GDI Engine's Transmission Adaptations for Fuel Saving

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Engine Evolution and Fuel Efficiency Goals

Gasoline Direct Injection (GDI) technology has evolved significantly since its commercial introduction in the late 1990s. The evolution pathway of GDI engines represents a critical advancement in internal combustion engine technology, moving from traditional port fuel injection systems to more precise direct injection methods. This transition has been driven by increasingly stringent global emissions regulations and consumer demand for improved fuel economy without sacrificing performance.

The first generation of GDI engines focused primarily on the fundamental injection technology, with relatively simple spray patterns and limited injection pressure capabilities of 50-100 bar. These early systems demonstrated modest fuel economy improvements of 3-5% compared to port fuel injection systems, primarily through charge cooling effects and reduced pumping losses.

Second-generation GDI systems (2005-2012) introduced multi-pulse injection strategies and increased injection pressures up to 200 bar. These advancements enabled more precise fuel delivery timing and improved atomization, resulting in fuel economy gains of 5-10% while simultaneously reducing particulate emissions.

Current third-generation GDI technology incorporates sophisticated injection pressures exceeding 350 bar, advanced spray targeting, and integration with other efficiency-enhancing technologies such as variable valve timing, turbocharging, and cylinder deactivation. This holistic approach has pushed fuel efficiency improvements to 15-20% compared to equivalent port-injected engines.

The primary fuel efficiency goals for GDI engine development center around several key technical objectives. First is the optimization of combustion processes through stratified charge operation, where fuel is concentrated around the spark plug in lean overall conditions. This approach can reduce throttling losses and improve thermal efficiency, particularly at part-load conditions where engines typically operate during normal driving.

Another critical goal involves minimizing heat losses through improved thermal management and reducing friction within the engine and transmission systems. Advanced coating technologies and optimized cooling strategies are being deployed to retain more combustion energy for useful work rather than waste heat.

Integration with transmission systems represents a particularly promising frontier for GDI fuel efficiency. Adaptive transmission control strategies that optimize shift points based on GDI engine efficiency maps can yield additional 3-7% fuel economy improvements. The development of transmission systems specifically calibrated for GDI engines' unique torque characteristics enables operation in the most efficient regions of the engine map more frequently.

Looking forward, the industry aims to achieve a cumulative 25-30% improvement in fuel efficiency through next-generation GDI systems coupled with advanced transmission technologies, representing a significant contribution to meeting increasingly stringent fleet fuel economy standards worldwide.

The first generation of GDI engines focused primarily on the fundamental injection technology, with relatively simple spray patterns and limited injection pressure capabilities of 50-100 bar. These early systems demonstrated modest fuel economy improvements of 3-5% compared to port fuel injection systems, primarily through charge cooling effects and reduced pumping losses.

Second-generation GDI systems (2005-2012) introduced multi-pulse injection strategies and increased injection pressures up to 200 bar. These advancements enabled more precise fuel delivery timing and improved atomization, resulting in fuel economy gains of 5-10% while simultaneously reducing particulate emissions.

Current third-generation GDI technology incorporates sophisticated injection pressures exceeding 350 bar, advanced spray targeting, and integration with other efficiency-enhancing technologies such as variable valve timing, turbocharging, and cylinder deactivation. This holistic approach has pushed fuel efficiency improvements to 15-20% compared to equivalent port-injected engines.

The primary fuel efficiency goals for GDI engine development center around several key technical objectives. First is the optimization of combustion processes through stratified charge operation, where fuel is concentrated around the spark plug in lean overall conditions. This approach can reduce throttling losses and improve thermal efficiency, particularly at part-load conditions where engines typically operate during normal driving.

Another critical goal involves minimizing heat losses through improved thermal management and reducing friction within the engine and transmission systems. Advanced coating technologies and optimized cooling strategies are being deployed to retain more combustion energy for useful work rather than waste heat.

