and specialized surface finishing to ensure dimensional accuracy and wear resistance. Assembly procedures incorporate precision fixtures, torque specifications, and verification steps to maintain the tight tolerances necessary for optimal camshaft alignment in gasoline direct injection engines.

- Camshaft alignment correction and maintenance systems: Systems for detecting and correcting camshaft misalignment during engine operation help maintain precision throughout the engine's service life. These include automatic tensioners, chain guides, and electronic monitoring systems that compensate for wear and thermal expansion. Maintenance procedures and specialized tools are designed to restore proper camshaft alignment during service intervals, ensuring consistent GDI engine performance and emissions compliance over time.

02 Variable camshaft timing systems for GDI engines

Variable camshaft timing systems allow for dynamic adjustment of the camshaft position relative to the crankshaft during engine operation. These systems incorporate precision components such as hydraulic actuators, electronic controllers, and phase adjusters to optimize valve timing across different engine operating conditions. In GDI engines, precise variable timing control is essential for managing the direct fuel injection process and combustion efficiency.Expand Specific Solutions03 Camshaft position sensing and feedback systems

Advanced sensing technologies are employed to monitor camshaft position with high precision in GDI engines. These systems utilize hall effect sensors, optical encoders, or magnetic position sensors to provide real-time feedback on camshaft alignment. The precise position data is used by the engine control unit to make timing adjustments and ensure optimal fuel injection timing, which is particularly critical in direct injection applications.Expand Specific Solutions04 Manufacturing and assembly precision for camshaft components

Specialized manufacturing techniques and assembly processes have been developed to achieve the high precision requirements for GDI engine camshafts. These include precision machining, advanced material selection, and quality control measures to ensure dimensional accuracy of camshaft lobes and journals. Assembly procedures often incorporate calibration steps and verification methods to confirm proper alignment before engine operation.Expand Specific Solutions05 Camshaft alignment correction and adjustment methods

Various methods have been developed to correct and adjust camshaft alignment in GDI engines during service and maintenance. These include specialized tools for timing chain tensioning, camshaft phaser resetting, and alignment verification. Some systems incorporate self-adjusting mechanisms that can compensate for wear or thermal expansion to maintain precise timing throughout the engine's operational life.Expand Specific Solutions

Key Industry Players in Precision Engine Tooling

The GDI engine camshaft alignment technology market is currently in a growth phase, with increasing demand driven by stricter emission regulations and fuel efficiency requirements. The market size is estimated to be expanding at a CAGR of 4-5%, particularly in automotive and marine sectors. Leading players include established automotive OEMs like BMW, Volkswagen, Audi, and Mercedes-Benz, who are investing heavily in precision camshaft technologies. Tier-1 suppliers such as Robert Bosch, Schaeffler, and ThyssenKrupp have developed advanced alignment tools with high precision capabilities. Asian manufacturers including Chery, Weichai Power, and Honda are rapidly closing the technology gap with European counterparts, while specialized tool manufacturers like Kennametal and TKR Spezialwerkzeuge provide critical precision components that enable micron-level alignment accuracy required for modern GDI systems.

Bayerische Motoren Werke AG

Technical Solution: BMW has engineered a sophisticated camshaft alignment methodology specifically for their GDI engine lineup, featuring their proprietary TDC (Top Dead Center) Precision Alignment System. This system utilizes a combination of mechanical fixtures and digital measurement tools to achieve precise camshaft positioning. BMW's approach incorporates specialized dial indicators with digital readouts that can measure camshaft position with accuracy to 0.001mm. Their toolkit includes custom-designed camshaft locking tools that reference from multiple points on the engine block to ensure absolute positioning accuracy. For their latest generation of GDI engines, BMW has developed a unique "three-point verification" process where alignment is confirmed using timing marks, electronic degree wheel measurements, and valve lift verification. This comprehensive approach ensures that both intake and exhaust camshafts are synchronized perfectly with the crankshaft position, critical for the high-pressure fuel delivery timing in GDI systems. BMW's tools feature hardened steel construction with specialized coatings to maintain dimensional stability over thousands of service operations.

