How to Augment GDI Engine Pressure Via Turbocharger

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbocharging Technology Background and Objectives

Turbocharging technology has evolved significantly since its inception in the early 20th century. Originally developed for aircraft engines, turbochargers found their way into automotive applications in the 1960s and have since become a cornerstone of engine efficiency enhancement. The fundamental principle remains unchanged: utilizing exhaust gas energy to drive a turbine that compresses intake air, thereby increasing oxygen density for combustion and enhancing engine power output without increasing displacement.

The evolution of turbocharging technology has accelerated in recent decades, driven by increasingly stringent emissions regulations and the industry-wide push for improved fuel efficiency. Modern turbochargers feature advanced materials like titanium aluminide and ceramic ball bearings, enabling higher temperature operation and reduced turbo lag. Variable geometry turbochargers (VGT) and twin-scroll designs represent significant advancements that have addressed historical limitations of turbocharging systems.

Gasoline Direct Injection (GDI) engines present unique opportunities and challenges for turbocharging applications. Unlike port fuel injection systems, GDI enables precise fuel delivery directly into the combustion chamber, allowing for higher compression ratios and improved thermal efficiency. When combined with turbocharging, GDI engines can achieve significant power density improvements while maintaining favorable emissions profiles.

The primary technical objective in augmenting GDI engine pressure via turbocharging is to optimize the balance between performance enhancement and system reliability. This involves developing turbocharging solutions that can deliver higher boost pressures while managing the increased thermal and mechanical stresses inherent to GDI systems. Specific goals include achieving boost pressures of 2.5-3.0 bar while maintaining thermal efficiency and minimizing turbo lag across a wide operating range.

Secondary objectives focus on addressing GDI-specific challenges, such as managing increased particulate emissions that can result from higher pressure operation, preventing low-speed pre-ignition (LSPI), and optimizing fuel injection timing relative to boost pressure delivery. Integration of advanced control systems that can dynamically adjust boost pressure based on real-time combustion analysis represents a frontier in this technology domain.

The long-term trajectory for GDI turbocharging technology points toward integration with electrification. Electric turbochargers and hybrid boosting systems that combine conventional turbochargers with electrically driven compressors are emerging as promising solutions for eliminating turbo lag and providing precise boost control across all engine operating conditions. These developments align with broader industry trends toward 48V electrical systems and mild hybridization.

The evolution of turbocharging technology has accelerated in recent decades, driven by increasingly stringent emissions regulations and the industry-wide push for improved fuel efficiency. Modern turbochargers feature advanced materials like titanium aluminide and ceramic ball bearings, enabling higher temperature operation and reduced turbo lag. Variable geometry turbochargers (VGT) and twin-scroll designs represent significant advancements that have addressed historical limitations of turbocharging systems.

Gasoline Direct Injection (GDI) engines present unique opportunities and challenges for turbocharging applications. Unlike port fuel injection systems, GDI enables precise fuel delivery directly into the combustion chamber, allowing for higher compression ratios and improved thermal efficiency. When combined with turbocharging, GDI engines can achieve significant power density improvements while maintaining favorable emissions profiles.

The primary technical objective in augmenting GDI engine pressure via turbocharging is to optimize the balance between performance enhancement and system reliability. This involves developing turbocharging solutions that can deliver higher boost pressures while managing the increased thermal and mechanical stresses inherent to GDI systems. Specific goals include achieving boost pressures of 2.5-3.0 bar while maintaining thermal efficiency and minimizing turbo lag across a wide operating range.

Secondary objectives focus on addressing GDI-specific challenges, such as managing increased particulate emissions that can result from higher pressure operation, preventing low-speed pre-ignition (LSPI), and optimizing fuel injection timing relative to boost pressure delivery. Integration of advanced control systems that can dynamically adjust boost pressure based on real-time combustion analysis represents a frontier in this technology domain.

The long-term trajectory for GDI turbocharging technology points toward integration with electrification. Electric turbochargers and hybrid boosting systems that combine conventional turbochargers with electrically driven compressors are emerging as promising solutions for eliminating turbo lag and providing precise boost control across all engine operating conditions. These developments align with broader industry trends toward 48V electrical systems and mild hybridization.