Integration with transmission systems represents a particularly promising frontier for GDI fuel efficiency. Adaptive transmission control strategies that optimize shift points based on GDI engine efficiency maps can yield additional 3-7% fuel economy improvements. The development of transmission systems specifically calibrated for GDI engines' unique torque characteristics enables operation in the most efficient regions of the engine map more frequently.

Looking forward, the industry aims to achieve a cumulative 25-30% improvement in fuel efficiency through next-generation GDI systems coupled with advanced transmission technologies, representing a significant contribution to meeting increasingly stringent fleet fuel economy standards worldwide.

Market Demand for Fuel-Efficient Transmission Systems

The global automotive industry is witnessing a significant shift towards fuel-efficient technologies, with transmission systems playing a crucial role in this transformation. Market research indicates that the fuel-efficient transmission systems market was valued at approximately $26.4 billion in 2022 and is projected to reach $45.7 billion by 2030, growing at a CAGR of 7.1%. This growth is primarily driven by stringent emission regulations, rising fuel costs, and increasing consumer demand for economical vehicles.

Consumer preferences have evolved substantially over the past decade, with fuel economy now ranking among the top three purchase considerations for new vehicle buyers across major markets including North America, Europe, and Asia. A recent J.D. Power survey revealed that 78% of prospective car buyers consider fuel efficiency "extremely important" or "very important" in their purchasing decisions, representing a 12% increase from five years ago.

Regulatory pressures continue to be a significant market driver. The European Union's target to reduce CO2 emissions by 55% by 2030 compared to 1990 levels, China's dual-credit policy, and the United States' Corporate Average Fuel Economy (CAFE) standards are compelling automakers to invest heavily in transmission technologies that complement GDI engines for optimal fuel efficiency.

Fleet operators and commercial vehicle segments represent another substantial market demand vector. With fuel costs accounting for approximately 30% of operational expenses for commercial fleets, the return on investment for advanced transmission systems paired with GDI engines is particularly compelling. Fleet managers increasingly prioritize total cost of ownership calculations that favor fuel-saving technologies.

Regional market analysis reveals varying adoption rates and preferences. While automatic transmissions with 8-10 speeds dominate the North American market, European consumers show stronger preference for dual-clutch transmissions (DCTs) and automated manual transmissions (AMTs) paired with GDI engines. The Asia-Pacific region, particularly China and India, is experiencing the fastest growth rate for fuel-efficient transmission systems, driven by rapid urbanization and growing middle-class populations.

Emerging markets present significant growth opportunities, with countries like Brazil, Mexico, and Thailand showing increased demand for vehicles equipped with fuel-efficient transmission systems. These markets are particularly sensitive to fuel prices, making GDI engine-transmission pairings an attractive selling proposition.

The aftermarket segment for transmission upgrades compatible with GDI engines is also expanding, with a market size of approximately $3.8 billion in 2022. This indicates growing consumer willingness to invest in post-purchase modifications to improve fuel economy in existing vehicles, creating additional revenue streams for transmission technology providers.

Consumer preferences have evolved substantially over the past decade, with fuel economy now ranking among the top three purchase considerations for new vehicle buyers across major markets including North America, Europe, and Asia. A recent J.D. Power survey revealed that 78% of prospective car buyers consider fuel efficiency "extremely important" or "very important" in their purchasing decisions, representing a 12% increase from five years ago.

Regulatory pressures continue to be a significant market driver. The European Union's target to reduce CO2 emissions by 55% by 2030 compared to 1990 levels, China's dual-credit policy, and the United States' Corporate Average Fuel Economy (CAFE) standards are compelling automakers to invest heavily in transmission technologies that complement GDI engines for optimal fuel efficiency.

Fleet operators and commercial vehicle segments represent another substantial market demand vector. With fuel costs accounting for approximately 30% of operational expenses for commercial fleets, the return on investment for advanced transmission systems paired with GDI engines is particularly compelling. Fleet managers increasingly prioritize total cost of ownership calculations that favor fuel-saving technologies.

