How to Evaluate GDI Engine Cooling Fluid Efficiency

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Engine Cooling Technology Background and Objectives

Gasoline Direct Injection (GDI) engine technology has evolved significantly over the past three decades, revolutionizing the automotive industry with improved fuel efficiency and reduced emissions. The cooling system in GDI engines plays a critical role in maintaining optimal operating temperatures, directly impacting engine performance, durability, and emissions control. Traditional cooling methods have become increasingly inadequate as GDI engines generate higher combustion temperatures and more localized heat concentrations than port fuel injection systems.

The evolution of GDI cooling technology began in the early 1990s with basic adaptations of conventional cooling systems. By the mid-2000s, manufacturers introduced more sophisticated cooling strategies to address the unique thermal management challenges of direct injection. Recent advancements have focused on precision cooling techniques that target specific high-heat components such as injectors, cylinder heads, and exhaust valves with dedicated cooling channels.

Current technological trends in GDI engine cooling include the development of split cooling systems that maintain different temperature zones within the engine, variable-flow cooling pumps that adjust coolant circulation based on real-time thermal demands, and advanced coolant formulations designed specifically for the thermal characteristics of GDI engines. These innovations aim to balance the competing requirements of rapid warm-up for emissions reduction and effective heat dissipation during high-load operation.

The primary objective of GDI cooling fluid efficiency evaluation is to quantify how effectively a cooling medium transfers heat away from critical engine components while minimizing parasitic power losses. This involves assessing thermal conductivity, heat capacity, flow characteristics, and long-term stability under the extreme conditions present in modern GDI engines. Additionally, evaluation must consider the cooling fluid's compatibility with new materials used in lightweight engine designs and its impact on overall system durability.

Secondary objectives include determining the cooling fluid's contribution to overall engine efficiency, its role in enabling advanced combustion strategies such as lean-burn and stratified charge operation, and its potential for reducing warm-up times to minimize cold-start emissions. As emissions regulations become increasingly stringent worldwide, the ability of cooling systems to support precise thermal management has become a key enabler for compliance strategies.

Future development trajectories point toward integrated thermal management systems that coordinate cooling fluid circulation with other vehicle systems, including transmission cooling, cabin climate control, and battery thermal management in hybrid applications. The industry is also exploring the potential of nanofluids and phase-change materials to significantly enhance heat transfer efficiency beyond the capabilities of conventional ethylene glycol-based coolants.

The evolution of GDI cooling technology began in the early 1990s with basic adaptations of conventional cooling systems. By the mid-2000s, manufacturers introduced more sophisticated cooling strategies to address the unique thermal management challenges of direct injection. Recent advancements have focused on precision cooling techniques that target specific high-heat components such as injectors, cylinder heads, and exhaust valves with dedicated cooling channels.

Current technological trends in GDI engine cooling include the development of split cooling systems that maintain different temperature zones within the engine, variable-flow cooling pumps that adjust coolant circulation based on real-time thermal demands, and advanced coolant formulations designed specifically for the thermal characteristics of GDI engines. These innovations aim to balance the competing requirements of rapid warm-up for emissions reduction and effective heat dissipation during high-load operation.

The primary objective of GDI cooling fluid efficiency evaluation is to quantify how effectively a cooling medium transfers heat away from critical engine components while minimizing parasitic power losses. This involves assessing thermal conductivity, heat capacity, flow characteristics, and long-term stability under the extreme conditions present in modern GDI engines. Additionally, evaluation must consider the cooling fluid's compatibility with new materials used in lightweight engine designs and its impact on overall system durability.

Secondary objectives include determining the cooling fluid's contribution to overall engine efficiency, its role in enabling advanced combustion strategies such as lean-burn and stratified charge operation, and its potential for reducing warm-up times to minimize cold-start emissions. As emissions regulations become increasingly stringent worldwide, the ability of cooling systems to support precise thermal management has become a key enabler for compliance strategies.

