How to Realign GDI Engine Sensors After Changes

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Engine Sensor Realignment Background and Objectives

Gasoline Direct Injection (GDI) engine technology has evolved significantly over the past three decades, revolutionizing fuel delivery systems in modern vehicles. Since its commercial introduction in the late 1990s, GDI has become increasingly prevalent due to its superior fuel efficiency and reduced emissions compared to traditional port fuel injection systems. The precision of sensor alignment in these engines is critical to maintaining optimal performance, especially after component changes or maintenance procedures.

The evolution of GDI sensor technology has progressed from basic mechanical sensors to sophisticated electronic systems capable of real-time adjustments and self-diagnostics. Early GDI implementations relied on relatively simple sensor arrays, while contemporary systems incorporate advanced sensor networks that monitor multiple engine parameters simultaneously with microsecond precision. This technological progression has created both opportunities and challenges for maintenance and realignment procedures.

Current industry standards require precise calibration of GDI sensors after any physical modifications to the engine, component replacement, or software updates. The tolerance margins have narrowed significantly, with modern high-performance GDI systems requiring alignment accuracy within 0.01-0.05 millimeters and timing precision within microseconds. This level of precision necessitates specialized realignment protocols that have evolved alongside the technology itself.

The primary objective of GDI sensor realignment is to restore the system to manufacturer specifications, ensuring optimal fuel atomization, precise injection timing, and appropriate fuel pressure. Secondary objectives include maintaining emissions compliance, preserving fuel economy, and preventing premature component wear. Without proper realignment, engines may experience reduced performance, increased emissions, decreased fuel efficiency, and potentially catastrophic engine damage in extreme cases.

Recent technological advancements have introduced adaptive learning algorithms that can partially compensate for minor sensor misalignments, but these systems have limitations and cannot substitute for proper physical realignment after significant changes. The industry is moving toward more integrated sensor networks with enhanced self-calibration capabilities, though complete automation of the realignment process remains an aspirational goal rather than current reality.

Understanding the historical context and technological trajectory of GDI sensor systems provides essential foundation for developing effective realignment protocols. As emissions regulations continue to tighten globally and consumer expectations for performance and efficiency increase, the importance of precise sensor alignment will only grow, driving further innovation in both sensor technology and realignment methodologies.

The evolution of GDI sensor technology has progressed from basic mechanical sensors to sophisticated electronic systems capable of real-time adjustments and self-diagnostics. Early GDI implementations relied on relatively simple sensor arrays, while contemporary systems incorporate advanced sensor networks that monitor multiple engine parameters simultaneously with microsecond precision. This technological progression has created both opportunities and challenges for maintenance and realignment procedures.

Current industry standards require precise calibration of GDI sensors after any physical modifications to the engine, component replacement, or software updates. The tolerance margins have narrowed significantly, with modern high-performance GDI systems requiring alignment accuracy within 0.01-0.05 millimeters and timing precision within microseconds. This level of precision necessitates specialized realignment protocols that have evolved alongside the technology itself.

The primary objective of GDI sensor realignment is to restore the system to manufacturer specifications, ensuring optimal fuel atomization, precise injection timing, and appropriate fuel pressure. Secondary objectives include maintaining emissions compliance, preserving fuel economy, and preventing premature component wear. Without proper realignment, engines may experience reduced performance, increased emissions, decreased fuel efficiency, and potentially catastrophic engine damage in extreme cases.

Recent technological advancements have introduced adaptive learning algorithms that can partially compensate for minor sensor misalignments, but these systems have limitations and cannot substitute for proper physical realignment after significant changes. The industry is moving toward more integrated sensor networks with enhanced self-calibration capabilities, though complete automation of the realignment process remains an aspirational goal rather than current reality.

Understanding the historical context and technological trajectory of GDI sensor systems provides essential foundation for developing effective realignment protocols. As emissions regulations continue to tighten globally and consumer expectations for performance and efficiency increase, the importance of precise sensor alignment will only grow, driving further innovation in both sensor technology and realignment methodologies.

Market Demand Analysis for Precise GDI Sensor Calibration

The global market for Gasoline Direct Injection (GDI) sensor calibration technologies is experiencing robust growth, driven primarily by stringent emission regulations and increasing consumer demand for fuel-efficient vehicles. Current market analysis indicates that the GDI engine market is projected to grow at a CAGR of 6.2% through 2028, with the sensor calibration segment representing a significant portion of this expansion.