Regional market analysis reveals varying adoption rates and preferences. While automatic transmissions with 8-10 speeds dominate the North American market, European consumers show stronger preference for dual-clutch transmissions (DCTs) and automated manual transmissions (AMTs) paired with GDI engines. The Asia-Pacific region, particularly China and India, is experiencing the fastest growth rate for fuel-efficient transmission systems, driven by rapid urbanization and growing middle-class populations.

Emerging markets present significant growth opportunities, with countries like Brazil, Mexico, and Thailand showing increased demand for vehicles equipped with fuel-efficient transmission systems. These markets are particularly sensitive to fuel prices, making GDI engine-transmission pairings an attractive selling proposition.

The aftermarket segment for transmission upgrades compatible with GDI engines is also expanding, with a market size of approximately $3.8 billion in 2022. This indicates growing consumer willingness to invest in post-purchase modifications to improve fuel economy in existing vehicles, creating additional revenue streams for transmission technology providers.

Technical Challenges in GDI-Transmission Integration

The integration of Gasoline Direct Injection (GDI) engines with advanced transmission systems presents significant technical challenges that must be addressed to maximize fuel efficiency benefits. The primary obstacle lies in the synchronization of engine operation parameters with transmission shift strategies, as GDI engines operate with precise fuel injection timing that must align with transmission gear changes to maintain optimal combustion efficiency.

One major challenge is managing the transient response during gear shifts. GDI engines typically operate with stratified charge combustion at part-load conditions to improve fuel economy, but this combustion mode is sensitive to rapid load changes that occur during transmission shifts. Engineers must develop sophisticated control algorithms that anticipate gear changes and adjust injection timing and quantity accordingly to prevent combustion instability or increased emissions during these transient events.

Thermal management presents another significant hurdle in GDI-transmission integration. GDI engines generally run at higher temperatures than port fuel injection systems, requiring more robust cooling systems. This thermal characteristic must be considered when designing transmission fluid cooling systems, as excessive heat transfer between engine and transmission components can degrade transmission fluid properties and reduce shifting performance and component longevity.

The complexity of control systems integration cannot be overstated. Modern GDI engines utilize sophisticated electronic control units (ECUs) that must communicate seamlessly with transmission control modules (TCMs). Latency in communication between these systems can result in suboptimal shift timing, negating potential fuel economy benefits. Developing robust communication protocols with minimal latency remains a persistent challenge for system integrators.

Calibration complexity increases exponentially when integrating GDI engines with advanced transmissions. Engineers must optimize thousands of calibration parameters across various operating conditions, including cold starts, warm-up phases, and different driving modes. This calibration process is further complicated by the need to meet stringent emissions regulations while maximizing fuel economy benefits.

Material compatibility issues also emerge at the interface between GDI engines and transmissions. Higher operating temperatures and pressures in GDI systems require transmission components that can withstand these conditions without premature wear or failure. Additionally, the vibration characteristics of GDI engines differ from conventional engines, necessitating careful design of mounting points and damping systems to prevent transmission damage and maintain shift quality.

Finally, packaging constraints present significant engineering challenges. The additional components required for GDI systems, such as high-pressure fuel pumps and fuel rails, compete for space with transmission components, particularly in compact vehicle platforms. This spatial competition often forces compromises in component design that can impact overall system performance and serviceability.

One major challenge is managing the transient response during gear shifts. GDI engines typically operate with stratified charge combustion at part-load conditions to improve fuel economy, but this combustion mode is sensitive to rapid load changes that occur during transmission shifts. Engineers must develop sophisticated control algorithms that anticipate gear changes and adjust injection timing and quantity accordingly to prevent combustion instability or increased emissions during these transient events.

Thermal management presents another significant hurdle in GDI-transmission integration. GDI engines generally run at higher temperatures than port fuel injection systems, requiring more robust cooling systems. This thermal characteristic must be considered when designing transmission fluid cooling systems, as excessive heat transfer between engine and transmission components can degrade transmission fluid properties and reduce shifting performance and component longevity.