Future development trajectories point toward integrated thermal management systems that coordinate cooling fluid circulation with other vehicle systems, including transmission cooling, cabin climate control, and battery thermal management in hybrid applications. The industry is also exploring the potential of nanofluids and phase-change materials to significantly enhance heat transfer efficiency beyond the capabilities of conventional ethylene glycol-based coolants.

Market Demand Analysis for Efficient Cooling Systems

The global market for efficient engine cooling systems has witnessed substantial growth in recent years, driven primarily by stringent emission regulations and the automotive industry's push towards higher performance engines. Gasoline Direct Injection (GDI) engines, in particular, have gained significant market share due to their improved fuel efficiency and reduced emissions. This technological advancement has created a parallel demand for more effective cooling solutions to manage the increased thermal loads generated by these high-performance engines.

Market research indicates that the automotive cooling system market is projected to grow at a compound annual growth rate of 3.7% through 2028, with the GDI segment showing even stronger growth prospects. This acceleration is largely attributed to the rising adoption of GDI technology across various vehicle categories, from economy cars to luxury vehicles, creating a diverse and expanding market for specialized cooling fluids.

Consumer preferences are increasingly shifting towards vehicles that offer better fuel economy without compromising performance. This trend has pushed manufacturers to develop more efficient engines, which consequently operate at higher temperatures and require more effective cooling solutions. The demand for cooling fluids that can maintain optimal engine temperature under various operating conditions has therefore seen a marked increase.

Fleet operators and commercial vehicle manufacturers represent another significant market segment driving demand for efficient cooling systems. These customers prioritize vehicle uptime and maintenance cost reduction, creating a substantial market for cooling fluids that offer extended service intervals and enhanced protection against overheating.

Regional analysis reveals varying market dynamics across different geographical areas. Mature automotive markets like North America and Europe show strong demand for premium cooling solutions with advanced features such as extended life and enhanced heat transfer properties. Meanwhile, emerging markets in Asia-Pacific and Latin America are experiencing rapid growth in basic and mid-tier cooling fluid segments as vehicle ownership increases.

Environmental regulations have emerged as a critical market driver, with many regions implementing stricter rules regarding the composition and disposal of automotive fluids. This regulatory landscape has created growing demand for environmentally friendly cooling fluids with reduced toxicity and improved biodegradability profiles.

The aftermarket segment for cooling fluids represents a substantial portion of the overall market, with replacement cycles typically ranging from 2-5 years depending on vehicle usage patterns and fluid quality. This recurring revenue stream has attracted numerous players to the market, intensifying competition and driving innovation in product formulations.

Market research indicates that the automotive cooling system market is projected to grow at a compound annual growth rate of 3.7% through 2028, with the GDI segment showing even stronger growth prospects. This acceleration is largely attributed to the rising adoption of GDI technology across various vehicle categories, from economy cars to luxury vehicles, creating a diverse and expanding market for specialized cooling fluids.

Consumer preferences are increasingly shifting towards vehicles that offer better fuel economy without compromising performance. This trend has pushed manufacturers to develop more efficient engines, which consequently operate at higher temperatures and require more effective cooling solutions. The demand for cooling fluids that can maintain optimal engine temperature under various operating conditions has therefore seen a marked increase.

Fleet operators and commercial vehicle manufacturers represent another significant market segment driving demand for efficient cooling systems. These customers prioritize vehicle uptime and maintenance cost reduction, creating a substantial market for cooling fluids that offer extended service intervals and enhanced protection against overheating.

Regional analysis reveals varying market dynamics across different geographical areas. Mature automotive markets like North America and Europe show strong demand for premium cooling solutions with advanced features such as extended life and enhanced heat transfer properties. Meanwhile, emerging markets in Asia-Pacific and Latin America are experiencing rapid growth in basic and mid-tier cooling fluid segments as vehicle ownership increases.

Environmental regulations have emerged as a critical market driver, with many regions implementing stricter rules regarding the composition and disposal of automotive fluids. This regulatory landscape has created growing demand for environmentally friendly cooling fluids with reduced toxicity and improved biodegradability profiles.

