GDI vs MPFI Engine: Efficiency and Emission Differences

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI and MPFI Technology Evolution and Objectives

The evolution of fuel injection systems in internal combustion engines represents one of the most significant technological advancements in automotive engineering over the past century. Multi-Point Fuel Injection (MPFI) emerged in the 1980s as a revolutionary replacement for carburetors, offering more precise fuel delivery by injecting fuel at each intake port. This technology dominated the market for decades until the late 1990s when Gasoline Direct Injection (GDI) began gaining prominence.

MPFI systems inject fuel into the intake manifold or port where it mixes with air before entering the combustion chamber. This technology represented a significant improvement over carburetors by providing better fuel atomization, more precise fuel metering, and improved throttle response. The evolution of MPFI included advancements in electronic control units (ECUs) that enabled real-time adjustments based on various engine parameters.

GDI technology, by contrast, injects fuel directly into the combustion chamber at much higher pressures (up to 200 bar compared to MPFI's 3-5 bar). This fundamental difference allows for more precise fuel delivery timing and quantity control. The development of GDI can be traced back to the early 20th century, but practical implementation in mass-produced vehicles only became feasible with advances in electronic control systems and materials science in the late 1990s.

The technological trajectory of both systems has been primarily driven by increasingly stringent emission regulations worldwide and the pursuit of improved fuel efficiency. MPFI systems evolved from mechanical to electronic control, while GDI systems have progressed through multiple generations with improvements in injector design, spray patterns, and pressure capabilities.

The primary objectives behind the development of these technologies include maximizing thermal efficiency, minimizing emissions (particularly NOx, CO, and particulate matter), improving power output, and enhancing fuel economy. GDI systems specifically aim to enable stratified charge combustion at part load conditions, which allows for ultra-lean burning and significant efficiency improvements.

Recent technological objectives include the integration of these systems with other advanced technologies such as variable valve timing, turbocharging, and hybrid powertrains. The industry is also focused on addressing GDI-specific challenges such as intake valve deposit formation and particulate emissions through innovations in injector design and fuel formulation.

The evolution continues with the development of dual-injection systems that combine the benefits of both GDI and MPFI, representing a hybrid approach that aims to maximize efficiency while minimizing the drawbacks of each individual technology. This convergence illustrates how the technological evolution is increasingly focused on optimizing the entire combustion process rather than just the fuel delivery mechanism.

MPFI systems inject fuel into the intake manifold or port where it mixes with air before entering the combustion chamber. This technology represented a significant improvement over carburetors by providing better fuel atomization, more precise fuel metering, and improved throttle response. The evolution of MPFI included advancements in electronic control units (ECUs) that enabled real-time adjustments based on various engine parameters.

GDI technology, by contrast, injects fuel directly into the combustion chamber at much higher pressures (up to 200 bar compared to MPFI's 3-5 bar). This fundamental difference allows for more precise fuel delivery timing and quantity control. The development of GDI can be traced back to the early 20th century, but practical implementation in mass-produced vehicles only became feasible with advances in electronic control systems and materials science in the late 1990s.

The technological trajectory of both systems has been primarily driven by increasingly stringent emission regulations worldwide and the pursuit of improved fuel efficiency. MPFI systems evolved from mechanical to electronic control, while GDI systems have progressed through multiple generations with improvements in injector design, spray patterns, and pressure capabilities.

The primary objectives behind the development of these technologies include maximizing thermal efficiency, minimizing emissions (particularly NOx, CO, and particulate matter), improving power output, and enhancing fuel economy. GDI systems specifically aim to enable stratified charge combustion at part load conditions, which allows for ultra-lean burning and significant efficiency improvements.

Recent technological objectives include the integration of these systems with other advanced technologies such as variable valve timing, turbocharging, and hybrid powertrains. The industry is also focused on addressing GDI-specific challenges such as intake valve deposit formation and particulate emissions through innovations in injector design and fuel formulation.

The evolution continues with the development of dual-injection systems that combine the benefits of both GDI and MPFI, representing a hybrid approach that aims to maximize efficiency while minimizing the drawbacks of each individual technology. This convergence illustrates how the technological evolution is increasingly focused on optimizing the entire combustion process rather than just the fuel delivery mechanism.