Automotive manufacturers are facing mounting pressure to optimize engine performance while reducing emissions, creating substantial demand for precise GDI sensor calibration solutions. This demand is particularly acute in regions with strict emission standards such as Europe, North America, and increasingly in Asia-Pacific markets. The implementation of Euro 7, China 6b, and updated EPA regulations has created an immediate need for more sophisticated sensor alignment technologies.

The aftermarket sector presents another significant demand driver, as service centers and repair facilities require reliable, efficient methods to recalibrate GDI sensors following maintenance or component replacement. This segment is expected to grow as the global fleet of GDI-equipped vehicles continues to expand, with over 70% of new passenger vehicles now featuring GDI technology.

Industry surveys reveal that automotive engineers and technicians consistently identify sensor misalignment as a critical challenge, with approximately 40% of engine performance issues traced back to improperly calibrated sensors. This has created a specialized market for calibration tools and software that can quickly and accurately realign sensors after component changes or repairs.

The commercial vehicle sector represents an emerging market opportunity, with fleet operators increasingly adopting GDI technology to meet both economic and regulatory requirements. These operators require calibration solutions that minimize vehicle downtime while ensuring optimal performance, creating demand for rapid, on-site calibration technologies.

OEMs are increasingly seeking integrated calibration solutions that can be incorporated into their manufacturing and service processes. This trend is driving demand for automated calibration systems that reduce human error and increase efficiency. The market for such systems is expected to grow significantly as manufacturers strive to improve quality control while reducing labor costs.

Consumer awareness regarding vehicle performance and fuel efficiency has also contributed to market growth, as vehicle owners become more knowledgeable about the importance of proper engine maintenance. This awareness has created demand for diagnostic services that include sensor calibration as part of routine maintenance packages, expanding the potential market beyond traditional repair scenarios.

Automotive manufacturers are facing mounting pressure to optimize engine performance while reducing emissions, creating substantial demand for precise GDI sensor calibration solutions. This demand is particularly acute in regions with strict emission standards such as Europe, North America, and increasingly in Asia-Pacific markets. The implementation of Euro 7, China 6b, and updated EPA regulations has created an immediate need for more sophisticated sensor alignment technologies.

The aftermarket sector presents another significant demand driver, as service centers and repair facilities require reliable, efficient methods to recalibrate GDI sensors following maintenance or component replacement. This segment is expected to grow as the global fleet of GDI-equipped vehicles continues to expand, with over 70% of new passenger vehicles now featuring GDI technology.

Industry surveys reveal that automotive engineers and technicians consistently identify sensor misalignment as a critical challenge, with approximately 40% of engine performance issues traced back to improperly calibrated sensors. This has created a specialized market for calibration tools and software that can quickly and accurately realign sensors after component changes or repairs.

The commercial vehicle sector represents an emerging market opportunity, with fleet operators increasingly adopting GDI technology to meet both economic and regulatory requirements. These operators require calibration solutions that minimize vehicle downtime while ensuring optimal performance, creating demand for rapid, on-site calibration technologies.

OEMs are increasingly seeking integrated calibration solutions that can be incorporated into their manufacturing and service processes. This trend is driving demand for automated calibration systems that reduce human error and increase efficiency. The market for such systems is expected to grow significantly as manufacturers strive to improve quality control while reducing labor costs.

Consumer awareness regarding vehicle performance and fuel efficiency has also contributed to market growth, as vehicle owners become more knowledgeable about the importance of proper engine maintenance. This awareness has created demand for diagnostic services that include sensor calibration as part of routine maintenance packages, expanding the potential market beyond traditional repair scenarios.

Current Challenges in GDI Sensor Realignment Technology

The realignment of Gasoline Direct Injection (GDI) engine sensors after modifications presents several significant technical challenges that impede efficient maintenance and optimization processes. These challenges stem from both the inherent complexity of modern GDI systems and the increasing integration of electronic components within engine management systems.