Market Analysis for Turbocharged GDI Engines

The global market for turbocharged Gasoline Direct Injection (GDI) engines has experienced significant growth over the past decade, driven primarily by stringent emission regulations and increasing consumer demand for fuel-efficient vehicles without compromising performance. The market value reached approximately $12.3 billion in 2022 and is projected to grow at a CAGR of 6.8% through 2028.

Regionally, Europe leads the turbocharged GDI engine market with nearly 40% market share, followed by North America and Asia-Pacific. European dominance stems from early adoption of strict emission standards and consumer preference for smaller, more efficient engines. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with projected growth rates exceeding 8% annually due to rapid automotive industry expansion and increasing disposable incomes.

Consumer demand patterns reveal a clear shift toward vehicles offering improved fuel economy without sacrificing performance. Market research indicates that vehicles equipped with turbocharged GDI engines typically achieve 15-20% better fuel efficiency compared to conventional port fuel injection systems, while simultaneously delivering 10-15% more torque at lower RPMs. This performance-efficiency balance has become a critical selling point for manufacturers.

The passenger vehicle segment currently dominates the application landscape, accounting for approximately 65% of turbocharged GDI engine installations. However, the light commercial vehicle segment is showing accelerated adoption rates as businesses seek to reduce fleet operating costs through improved fuel economy.

Market analysis reveals several key drivers propelling growth in this sector. Environmental regulations, particularly Euro 7 standards in Europe and CAFE standards in the United States, continue to push manufacturers toward more efficient powertrain solutions. Additionally, volatile fuel prices have heightened consumer sensitivity to fuel economy, creating sustained demand for turbocharged GDI technology.

Competitive pricing remains a challenge as manufacturers work to offset the higher production costs associated with turbocharged GDI systems. Premium pricing for this technology has decreased from 15% to approximately 8% over conventional systems in the past five years as production volumes have increased and manufacturing processes have matured.

Market forecasts indicate continued growth for turbocharged GDI engines through 2030, though at a moderating pace as hybrid and electric powertrains gain market share. The technology is expected to maintain relevance as a transitional solution in markets where charging infrastructure remains underdeveloped and as a component in hybrid powertrain systems.

Regionally, Europe leads the turbocharged GDI engine market with nearly 40% market share, followed by North America and Asia-Pacific. European dominance stems from early adoption of strict emission standards and consumer preference for smaller, more efficient engines. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with projected growth rates exceeding 8% annually due to rapid automotive industry expansion and increasing disposable incomes.

Consumer demand patterns reveal a clear shift toward vehicles offering improved fuel economy without sacrificing performance. Market research indicates that vehicles equipped with turbocharged GDI engines typically achieve 15-20% better fuel efficiency compared to conventional port fuel injection systems, while simultaneously delivering 10-15% more torque at lower RPMs. This performance-efficiency balance has become a critical selling point for manufacturers.

The passenger vehicle segment currently dominates the application landscape, accounting for approximately 65% of turbocharged GDI engine installations. However, the light commercial vehicle segment is showing accelerated adoption rates as businesses seek to reduce fleet operating costs through improved fuel economy.

Market analysis reveals several key drivers propelling growth in this sector. Environmental regulations, particularly Euro 7 standards in Europe and CAFE standards in the United States, continue to push manufacturers toward more efficient powertrain solutions. Additionally, volatile fuel prices have heightened consumer sensitivity to fuel economy, creating sustained demand for turbocharged GDI technology.

Competitive pricing remains a challenge as manufacturers work to offset the higher production costs associated with turbocharged GDI systems. Premium pricing for this technology has decreased from 15% to approximately 8% over conventional systems in the past five years as production volumes have increased and manufacturing processes have matured.

Market forecasts indicate continued growth for turbocharged GDI engines through 2030, though at a moderating pace as hybrid and electric powertrains gain market share. The technology is expected to maintain relevance as a transitional solution in markets where charging infrastructure remains underdeveloped and as a component in hybrid powertrain systems.

Current Challenges in GDI Pressure Augmentation

Despite significant advancements in Gasoline Direct Injection (GDI) technology, several critical challenges persist in effectively augmenting pressure through turbocharging systems. The primary obstacle remains the integration complexity between high-pressure GDI systems and turbochargers, particularly in maintaining optimal fuel atomization across varying engine loads and speeds.

