GDI Engine Exhaust Sound Tuning for Preference

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Engine Sound Evolution and Objectives

Gasoline Direct Injection (GDI) engine technology has undergone significant evolution since its commercial introduction in the late 1990s. Initially developed to improve fuel efficiency and reduce emissions, GDI engines have transformed the automotive industry by enabling precise control over the fuel injection process. This technological advancement has inadvertently created distinctive acoustic characteristics that differ substantially from traditional port fuel injection engines.

The sound profile of GDI engines is characterized by a higher frequency content and more pronounced mechanical noise, primarily due to the high-pressure fuel injection system operating at pressures exceeding 200 bar. This creates a distinctive "ticking" sound that many consumers initially perceived as unrefined or indicative of mechanical problems, despite being a normal operational characteristic.

Early GDI implementations focused primarily on performance and efficiency metrics, with sound quality considerations being secondary. However, as consumer expectations evolved, the acoustic signature of engines became increasingly important in overall vehicle perception and brand identity. Market research indicates that engine sound significantly influences purchasing decisions, with studies showing that up to 30% of premium vehicle buyers consider sound character an important factor.

The evolution of GDI engine sound tuning has progressed through several distinct phases. The first generation (1997-2005) prioritized functional implementation with minimal sound engineering. The second generation (2006-2014) introduced basic acoustic treatments such as enhanced engine covers and sound-absorbing materials. The current generation (2015-present) employs sophisticated approaches including active noise cancellation, sound enhancement systems, and comprehensive NVH (Noise, Vibration, Harshness) engineering.

Industry objectives for GDI engine sound tuning have shifted from merely reducing unpleasant noise to actively crafting desirable acoustic signatures that enhance the driving experience. Premium automakers now employ dedicated sound engineering teams to develop brand-specific "sound DNA" that differentiates their vehicles in the marketplace.

The primary technical objectives for modern GDI engine sound tuning include: reducing high-frequency injection noise while preserving beneficial mid-frequency content; enhancing perceived power through strategic amplification of certain frequency bands; ensuring consistency across operating conditions; and developing sound profiles that align with brand values and target demographics.

Future objectives in this field include the development of personalized sound profiles that can be selected by drivers, adaptive sound tuning that responds to driving conditions and driver behavior, and the integration of artificial intelligence to continuously optimize sound characteristics based on user preferences and environmental factors.

The sound profile of GDI engines is characterized by a higher frequency content and more pronounced mechanical noise, primarily due to the high-pressure fuel injection system operating at pressures exceeding 200 bar. This creates a distinctive "ticking" sound that many consumers initially perceived as unrefined or indicative of mechanical problems, despite being a normal operational characteristic.

Early GDI implementations focused primarily on performance and efficiency metrics, with sound quality considerations being secondary. However, as consumer expectations evolved, the acoustic signature of engines became increasingly important in overall vehicle perception and brand identity. Market research indicates that engine sound significantly influences purchasing decisions, with studies showing that up to 30% of premium vehicle buyers consider sound character an important factor.

The evolution of GDI engine sound tuning has progressed through several distinct phases. The first generation (1997-2005) prioritized functional implementation with minimal sound engineering. The second generation (2006-2014) introduced basic acoustic treatments such as enhanced engine covers and sound-absorbing materials. The current generation (2015-present) employs sophisticated approaches including active noise cancellation, sound enhancement systems, and comprehensive NVH (Noise, Vibration, Harshness) engineering.

Industry objectives for GDI engine sound tuning have shifted from merely reducing unpleasant noise to actively crafting desirable acoustic signatures that enhance the driving experience. Premium automakers now employ dedicated sound engineering teams to develop brand-specific "sound DNA" that differentiates their vehicles in the marketplace.

The primary technical objectives for modern GDI engine sound tuning include: reducing high-frequency injection noise while preserving beneficial mid-frequency content; enhancing perceived power through strategic amplification of certain frequency bands; ensuring consistency across operating conditions; and developing sound profiles that align with brand values and target demographics.

Future objectives in this field include the development of personalized sound profiles that can be selected by drivers, adaptive sound tuning that responds to driving conditions and driver behavior, and the integration of artificial intelligence to continuously optimize sound characteristics based on user preferences and environmental factors.