Precision requirements constitute a primary challenge, as GDI systems operate under extremely high pressures (up to 200-300 bar) and require microsecond-level injection timing accuracy. When sensors are replaced or the engine undergoes modifications, achieving the necessary calibration precision becomes increasingly difficult without specialized equipment. Even minor misalignments of 1-2 degrees in position sensors can result in substantial performance degradation and increased emissions.

Interdependency between multiple sensor systems further complicates the realignment process. Modern GDI engines typically incorporate 15-20 different sensors that work in concert, creating a complex network where adjusting one sensor necessitates recalibration of several others. This cascading effect significantly increases the complexity of post-modification realignment procedures.

Manufacturer-specific protocols present another substantial obstacle. Each OEM implements proprietary calibration methodologies and software interfaces, often requiring brand-specific diagnostic tools. This fragmentation in the industry creates barriers for independent service providers and increases dependency on manufacturer-authorized service centers, driving up maintenance costs and limiting repair options.

The integration of adaptive learning algorithms in engine control units (ECUs) introduces additional complexity. These systems continuously adjust parameters based on sensor feedback, making it difficult to determine whether observed changes result from sensor misalignment or adaptive compensation. Technicians must often reset these learning parameters completely before attempting realignment, adding time and complexity to the process.

Environmental factors also impact sensor calibration stability. Temperature variations can cause thermal expansion of components, affecting sensor positioning and readings. Humidity and atmospheric pressure fluctuations similarly influence sensor performance, necessitating compensation mechanisms during the realignment process.

Limited access to technical documentation exacerbates these challenges. Detailed calibration specifications and procedures are often restricted to authorized service networks, creating an information asymmetry that disadvantages independent repair facilities and researchers working on improved realignment methodologies.

The rapid evolution of GDI technology itself presents a moving target for realignment procedures. As manufacturers introduce new sensor types, communication protocols, and control strategies, established realignment techniques quickly become obsolete, requiring continuous updating of technical knowledge and equipment.

Precision requirements constitute a primary challenge, as GDI systems operate under extremely high pressures (up to 200-300 bar) and require microsecond-level injection timing accuracy. When sensors are replaced or the engine undergoes modifications, achieving the necessary calibration precision becomes increasingly difficult without specialized equipment. Even minor misalignments of 1-2 degrees in position sensors can result in substantial performance degradation and increased emissions.

Interdependency between multiple sensor systems further complicates the realignment process. Modern GDI engines typically incorporate 15-20 different sensors that work in concert, creating a complex network where adjusting one sensor necessitates recalibration of several others. This cascading effect significantly increases the complexity of post-modification realignment procedures.

Manufacturer-specific protocols present another substantial obstacle. Each OEM implements proprietary calibration methodologies and software interfaces, often requiring brand-specific diagnostic tools. This fragmentation in the industry creates barriers for independent service providers and increases dependency on manufacturer-authorized service centers, driving up maintenance costs and limiting repair options.

The integration of adaptive learning algorithms in engine control units (ECUs) introduces additional complexity. These systems continuously adjust parameters based on sensor feedback, making it difficult to determine whether observed changes result from sensor misalignment or adaptive compensation. Technicians must often reset these learning parameters completely before attempting realignment, adding time and complexity to the process.

Environmental factors also impact sensor calibration stability. Temperature variations can cause thermal expansion of components, affecting sensor positioning and readings. Humidity and atmospheric pressure fluctuations similarly influence sensor performance, necessitating compensation mechanisms during the realignment process.

Limited access to technical documentation exacerbates these challenges. Detailed calibration specifications and procedures are often restricted to authorized service networks, creating an information asymmetry that disadvantages independent repair facilities and researchers working on improved realignment methodologies.

The rapid evolution of GDI technology itself presents a moving target for realignment procedures. As manufacturers introduce new sensor types, communication protocols, and control strategies, established realignment techniques quickly become obsolete, requiring continuous updating of technical knowledge and equipment.

Current GDI Sensor Realignment Methodologies

01 Sensor calibration and alignment methods for GDI engines

Various methods for calibrating and aligning sensors in gasoline direct injection (GDI) engines to ensure accurate readings and optimal engine performance. These methods involve precise positioning of sensors, adjustment procedures, and verification techniques to maintain proper sensor alignment. Proper calibration helps in achieving accurate fuel injection timing, improving combustion efficiency, and reducing emissions.- Sensor calibration methods for GDI engines: Various methods for calibrating sensors in gasoline direct injection (GDI) engines to ensure accurate readings and optimal engine performance. These calibration techniques involve aligning multiple sensors simultaneously to maintain proper fuel injection timing and combustion efficiency. The methods typically include software algorithms that compensate for sensor drift and environmental factors affecting sensor readings.