The complexity of control systems integration cannot be overstated. Modern GDI engines utilize sophisticated electronic control units (ECUs) that must communicate seamlessly with transmission control modules (TCMs). Latency in communication between these systems can result in suboptimal shift timing, negating potential fuel economy benefits. Developing robust communication protocols with minimal latency remains a persistent challenge for system integrators.

Calibration complexity increases exponentially when integrating GDI engines with advanced transmissions. Engineers must optimize thousands of calibration parameters across various operating conditions, including cold starts, warm-up phases, and different driving modes. This calibration process is further complicated by the need to meet stringent emissions regulations while maximizing fuel economy benefits.

Material compatibility issues also emerge at the interface between GDI engines and transmissions. Higher operating temperatures and pressures in GDI systems require transmission components that can withstand these conditions without premature wear or failure. Additionally, the vibration characteristics of GDI engines differ from conventional engines, necessitating careful design of mounting points and damping systems to prevent transmission damage and maintain shift quality.

Finally, packaging constraints present significant engineering challenges. The additional components required for GDI systems, such as high-pressure fuel pumps and fuel rails, compete for space with transmission components, particularly in compact vehicle platforms. This spatial competition often forces compromises in component design that can impact overall system performance and serviceability.

Current GDI-Transmission Coupling Solutions

01 GDI Engine Optimization for Fuel Efficiency

Gasoline Direct Injection (GDI) engines can be optimized to improve fuel efficiency through various techniques. These include optimizing the fuel injection timing, pressure, and spray pattern to ensure complete combustion. Advanced control strategies for the air-fuel mixture and combustion process can significantly reduce fuel consumption. These optimizations directly impact the overall efficiency of the powertrain system when integrated with transmission technologies.- GDI engine optimization for fuel efficiency: Gasoline Direct Injection (GDI) engines can be optimized to improve fuel efficiency through various techniques. These include optimizing the fuel injection timing, pressure, and spray pattern to ensure complete combustion. Advanced control strategies can adjust these parameters based on driving conditions to minimize fuel consumption while maintaining performance. These optimizations directly impact the overall fuel economy of vehicles equipped with GDI engines.

- Transmission technologies for GDI engine systems: Specialized transmission technologies designed to work with GDI engines can significantly improve fuel economy. These include continuously variable transmissions (CVTs), dual-clutch transmissions (DCTs), and automated manual transmissions that optimize gear ratios based on engine load and speed. Advanced transmission control units can communicate with the engine management system to select the most efficient operating points, reducing fuel consumption during various driving conditions.

- Integration of GDI with hybrid powertrain systems: Combining GDI engines with hybrid powertrain technologies creates synergistic fuel-saving benefits. These systems can include mild hybrid, full hybrid, or plug-in hybrid configurations that use electric motors to assist the GDI engine during high-load conditions. The integration allows for engine downsizing while maintaining performance, start-stop functionality, regenerative braking, and electric-only operation at low speeds, all contributing to significant improvements in fuel economy.

- Advanced control strategies for GDI and transmission coordination: Sophisticated control algorithms can coordinate GDI engine operation with transmission behavior to maximize fuel efficiency. These strategies include predictive control based on GPS and traffic data, adaptive learning of driver behavior, and real-time optimization of engine-transmission operating points. By ensuring the engine operates in its most efficient regions and the transmission selects optimal gear ratios, these control systems can significantly reduce fuel consumption across various driving scenarios.

- Thermal management systems for GDI efficiency: Innovative thermal management systems can enhance GDI engine efficiency and reduce fuel consumption. These include advanced cooling systems that maintain optimal operating temperatures, exhaust heat recovery systems that capture waste heat for faster warm-up or conversion to useful energy, and thermal barrier coatings that reduce heat losses. By optimizing the thermal conditions of the engine and transmission, these systems help improve combustion efficiency and reduce mechanical losses, leading to better fuel economy.