Thermal management presents a substantial challenge as turbochargers generate significant heat that can affect fuel properties in GDI systems. When fuel temperatures exceed critical thresholds (typically above 120°C), vapor lock and pre-ignition issues become prevalent, compromising both performance and engine longevity. Current cooling solutions often add weight and complexity without fully resolving these thermal concerns.

Pressure pulsation and instability represent another significant hurdle. The inherent pressure fluctuations in turbocharged systems can disrupt the precise fuel metering required in GDI engines. Engineers struggle to maintain consistent rail pressure during transient operations, particularly during rapid acceleration events when turbo lag coincides with increased fuel demand.

Material limitations further constrain advancement in this field. Current injector components and fuel rail materials face durability challenges when subjected to both the elevated pressures (exceeding 300 bar in advanced systems) and the thermal cycling inherent in turbocharged applications. The metallurgical requirements for these components often conflict with cost and manufacturing constraints.

Control system integration remains problematic, with many ECUs struggling to optimize the complex relationship between boost pressure, fuel pressure, and injection timing. The computational demands for real-time adjustment of these parameters exceed the capabilities of many production-grade engine management systems, resulting in compromised efficiency.

Emissions compliance adds another layer of complexity. Turbocharged GDI engines tend to produce higher particulate matter emissions due to wall wetting issues that worsen under boosted conditions. Meeting stringent Euro 7 and equivalent standards requires sophisticated aftertreatment systems that add cost and packaging challenges.

Market adoption barriers exist due to the increased system complexity and cost. While premium vehicle segments have embraced turbocharged GDI technology, mass-market implementation faces resistance due to higher manufacturing costs and concerns about long-term reliability. The additional components required for effective pressure augmentation add approximately 15-20% to powertrain costs compared to naturally aspirated alternatives.

These multifaceted challenges necessitate innovative approaches that address not only the mechanical aspects of pressure augmentation but also the thermal, material, and control system limitations that currently constrain the technology's full potential.

Thermal management presents a substantial challenge as turbochargers generate significant heat that can affect fuel properties in GDI systems. When fuel temperatures exceed critical thresholds (typically above 120°C), vapor lock and pre-ignition issues become prevalent, compromising both performance and engine longevity. Current cooling solutions often add weight and complexity without fully resolving these thermal concerns.

Pressure pulsation and instability represent another significant hurdle. The inherent pressure fluctuations in turbocharged systems can disrupt the precise fuel metering required in GDI engines. Engineers struggle to maintain consistent rail pressure during transient operations, particularly during rapid acceleration events when turbo lag coincides with increased fuel demand.

Material limitations further constrain advancement in this field. Current injector components and fuel rail materials face durability challenges when subjected to both the elevated pressures (exceeding 300 bar in advanced systems) and the thermal cycling inherent in turbocharged applications. The metallurgical requirements for these components often conflict with cost and manufacturing constraints.

Control system integration remains problematic, with many ECUs struggling to optimize the complex relationship between boost pressure, fuel pressure, and injection timing. The computational demands for real-time adjustment of these parameters exceed the capabilities of many production-grade engine management systems, resulting in compromised efficiency.

Emissions compliance adds another layer of complexity. Turbocharged GDI engines tend to produce higher particulate matter emissions due to wall wetting issues that worsen under boosted conditions. Meeting stringent Euro 7 and equivalent standards requires sophisticated aftertreatment systems that add cost and packaging challenges.

Market adoption barriers exist due to the increased system complexity and cost. While premium vehicle segments have embraced turbocharged GDI technology, mass-market implementation faces resistance due to higher manufacturing costs and concerns about long-term reliability. The additional components required for effective pressure augmentation add approximately 15-20% to powertrain costs compared to naturally aspirated alternatives.

These multifaceted challenges necessitate innovative approaches that address not only the mechanical aspects of pressure augmentation but also the thermal, material, and control system limitations that currently constrain the technology's full potential.