The aftermarket segment for cooling fluids represents a substantial portion of the overall market, with replacement cycles typically ranging from 2-5 years depending on vehicle usage patterns and fluid quality. This recurring revenue stream has attracted numerous players to the market, intensifying competition and driving innovation in product formulations.

Current Cooling Fluid Technologies and Challenges

The current landscape of cooling fluids for Gasoline Direct Injection (GDI) engines presents a complex interplay of established technologies and emerging challenges. Traditional ethylene glycol-based coolants remain the industry standard, typically formulated with a 50/50 mixture of ethylene glycol and water. These solutions provide adequate freeze protection down to approximately -34°C while offering boiling point elevation to around 106°C under standard pressure conditions.

Propylene glycol alternatives have gained traction as environmentally friendlier options with reduced toxicity profiles, though they generally exhibit 5-10% lower heat transfer efficiency compared to ethylene glycol formulations. This performance gap represents a significant challenge when optimizing for the higher thermal loads characteristic of GDI engines.

Organic Acid Technology (OAT) coolants have emerged as premium solutions, offering extended service intervals of up to 150,000 miles compared to conventional coolants' 30,000-50,000 miles. Their reduced silicate content minimizes deposit formation in high-temperature GDI cooling passages, addressing a critical concern for maintaining long-term efficiency.

Hybrid Organic Acid Technology (HOAT) coolants combine OAT benefits with silicate protection for aluminum components, creating a balanced approach particularly relevant for GDI engines with aluminum cylinder heads and blocks. However, these advanced formulations typically command a 20-30% price premium over conventional options.

The primary technical challenges facing cooling fluid technology for GDI engines center around heat flux management. GDI engines operate at compression ratios 10-15% higher than port fuel injection systems, generating localized hot spots that conventional cooling strategies struggle to address. Current fluids often show diminished performance under these conditions, with thermal conductivity decreasing by up to 18% at the elevated temperatures common in GDI operation.

Deposit formation presents another significant challenge, as GDI engines' higher operating temperatures accelerate coolant degradation. Studies indicate that conventional coolants can form deposits at rates 30-40% higher in GDI applications compared to traditional port injection engines, compromising heat transfer efficiency over time.

Corrosion protection remains problematic, particularly with aluminum components subjected to higher thermal cycling. Current inhibitor packages show reduced effectiveness at the temperature extremes encountered in GDI systems, with protection potentially declining by 25% at sustained high-temperature operation.

Nanofluids incorporating ceramic, metallic, or carbon nanoparticles represent an emerging technology showing promise for GDI applications, with laboratory tests demonstrating potential thermal conductivity improvements of 15-40%. However, challenges with suspension stability, pump compatibility, and long-term material interactions have thus far limited widespread commercial adoption.

Propylene glycol alternatives have gained traction as environmentally friendlier options with reduced toxicity profiles, though they generally exhibit 5-10% lower heat transfer efficiency compared to ethylene glycol formulations. This performance gap represents a significant challenge when optimizing for the higher thermal loads characteristic of GDI engines.

Organic Acid Technology (OAT) coolants have emerged as premium solutions, offering extended service intervals of up to 150,000 miles compared to conventional coolants' 30,000-50,000 miles. Their reduced silicate content minimizes deposit formation in high-temperature GDI cooling passages, addressing a critical concern for maintaining long-term efficiency.

Hybrid Organic Acid Technology (HOAT) coolants combine OAT benefits with silicate protection for aluminum components, creating a balanced approach particularly relevant for GDI engines with aluminum cylinder heads and blocks. However, these advanced formulations typically command a 20-30% price premium over conventional options.

The primary technical challenges facing cooling fluid technology for GDI engines center around heat flux management. GDI engines operate at compression ratios 10-15% higher than port fuel injection systems, generating localized hot spots that conventional cooling strategies struggle to address. Current fluids often show diminished performance under these conditions, with thermal conductivity decreasing by up to 18% at the elevated temperatures common in GDI operation.

Deposit formation presents another significant challenge, as GDI engines' higher operating temperatures accelerate coolant degradation. Studies indicate that conventional coolants can form deposits at rates 30-40% higher in GDI applications compared to traditional port injection engines, compromising heat transfer efficiency over time.