02 Transmission Control Systems for GDI Engines

Specialized transmission control systems designed for GDI engines can substantially improve fuel economy. These systems optimize gear shifting patterns based on engine load, vehicle speed, and driving conditions. Adaptive transmission control algorithms can learn driver behavior and road conditions to select the most efficient gear ratios. Integration of transmission control with the engine management system ensures optimal coordination between fuel injection and gear selection for maximum efficiency.Expand Specific Solutions03 Hybrid Transmission Systems with GDI Technology

Combining GDI engine technology with hybrid transmission systems offers significant fuel savings. These systems integrate electric motors with conventional transmissions to provide power assistance during acceleration and energy recovery during deceleration. The hybrid transmission can allow the GDI engine to operate in its most efficient range more frequently. Some systems include start-stop functionality that shuts down the engine during idle periods, further reducing fuel consumption.Expand Specific Solutions04 Thermal Management for GDI Transmission Systems

Effective thermal management systems for GDI engines and their transmissions can significantly improve fuel efficiency. These systems optimize operating temperatures for both the engine and transmission fluid to reduce friction losses. Advanced cooling systems ensure that components operate within ideal temperature ranges, preventing overheating while maintaining efficiency. Some designs incorporate heat recovery systems that capture waste heat from the engine to warm transmission fluid more quickly, reducing energy losses during cold starts.Expand Specific Solutions05 Lightweight Materials and Design for GDI Powertrains

The use of lightweight materials and innovative designs in GDI engine and transmission components can lead to substantial fuel savings. Reducing the weight of powertrain components decreases the overall vehicle mass, requiring less energy for acceleration. Advanced materials such as aluminum alloys, high-strength steels, and composites are used to create lighter yet durable transmission housings and internal components. Optimized designs that reduce friction and improve power transfer efficiency further enhance fuel economy in GDI-equipped vehicles.Expand Specific Solutions

Key Manufacturers in GDI Engine Transmission Market

GDI Engine's Transmission Adaptations for Fuel Saving technology is currently in a growth phase, with an expanding market estimated to reach $5-7 billion by 2025. The competitive landscape features established automotive manufacturers like Hyundai, Ford, and Kia leading development alongside specialized component suppliers such as Delphi Technologies and Lubrizol. Technical maturity varies across implementations, with Hyundai and Ford demonstrating advanced integration of GDI with transmission optimization, while companies like Southwest Research Institute and AVL List provide crucial R&D support. Chinese manufacturers including FAW, Chery, and Changan are rapidly closing the technology gap, particularly in cost-effective adaptations for emerging markets.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has pioneered a comprehensive GDI transmission adaptation system called Continuously Variable Valve Duration (CVVD) technology that works in conjunction with their SmartStream transmission systems. This innovative approach continuously adjusts valve duration according to driving conditions and transmission states, optimizing both power output and fuel efficiency. The system incorporates transmission-aware fuel injection mapping that precisely controls the amount and timing of fuel delivery based on current gear, torque converter status, and anticipated shift patterns. Hyundai's technology also features an integrated thermal management system that optimizes engine and transmission operating temperatures to reduce friction losses and improve combustion efficiency. Their implementation includes advanced knock detection algorithms that allow higher compression ratios while preventing detonation across various transmission load conditions, resulting in approximately 12% better fuel economy and 4% more torque compared to conventional systems.

Strengths: Innovative valve duration control provides exceptional flexibility across operating conditions; excellent balance between performance and efficiency; relatively simple mechanical implementation. Weaknesses: Requires sophisticated electronic controls and sensors; potential reliability concerns with newer technology; higher manufacturing complexity compared to traditional systems.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced GDI engine transmission adaptation system that dynamically adjusts fuel injection timing and quantity based on real-time transmission data. Their system incorporates predictive algorithms that anticipate gear shifts and optimize fuel delivery accordingly. Ford's technology includes cylinder deactivation that works in harmony with transmission states, allowing the engine to operate on fewer cylinders during light load conditions while maintaining seamless power delivery through the transmission. The system also features adaptive learning capabilities that continuously refine fuel delivery strategies based on driving patterns and transmission wear characteristics. Ford has implemented this technology across their EcoBoost engine lineup, achieving up to 15% improvement in fuel economy compared to conventional port fuel injection systems when integrated with their 10-speed automatic transmissions.