Current Turbocharging Solutions for GDI Engines

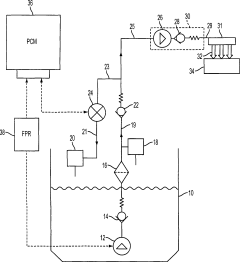

01 Turbocharger pressure control systems for GDI engines

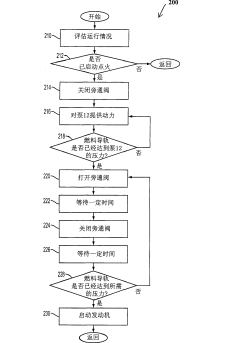

Advanced control systems are implemented to regulate turbocharger pressure in gasoline direct injection engines. These systems monitor various engine parameters and adjust the turbocharger operation accordingly to maintain optimal boost pressure. The control systems may include electronic controllers, sensors, and actuators that work together to ensure efficient engine performance while preventing over-boosting that could damage engine components.- Turbocharger pressure control systems for GDI engines: Various control systems are designed to optimize turbocharger pressure in gasoline direct injection engines. These systems monitor and adjust boost pressure based on engine operating conditions to enhance performance and efficiency. Advanced control algorithms can regulate wastegate operation, compressor speed, and bypass valves to maintain optimal boost levels while preventing engine knock and ensuring reliable operation across different driving conditions.

- Fuel injection timing and pressure optimization with turbocharging: Specialized systems coordinate fuel injection timing and pressure with turbocharger boost levels in GDI engines. By precisely controlling when and how fuel is injected relative to the turbocharger pressure, these innovations improve combustion efficiency, reduce emissions, and enhance power output. The systems can dynamically adjust injection parameters based on boost pressure to maintain optimal air-fuel ratios across various engine loads and speeds.

- Exhaust gas recirculation integration with turbocharged GDI systems: Innovations that combine exhaust gas recirculation (EGR) with turbocharged GDI engines to control combustion temperatures and reduce emissions. These systems carefully balance EGR rates with turbocharger boost pressure to optimize engine performance while meeting stringent emission standards. Advanced control strategies determine the ideal EGR flow based on engine load, speed, and boost pressure to minimize NOx formation without compromising power output.

- Knock prevention and mitigation in turbocharged GDI engines: Technologies specifically designed to prevent and mitigate engine knock in turbocharged GDI engines. These systems employ various strategies including spark timing adjustment, fuel enrichment, and boost pressure limitation based on knock sensor feedback. Advanced algorithms can predict knock conditions before they occur and take preventive measures to protect the engine while maintaining maximum possible performance under varying operating conditions.

- Turbocharger design optimizations for GDI applications: Specialized turbocharger designs and configurations optimized specifically for GDI engine applications. These innovations include variable geometry turbochargers, twin-scroll designs, and electric assist systems that reduce lag and improve boost response. The turbocharger components are engineered to withstand the unique thermal and pressure conditions of GDI engines while providing optimal air flow characteristics across the engine's operating range.

02 Waste gate mechanisms for turbocharger pressure regulation

Waste gate mechanisms are utilized in turbocharged GDI engines to regulate boost pressure by controlling exhaust gas flow to the turbine. When the boost pressure exceeds a predetermined threshold, the waste gate opens to bypass some exhaust gas around the turbine, thereby limiting the turbocharger speed and boost pressure. These mechanisms can be mechanically or electronically controlled to provide precise pressure regulation under various operating conditions.Expand Specific Solutions03 Integration of GDI and turbocharging for improved fuel efficiency

The combination of gasoline direct injection and turbocharging technologies enables significant improvements in fuel efficiency while maintaining or enhancing engine performance. This integration allows for precise fuel delivery directly into the combustion chamber along with increased air density from the turbocharger, resulting in more complete combustion. The synergistic effect of these technologies helps reduce fuel consumption and emissions while providing better throttle response and power output.Expand Specific Solutions04 Variable geometry turbochargers for GDI applications

Variable geometry turbochargers (VGT) are implemented in GDI engines to provide optimal boost pressure across a wide range of engine speeds. By adjusting the geometry of the turbine housing or the angle of the turbine vanes, these turbochargers can effectively vary the flow area and velocity of exhaust gases driving the turbine. This technology helps eliminate turbo lag, improves low-end torque, and enhances overall engine responsiveness while maintaining efficient operation at higher speeds.Expand Specific Solutions05 Cooling and thermal management for turbocharged GDI engines