Corrosion protection remains problematic, particularly with aluminum components subjected to higher thermal cycling. Current inhibitor packages show reduced effectiveness at the temperature extremes encountered in GDI systems, with protection potentially declining by 25% at sustained high-temperature operation.

Nanofluids incorporating ceramic, metallic, or carbon nanoparticles represent an emerging technology showing promise for GDI applications, with laboratory tests demonstrating potential thermal conductivity improvements of 15-40%. However, challenges with suspension stability, pump compatibility, and long-term material interactions have thus far limited widespread commercial adoption.

Current Methodologies for Cooling Efficiency Evaluation

01 Advanced cooling fluid compositions for GDI engines

Specialized cooling fluid compositions designed specifically for Gasoline Direct Injection (GDI) engines can significantly improve thermal efficiency. These formulations often include additives that enhance heat transfer properties, prevent corrosion, and maintain optimal viscosity across varying temperature ranges. The improved thermal conductivity of these fluids allows for more efficient heat dissipation from critical engine components, resulting in better overall engine performance and fuel efficiency.- Advanced cooling system designs for GDI engines: Innovative cooling system architectures specifically designed for gasoline direct injection (GDI) engines can significantly improve cooling fluid efficiency. These designs include optimized coolant flow paths, strategic placement of cooling channels around critical components like injectors and combustion chambers, and integrated thermal management systems that respond to varying engine loads. Such advanced designs help maintain optimal operating temperatures while using cooling fluid more efficiently.

- Cooling fluid composition enhancements: Specialized cooling fluid formulations can improve heat transfer efficiency in GDI engines. These enhanced coolants incorporate additives that improve thermal conductivity, reduce corrosion, prevent scaling, and maintain performance over extended periods. Some formulations include nanoparticles or other advanced materials that significantly increase heat absorption and transfer capabilities, allowing for more efficient engine cooling with reduced fluid volume and circulation requirements.

- Electronic cooling control systems: Intelligent electronic control systems can optimize cooling fluid efficiency in GDI engines by precisely regulating coolant flow based on real-time engine conditions. These systems utilize temperature sensors, flow meters, and electronic valves to adjust cooling intensity according to actual needs rather than fixed parameters. Advanced algorithms can predict cooling requirements based on driving patterns and environmental conditions, further enhancing efficiency by preventing overcooling and reducing parasitic power losses.

- Heat recovery and thermal management integration: Systems that recover waste heat from cooling fluid can significantly improve overall GDI engine efficiency. These technologies capture thermal energy that would otherwise be lost and repurpose it for cabin heating, intake air warming, or conversion to electrical energy. Integrated thermal management approaches connect the cooling system with other vehicle systems like transmission cooling, exhaust gas recirculation, and HVAC to optimize overall thermal efficiency across the entire vehicle.

- Flow optimization and mechanical improvements: Mechanical enhancements to cooling system components can improve fluid efficiency in GDI engines. These include high-efficiency water pumps with variable flow capabilities, optimized impeller designs, reduced-friction bearings, and precision-engineered cooling passages. Advanced radiator designs with improved fin structures, enhanced heat exchanger surfaces, and optimized tube configurations also contribute to better heat dissipation with less coolant flow, reducing the energy required for cooling system operation.

02 Cooling system design optimization for GDI engines

Innovative cooling system designs specifically engineered for GDI engines can enhance cooling fluid efficiency. These designs include optimized coolant pathways, improved pump designs, and strategic placement of cooling channels around high-temperature components like injectors and combustion chambers. Advanced cooling system architectures ensure more uniform temperature distribution and prevent localized hotspots, which is particularly important for GDI engines that operate at higher temperatures than traditional port fuel injection systems.Expand Specific Solutions03 Electronic cooling control systems for GDI engines