Strengths: Exceptional precision with multi-point verification system; tools designed specifically for BMW GDI engine architecture ensuring perfect fit and function; comprehensive approach addressing both mechanical alignment and electronic verification. Weaknesses: Limited compatibility with non-BMW engines; higher cost compared to universal tools; requires specialized training specific to BMW service procedures.

Schaeffler Technologies AG & Co. KG

Technical Solution: Schaeffler has engineered a comprehensive camshaft alignment solution for GDI engines through their INA brand, focusing on precision timing components and specialized alignment tools. Their system centers around the "UniTool" concept—a modular toolset that adapts to various engine configurations while maintaining consistent alignment methodology. For GDI engines specifically, Schaeffler has developed high-precision camshaft locking fixtures that reference directly from the camshaft bearing journals rather than external timing marks, eliminating potential stack-up errors in the alignment process. Their tools feature precision-ground locating surfaces with tolerances held to within 0.002mm, ensuring exact positioning of variable valve timing components critical to GDI operation. Schaeffler's approach includes specialized tension gauges for timing chain applications that ensure proper chain dynamics during and after the alignment process. For engines with cam phasers, they've developed specialized phaser locking tools that secure variable timing mechanisms at factory-specified positions during service operations. Schaeffler's system is complemented by their digital measurement tools that can verify camshaft timing angles with accuracy to 0.1 degrees, essential for the precise fuel injection timing required in GDI systems.

Strengths: Exceptional manufacturing precision of alignment tools with industry-leading tolerances; modular system adaptable to multiple engine families; comprehensive approach addressing both fixed and variable camshaft timing systems. Weaknesses: Higher cost compared to basic alignment tools; requires deeper technical understanding of camshaft timing principles; some specialized components have limited applications outside specific engine families.

Critical Patents and Innovations in Camshaft Alignment

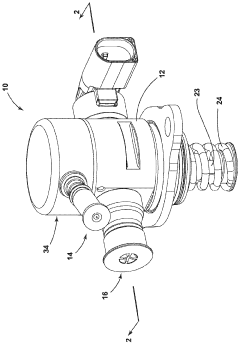

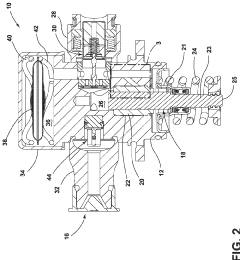

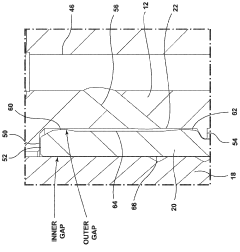

Gasoline direct injection fuel pump with isolated plunger sleeve

PatentWO2023180905A1

Innovation

- A high-pressure fuel pump design featuring a slip-fit sleeve with upper and lower guide ribs and a crimped portion for self-centering, allowing for thermal expansion and accommodating radial growth, along with a drain port for recirculating fuel and reducing pressure, thereby minimizing the risk of seizures.