Market Demand Analysis for Fuel-Efficient Engines

The global automotive industry is witnessing a significant shift towards fuel-efficient engines driven by stringent emission regulations, rising fuel costs, and increasing environmental consciousness among consumers. Market research indicates that the demand for fuel-efficient engines has grown at an annual rate of 5.7% over the past five years, with projections suggesting continued growth through 2030.

Consumer preferences have evolved substantially, with 68% of new vehicle buyers now citing fuel efficiency as a "very important" factor in their purchasing decisions, compared to just 42% a decade ago. This shift is particularly pronounced in urban markets where fuel prices tend to be higher and environmental regulations more stringent.

The market for GDI (Gasoline Direct Injection) engines has experienced remarkable growth, capturing approximately 45% of the global gasoline engine market, up from 15% in 2010. This growth trajectory is expected to continue as manufacturers increasingly adopt GDI technology to meet both consumer demands and regulatory requirements. The premium vehicle segment has already achieved nearly 85% penetration of GDI technology.

Regional analysis reveals varying adoption rates, with Europe leading at 62% GDI implementation across new vehicles, followed by North America at 51% and Asia-Pacific at 38%. Developing markets show accelerated adoption curves as they implement newer emission standards, effectively leapfrogging older technologies.

Economic factors significantly influence market demand patterns. Fuel price volatility has historically correlated with increased consumer interest in fuel-efficient technologies, with market data showing a 12% increase in fuel-efficient vehicle searches during periods of fuel price spikes. The total cost of ownership calculations increasingly favor more efficient engine technologies despite their higher initial cost.

Regulatory landscapes worldwide continue to tighten emission standards, with the European Union's Euro 7 standards, China's China 6b, and the United States' Tier 3 regulations all pushing manufacturers toward more efficient combustion technologies. These regulations have created a market environment where efficiency improvements are not merely competitive advantages but essential compliance requirements.

Market segmentation analysis reveals that mid-size sedans and compact SUVs represent the largest market segments for advanced fuel-efficient engines, collectively accounting for 58% of GDI implementations. The luxury segment, while smaller in volume, demonstrates higher willingness to adopt premium efficiency technologies, serving as an early adoption pathway for innovations that later cascade to mass-market vehicles.

Fleet operators and commercial vehicle markets present a distinct demand profile, with emphasis on total lifecycle costs rather than initial purchase price, creating a growing market for advanced efficiency technologies with demonstrable return on investment through reduced operating expenses.

Consumer preferences have evolved substantially, with 68% of new vehicle buyers now citing fuel efficiency as a "very important" factor in their purchasing decisions, compared to just 42% a decade ago. This shift is particularly pronounced in urban markets where fuel prices tend to be higher and environmental regulations more stringent.

The market for GDI (Gasoline Direct Injection) engines has experienced remarkable growth, capturing approximately 45% of the global gasoline engine market, up from 15% in 2010. This growth trajectory is expected to continue as manufacturers increasingly adopt GDI technology to meet both consumer demands and regulatory requirements. The premium vehicle segment has already achieved nearly 85% penetration of GDI technology.

Regional analysis reveals varying adoption rates, with Europe leading at 62% GDI implementation across new vehicles, followed by North America at 51% and Asia-Pacific at 38%. Developing markets show accelerated adoption curves as they implement newer emission standards, effectively leapfrogging older technologies.

Economic factors significantly influence market demand patterns. Fuel price volatility has historically correlated with increased consumer interest in fuel-efficient technologies, with market data showing a 12% increase in fuel-efficient vehicle searches during periods of fuel price spikes. The total cost of ownership calculations increasingly favor more efficient engine technologies despite their higher initial cost.

Regulatory landscapes worldwide continue to tighten emission standards, with the European Union's Euro 7 standards, China's China 6b, and the United States' Tier 3 regulations all pushing manufacturers toward more efficient combustion technologies. These regulations have created a market environment where efficiency improvements are not merely competitive advantages but essential compliance requirements.