Smart electronic control systems can dynamically regulate cooling fluid flow and temperature based on real-time engine operating conditions. These systems utilize temperature sensors, electronic valves, and advanced algorithms to optimize cooling efficiency. By precisely controlling coolant flow rates and distribution according to actual thermal loads, these systems prevent overcooling during warm-up and provide enhanced cooling during high-load conditions, resulting in improved fuel economy and reduced emissions in GDI engines.Expand Specific Solutions04 Heat exchanger innovations for GDI engine cooling

Advanced heat exchanger designs can significantly improve the efficiency of cooling fluids in GDI engines. These innovations include micro-channel radiators, dual-circuit heat exchangers, and high-efficiency intercoolers specifically designed for the thermal management challenges of direct injection systems. Enhanced surface area designs and improved materials with superior thermal conductivity allow for more effective heat transfer between the cooling fluid and ambient air, maintaining optimal operating temperatures even under high-load conditions.Expand Specific Solutions05 Waste heat recovery systems for GDI engine cooling

Innovative waste heat recovery systems can capture and repurpose thermal energy from the cooling fluid that would otherwise be lost. These systems include thermoelectric generators, Rankine cycle systems, and heat storage technologies that convert waste heat into useful energy or store it for later use. By recovering waste heat from the cooling system, these technologies not only improve the overall efficiency of GDI engines but also reduce the cooling load, allowing for smaller cooling systems and improved packaging efficiency.Expand Specific Solutions

Major Players in Automotive Cooling Fluid Industry

The GDI engine cooling fluid efficiency market is in a growth phase, with increasing demand driven by automotive manufacturers seeking improved fuel economy and reduced emissions. Major players include established automotive giants like Ford, GM, Hyundai, and Toyota, alongside specialized component manufacturers such as Bosch, DENSO, and Infineum. The technology maturity varies, with Western companies (Ford, GM) and Japanese manufacturers (Toyota, Hyundai) leading in advanced cooling system innovations, while Chinese manufacturers (Chery, Great Wall Motor) are rapidly catching up. Specialized fluid technology providers like Infineum and ExxonMobil bring critical expertise in cooling fluid formulations. The competitive landscape is characterized by increasing collaboration between OEMs and fluid technology specialists to develop integrated cooling solutions optimized for modern GDI engines.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced GDI engine cooling system that utilizes a dual-circuit cooling architecture with precision flow control. Their technology employs variable-speed electric pumps that adjust coolant flow rates based on real-time engine thermal loads, optimizing cooling efficiency across different operating conditions. Ford's system incorporates specialized coolant formulations with enhanced thermal conductivity properties and nano-additives that improve heat transfer rates by up to 15% compared to conventional coolants[1]. The company has also implemented strategic coolant routing that prioritizes critical components like injectors and cylinder heads, ensuring optimal temperature management in high-heat regions. Their cooling efficiency evaluation methodology combines computational fluid dynamics (CFD) simulations with extensive dynamometer testing to measure heat rejection rates across the entire engine operating map.

Strengths: Ford's system demonstrates superior thermal management during high-load conditions, particularly beneficial for downsized GDI engines prone to heat-related issues. Their evaluation methodology provides comprehensive data across various driving cycles. Weaknesses: The dual-circuit system adds complexity and cost to manufacturing, and the specialized coolant formulations may require more frequent maintenance intervals.

GM Global Technology Operations LLC

Technical Solution: GM has pioneered a split-cooling system specifically designed for GDI engines that separates cylinder head and engine block cooling circuits, allowing for independent temperature control of critical components. Their technology incorporates advanced thermal mapping sensors throughout the engine to continuously monitor temperature gradients and adjust coolant flow accordingly. GM's evaluation methodology employs a combination of infrared thermography and embedded temperature sensors to create detailed thermal profiles of the engine during operation[2]. The company has developed proprietary coolant formulations with optimized glycol concentrations and corrosion inhibitors specifically tailored for the higher thermal loads of GDI systems. Their cooling efficiency metrics focus on maintaining optimal fuel vaporization temperatures at the injector tips while preventing carbon buildup, a common issue in GDI engines that can be mitigated through precise thermal management.