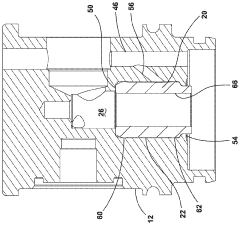

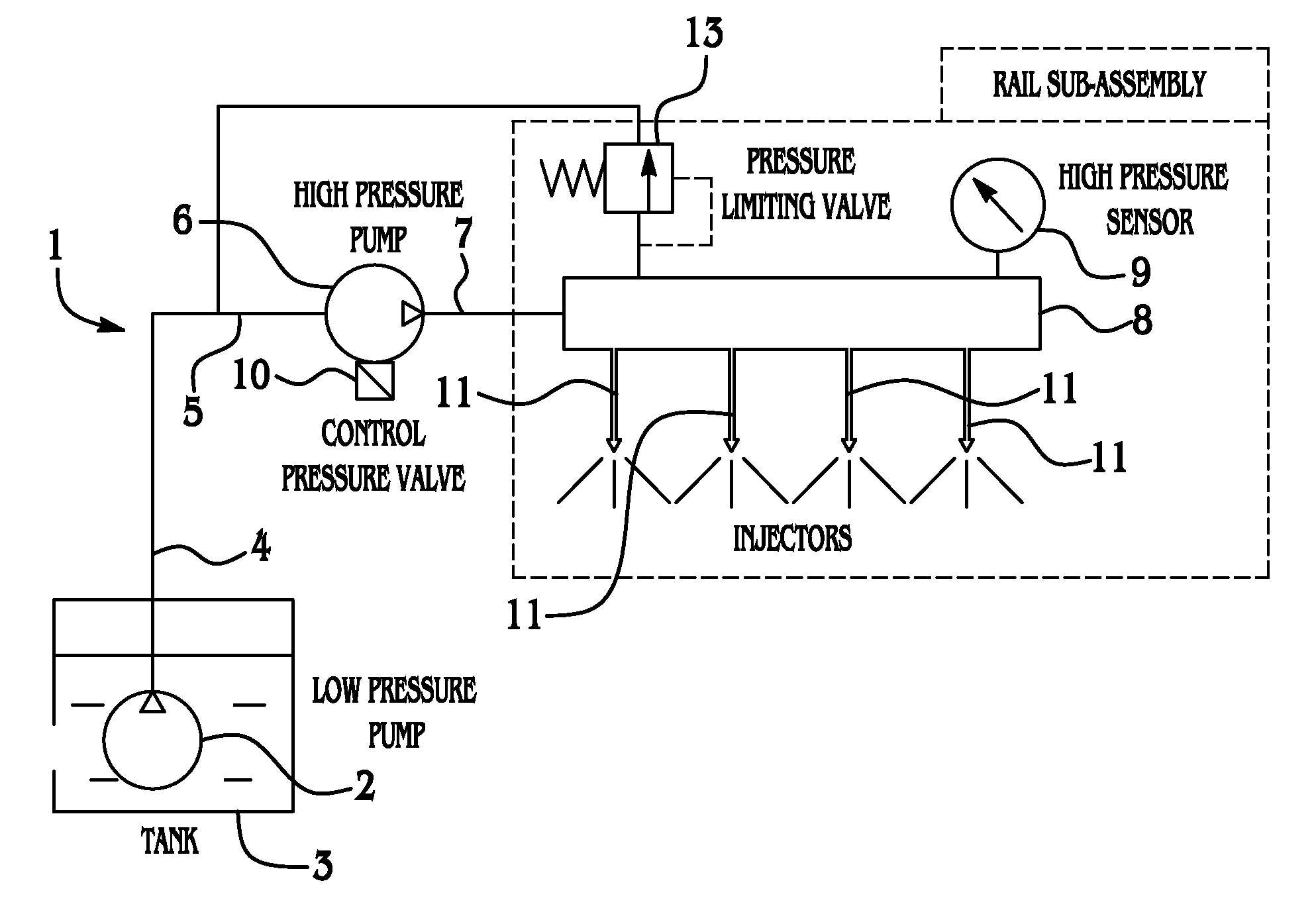

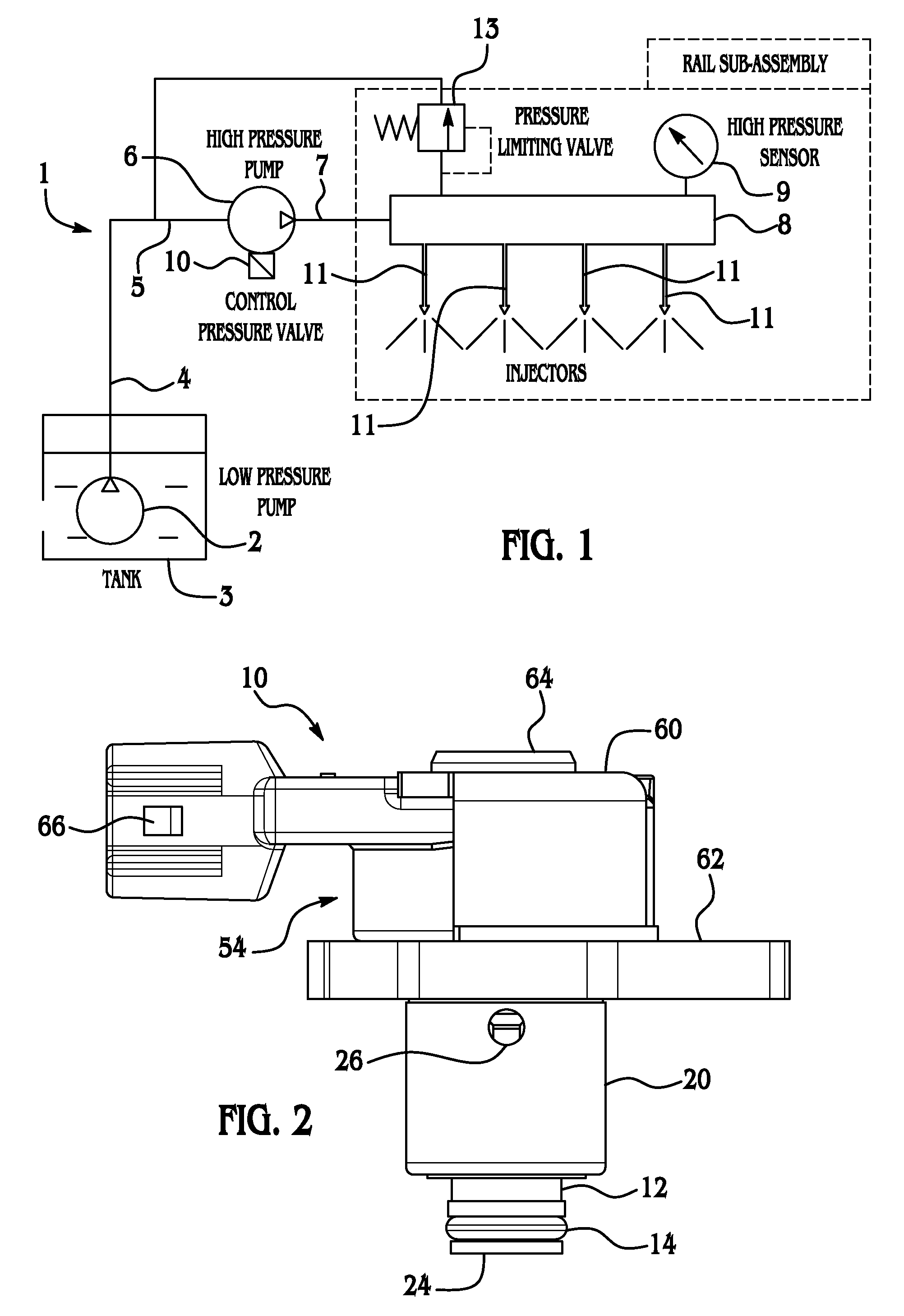

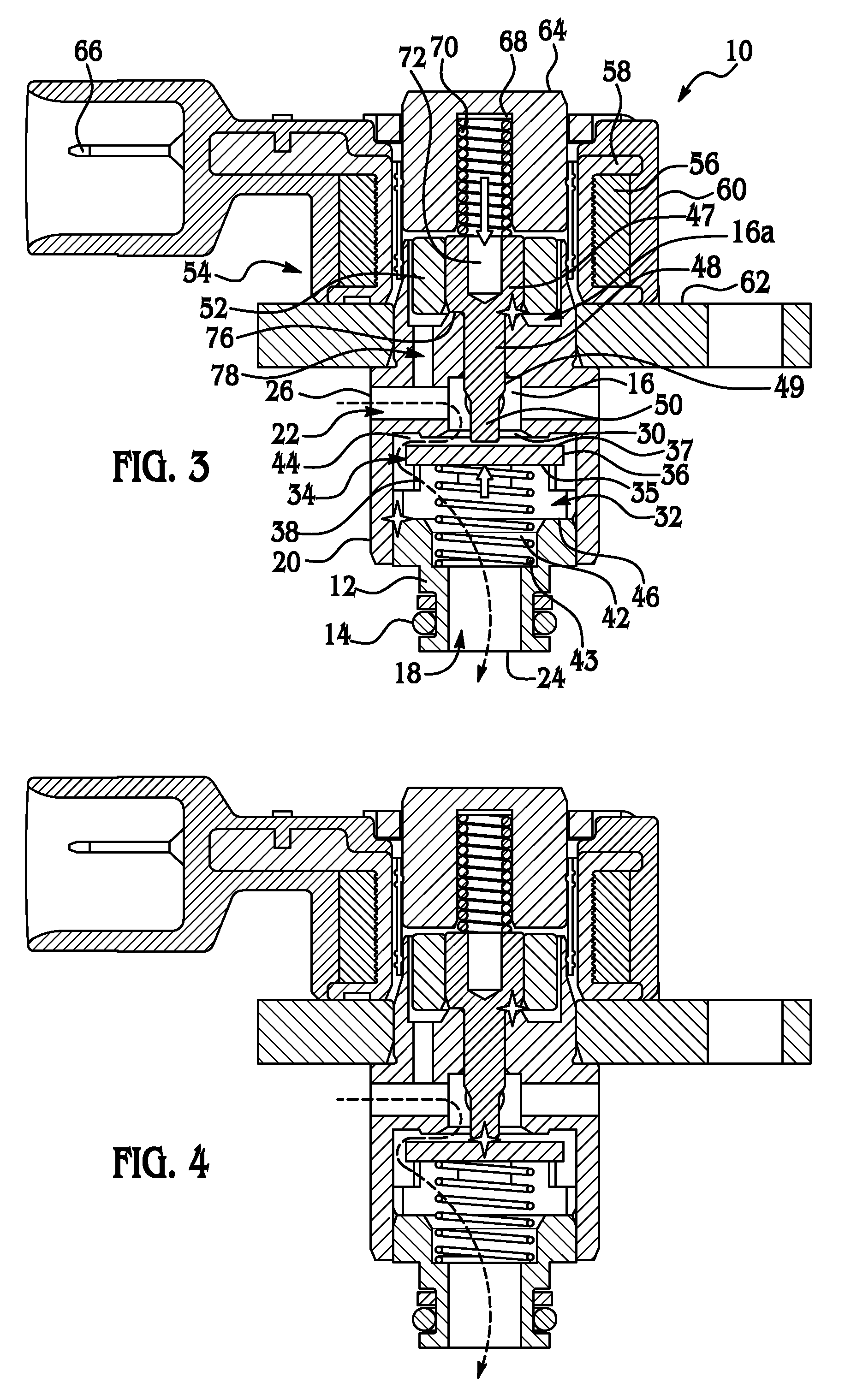

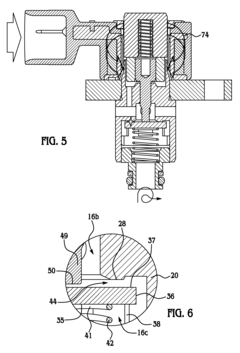

Control valve for a gas direct injection fuel system

PatentInactiveUS20080203347A1

Innovation

- A control valve design featuring a poppet mechanism and actuator system that regulates fluid communication between fluid paths, utilizing dual springs and an electrical actuator to manage pressure and flow rates, allowing for precise control of fuel injection by transitioning between open and closed states rapidly in response to engine conditions.