Specialized cooling and thermal management systems are essential for turbocharged GDI engines to handle the increased heat generated by higher compression ratios and boost pressures. These systems may include intercoolers to reduce the temperature of compressed air, enhanced engine cooling circuits, and oil cooling mechanisms for the turbocharger. Effective thermal management prevents detonation, protects engine components from thermal stress, and maintains optimal combustion conditions for performance and emissions control.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The turbocharger-based GDI engine pressure augmentation technology is currently in a growth phase, with the global market expected to reach $25 billion by 2027. The competitive landscape is dominated by established automotive manufacturers and specialized component suppliers. BorgWarner, Cummins, and Caterpillar lead in turbocharger innovation, while major automakers like Toyota, Ford, Volkswagen, and Hyundai are integrating advanced turbocharging systems into their GDI engines. Technical maturity varies significantly, with premium manufacturers like Porsche demonstrating highly sophisticated implementations, while companies like Weichai Power and Southwest Research Institute focus on improving efficiency and reducing emissions. Chinese manufacturers including Great Wall Motor and Dongfeng are rapidly advancing their capabilities to compete with established Western players.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced EcoBoost turbocharging system that specifically targets GDI (Gasoline Direct Injection) engine pressure augmentation. Their technology utilizes twin-scroll turbochargers with integrated exhaust manifolds that minimize turbo lag while maximizing boost pressure. The system incorporates variable geometry turbine technology that adjusts the effective aspect ratio of the turbine housing based on engine operating conditions. Ford's approach includes sophisticated electronic wastegate control systems that precisely regulate boost pressure across the entire RPM range. Additionally, they've implemented water-cooled charge air coolers that maintain lower intake temperatures, allowing for higher compression ratios and increased boost without detonation issues. Ford's system is particularly notable for its integration with their patented dual-fuel injection strategy, which combines port and direct injection to optimize combustion efficiency while maintaining high boost pressures.

Strengths: Excellent integration with existing EcoBoost architecture; proven reliability in production vehicles; sophisticated electronic control systems that optimize boost across various driving conditions. Weaknesses: Higher manufacturing complexity compared to simpler turbocharging solutions; requires premium fuel for maximum performance; potential thermal management challenges in high-output applications.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has pioneered the Continuously Variable Valve Duration (CVVD) technology that works in conjunction with their turbocharging systems to augment GDI engine pressure. This innovative approach allows for precise control of valve opening duration, which optimizes the air-fuel mixture entering the combustion chamber under various boost conditions. Their turbocharging solution incorporates an electric compressor that works alongside a conventional turbocharger in a sequential arrangement, providing immediate boost at low RPMs while the conventional turbo spools up. Hyundai's system features an advanced intercooling setup with a water-to-air heat exchanger that maintains consistent intake temperatures regardless of ambient conditions. The company has also developed proprietary coating technologies for turbocharger components that reduce friction and improve thermal efficiency, allowing for higher sustained boost pressures without compromising reliability.

Strengths: Revolutionary CVVD technology provides unprecedented control over combustion parameters; electric compressor virtually eliminates turbo lag; excellent thermal management. Weaknesses: Higher system complexity increases potential failure points; requires sophisticated electronic control systems; higher production costs compared to conventional turbocharging solutions.

Key Innovations in Pressure Augmentation Technology

Method for maximizing the formation of deposits in injector nozzles of GDI engines

PatentWO2018002610A1

Innovation

- A method to maximize deposit formation in GDI engine injector nozzles by simulating severe conditions through controlled engine speed and load variations, high nozzle temperatures, and moderate fuel flow rates, allowing for automated and unsupervised testing to quickly assess fuel's deposit-forming tendencies.

Direct injection fuel system utilizing water hammer effect

PatentInactiveCN101418734A

Innovation

- By utilizing the water hammer effect to generate a high-pressure wave that increases pressure within the fuel rail, and utilizing the high-pressure pump downstream to deliver the high-pressure wave to increase pressure within the fuel rail before engine start, the lift pump is reduced in size and the overall efficiency of the fuel system is improved.