Market Analysis of Premium Exhaust Sound Preferences

The premium exhaust sound market has witnessed significant growth over the past decade, driven by increasing consumer demand for enhanced driving experiences. Current market research indicates that luxury vehicle owners are willing to pay substantial premiums for distinctive exhaust notes, with some premium sound packages commanding upwards of $3,000 in high-end vehicles. This trend is particularly pronounced in markets such as North America, Europe, and China, where automotive customization continues to gain traction.

Consumer preference studies reveal that exhaust sound is now considered a critical component of brand identity and vehicle character. According to recent surveys, approximately 78% of premium vehicle buyers consider engine sound as an important factor in their purchasing decision. The market segmentation shows clear distinctions between preferences across different vehicle categories - sports car owners typically favor aggressive, high-frequency notes, while luxury sedan customers prefer refined, subdued tones with selective amplification during acceleration.

The competitive landscape shows traditional premium manufacturers like Porsche, BMW, and Mercedes-Benz investing heavily in exhaust sound engineering, with dedicated acoustic teams focusing specifically on GDI engine sound optimization. Aftermarket solutions from companies like Akrapovič, Borla, and Milltek have also captured significant market share, offering customizable sound profiles that appeal to enthusiasts seeking personalization options.

Market forecasts project the premium exhaust sound segment to grow at a compound annual rate of 7.2% through 2028, outpacing the general automotive accessories market. This growth is fueled by technological advancements in active sound design systems and increasing integration of digital sound enhancement technologies in mid-range vehicles, effectively democratizing what was once exclusively a premium feature.

Regional analysis indicates varying preferences, with European markets favoring more restrained, sophisticated exhaust notes, while North American consumers typically prefer more pronounced, muscular sounds. Asian markets, particularly Japan and South Korea, show growing interest in technologically advanced sound management systems that offer customizable profiles.

The emergence of electric vehicles presents both a challenge and opportunity for the exhaust sound market. With traditional combustion engine sounds disappearing, manufacturers are developing artificial sound generation systems that mimic or reimagine engine notes. This has created a new sub-segment within the market focused on sound design for electrified vehicles, with projected revenues reaching $1.2 billion by 2030.

Consumer willingness to pay for premium sound experiences remains strong, with market elasticity studies showing minimal price sensitivity among luxury vehicle buyers when it comes to acoustic enhancements. This resilience suggests continued growth potential for GDI engine sound tuning technologies that can deliver distinctive, brand-appropriate exhaust notes.

Consumer preference studies reveal that exhaust sound is now considered a critical component of brand identity and vehicle character. According to recent surveys, approximately 78% of premium vehicle buyers consider engine sound as an important factor in their purchasing decision. The market segmentation shows clear distinctions between preferences across different vehicle categories - sports car owners typically favor aggressive, high-frequency notes, while luxury sedan customers prefer refined, subdued tones with selective amplification during acceleration.

The competitive landscape shows traditional premium manufacturers like Porsche, BMW, and Mercedes-Benz investing heavily in exhaust sound engineering, with dedicated acoustic teams focusing specifically on GDI engine sound optimization. Aftermarket solutions from companies like Akrapovič, Borla, and Milltek have also captured significant market share, offering customizable sound profiles that appeal to enthusiasts seeking personalization options.

Market forecasts project the premium exhaust sound segment to grow at a compound annual rate of 7.2% through 2028, outpacing the general automotive accessories market. This growth is fueled by technological advancements in active sound design systems and increasing integration of digital sound enhancement technologies in mid-range vehicles, effectively democratizing what was once exclusively a premium feature.

Regional analysis indicates varying preferences, with European markets favoring more restrained, sophisticated exhaust notes, while North American consumers typically prefer more pronounced, muscular sounds. Asian markets, particularly Japan and South Korea, show growing interest in technologically advanced sound management systems that offer customizable profiles.

The emergence of electric vehicles presents both a challenge and opportunity for the exhaust sound market. With traditional combustion engine sounds disappearing, manufacturers are developing artificial sound generation systems that mimic or reimagine engine notes. This has created a new sub-segment within the market focused on sound design for electrified vehicles, with projected revenues reaching $1.2 billion by 2030.

Consumer willingness to pay for premium sound experiences remains strong, with market elasticity studies showing minimal price sensitivity among luxury vehicle buyers when it comes to acoustic enhancements. This resilience suggests continued growth potential for GDI engine sound tuning technologies that can deliver distinctive, brand-appropriate exhaust notes.