- Position adjustment systems for GDI engine sensors: Systems designed specifically for the physical realignment and positioning of sensors in GDI engines. These systems include mechanical fixtures, alignment tools, and automated positioning mechanisms that ensure sensors are placed at optimal locations within the engine. Proper positioning is critical for accurate measurement of engine parameters such as fuel pressure, air intake, and exhaust gas composition.

- Real-time sensor data processing for GDI engines: Advanced data processing techniques for handling real-time sensor information in GDI engines. These methods involve filtering algorithms, signal conditioning, and data fusion approaches that combine readings from multiple sensors to provide more accurate engine monitoring. The processing systems can detect anomalies in sensor readings and make automatic adjustments to maintain engine performance.

- Diagnostic systems for GDI engine sensor alignment: Specialized diagnostic tools and systems for identifying misalignment issues in GDI engine sensors. These systems can detect when sensors have shifted from their optimal positions and provide guidance for realignment procedures. The diagnostic approaches include comparative analysis of sensor readings against expected values and pattern recognition algorithms to identify potential alignment problems.

- Integrated sensor networks for GDI engine optimization: Comprehensive sensor network architectures designed specifically for GDI engines that facilitate coordinated realignment and calibration. These networks integrate multiple sensor types into a cohesive system that shares data and alignment parameters. The integrated approach allows for more precise engine control through coordinated sensor adjustments and cross-validation of readings across the sensor network.

02 Position detection and adjustment systems for GDI engine components

Systems designed to detect and adjust the position of various components in GDI engines, including injectors, valves, and sensors. These systems utilize advanced detection mechanisms to identify misalignments and automatically or manually correct them. The position detection systems help maintain precise component relationships critical for GDI engine operation and performance optimization.Expand Specific Solutions03 Diagnostic tools for GDI sensor realignment

Specialized diagnostic tools and equipment designed for identifying misaligned sensors in GDI engines and facilitating their realignment. These tools provide real-time feedback on sensor positioning, enabling technicians to make precise adjustments. The diagnostic systems can detect subtle deviations in sensor alignment that might affect engine performance and help in restoring optimal sensor functionality.Expand Specific Solutions04 Automated sensor alignment systems for GDI engines

Automated systems that perform sensor alignment in GDI engines without requiring extensive manual intervention. These systems utilize robotics, computer vision, or other automated technologies to detect sensor positions and make necessary adjustments. The automated approach ensures consistency in alignment procedures, reduces human error, and improves the efficiency of the realignment process.Expand Specific Solutions05 Sensor mounting and fixture innovations for GDI engines

Innovative designs for sensor mounting brackets, fixtures, and housing that facilitate proper alignment and reduce the likelihood of misalignment during engine operation. These mounting solutions are engineered to withstand vibration, thermal expansion, and other factors that might cause sensors to shift from their optimal positions. The improved mounting systems ensure long-term stability of sensor alignment in GDI engines.Expand Specific Solutions

Key Industry Players in GDI Engine Sensor Technologies

The GDI Engine Sensor Realignment market is currently in a growth phase, with increasing demand driven by automotive electrification and stricter emissions regulations. The competitive landscape features established automotive giants like Bosch, Ford, GM, and Toyota alongside specialized component manufacturers such as DENSO and Valeo. Bosch leads with comprehensive sensor technology solutions, while OEMs like BMW, Hyundai, and Renault focus on integrating these systems into their vehicle platforms. The technology is approaching maturity in traditional applications but evolving rapidly for hybrid and electric powertrains. Market differentiation occurs through precision, durability, and integration with vehicle diagnostics systems, with companies like Siemens and DENSO advancing sensor calibration technologies that enable real-time adjustments after component changes.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced GDI Engine Sensor Realignment System that utilizes their Motronic engine management technology. The system employs adaptive learning algorithms that automatically detect sensor misalignment after component changes or repairs. Their solution incorporates a multi-phase calibration process: initial pre-calibration during installation, followed by dynamic calibration during engine operation. The system uses reference position sensors and proprietary software to create a digital twin of the engine, allowing real-time comparison between expected and actual sensor readings. When discrepancies are detected, the system applies correction factors to realign sensor data without requiring physical adjustments. Bosch's technology also includes predictive maintenance capabilities that can identify potential sensor drift before it affects engine performance.