Emissions Regulations Impact on Turbocharger Design

Emissions regulations worldwide have become increasingly stringent over the past two decades, fundamentally reshaping turbocharger design for GDI (Gasoline Direct Injection) engines. The European Union's Euro 6d standards, the United States EPA's Tier 3 regulations, and China's China 6 standards have all established progressively lower limits for particulate matter (PM), nitrogen oxides (NOx), and carbon dioxide (CO2) emissions.

These regulatory frameworks have driven significant innovations in turbocharger technology, particularly for pressure augmentation in GDI engines. Manufacturers must now design turbochargers that not only increase power output but simultaneously reduce emissions through more precise boost control and improved thermal efficiency. Variable geometry turbochargers (VGT), once primarily used in diesel applications, have been adapted for gasoline engines specifically to meet these dual requirements.

The need to reduce particulate emissions has led to the development of electrically-assisted turbochargers that minimize lag and provide more responsive boost pressure at lower engine speeds. This technology enables more efficient combustion cycles, reducing the formation of particulates during cold starts and transient operations - critical phases for emissions compliance.

Regulatory focus on real-world driving emissions (RDE) testing has further complicated turbocharger design. Engineers must now ensure optimal performance across a much wider operating range rather than optimizing for standardized test cycles. This has prompted the integration of advanced materials such as titanium aluminide turbine wheels and ceramic ball bearings that can withstand higher temperatures while providing faster response times.

The implementation of 48V mild hybrid systems alongside turbochargers represents another regulatory-driven innovation. These systems can provide instantaneous torque while the turbocharger builds pressure, allowing for smaller turbocharger dimensions that spool more quickly while maintaining overall performance targets. This downsizing approach directly addresses CO2 reduction mandates.

Waste heat recovery systems have also become integral to modern turbocharger designs, with regulations incentivizing technologies that convert exhaust energy into usable power. Electric turbo-compounding and integrated exhaust gas recirculation (EGR) coolers work in tandem with turbochargers to maximize thermal efficiency and minimize emissions simultaneously.

Looking forward, upcoming Euro 7 and equivalent global standards will likely require even more sophisticated turbocharger solutions, potentially including multi-stage systems with integrated electric compressors and advanced control algorithms that can predict and adapt to changing driving conditions in real-time to maintain optimal emissions performance.

These regulatory frameworks have driven significant innovations in turbocharger technology, particularly for pressure augmentation in GDI engines. Manufacturers must now design turbochargers that not only increase power output but simultaneously reduce emissions through more precise boost control and improved thermal efficiency. Variable geometry turbochargers (VGT), once primarily used in diesel applications, have been adapted for gasoline engines specifically to meet these dual requirements.

The need to reduce particulate emissions has led to the development of electrically-assisted turbochargers that minimize lag and provide more responsive boost pressure at lower engine speeds. This technology enables more efficient combustion cycles, reducing the formation of particulates during cold starts and transient operations - critical phases for emissions compliance.

Regulatory focus on real-world driving emissions (RDE) testing has further complicated turbocharger design. Engineers must now ensure optimal performance across a much wider operating range rather than optimizing for standardized test cycles. This has prompted the integration of advanced materials such as titanium aluminide turbine wheels and ceramic ball bearings that can withstand higher temperatures while providing faster response times.

The implementation of 48V mild hybrid systems alongside turbochargers represents another regulatory-driven innovation. These systems can provide instantaneous torque while the turbocharger builds pressure, allowing for smaller turbocharger dimensions that spool more quickly while maintaining overall performance targets. This downsizing approach directly addresses CO2 reduction mandates.

Waste heat recovery systems have also become integral to modern turbocharger designs, with regulations incentivizing technologies that convert exhaust energy into usable power. Electric turbo-compounding and integrated exhaust gas recirculation (EGR) coolers work in tandem with turbochargers to maximize thermal efficiency and minimize emissions simultaneously.

Looking forward, upcoming Euro 7 and equivalent global standards will likely require even more sophisticated turbocharger solutions, potentially including multi-stage systems with integrated electric compressors and advanced control algorithms that can predict and adapt to changing driving conditions in real-time to maintain optimal emissions performance.

Thermal Management Strategies for Turbocharged GDI

Thermal management represents a critical aspect of turbocharged Gasoline Direct Injection (GDI) engine systems, directly impacting performance, efficiency, and component longevity. As boost pressure increases to augment engine output, thermal loads escalate proportionally, necessitating sophisticated management strategies to maintain optimal operating conditions.