Current Challenges in GDI Engine Sound Engineering

Despite significant advancements in GDI (Gasoline Direct Injection) engine technology, sound engineering remains a complex challenge with multiple technical barriers. Current GDI engines produce distinctive acoustic signatures that differ substantially from traditional port fuel injection systems, creating unique hurdles for sound engineers. The high-pressure fuel injection process generates characteristic "ticking" sounds that consumers often perceive negatively, associating them with diesel engines rather than premium gasoline powertrains.

The primary technical challenge lies in the inherent trade-off between performance optimization and sound quality. GDI systems improve fuel efficiency and reduce emissions through precise fuel delivery, but these same mechanisms create acoustic artifacts that require extensive mitigation. Engineers must balance competing priorities without compromising the core benefits of GDI technology.

Another significant obstacle is the complexity of isolating and addressing multiple sound sources within the GDI system. The sound profile comprises contributions from fuel injectors, high-pressure pumps, combustion dynamics, and exhaust components, each requiring different treatment approaches. Current sound engineering methodologies struggle to effectively decompose these overlapping acoustic signatures for targeted modification.

Market expectations present additional complications, as consumer preferences for engine sounds vary significantly across different vehicle segments and geographical markets. Premium vehicle buyers typically expect refined, powerful sounds, while performance-oriented customers may prefer more aggressive acoustic feedback. This diversity of preferences necessitates customizable sound engineering solutions rather than one-size-fits-all approaches.

Regulatory constraints further complicate GDI sound engineering. Increasingly stringent noise regulations in urban environments conflict with consumer preferences for distinctive engine sounds, creating a challenging regulatory landscape that varies by region. Engineers must develop solutions that satisfy both regulatory requirements and market expectations.

The digital transformation of vehicles introduces new challenges in sound authenticity. As vehicles incorporate more electronic systems and sound enhancement technologies, maintaining authentic engine sounds becomes increasingly difficult. Current approaches often struggle to create natural-sounding augmentation that seamlessly integrates with the actual mechanical sounds of GDI engines.

Finally, the industry faces significant methodological limitations in quantifying and evaluating sound quality. Subjective assessment methods remain prevalent but lack consistency and reproducibility. Objective metrics exist but frequently fail to correlate with human perception, creating a measurement gap that hinders systematic improvement of GDI engine sound profiles.

The primary technical challenge lies in the inherent trade-off between performance optimization and sound quality. GDI systems improve fuel efficiency and reduce emissions through precise fuel delivery, but these same mechanisms create acoustic artifacts that require extensive mitigation. Engineers must balance competing priorities without compromising the core benefits of GDI technology.

Another significant obstacle is the complexity of isolating and addressing multiple sound sources within the GDI system. The sound profile comprises contributions from fuel injectors, high-pressure pumps, combustion dynamics, and exhaust components, each requiring different treatment approaches. Current sound engineering methodologies struggle to effectively decompose these overlapping acoustic signatures for targeted modification.

Market expectations present additional complications, as consumer preferences for engine sounds vary significantly across different vehicle segments and geographical markets. Premium vehicle buyers typically expect refined, powerful sounds, while performance-oriented customers may prefer more aggressive acoustic feedback. This diversity of preferences necessitates customizable sound engineering solutions rather than one-size-fits-all approaches.

Regulatory constraints further complicate GDI sound engineering. Increasingly stringent noise regulations in urban environments conflict with consumer preferences for distinctive engine sounds, creating a challenging regulatory landscape that varies by region. Engineers must develop solutions that satisfy both regulatory requirements and market expectations.

The digital transformation of vehicles introduces new challenges in sound authenticity. As vehicles incorporate more electronic systems and sound enhancement technologies, maintaining authentic engine sounds becomes increasingly difficult. Current approaches often struggle to create natural-sounding augmentation that seamlessly integrates with the actual mechanical sounds of GDI engines.

Finally, the industry faces significant methodological limitations in quantifying and evaluating sound quality. Subjective assessment methods remain prevalent but lack consistency and reproducibility. Objective metrics exist but frequently fail to correlate with human perception, creating a measurement gap that hinders systematic improvement of GDI engine sound profiles.