Strengths: Excellent integration with existing powertrain systems; proven fuel economy benefits across diverse driving conditions; mature technology with extensive real-world validation. Weaknesses: Higher initial system complexity and cost; requires sophisticated control algorithms that need extensive calibration for each vehicle application.

Innovative Patents in GDI Transmission Optimization

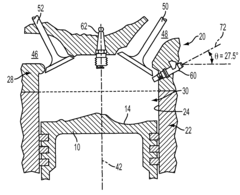

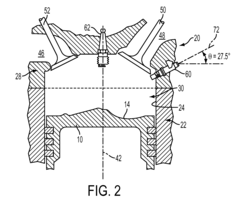

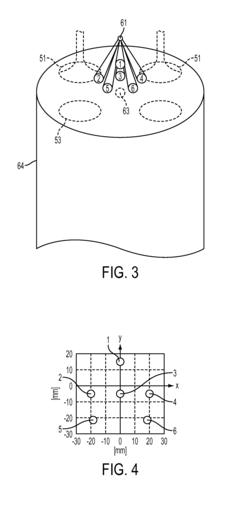

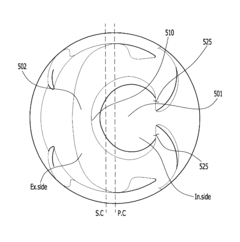

Shallow piston bowl and injector spray pattern for a gasoline, direct-injection engine

PatentActiveUS8056531B2

Innovation

- A combustion system design featuring a piston with a shallow spherical bowl and a fuel injector with six orifices, where the injector axis forms an angle greater than 60 degrees with the cylinder bore axis, and two orifices are directed toward the bowl to create a stable stratified mixture around the spark plug, minimizing soot emissions and improving thermal efficiency.

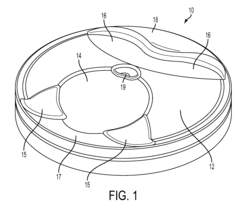

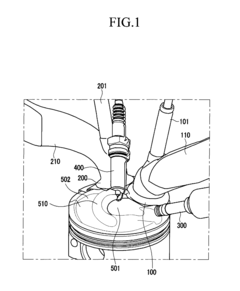

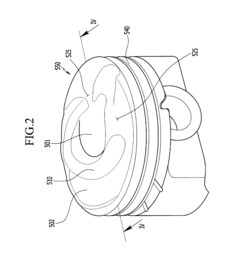

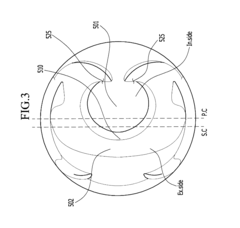

Gasoline direct injection engine

PatentInactiveUS8251040B2

Innovation

- The engine design includes a piston head with a first cavity for fuel return to the spark plug and a protrusion offset towards the exhaust valve, featuring a second cavity of a smaller height, allowing for differential control of intake and exhaust valve volumes to optimize the combustion chamber's volume ratio.

Emissions Regulations Impact on GDI Transmission Design

Emissions regulations have become increasingly stringent worldwide, directly influencing the design and operation of Gasoline Direct Injection (GDI) transmission systems. The European Union's Euro 6d standards and the United States' EPA Tier 3 regulations have established unprecedented limits on particulate matter and NOx emissions, forcing manufacturers to fundamentally rethink transmission strategies for GDI engines.

These regulatory frameworks have catalyzed significant adaptations in transmission design, particularly in shift strategies and gear ratio optimization. Engineers now prioritize keeping the engine operating within its most efficient and cleanest combustion zones, often requiring more frequent gear changes and modified shift patterns compared to previous generations. The integration of Real Driving Emissions (RDE) testing has further complicated transmission calibration, as systems must now perform optimally across a wider range of driving conditions rather than just standardized test cycles.