The primary thermal challenges in turbocharged GDI systems stem from increased combustion temperatures and heat generation in the turbocharger itself. Exhaust gas temperatures in boosted GDI engines can exceed 950°C under high load conditions, while the turbocharger turbine housing may reach temperatures of 800-850°C. These extreme thermal conditions accelerate component degradation and can lead to knock phenomena, reducing engine efficiency and potentially causing catastrophic failure.

Advanced cooling systems have emerged as fundamental solutions, with dual-circuit cooling architectures gaining prominence. These systems employ separate cooling circuits for the cylinder head and block, allowing for differential temperature management that optimizes combustion efficiency while protecting critical components. Implementation of precision electronic thermostats enables dynamic temperature control based on operating conditions, maintaining ideal thermal states across varying boost levels.

Intercooling technology has evolved significantly, with air-to-liquid intercoolers demonstrating superior cooling efficiency compared to traditional air-to-air designs. Recent developments include two-stage intercooling systems that can reduce charge air temperatures by up to 40% compared to single-stage solutions, directly enhancing volumetric efficiency and allowing for higher boost pressures without increasing knock tendency.

Heat-resistant materials and thermal barrier coatings represent another crucial advancement in thermal management. Silicon nitride turbine wheels offer superior heat resistance compared to traditional Inconel alloys, while ceramic thermal barrier coatings on combustion chamber surfaces can reduce heat transfer by 15-20%, improving thermal efficiency and protecting engine components from extreme temperatures.

Integrated exhaust manifolds (IEM) have gained traction as an effective thermal management solution, incorporating the exhaust manifold directly into the cylinder head casting. This design enables faster catalyst light-off during cold starts while providing better temperature control during high-load operation. Studies indicate that IEM configurations can reduce turbocharger inlet temperatures by up to 30°C during transient operation, significantly extending turbocharger lifespan.

Active thermal management systems utilizing electronically controlled valves and pumps represent the cutting edge of this technology, allowing for precise, demand-based cooling that optimizes engine temperatures across all operating conditions while minimizing parasitic losses associated with traditional mechanical cooling systems.

The primary thermal challenges in turbocharged GDI systems stem from increased combustion temperatures and heat generation in the turbocharger itself. Exhaust gas temperatures in boosted GDI engines can exceed 950°C under high load conditions, while the turbocharger turbine housing may reach temperatures of 800-850°C. These extreme thermal conditions accelerate component degradation and can lead to knock phenomena, reducing engine efficiency and potentially causing catastrophic failure.

Advanced cooling systems have emerged as fundamental solutions, with dual-circuit cooling architectures gaining prominence. These systems employ separate cooling circuits for the cylinder head and block, allowing for differential temperature management that optimizes combustion efficiency while protecting critical components. Implementation of precision electronic thermostats enables dynamic temperature control based on operating conditions, maintaining ideal thermal states across varying boost levels.

Intercooling technology has evolved significantly, with air-to-liquid intercoolers demonstrating superior cooling efficiency compared to traditional air-to-air designs. Recent developments include two-stage intercooling systems that can reduce charge air temperatures by up to 40% compared to single-stage solutions, directly enhancing volumetric efficiency and allowing for higher boost pressures without increasing knock tendency.

Heat-resistant materials and thermal barrier coatings represent another crucial advancement in thermal management. Silicon nitride turbine wheels offer superior heat resistance compared to traditional Inconel alloys, while ceramic thermal barrier coatings on combustion chamber surfaces can reduce heat transfer by 15-20%, improving thermal efficiency and protecting engine components from extreme temperatures.

Integrated exhaust manifolds (IEM) have gained traction as an effective thermal management solution, incorporating the exhaust manifold directly into the cylinder head casting. This design enables faster catalyst light-off during cold starts while providing better temperature control during high-load operation. Studies indicate that IEM configurations can reduce turbocharger inlet temperatures by up to 30°C during transient operation, significantly extending turbocharger lifespan.

Active thermal management systems utilizing electronically controlled valves and pumps represent the cutting edge of this technology, allowing for precise, demand-based cooling that optimizes engine temperatures across all operating conditions while minimizing parasitic losses associated with traditional mechanical cooling systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!