Contemporary GDI Exhaust Sound Tuning Methodologies

01 Exhaust sound control systems for GDI engines

Various systems are designed to control the exhaust sound of GDI (Gasoline Direct Injection) engines. These systems typically include sound control valves, resonators, and mufflers that can be adjusted to modify the acoustic characteristics of the exhaust. By controlling the flow path of exhaust gases, these systems can reduce noise levels while maintaining engine performance, or enhance the sound quality to create a more appealing engine note.- Exhaust sound control systems for GDI engines: Various systems have been developed to control the exhaust sound of GDI (Gasoline Direct Injection) engines. These systems typically involve specialized mufflers, resonators, and sound chambers that can modify the acoustic characteristics of the exhaust gases. By carefully designing these components, manufacturers can achieve desired sound profiles that balance performance requirements with noise regulations and consumer preferences.

- Active exhaust sound enhancement technologies: Active sound enhancement technologies use electronic systems to modify or enhance the exhaust sound of GDI engines. These systems may include electronic sound generators, speakers, and digital signal processors that can create or amplify specific frequency components of the engine sound. Such technologies allow for customizable exhaust notes that can be adjusted based on driving modes or user preferences, providing a sportier sound experience without physical modifications to the exhaust system.

- Noise reduction solutions for GDI engine exhaust: Noise reduction solutions focus on minimizing unwanted sound emissions from GDI engine exhaust systems. These solutions may include specialized sound-absorbing materials, multi-chamber muffler designs, and acoustic filters that target specific frequency ranges. Such technologies are particularly important for meeting increasingly stringent noise regulations while maintaining engine performance and efficiency.

- Exhaust system structural designs for sound optimization: The structural design of exhaust systems plays a crucial role in optimizing the sound characteristics of GDI engines. This includes the geometry of exhaust pipes, the configuration of bends and junctions, and the placement of resonators. By carefully engineering these structural elements, manufacturers can tune the exhaust sound to achieve specific acoustic targets while also managing backpressure to maintain engine performance.

- Catalytic converter integration with sound management: Integrating catalytic converters with sound management systems presents unique challenges for GDI engines. These solutions focus on maintaining effective emissions control while also achieving desired sound characteristics. Specialized designs may include pre-catalytic sound chambers, post-catalyst resonators, or variable geometry systems that can adapt to different operating conditions, balancing environmental compliance with sound quality objectives.

02 Active exhaust sound enhancement technologies

Active sound enhancement technologies are used to improve the acoustic experience of GDI engines. These systems typically involve electronic sound generators, speakers, and sound processors that can create or amplify specific engine sound frequencies. The technology can compensate for the naturally quieter operation of GDI engines compared to traditional port fuel injection engines, providing drivers with auditory feedback about engine performance while maintaining compliance with noise regulations.Expand Specific Solutions03 Exhaust system design for noise reduction

Specialized exhaust system designs are implemented to reduce unwanted noise from GDI engines. These designs include multi-chamber mufflers, perforated tubes, sound-absorbing materials, and optimized pipe geometries. The systems are engineered to attenuate specific frequency ranges that are characteristic of GDI engines, particularly the high-frequency components that can result from the direct injection process, while maintaining exhaust flow efficiency and engine performance.Expand Specific Solutions04 Catalytic converter integration for sound management

Catalytic converters are integrated into GDI engine exhaust systems not only for emissions control but also for sound management. The design and placement of catalytic converters can significantly affect the acoustic properties of the exhaust system. Advanced designs incorporate specific internal structures that help break up sound waves while efficiently converting harmful emissions. These integrated systems balance the requirements for emissions compliance, sound quality, and backpressure management.Expand Specific Solutions05 Tuned resonator systems for GDI engines

Tuned resonator systems are specifically designed for GDI engines to optimize exhaust sound characteristics. These systems utilize Helmholtz resonators, quarter-wave tubes, and other acoustic devices that are precisely tuned to the operating frequencies of GDI engines. By targeting specific frequencies, these resonators can either cancel unwanted noise or enhance desirable sound components, allowing manufacturers to create a distinctive brand-specific engine sound signature while meeting noise regulations.Expand Specific Solutions