Transmission control units increasingly incorporate emissions-focused algorithms that dynamically adjust shift points based on real-time emissions monitoring. This represents a paradigm shift from traditional shift strategies that primarily prioritized performance or fuel economy. Modern GDI transmissions now feature adaptive learning capabilities that continuously optimize gear selection to maintain ideal air-fuel ratios and minimize particulate formation during transient operations.

The regulatory push toward electrification has also influenced GDI transmission design, with many manufacturers adopting hybrid-compatible transmissions that can seamlessly integrate electric motors. These systems enable engine-off operation during specific driving conditions, dramatically reducing urban emissions where air quality concerns are most acute. P2 hybrid configurations, where the electric motor is positioned between the engine and transmission, have become particularly prevalent as they allow for emissions reduction while maintaining conventional transmission architecture.

Cold-start emissions, which account for a disproportionate percentage of total vehicle emissions, have driven specific transmission adaptations. Modern GDI transmissions incorporate thermal management strategies that accelerate catalyst light-off and maintain optimal operating temperatures. This includes modified shift patterns during warm-up phases and integration with exhaust heat recovery systems.

The global regulatory divergence presents additional challenges, as manufacturers must design transmission systems capable of meeting different regional standards. This has led to modular transmission designs with region-specific calibrations and the increasing adoption of over-the-air update capabilities to adapt to evolving regulatory requirements without hardware modifications.

These regulatory frameworks have catalyzed significant adaptations in transmission design, particularly in shift strategies and gear ratio optimization. Engineers now prioritize keeping the engine operating within its most efficient and cleanest combustion zones, often requiring more frequent gear changes and modified shift patterns compared to previous generations. The integration of Real Driving Emissions (RDE) testing has further complicated transmission calibration, as systems must now perform optimally across a wider range of driving conditions rather than just standardized test cycles.

Transmission control units increasingly incorporate emissions-focused algorithms that dynamically adjust shift points based on real-time emissions monitoring. This represents a paradigm shift from traditional shift strategies that primarily prioritized performance or fuel economy. Modern GDI transmissions now feature adaptive learning capabilities that continuously optimize gear selection to maintain ideal air-fuel ratios and minimize particulate formation during transient operations.

The regulatory push toward electrification has also influenced GDI transmission design, with many manufacturers adopting hybrid-compatible transmissions that can seamlessly integrate electric motors. These systems enable engine-off operation during specific driving conditions, dramatically reducing urban emissions where air quality concerns are most acute. P2 hybrid configurations, where the electric motor is positioned between the engine and transmission, have become particularly prevalent as they allow for emissions reduction while maintaining conventional transmission architecture.

Cold-start emissions, which account for a disproportionate percentage of total vehicle emissions, have driven specific transmission adaptations. Modern GDI transmissions incorporate thermal management strategies that accelerate catalyst light-off and maintain optimal operating temperatures. This includes modified shift patterns during warm-up phases and integration with exhaust heat recovery systems.

The global regulatory divergence presents additional challenges, as manufacturers must design transmission systems capable of meeting different regional standards. This has led to modular transmission designs with region-specific calibrations and the increasing adoption of over-the-air update capabilities to adapt to evolving regulatory requirements without hardware modifications.

Cost-Benefit Analysis of Advanced GDI Transmission Systems

The implementation of advanced GDI (Gasoline Direct Injection) transmission systems represents a significant investment for automotive manufacturers. This analysis examines the economic implications of these systems against their fuel-saving benefits to determine their overall value proposition.

Initial investment costs for advanced GDI transmission systems typically range from $800 to $1,500 per vehicle, depending on complexity and integration requirements. This includes hardware components such as high-precision injectors, advanced electronic control units, and specialized transmission components designed to optimize fuel delivery and power transfer. Manufacturing adaptation costs add approximately $200-$400 per unit during early production phases.