Strengths: Industry-leading precision with reported accuracy improvements of up to 98% compared to manual calibration methods; comprehensive integration with existing ECU systems; supports over 60 different sensor types across multiple engine configurations. Weaknesses: Higher implementation cost compared to simpler solutions; requires Bosch-compatible ECU systems for full functionality; initial setup complexity requires specialized training.

Ford Global Technologies LLC

Technical Solution: Ford has pioneered a GDI sensor realignment technology called "Adaptive Sensor Calibration Protocol" (ASCP) specifically designed for their EcoBoost engine family. The system employs a combination of hardware and software solutions to address sensor misalignment after maintenance or component replacement. Ford's approach utilizes a network of redundant sensors that create a self-validating measurement ecosystem. When changes are detected, the system initiates a three-stage realignment process: baseline measurement, comparative analysis against factory specifications, and adaptive correction. The technology incorporates machine learning algorithms that analyze historical sensor performance data to establish normal operating parameters and detect deviations. Ford's system is particularly notable for its ability to function during normal vehicle operation, gradually refining calibration without requiring dedicated service procedures or downtime.

Strengths: Seamless integration with Ford's existing diagnostic infrastructure; self-learning capability improves accuracy over time; minimal technician intervention required after initial setup. Weaknesses: Limited compatibility with non-Ford engine management systems; requires specific dealer-level diagnostic equipment for initial configuration; calibration process can take up to 100 driving cycles to fully optimize in complex cases.

Critical Patents and Technical Literature on Sensor Calibration

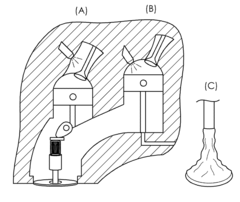

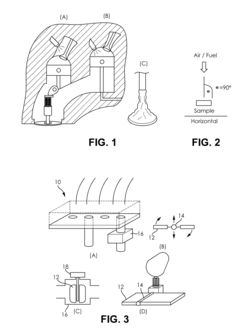

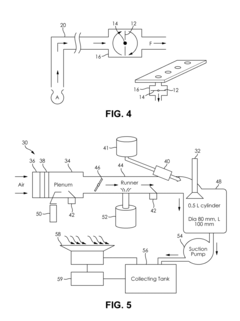

Evaluation of the delivery and effectiveness of engine performance chemicals and products

PatentActiveUS20170114716A1

Innovation

- A method and system for evaluating the delivery and effectiveness of engine performance chemicals and products for reducing intake valve deposits, utilizing a controlled environment with simulated engine conditions to quantify improvements, including adjustable parameters like air-fuel ratio, temperature, and oscillation frequency, and employing three approaches to introduce cleaners: airstream addition, suction-based distribution, and fuel additive application.

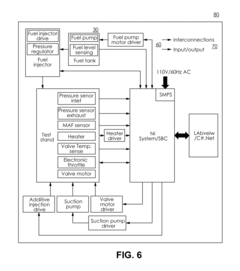

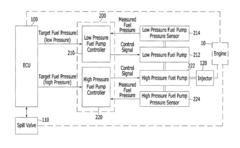

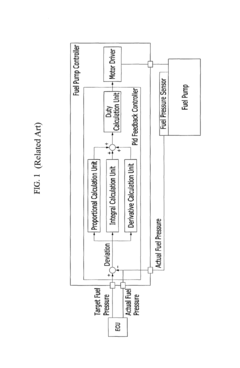

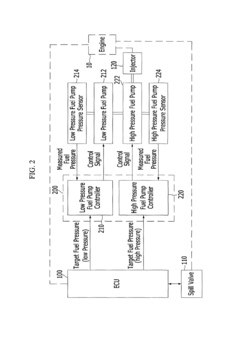

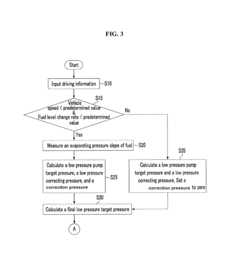

Control system of low pressure fuel pump for gasoline direct injection engine and method thereof

PatentActiveUS9938949B2

Innovation

- A control system for a low pressure fuel pump that adjusts fuel pressure by correcting a reference pressure using a low pressure correcting pressure and a correction pressure, based on temperature, fuel level, and evaporating pressure slope, to prevent vapor lock and maintain optimal fuel injection pressure across different driving conditions.