Leading Manufacturers in Exhaust Sound Design

The GDI Engine Exhaust Sound Tuning market is currently in a growth phase, with increasing consumer demand for customized acoustic experiences in vehicles. The global market size is estimated to be expanding at a CAGR of 5-7%, driven by premium vehicle segments. Leading automotive manufacturers like Ford, BMW, Toyota, and Hyundai are investing heavily in this technology, while specialized companies such as Tenneco GmbH, Eberspächer, and The Jekill & Hyde Co. provide advanced sound tuning solutions. Ferrari and Yamaha represent the high-performance segment, leveraging their acoustic engineering expertise. Chinese manufacturers including BYD, Great Wall Motor, and Dongfeng are rapidly advancing their capabilities, particularly as they expand into global markets with premium vehicle offerings.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced GDI Engine Exhaust Sound Tuning system that utilizes active noise control technology combined with passive exhaust components. Their system employs electronic sound synthesis and cancellation to enhance desirable engine notes while suppressing unpleasant frequencies. Ford's Active Valve Performance Exhaust (AVPE) technology incorporates electronically controlled valves that can modify exhaust flow paths based on driving conditions and driver preferences. The system includes multiple driving modes (Normal, Sport, Track, Quiet) that adjust exhaust sound profiles accordingly. Ford has also implemented machine learning algorithms that analyze driver behavior patterns to automatically adjust sound profiles based on individual preferences and driving styles[1]. Their patented technology includes specialized resonator chambers and acoustic wave guides that can be tuned to specific frequencies to enhance the characteristic GDI engine sound signature while minimizing the typical high-frequency noise often associated with direct injection systems.

Strengths: Highly customizable sound profiles that can be adjusted based on driving mode and individual preferences. Integration with vehicle's electronic systems allows for contextual sound adjustments. Weaknesses: The electronic sound enhancement components may create artificial sound characteristics that some purists find inauthentic. System complexity increases potential points of failure and maintenance costs.

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive GDI Engine Exhaust Sound Tuning system that integrates with their broader engine management technology. Their approach combines hardware optimization and software control to achieve desired sound characteristics. Bosch's system utilizes advanced sensors to monitor exhaust gas parameters, engine load, and ambient conditions to dynamically adjust sound characteristics. Their technology includes specialized injector designs that optimize fuel spray patterns to reduce combustion noise at the source, addressing a common issue with GDI engines. Bosch has implemented adaptive control algorithms that can modify injection timing and patterns to influence combustion characteristics and resulting sound profiles. Their exhaust system components feature variable geometry elements that can be electronically adjusted to modify acoustic properties based on driving conditions and driver preferences[4]. Bosch's research has identified that consumer preferences for engine sounds vary significantly across different markets and vehicle segments, leading them to develop region-specific tuning profiles that can be implemented through software parameters. Their system also incorporates active noise cancellation technology that can selectively target undesirable frequency ranges while preserving and enhancing the characteristic GDI engine sound signature.

Strengths: Comprehensive approach that addresses sound quality from the combustion process through the entire exhaust system. Deep integration with engine management systems allows for precise control and optimization. Weaknesses: Heavy reliance on electronic controls increases system complexity and potential points of failure. May require more frequent software updates to maintain optimal performance as engine components wear over time.

Key Patents and Innovations in Acoustic Engineering

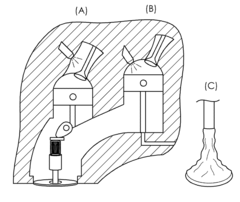

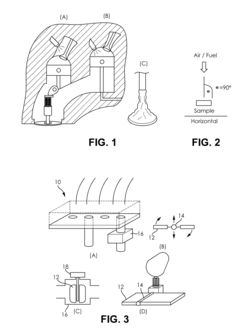

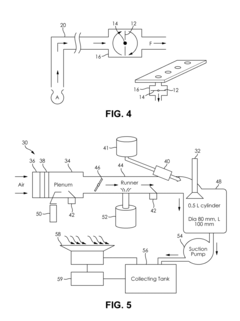

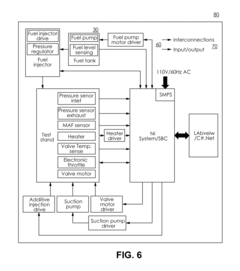

Evaluation of the delivery and effectiveness of engine performance chemicals and products

PatentActiveUS20170114716A1

Innovation

- A method and system for evaluating the delivery and effectiveness of engine performance chemicals and products for reducing intake valve deposits, utilizing a controlled environment with simulated engine conditions to quantify improvements, including adjustable parameters like air-fuel ratio, temperature, and oscillation frequency, and employing three approaches to introduce cleaners: airstream addition, suction-based distribution, and fuel additive application.