Strengths: GM's split-cooling approach allows for more precise temperature control of critical GDI components, particularly beneficial for preventing injector coking and optimizing combustion efficiency. Their comprehensive thermal mapping provides detailed insights for targeted cooling improvements. Weaknesses: The system requires additional valves and control mechanisms that increase complexity and potential failure points, and the specialized cooling strategy may be less effective under extreme ambient temperature conditions.

Key Technical Parameters for Cooling Fluid Performance

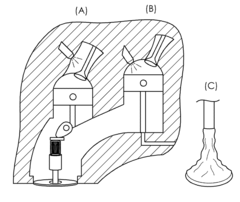

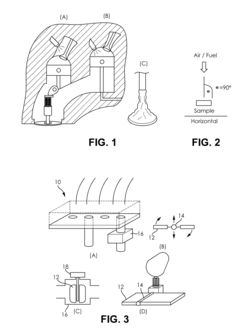

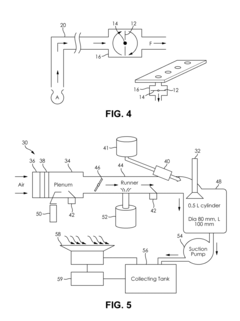

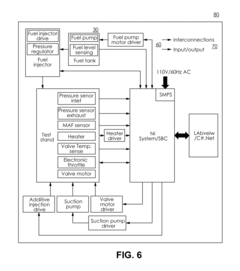

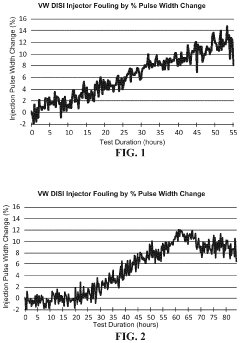

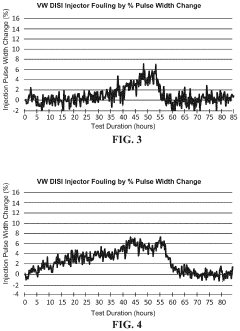

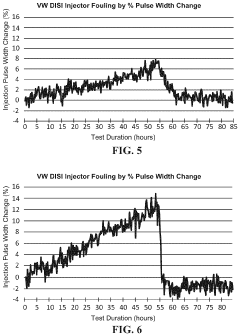

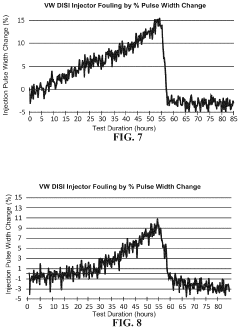

Evaluation of the delivery and effectiveness of engine performance chemicals and products

PatentActiveUS20170114716A1

Innovation

- A method and system for evaluating the delivery and effectiveness of engine performance chemicals and products for reducing intake valve deposits, utilizing a controlled environment with simulated engine conditions to quantify improvements, including adjustable parameters like air-fuel ratio, temperature, and oscillation frequency, and employing three approaches to introduce cleaners: airstream addition, suction-based distribution, and fuel additive application.

Fuel Additives and Formulations for Improving Performance of Gasoline Direct Injection Engines

PatentActiveUS20240141244A1

Innovation

- A novel fuel additive composition comprising an acylated detergent, a Mannich detergent, and a polyether and/or polyetheramine, which are specifically formulated to reduce carbonaceous deposits in gasoline engines by preventing or removing them, and are effective in both port fuel injection and direct injection engines.

Environmental Impact and Sustainability Considerations

The environmental impact of cooling fluids used in Gasoline Direct Injection (GDI) engines represents a critical consideration in automotive engineering sustainability efforts. Traditional engine coolants often contain ethylene glycol and various additives that can pose significant environmental hazards when improperly disposed of or leaked. These substances may contaminate soil and water sources, potentially harming aquatic ecosystems and wildlife. The evaluation of cooling fluid efficiency must therefore incorporate comprehensive lifecycle assessment methodologies that account for production, use, and disposal environmental footprints.