Market segmentation analysis reveals that mid-size sedans and compact SUVs represent the largest market segments for advanced fuel-efficient engines, collectively accounting for 58% of GDI implementations. The luxury segment, while smaller in volume, demonstrates higher willingness to adopt premium efficiency technologies, serving as an early adoption pathway for innovations that later cascade to mass-market vehicles.

Fleet operators and commercial vehicle markets present a distinct demand profile, with emphasis on total lifecycle costs rather than initial purchase price, creating a growing market for advanced efficiency technologies with demonstrable return on investment through reduced operating expenses.

Current Technical Challenges in Fuel Injection Systems

Despite significant advancements in fuel injection technology, several critical challenges persist in both Gasoline Direct Injection (GDI) and Multipoint Fuel Injection (MPFI) systems. One of the most pressing issues facing GDI systems is particulate matter (PM) emissions, particularly ultrafine particles that pose serious health concerns. These emissions occur primarily during cold starts and high-load conditions when fuel atomization is suboptimal, creating a technical paradox where efficiency gains come with environmental costs.

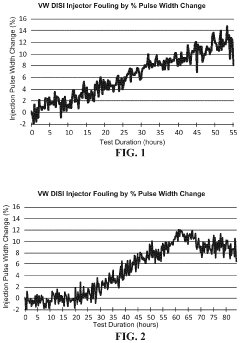

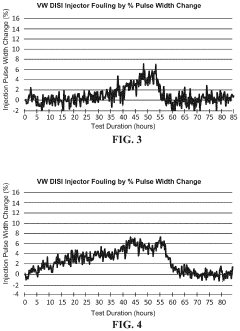

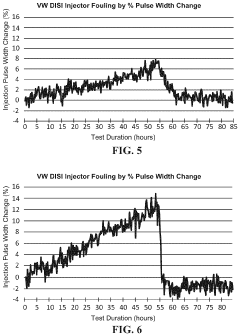

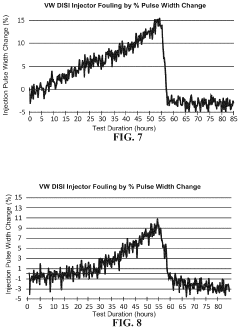

Deposit formation represents another significant challenge, with GDI systems particularly susceptible to injector coking due to their exposure to higher combustion temperatures. These carbon deposits gradually restrict fuel flow, alter spray patterns, and ultimately compromise both performance and emissions control. Industry data suggests that severe injector fouling can reduce fuel economy by up to 5% and increase emissions by 7-10% after just 10,000 miles of operation.

Fuel-air mixture homogeneity remains problematic, especially in GDI systems where there is limited time for fuel vaporization and mixing before ignition. This challenge becomes more pronounced at higher engine speeds and loads, resulting in combustion instability and increased emissions. The industry continues to struggle with optimizing injector spray patterns and timing strategies to achieve consistent mixture formation across all operating conditions.

Cold-start emissions control presents a persistent challenge for both systems, though more pronounced in GDI engines. During cold starts, fuel vaporization is poor, leading to incomplete combustion and significantly higher hydrocarbon and particulate emissions. Current solutions involving enrichment strategies and catalyst heating routines often compromise fuel efficiency during these critical phases.

Durability and reliability issues affect both technologies but manifest differently. MPFI systems generally demonstrate excellent longevity but face challenges with fuel pressure regulation and injector flow matching over time. GDI systems, while offering superior performance, experience more aggressive wear patterns due to higher operating pressures (up to 200 bar versus 3-5 bar in MPFI) and exposure to combustion byproducts.

The integration of alternative fuels presents additional challenges, particularly for precisely calibrated GDI systems. Ethanol blends, increasingly common worldwide, create complications due to different stoichiometric ratios, energy content, and vaporization characteristics. Current injection systems require substantial recalibration to maintain efficiency when fuel compositions change, limiting flexibility in real-world applications.

Finally, cost-effectiveness remains a significant hurdle, especially for advanced GDI technologies. The precision components required for high-pressure direct injection systems typically increase manufacturing costs by 15-25% compared to equivalent MPFI systems, creating adoption barriers particularly in cost-sensitive market segments.