Environmental Impact of GDI Sensor Calibration Processes

The calibration and realignment processes for Gasoline Direct Injection (GDI) engine sensors carry significant environmental implications that warrant careful consideration. These processes typically involve the use of specialized equipment, chemicals, and testing procedures that generate various forms of waste and emissions. The calibration fluids used during sensor realignment often contain volatile organic compounds (VOCs) and other potentially harmful substances that can contribute to air pollution when released into the atmosphere. Additionally, the energy consumption associated with diagnostic equipment and testing facilities represents a notable carbon footprint component of the calibration process.

Waste management presents another environmental challenge, as sensor calibration generates electronic waste from replaced components, contaminated calibration fluids, and disposable testing materials. Without proper disposal protocols, these materials may introduce hazardous substances into soil and water systems. The manufacturing of replacement sensors and calibration equipment also contributes to resource depletion and carbon emissions throughout the supply chain.

Recent industry developments have focused on creating more environmentally sustainable calibration methodologies. Advanced diagnostic systems now enable more precise calibration with reduced chemical usage and waste generation. Some manufacturers have implemented closed-loop calibration systems that capture and recycle calibration fluids, significantly reducing the volume of hazardous waste produced during the process. Additionally, remote diagnostic capabilities allow for some sensor adjustments without physical intervention, minimizing the environmental impact associated with service center visits.

Regulatory frameworks increasingly address the environmental aspects of automotive maintenance procedures. The European Union's End-of-Life Vehicle Directive and similar regulations in other regions mandate specific handling procedures for automotive components and maintenance waste. These regulations have prompted manufacturers to develop more environmentally friendly calibration methods and materials that comply with increasingly stringent environmental standards.

Looking forward, emerging technologies promise further reductions in environmental impact. Self-calibrating sensor systems that minimize the need for manual realignment are becoming more prevalent in newer GDI engine designs. Biodegradable calibration fluids and environmentally benign cleaning agents are also under development, potentially reducing the toxicity of waste generated during sensor maintenance. As vehicle electrification advances, hybrid calibration approaches that optimize both traditional and electric propulsion systems will require new environmental considerations in sensor management protocols.

Waste management presents another environmental challenge, as sensor calibration generates electronic waste from replaced components, contaminated calibration fluids, and disposable testing materials. Without proper disposal protocols, these materials may introduce hazardous substances into soil and water systems. The manufacturing of replacement sensors and calibration equipment also contributes to resource depletion and carbon emissions throughout the supply chain.

Recent industry developments have focused on creating more environmentally sustainable calibration methodologies. Advanced diagnostic systems now enable more precise calibration with reduced chemical usage and waste generation. Some manufacturers have implemented closed-loop calibration systems that capture and recycle calibration fluids, significantly reducing the volume of hazardous waste produced during the process. Additionally, remote diagnostic capabilities allow for some sensor adjustments without physical intervention, minimizing the environmental impact associated with service center visits.

Regulatory frameworks increasingly address the environmental aspects of automotive maintenance procedures. The European Union's End-of-Life Vehicle Directive and similar regulations in other regions mandate specific handling procedures for automotive components and maintenance waste. These regulations have prompted manufacturers to develop more environmentally friendly calibration methods and materials that comply with increasingly stringent environmental standards.

Looking forward, emerging technologies promise further reductions in environmental impact. Self-calibrating sensor systems that minimize the need for manual realignment are becoming more prevalent in newer GDI engine designs. Biodegradable calibration fluids and environmentally benign cleaning agents are also under development, potentially reducing the toxicity of waste generated during sensor maintenance. As vehicle electrification advances, hybrid calibration approaches that optimize both traditional and electric propulsion systems will require new environmental considerations in sensor management protocols.