Quality Control Standards for Engine Component Alignment

Quality control standards for GDI engine camshaft alignment represent a critical framework that ensures consistent precision and reliability in engine manufacturing. These standards typically follow ISO 9001 quality management principles while incorporating specific tolerances defined by automotive engineering bodies such as SAE International and ASME. For GDI (Gasoline Direct Injection) engines, camshaft alignment tolerances are particularly stringent, generally requiring precision within 0.002-0.005 mm to ensure optimal valve timing and fuel efficiency.

The measurement verification protocols for camshaft alignment include multi-point inspection procedures that validate alignment across the entire camshaft length. These protocols mandate the use of calibrated measurement tools such as dial indicators, digital micrometers, and laser alignment systems with NIST-traceable calibration certificates. Documentation requirements specify that all measurements must be recorded with timestamp data, operator identification, and environmental conditions including temperature and humidity.

Statistical process control (SPC) methodologies are integrated into these standards, requiring manufacturers to maintain Cpk values of at least 1.33 for critical alignment parameters. This ensures that the manufacturing process consistently produces camshafts that meet specifications with minimal variation. Control charts must be maintained to track alignment trends over time, with defined action limits that trigger investigation when measurements approach tolerance boundaries.

Failure mode analysis standards require manufacturers to implement FMEA (Failure Mode and Effects Analysis) specifically addressing potential alignment issues. These standards define acceptable failure rates, typically less than 10 PPM (parts per million) for critical alignment parameters. Manufacturers must establish clear corrective action procedures that include root cause analysis methodologies and verification testing protocols to confirm that identified issues have been properly resolved.

Training certification requirements ensure that technicians performing camshaft alignment procedures possess documented competency. These standards typically mandate minimum training hours, practical demonstration of skills, and periodic recertification. The standards also specify environmental controls for alignment procedures, including temperature-controlled environments (20°C ± 1°C) and vibration-isolated workstations to eliminate external factors that could compromise measurement accuracy.

Audit procedures within these standards establish regular internal and third-party verification of alignment processes. These audits must evaluate both the technical accuracy of measurements and the procedural compliance with documented work instructions. Traceability requirements ensure that each engine's camshaft alignment data can be linked to specific measurement tools, operators, and environmental conditions, creating a comprehensive quality history for each component.

The measurement verification protocols for camshaft alignment include multi-point inspection procedures that validate alignment across the entire camshaft length. These protocols mandate the use of calibrated measurement tools such as dial indicators, digital micrometers, and laser alignment systems with NIST-traceable calibration certificates. Documentation requirements specify that all measurements must be recorded with timestamp data, operator identification, and environmental conditions including temperature and humidity.

Statistical process control (SPC) methodologies are integrated into these standards, requiring manufacturers to maintain Cpk values of at least 1.33 for critical alignment parameters. This ensures that the manufacturing process consistently produces camshafts that meet specifications with minimal variation. Control charts must be maintained to track alignment trends over time, with defined action limits that trigger investigation when measurements approach tolerance boundaries.

Failure mode analysis standards require manufacturers to implement FMEA (Failure Mode and Effects Analysis) specifically addressing potential alignment issues. These standards define acceptable failure rates, typically less than 10 PPM (parts per million) for critical alignment parameters. Manufacturers must establish clear corrective action procedures that include root cause analysis methodologies and verification testing protocols to confirm that identified issues have been properly resolved.

Training certification requirements ensure that technicians performing camshaft alignment procedures possess documented competency. These standards typically mandate minimum training hours, practical demonstration of skills, and periodic recertification. The standards also specify environmental controls for alignment procedures, including temperature-controlled environments (20°C ± 1°C) and vibration-isolated workstations to eliminate external factors that could compromise measurement accuracy.

Audit procedures within these standards establish regular internal and third-party verification of alignment processes. These audits must evaluate both the technical accuracy of measurements and the procedural compliance with documented work instructions. Traceability requirements ensure that each engine's camshaft alignment data can be linked to specific measurement tools, operators, and environmental conditions, creating a comprehensive quality history for each component.