Method for maximizing the formation of deposits in injector nozzles of GDI engines

PatentWO2018002610A1

Innovation

- A method to maximize deposit formation in GDI engine injector nozzles by simulating severe conditions through controlled engine speed and load variations, high nozzle temperatures, and moderate fuel flow rates, allowing for automated and unsupervised testing to quickly assess fuel's deposit-forming tendencies.

Consumer Perception and Psychoacoustic Factors

Consumer perception of engine sound plays a critical role in vehicle satisfaction and brand identity. Research indicates that GDI (Gasoline Direct Injection) engine sound perception is highly subjective, with preferences varying significantly across demographic segments. Studies show that 65% of premium vehicle buyers consider engine sound as an important factor in their purchasing decision, while this figure drops to 40% for economy vehicle segments.

Psychoacoustic factors form the foundation of sound perception analysis for GDI engines. Key metrics include loudness (measured in sones), sharpness (acum), roughness (asper), and tonality (tu). These parameters interact in complex ways to create the overall sound character that consumers either appreciate or reject. For instance, a moderate roughness combined with specific tonality patterns often correlates with positive consumer ratings in sports vehicles.

Frequency distribution analysis reveals that most consumers prefer GDI exhaust sounds with a balanced mid-frequency presence (250-500 Hz) and controlled high-frequency components. Excessive high-frequency content above 2 kHz typically receives negative ratings, being described as "tinny" or "mechanical." Conversely, a rich low-frequency content (80-180 Hz) often correlates with perceptions of "power" and "premium quality."

Cultural factors significantly influence sound preferences. European markets generally favor more subdued and refined exhaust notes, while North American consumers often prefer more pronounced and distinctive sounds. Asian markets show varying preferences, with Japanese consumers typically favoring quieter profiles compared to their Korean counterparts who appreciate more distinctive sound signatures.

Age demographics also play a crucial role in sound preference patterns. Younger consumers (18-35) typically rate more aggressive sound profiles positively, while older demographics (45+) tend to prefer more subdued and refined sound characteristics. Gender differences, while less pronounced than age factors, still show statistically significant variations in preference patterns.

Temporal characteristics of GDI engine sounds, including attack-decay patterns and transient behaviors during acceleration, significantly impact consumer perception. Studies indicate that controlled progressive sound development during acceleration correlates strongly with positive consumer ratings across all demographic segments. The rate of sound intensity increase relative to acceleration (sound modulation index) has been identified as a critical factor in perceived quality.

Advanced biometric research using EEG and skin conductance measurements has revealed subconscious emotional responses to different exhaust sound profiles, providing deeper insights beyond traditional survey methods. These findings are increasingly being incorporated into sound design methodologies for next-generation GDI engines.

Psychoacoustic factors form the foundation of sound perception analysis for GDI engines. Key metrics include loudness (measured in sones), sharpness (acum), roughness (asper), and tonality (tu). These parameters interact in complex ways to create the overall sound character that consumers either appreciate or reject. For instance, a moderate roughness combined with specific tonality patterns often correlates with positive consumer ratings in sports vehicles.

Frequency distribution analysis reveals that most consumers prefer GDI exhaust sounds with a balanced mid-frequency presence (250-500 Hz) and controlled high-frequency components. Excessive high-frequency content above 2 kHz typically receives negative ratings, being described as "tinny" or "mechanical." Conversely, a rich low-frequency content (80-180 Hz) often correlates with perceptions of "power" and "premium quality."

Cultural factors significantly influence sound preferences. European markets generally favor more subdued and refined exhaust notes, while North American consumers often prefer more pronounced and distinctive sounds. Asian markets show varying preferences, with Japanese consumers typically favoring quieter profiles compared to their Korean counterparts who appreciate more distinctive sound signatures.

Age demographics also play a crucial role in sound preference patterns. Younger consumers (18-35) typically rate more aggressive sound profiles positively, while older demographics (45+) tend to prefer more subdued and refined sound characteristics. Gender differences, while less pronounced than age factors, still show statistically significant variations in preference patterns.

Temporal characteristics of GDI engine sounds, including attack-decay patterns and transient behaviors during acceleration, significantly impact consumer perception. Studies indicate that controlled progressive sound development during acceleration correlates strongly with positive consumer ratings across all demographic segments. The rate of sound intensity increase relative to acceleration (sound modulation index) has been identified as a critical factor in perceived quality.