Research and development expenditures constitute a substantial portion of the overall cost structure. Automotive manufacturers invest between $50-100 million in developing advanced GDI transmission technologies, with ongoing refinement requiring 5-8% of annual R&D budgets. These investments must be amortized across production volumes to determine per-unit cost implications.

From a benefits perspective, advanced GDI transmission systems deliver fuel economy improvements ranging from 12-18% compared to conventional port injection systems with traditional transmissions. For an average consumer driving 15,000 miles annually with fuel costs at $3.50 per gallon, this translates to annual savings of $300-$450. Over a vehicle's 10-year lifespan, cumulative fuel savings can reach $3,000-$4,500, potentially exceeding the initial cost premium.

Maintenance considerations present a mixed economic picture. While GDI systems may require more expensive specialized maintenance (premium fuel recommendations, carbon cleaning procedures), they typically extend transmission fluid change intervals by 20-30%, reducing lifetime maintenance costs by approximately $200-$300.

Regulatory compliance benefits provide additional economic value. Advanced GDI transmission systems help manufacturers meet increasingly stringent CAFE standards and emissions regulations, potentially avoiding non-compliance penalties estimated at $90-$150 per vehicle. These systems also contribute to corporate carbon credit positions worth $75-$120 per vehicle in certain markets.

Consumer adoption analysis indicates that the payback period for advanced GDI transmission systems ranges from 3.2 to 5.8 years depending on driving patterns, fuel prices, and regional factors. This timeframe aligns with average vehicle ownership periods, suggesting positive lifetime value for most consumers.

The sensitivity analysis reveals that fuel price fluctuations significantly impact the cost-benefit equation. A 20% increase in fuel prices reduces the payback period by approximately 14 months, while a similar decrease extends it by 19 months. This variable represents the most significant factor affecting the economic viability of these systems.

Initial investment costs for advanced GDI transmission systems typically range from $800 to $1,500 per vehicle, depending on complexity and integration requirements. This includes hardware components such as high-precision injectors, advanced electronic control units, and specialized transmission components designed to optimize fuel delivery and power transfer. Manufacturing adaptation costs add approximately $200-$400 per unit during early production phases.

Research and development expenditures constitute a substantial portion of the overall cost structure. Automotive manufacturers invest between $50-100 million in developing advanced GDI transmission technologies, with ongoing refinement requiring 5-8% of annual R&D budgets. These investments must be amortized across production volumes to determine per-unit cost implications.

From a benefits perspective, advanced GDI transmission systems deliver fuel economy improvements ranging from 12-18% compared to conventional port injection systems with traditional transmissions. For an average consumer driving 15,000 miles annually with fuel costs at $3.50 per gallon, this translates to annual savings of $300-$450. Over a vehicle's 10-year lifespan, cumulative fuel savings can reach $3,000-$4,500, potentially exceeding the initial cost premium.

Maintenance considerations present a mixed economic picture. While GDI systems may require more expensive specialized maintenance (premium fuel recommendations, carbon cleaning procedures), they typically extend transmission fluid change intervals by 20-30%, reducing lifetime maintenance costs by approximately $200-$300.

Regulatory compliance benefits provide additional economic value. Advanced GDI transmission systems help manufacturers meet increasingly stringent CAFE standards and emissions regulations, potentially avoiding non-compliance penalties estimated at $90-$150 per vehicle. These systems also contribute to corporate carbon credit positions worth $75-$120 per vehicle in certain markets.

Consumer adoption analysis indicates that the payback period for advanced GDI transmission systems ranges from 3.2 to 5.8 years depending on driving patterns, fuel prices, and regional factors. This timeframe aligns with average vehicle ownership periods, suggesting positive lifetime value for most consumers.

The sensitivity analysis reveals that fuel price fluctuations significantly impact the cost-benefit equation. A 20% increase in fuel prices reduces the payback period by approximately 14 months, while a similar decrease extends it by 19 months. This variable represents the most significant factor affecting the economic viability of these systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!