Deposit formation represents another significant challenge, with GDI systems particularly susceptible to injector coking due to their exposure to higher combustion temperatures. These carbon deposits gradually restrict fuel flow, alter spray patterns, and ultimately compromise both performance and emissions control. Industry data suggests that severe injector fouling can reduce fuel economy by up to 5% and increase emissions by 7-10% after just 10,000 miles of operation.

Fuel-air mixture homogeneity remains problematic, especially in GDI systems where there is limited time for fuel vaporization and mixing before ignition. This challenge becomes more pronounced at higher engine speeds and loads, resulting in combustion instability and increased emissions. The industry continues to struggle with optimizing injector spray patterns and timing strategies to achieve consistent mixture formation across all operating conditions.

Cold-start emissions control presents a persistent challenge for both systems, though more pronounced in GDI engines. During cold starts, fuel vaporization is poor, leading to incomplete combustion and significantly higher hydrocarbon and particulate emissions. Current solutions involving enrichment strategies and catalyst heating routines often compromise fuel efficiency during these critical phases.

Durability and reliability issues affect both technologies but manifest differently. MPFI systems generally demonstrate excellent longevity but face challenges with fuel pressure regulation and injector flow matching over time. GDI systems, while offering superior performance, experience more aggressive wear patterns due to higher operating pressures (up to 200 bar versus 3-5 bar in MPFI) and exposure to combustion byproducts.

The integration of alternative fuels presents additional challenges, particularly for precisely calibrated GDI systems. Ethanol blends, increasingly common worldwide, create complications due to different stoichiometric ratios, energy content, and vaporization characteristics. Current injection systems require substantial recalibration to maintain efficiency when fuel compositions change, limiting flexibility in real-world applications.

Finally, cost-effectiveness remains a significant hurdle, especially for advanced GDI technologies. The precision components required for high-pressure direct injection systems typically increase manufacturing costs by 15-25% compared to equivalent MPFI systems, creating adoption barriers particularly in cost-sensitive market segments.

Comparative Analysis of GDI and MPFI Solutions

01 GDI engine efficiency improvements

Gasoline Direct Injection (GDI) engines offer improved fuel efficiency through precise fuel delivery directly into the combustion chamber. This technology allows for better atomization of fuel, stratified charge combustion, and more accurate fuel metering. These features result in reduced fuel consumption, especially at partial load conditions, compared to traditional port injection systems. Advanced GDI systems can achieve higher compression ratios without knock, further enhancing thermal efficiency.- GDI Engine Efficiency Improvements: Gasoline Direct Injection (GDI) engines offer improved fuel efficiency through precise fuel delivery directly into the combustion chamber. This technology enables better atomization of fuel, stratified charge combustion, and more accurate fuel metering. These features result in reduced fuel consumption, especially at partial load conditions, compared to traditional Multi-Point Fuel Injection (MPFI) systems. The direct injection approach also allows for higher compression ratios, contributing to thermal efficiency gains.

- Emission Control Technologies for GDI Systems: GDI engines face challenges with particulate matter emissions due to potential fuel wall wetting and incomplete combustion. Advanced emission control technologies include optimized injection strategies, improved injector designs, and specialized catalytic converters. These systems work to reduce NOx, HC, and particulate emissions while maintaining the efficiency benefits of direct injection. Some solutions incorporate exhaust gas recirculation (EGR) and advanced aftertreatment systems specifically designed for GDI emission profiles.

- MPFI System Optimization for Emissions Compliance: Multi-Point Fuel Injection (MPFI) systems continue to evolve to meet stricter emission standards. Improvements include enhanced fuel atomization, optimized intake port design, and advanced electronic control units that precisely manage air-fuel ratios. While MPFI systems typically produce fewer particulate emissions than GDI engines, they require specific optimizations to reduce NOx and HC emissions. Advanced MPFI systems incorporate improved oxygen sensors, variable valve timing, and sophisticated engine management systems to balance performance with emissions compliance.