Manufacturing processes for cooling fluids consume substantial energy and resources, contributing to carbon emissions and resource depletion. Advanced cooling fluids with improved efficiency can reduce these impacts by extending replacement intervals and decreasing the volume of waste generated throughout the vehicle's operational lifetime. Quantitative metrics such as carbon footprint per liter of coolant produced and toxicity indices should be integrated into efficiency evaluation frameworks to provide a holistic sustainability perspective.

Biodegradability characteristics represent another crucial dimension when assessing cooling fluid environmental performance. Next-generation propylene glycol-based formulations offer improved biodegradability compared to traditional ethylene glycol solutions, though they may present trade-offs in thermal efficiency. Evaluation methodologies should incorporate standardized biodegradation testing protocols such as OECD 301 and 302 to quantify environmental persistence and potential accumulation in ecosystems.

Regulatory compliance across global markets increasingly emphasizes reduced environmental impact, with restrictions on certain additives like silicates, phosphates, and nitrites in various regions. Efficiency evaluation protocols must account for these evolving regulatory landscapes to ensure cooling solutions remain viable across international markets while meeting sustainability targets. The European End-of-Life Vehicle Directive and similar regulations worldwide have established recovery and recycling requirements that directly impact cooling fluid formulation decisions.

Water consumption represents another significant environmental consideration, particularly in regions facing water scarcity. Advanced cooling systems that minimize water usage through improved thermal efficiency and reduced evaporative losses deliver substantial sustainability benefits. Evaluation frameworks should incorporate water footprint analysis alongside traditional thermal performance metrics to comprehensively assess environmental impact.

Emerging technologies such as organic acid technology (OAT) coolants and hybrid organic acid technology (HOAT) formulations offer promising pathways toward reduced environmental impact while maintaining or improving thermal efficiency. These innovations typically feature extended service intervals, reducing waste generation and resource consumption throughout the vehicle lifecycle. Comprehensive efficiency evaluation must therefore balance immediate thermal performance with long-term sustainability considerations to accurately reflect total environmental impact.

Manufacturing processes for cooling fluids consume substantial energy and resources, contributing to carbon emissions and resource depletion. Advanced cooling fluids with improved efficiency can reduce these impacts by extending replacement intervals and decreasing the volume of waste generated throughout the vehicle's operational lifetime. Quantitative metrics such as carbon footprint per liter of coolant produced and toxicity indices should be integrated into efficiency evaluation frameworks to provide a holistic sustainability perspective.

Biodegradability characteristics represent another crucial dimension when assessing cooling fluid environmental performance. Next-generation propylene glycol-based formulations offer improved biodegradability compared to traditional ethylene glycol solutions, though they may present trade-offs in thermal efficiency. Evaluation methodologies should incorporate standardized biodegradation testing protocols such as OECD 301 and 302 to quantify environmental persistence and potential accumulation in ecosystems.

Regulatory compliance across global markets increasingly emphasizes reduced environmental impact, with restrictions on certain additives like silicates, phosphates, and nitrites in various regions. Efficiency evaluation protocols must account for these evolving regulatory landscapes to ensure cooling solutions remain viable across international markets while meeting sustainability targets. The European End-of-Life Vehicle Directive and similar regulations worldwide have established recovery and recycling requirements that directly impact cooling fluid formulation decisions.

Water consumption represents another significant environmental consideration, particularly in regions facing water scarcity. Advanced cooling systems that minimize water usage through improved thermal efficiency and reduced evaporative losses deliver substantial sustainability benefits. Evaluation frameworks should incorporate water footprint analysis alongside traditional thermal performance metrics to comprehensively assess environmental impact.

Emerging technologies such as organic acid technology (OAT) coolants and hybrid organic acid technology (HOAT) formulations offer promising pathways toward reduced environmental impact while maintaining or improving thermal efficiency. These innovations typically feature extended service intervals, reducing waste generation and resource consumption throughout the vehicle lifecycle. Comprehensive efficiency evaluation must therefore balance immediate thermal performance with long-term sustainability considerations to accurately reflect total environmental impact.