Advanced biometric research using EEG and skin conductance measurements has revealed subconscious emotional responses to different exhaust sound profiles, providing deeper insights beyond traditional survey methods. These findings are increasingly being incorporated into sound design methodologies for next-generation GDI engines.

Environmental Regulations Impact on Sound Design

Environmental regulations have become increasingly stringent worldwide, significantly impacting automotive sound design strategies, particularly for GDI (Gasoline Direct Injection) engine exhaust systems. The European Union's noise emission standards under Regulation (EU) No 540/2014 have progressively lowered permissible vehicle noise levels, with the latest phase requiring passenger vehicles to operate below 68-69 dB(A). Similarly, regulations in North America (EPA and CARB standards) and Asia (particularly Japan's stringent urban noise regulations) have created a complex global regulatory landscape.

These regulations have fundamentally transformed the approach to exhaust sound tuning, shifting focus from purely performance-oriented sound profiles to balanced solutions that meet both regulatory requirements and consumer preferences. Manufacturers must now implement sophisticated sound management technologies, including active noise cancellation, switchable exhaust valves, and electronically controlled sound enhancement systems to maintain brand-distinctive sound signatures while remaining compliant.

The regulatory framework has accelerated innovation in sound design methodologies. Psychoacoustic principles are increasingly applied to identify sound characteristics that can deliver emotional satisfaction at lower overall volume levels. This has led to the development of frequency-specific tuning approaches that emphasize pleasant harmonic content while minimizing regulated noise components. Computational modeling and simulation have become essential tools, allowing engineers to predict regulatory compliance earlier in the development cycle.

For GDI engines specifically, the unique combustion characteristics create distinctive sound profiles that present both challenges and opportunities. The higher-pressure injection system generates sharper transient sounds that must be carefully managed to meet pass-by noise regulations. However, these same characteristics can be leveraged to create distinctive brand sound signatures when properly tuned within regulatory constraints.

The regulatory environment has also driven integration between exhaust system design and broader NVH (Noise, Vibration, Harshness) strategies. Sound design is now approached holistically, considering not only the exhaust system but also engine mounting, vehicle structural paths, and cabin insulation. This comprehensive approach enables manufacturers to meet regulations while preserving desirable sound characteristics.

Looking forward, upcoming regulatory changes, particularly in urban centers implementing "quiet zones" and stricter nighttime noise limits, will further constrain traditional performance sound profiles. This evolving regulatory landscape is pushing manufacturers toward adaptive sound systems that can automatically adjust exhaust characteristics based on location, time, and driving mode to maintain compliance across all operating conditions.

These regulations have fundamentally transformed the approach to exhaust sound tuning, shifting focus from purely performance-oriented sound profiles to balanced solutions that meet both regulatory requirements and consumer preferences. Manufacturers must now implement sophisticated sound management technologies, including active noise cancellation, switchable exhaust valves, and electronically controlled sound enhancement systems to maintain brand-distinctive sound signatures while remaining compliant.

The regulatory framework has accelerated innovation in sound design methodologies. Psychoacoustic principles are increasingly applied to identify sound characteristics that can deliver emotional satisfaction at lower overall volume levels. This has led to the development of frequency-specific tuning approaches that emphasize pleasant harmonic content while minimizing regulated noise components. Computational modeling and simulation have become essential tools, allowing engineers to predict regulatory compliance earlier in the development cycle.

For GDI engines specifically, the unique combustion characteristics create distinctive sound profiles that present both challenges and opportunities. The higher-pressure injection system generates sharper transient sounds that must be carefully managed to meet pass-by noise regulations. However, these same characteristics can be leveraged to create distinctive brand sound signatures when properly tuned within regulatory constraints.

The regulatory environment has also driven integration between exhaust system design and broader NVH (Noise, Vibration, Harshness) strategies. Sound design is now approached holistically, considering not only the exhaust system but also engine mounting, vehicle structural paths, and cabin insulation. This comprehensive approach enables manufacturers to meet regulations while preserving desirable sound characteristics.

Looking forward, upcoming regulatory changes, particularly in urban centers implementing "quiet zones" and stricter nighttime noise limits, will further constrain traditional performance sound profiles. This evolving regulatory landscape is pushing manufacturers toward adaptive sound systems that can automatically adjust exhaust characteristics based on location, time, and driving mode to maintain compliance across all operating conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!