- Hybrid GDI-MPFI Systems: Innovative hybrid injection systems combine elements of both GDI and MPFI technologies to maximize benefits while minimizing drawbacks. These systems can switch between direct and port injection modes depending on operating conditions, or use both simultaneously. At low loads, port injection may be favored for better emissions, while direct injection activates at higher loads for improved efficiency. This dual-mode approach helps optimize fuel economy while addressing the particulate emission challenges of pure GDI systems and the efficiency limitations of MPFI systems.

- Advanced Control Strategies for Engine Efficiency: Sophisticated control strategies play a crucial role in optimizing both GDI and MPFI engine performance. These include real-time combustion monitoring, adaptive fuel injection mapping, and intelligent thermal management systems. Advanced algorithms adjust injection timing, duration, and pressure based on multiple sensor inputs to maximize efficiency across various operating conditions. Some systems incorporate machine learning techniques to continuously optimize engine parameters, resulting in improved fuel economy and reduced emissions regardless of the basic injection architecture.

02 MPFI system optimization for emissions reduction

Multi-Point Fuel Injection (MPFI) systems have been optimized to reduce emissions through improved fuel atomization and distribution in the intake ports. Enhanced electronic control units allow for more precise air-fuel ratio management across various operating conditions. MPFI systems incorporate oxygen sensors and catalytic converters specifically designed to minimize harmful exhaust emissions. While not as efficient as GDI systems, modern MPFI engines achieve good emission control with simpler hardware and lower manufacturing costs.Expand Specific Solutions03 Hybrid GDI-MPFI systems

Hybrid injection systems combining both GDI and MPFI technologies have been developed to maximize the benefits of each approach. These systems can switch between direct injection for high-load conditions and port injection for low-load operation, optimizing both efficiency and emissions control. The dual-injection approach helps reduce particulate matter formation common in pure GDI systems while maintaining efficiency advantages. This hybrid approach also addresses carbon buildup issues on intake valves that typically affect GDI engines.Expand Specific Solutions04 Emission control technologies for GDI engines

GDI engines require specialized emission control technologies to address their unique emission characteristics, particularly higher particulate matter emissions. Advanced catalytic converters, gasoline particulate filters, and exhaust gas recirculation systems have been developed specifically for GDI applications. Sophisticated engine control strategies, including multiple injection events per cycle and variable valve timing, help reduce raw emissions. These technologies enable GDI engines to meet stringent emission standards while maintaining their efficiency advantages.Expand Specific Solutions05 Comparative performance analysis between GDI and MPFI

Comparative studies between GDI and MPFI systems show distinct performance characteristics across various operating conditions. GDI systems generally demonstrate 10-15% better fuel efficiency but may produce higher levels of particulate emissions. MPFI systems show better cold-start performance and lower particulate emissions but reduced efficiency at part-load conditions. The cost-benefit analysis between the two technologies depends on specific application requirements, emission regulations, and manufacturing considerations. Advanced sensing and control systems are crucial for optimizing performance in both injection technologies.Expand Specific Solutions

Major Automotive and Engine Technology Companies

The GDI vs MPFI engine technology landscape is currently in a mature development phase, with a global market size exceeding $30 billion. Major automotive manufacturers like Ford, Hyundai, Kia, and FCA have widely adopted GDI technology for its superior fuel efficiency and reduced emissions. Technology suppliers such as Delphi, AVL List, and Tula Technology are driving innovation in injection systems. Research institutions including Tianjin University and Xi'an Jiaotong University are advancing fundamental understanding, while energy companies like ExxonMobil, Shell, and BP are developing compatible fuels. The technology has reached commercial maturity with ongoing refinements focused on emissions reduction and efficiency optimization.

Delphi Technology, Inc.

Technical Solution: Delphi has pioneered advanced fuel injection technologies for both GDI and MPFI systems, with particular emphasis on their next-generation GDi solenoid and piezo injector technologies. Their GDI systems operate at pressures ranging from 200 to 350 bar, with their latest systems capable of reaching 500+ bar. Delphi's technology enables multiple injection events (up to 7 per combustion cycle) with precise control over injection timing, duration, and spray pattern. Their research demonstrates that high-pressure GDI systems can reduce fuel consumption by up to 15% compared to conventional MPFI systems while meeting stringent emission standards. Delphi has also developed innovative dual-fuel systems that combine the benefits of both GDI and MPFI, using port injection during cold starts and low loads while leveraging GDI for higher loads. Their injector designs feature optimized spray patterns that enhance air-fuel mixing and combustion efficiency while minimizing wall wetting, which helps address particulate emission challenges inherent to GDI technology.