Environmental Impact of Advanced Engine Manufacturing Processes

The manufacturing processes for GDI engine camshafts and precision alignment tools have significant environmental implications that warrant careful consideration. Traditional manufacturing methods often involve energy-intensive processes such as casting, forging, and precision machining that generate substantial carbon emissions. Recent studies indicate that the production of a single automotive camshaft can generate between 15-25 kg of CO2 equivalent emissions, depending on the manufacturing techniques employed.

Water consumption represents another critical environmental concern in camshaft manufacturing. Conventional cooling systems used during machining processes typically require 5-7 liters of water per camshaft, with additional water needed for cleaning operations. Advanced manufacturing facilities have begun implementing closed-loop water recycling systems, reducing freshwater consumption by up to 80% while maintaining the precision necessary for GDI engine components.

Waste generation during camshaft production and alignment tool manufacturing includes metal shavings, cutting fluids, and packaging materials. The industry has made notable progress in this area, with recovery rates for metal waste now exceeding 90% in state-of-the-art facilities. However, cutting fluids and lubricants continue to pose environmental challenges due to their chemical composition and disposal requirements.

Energy efficiency improvements in manufacturing processes represent a promising avenue for environmental impact reduction. The implementation of variable frequency drives in machining equipment has demonstrated energy savings of 15-30% compared to conventional systems. Additionally, the adoption of precision alignment technologies that utilize digital calibration rather than mechanical adjustment has reduced the energy requirements for camshaft alignment by approximately 40%.

Material selection also plays a crucial role in determining environmental footprint. The transition from traditional steel alloys to advanced materials with improved durability has extended camshaft service life by up to 25%, reducing the frequency of replacement and associated manufacturing impacts. Similarly, precision alignment tools manufactured from recycled materials can reduce embodied carbon by approximately 35% compared to virgin material alternatives.

Lifecycle assessment studies indicate that the environmental impact of GDI engine components extends beyond manufacturing to include use-phase considerations. Properly aligned camshafts contribute to engine efficiency improvements of 2-5%, translating to meaningful reductions in vehicle emissions over operational lifetimes. This highlights the importance of precision alignment not only for performance but also for environmental sustainability throughout the product lifecycle.

Water consumption represents another critical environmental concern in camshaft manufacturing. Conventional cooling systems used during machining processes typically require 5-7 liters of water per camshaft, with additional water needed for cleaning operations. Advanced manufacturing facilities have begun implementing closed-loop water recycling systems, reducing freshwater consumption by up to 80% while maintaining the precision necessary for GDI engine components.

Waste generation during camshaft production and alignment tool manufacturing includes metal shavings, cutting fluids, and packaging materials. The industry has made notable progress in this area, with recovery rates for metal waste now exceeding 90% in state-of-the-art facilities. However, cutting fluids and lubricants continue to pose environmental challenges due to their chemical composition and disposal requirements.

Energy efficiency improvements in manufacturing processes represent a promising avenue for environmental impact reduction. The implementation of variable frequency drives in machining equipment has demonstrated energy savings of 15-30% compared to conventional systems. Additionally, the adoption of precision alignment technologies that utilize digital calibration rather than mechanical adjustment has reduced the energy requirements for camshaft alignment by approximately 40%.

Material selection also plays a crucial role in determining environmental footprint. The transition from traditional steel alloys to advanced materials with improved durability has extended camshaft service life by up to 25%, reducing the frequency of replacement and associated manufacturing impacts. Similarly, precision alignment tools manufactured from recycled materials can reduce embodied carbon by approximately 35% compared to virgin material alternatives.

Lifecycle assessment studies indicate that the environmental impact of GDI engine components extends beyond manufacturing to include use-phase considerations. Properly aligned camshafts contribute to engine efficiency improvements of 2-5%, translating to meaningful reductions in vehicle emissions over operational lifetimes. This highlights the importance of precision alignment not only for performance but also for environmental sustainability throughout the product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!