Regulatory Compliance for GDI Engine Sensor Technologies

Regulatory compliance for GDI (Gasoline Direct Injection) engine sensor technologies has become increasingly stringent as automotive emissions standards evolve globally. When realigning GDI engine sensors after modifications or repairs, manufacturers must adhere to specific regulatory frameworks that vary by region but share common environmental protection goals.

The United States Environmental Protection Agency (EPA) and California Air Resources Board (CARB) maintain strict requirements for sensor calibration accuracy, particularly for oxygen sensors, fuel pressure sensors, and temperature sensors that directly impact emissions control. Under the Clean Air Act, any sensor realignment must ensure the vehicle maintains compliance with its original certification parameters, with deviations potentially resulting in significant penalties.

European regulations under Euro 6d and upcoming Euro 7 standards impose even more demanding requirements for sensor precision. The European On-Board Diagnostics (EOBD) system mandates that sensor realignment procedures must maintain detection capabilities for even minor emissions deviations, typically within 1.5 times the regulated limits. This necessitates highly accurate calibration processes following any sensor adjustments.

Asian markets, particularly China with its China 6 standards and Japan with its post-new long-term regulations, have similarly adopted comprehensive requirements for sensor performance. These regulations specifically address sensor drift compensation and recalibration procedures after component replacement or adjustment.

The International Organization for Standardization (ISO) provides standardized protocols for sensor calibration through ISO 15031 and ISO 27145 standards, which serve as global benchmarks for realignment procedures. These standards define communication protocols between diagnostic equipment and engine control units during recalibration processes.

Manufacturers must maintain detailed documentation of all sensor realignment procedures, including pre- and post-adjustment readings, calibration equipment certification, and technician qualifications. This documentation becomes particularly critical during regulatory audits or when addressing warranty claims related to emissions performance.

Non-compliance with these regulatory requirements can result in substantial consequences, including vehicle recall campaigns, financial penalties, and market access restrictions. The Volkswagen emissions scandal demonstrated the severe repercussions of circumventing sensor-based emissions controls, resulting in billions in penalties and permanent reputational damage.

As regulations continue to tighten globally, manufacturers are increasingly implementing tamper-resistant sensor designs and encrypted calibration protocols to prevent unauthorized adjustments that could compromise emissions performance after realignment procedures.

The United States Environmental Protection Agency (EPA) and California Air Resources Board (CARB) maintain strict requirements for sensor calibration accuracy, particularly for oxygen sensors, fuel pressure sensors, and temperature sensors that directly impact emissions control. Under the Clean Air Act, any sensor realignment must ensure the vehicle maintains compliance with its original certification parameters, with deviations potentially resulting in significant penalties.

European regulations under Euro 6d and upcoming Euro 7 standards impose even more demanding requirements for sensor precision. The European On-Board Diagnostics (EOBD) system mandates that sensor realignment procedures must maintain detection capabilities for even minor emissions deviations, typically within 1.5 times the regulated limits. This necessitates highly accurate calibration processes following any sensor adjustments.

Asian markets, particularly China with its China 6 standards and Japan with its post-new long-term regulations, have similarly adopted comprehensive requirements for sensor performance. These regulations specifically address sensor drift compensation and recalibration procedures after component replacement or adjustment.

The International Organization for Standardization (ISO) provides standardized protocols for sensor calibration through ISO 15031 and ISO 27145 standards, which serve as global benchmarks for realignment procedures. These standards define communication protocols between diagnostic equipment and engine control units during recalibration processes.

Manufacturers must maintain detailed documentation of all sensor realignment procedures, including pre- and post-adjustment readings, calibration equipment certification, and technician qualifications. This documentation becomes particularly critical during regulatory audits or when addressing warranty claims related to emissions performance.

Non-compliance with these regulatory requirements can result in substantial consequences, including vehicle recall campaigns, financial penalties, and market access restrictions. The Volkswagen emissions scandal demonstrated the severe repercussions of circumventing sensor-based emissions controls, resulting in billions in penalties and permanent reputational damage.

As regulations continue to tighten globally, manufacturers are increasingly implementing tamper-resistant sensor designs and encrypted calibration protocols to prevent unauthorized adjustments that could compromise emissions performance after realignment procedures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!