Strengths: Industry-leading injector precision and durability, flexible multi-injection capability, and comprehensive system integration expertise. Weaknesses: Higher system cost compared to traditional MPFI solutions, more complex calibration requirements, and increased sensitivity to fuel quality variations.

Ford Global Technologies LLC

Technical Solution: Ford has developed advanced GDI (Gasoline Direct Injection) systems for their EcoBoost engine family, which combines direct injection with turbocharging and variable valve timing. Their technology injects fuel directly into the combustion chamber at pressures up to 2,150 psi, allowing for precise fuel delivery and atomization. This enables multiple injection events per combustion cycle, optimizing fuel efficiency across various operating conditions. Ford's research shows their GDI systems deliver 10-20% better fuel economy compared to traditional MPFI (Multi-Point Fuel Injection) systems while reducing CO2 emissions by similar percentages. Their latest generation incorporates spray-guided injection patterns and advanced electronic controls to minimize particulate emissions—a traditional challenge for GDI systems. Ford has also developed hybrid solutions that leverage both GDI and port injection in certain operating conditions to maximize efficiency while minimizing carbon buildup issues.

Strengths: Superior fuel economy (10-20% improvement over MPFI), enhanced power density, better cold-start emissions, and precise control over injection timing and quantity. Weaknesses: Higher system complexity and cost, potential for increased particulate emissions under certain conditions, and carbon buildup on intake valves requiring additional engineering solutions.

Key Patents and Innovations in Fuel Injection

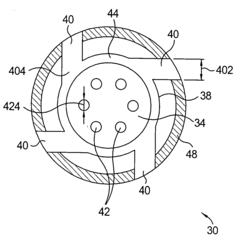

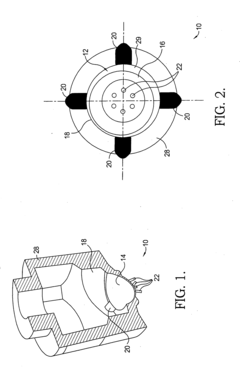

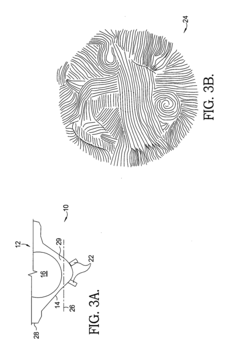

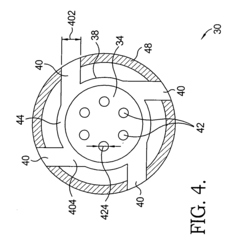

Fuel injection tip

PatentInactiveUS20090255998A1

Innovation

- The use of tangential inflow holes instead of perpendicular ones in the fuel injector tip creates a swirling fluid motion, reducing flow variations and impact force on the ball surface, allowing for a larger clearance between the ball and guide bore while maintaining or increasing mass flow rates through larger director holes.

Fuel Additives and Formulations for Improving Performance of Gasoline Direct Injection Engines

PatentActiveUS20240141244A1

Innovation

- A novel fuel additive composition comprising an acylated detergent, a Mannich detergent, and a polyether and/or polyetheramine, which are specifically formulated to reduce carbonaceous deposits in gasoline engines by preventing or removing them, and are effective in both port fuel injection and direct injection engines.

Emissions Regulations Impact on Injection Technology

Emissions regulations have become increasingly stringent worldwide, serving as primary drivers for the evolution of fuel injection technologies. The transition from carburetors to electronic fuel injection systems was largely catalyzed by the need to meet emissions standards established in the 1970s and 1980s. As regulations continued to tighten, Multi-Point Fuel Injection (MPFI) systems became the industry standard, offering improved fuel atomization and more precise control over the air-fuel mixture.