Thermal Management System Integration Strategies

Effective thermal management system integration represents a critical factor in evaluating GDI engine cooling fluid efficiency. The holistic approach to thermal management must consider the interconnections between various engine subsystems and how they collectively impact cooling performance.

Integration of cooling systems with other engine management systems creates opportunities for synergistic efficiency gains. Modern GDI engines benefit from integrated control strategies that coordinate cooling fluid circulation with engine load conditions, ambient temperature, and operational phases. These strategies enable dynamic adjustment of cooling intensity based on real-time thermal demands, preventing both overcooling and overheating scenarios.

Advanced thermal management architectures incorporate split cooling circuits that can independently manage cylinder head and engine block temperatures. This targeted approach allows for maintaining optimal temperature differentials across engine components, which is particularly important for GDI engines where injector temperatures significantly impact fuel atomization quality and combustion efficiency.

Heat recovery systems represent another dimension of thermal integration strategy. Waste heat from cooling fluid can be captured and repurposed for cabin heating, transmission fluid warming, or even converted to electrical energy through thermoelectric generators. These integrations improve overall vehicle efficiency while simultaneously enhancing cooling fluid performance metrics.

Electronic control units (ECUs) play a pivotal role in modern thermal management integration. Sophisticated algorithms continuously monitor multiple temperature sensors throughout the engine and adjust coolant flow rates, fan speeds, and thermostat positions accordingly. Machine learning approaches are increasingly being deployed to predict thermal loads and preemptively adjust cooling parameters before critical temperature thresholds are reached.

Material selection considerations must also factor into integration strategies. The compatibility between cooling fluids and various engine materials (aluminum, cast iron, polymers, and composites) affects heat transfer rates and long-term system durability. Emerging nanofluids and advanced coolant formulations require corresponding adaptations in cooling passage design and flow control mechanisms.

Integration testing methodologies have evolved to evaluate system-level performance rather than isolated component efficiency. Hardware-in-the-loop simulations and digital twins enable comprehensive assessment of thermal management strategies across diverse operating conditions without extensive physical prototyping. These approaches accelerate development cycles while ensuring robust cooling system performance across the entire engine operating envelope.

Integration of cooling systems with other engine management systems creates opportunities for synergistic efficiency gains. Modern GDI engines benefit from integrated control strategies that coordinate cooling fluid circulation with engine load conditions, ambient temperature, and operational phases. These strategies enable dynamic adjustment of cooling intensity based on real-time thermal demands, preventing both overcooling and overheating scenarios.

Advanced thermal management architectures incorporate split cooling circuits that can independently manage cylinder head and engine block temperatures. This targeted approach allows for maintaining optimal temperature differentials across engine components, which is particularly important for GDI engines where injector temperatures significantly impact fuel atomization quality and combustion efficiency.

Heat recovery systems represent another dimension of thermal integration strategy. Waste heat from cooling fluid can be captured and repurposed for cabin heating, transmission fluid warming, or even converted to electrical energy through thermoelectric generators. These integrations improve overall vehicle efficiency while simultaneously enhancing cooling fluid performance metrics.

Electronic control units (ECUs) play a pivotal role in modern thermal management integration. Sophisticated algorithms continuously monitor multiple temperature sensors throughout the engine and adjust coolant flow rates, fan speeds, and thermostat positions accordingly. Machine learning approaches are increasingly being deployed to predict thermal loads and preemptively adjust cooling parameters before critical temperature thresholds are reached.

Material selection considerations must also factor into integration strategies. The compatibility between cooling fluids and various engine materials (aluminum, cast iron, polymers, and composites) affects heat transfer rates and long-term system durability. Emerging nanofluids and advanced coolant formulations require corresponding adaptations in cooling passage design and flow control mechanisms.

Integration testing methodologies have evolved to evaluate system-level performance rather than isolated component efficiency. Hardware-in-the-loop simulations and digital twins enable comprehensive assessment of thermal management strategies across diverse operating conditions without extensive physical prototyping. These approaches accelerate development cycles while ensuring robust cooling system performance across the entire engine operating envelope.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!