The introduction of Euro standards in Europe, Tier regulations in the United States, and similar frameworks in other regions has progressively lowered permissible levels of nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate matter (PM). These regulatory pressures have significantly influenced the development and adoption of Gasoline Direct Injection (GDI) technology, which offers superior fuel economy and reduced CO2 emissions compared to MPFI systems.

Euro 6 and EPA Tier 3 standards have placed particular emphasis on reducing particulate emissions, presenting a challenge for GDI systems which, despite their efficiency advantages, tend to produce higher levels of particulate matter than their MPFI counterparts. This regulatory focus has necessitated the integration of particulate filters in many GDI vehicles, adding complexity and cost to these systems.

China's implementation of China 6 standards, among the world's most stringent, has accelerated the adoption of advanced injection technologies and after-treatment systems. Similarly, Japan's post-new long-term regulations have pushed manufacturers toward sophisticated emission control strategies that often leverage the precise injection control offered by GDI systems.

Real Driving Emissions (RDE) testing, introduced in Europe and gradually being adopted elsewhere, has further complicated compliance by requiring vehicles to meet emissions standards under actual driving conditions rather than just in laboratory settings. This shift has intensified the need for injection systems that can maintain optimal performance across diverse operating conditions.

The regulatory landscape continues to evolve, with many regions announcing plans for even stricter standards in the coming years. These future regulations are expected to further narrow the permissible emissions gap between gasoline and diesel engines, potentially accelerating the convergence of injection technologies across fuel types and driving innovation in hybrid injection systems that combine the benefits of both GDI and MPFI approaches.

The introduction of Euro standards in Europe, Tier regulations in the United States, and similar frameworks in other regions has progressively lowered permissible levels of nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate matter (PM). These regulatory pressures have significantly influenced the development and adoption of Gasoline Direct Injection (GDI) technology, which offers superior fuel economy and reduced CO2 emissions compared to MPFI systems.

Euro 6 and EPA Tier 3 standards have placed particular emphasis on reducing particulate emissions, presenting a challenge for GDI systems which, despite their efficiency advantages, tend to produce higher levels of particulate matter than their MPFI counterparts. This regulatory focus has necessitated the integration of particulate filters in many GDI vehicles, adding complexity and cost to these systems.

China's implementation of China 6 standards, among the world's most stringent, has accelerated the adoption of advanced injection technologies and after-treatment systems. Similarly, Japan's post-new long-term regulations have pushed manufacturers toward sophisticated emission control strategies that often leverage the precise injection control offered by GDI systems.

Real Driving Emissions (RDE) testing, introduced in Europe and gradually being adopted elsewhere, has further complicated compliance by requiring vehicles to meet emissions standards under actual driving conditions rather than just in laboratory settings. This shift has intensified the need for injection systems that can maintain optimal performance across diverse operating conditions.

The regulatory landscape continues to evolve, with many regions announcing plans for even stricter standards in the coming years. These future regulations are expected to further narrow the permissible emissions gap between gasoline and diesel engines, potentially accelerating the convergence of injection technologies across fuel types and driving innovation in hybrid injection systems that combine the benefits of both GDI and MPFI approaches.

Cost-Benefit Analysis of GDI vs MPFI Implementation

When evaluating the implementation of Gasoline Direct Injection (GDI) versus Multipoint Fuel Injection (MPFI) systems, a comprehensive cost-benefit analysis reveals significant economic considerations for manufacturers and consumers alike.

Initial manufacturing costs for GDI systems are approximately 5-10% higher than traditional MPFI systems due to the need for higher-pressure fuel pumps, more precise injectors, and more sophisticated engine control units. This translates to an additional $200-500 per vehicle in production costs, which manufacturers typically pass on to consumers.

However, the long-term operational economics present a different picture. GDI engines demonstrate 10-15% better fuel efficiency compared to MPFI counterparts, resulting in estimated savings of $300-600 annually for average drivers (15,000 miles/year) at current fuel prices. This efficiency advantage means the higher initial investment can be recouped within 1-2 years of vehicle operation.

Maintenance considerations also factor into the equation. GDI systems are more prone to carbon buildup on intake valves, potentially requiring specialized cleaning procedures every 30,000-50,000 miles at costs ranging from $300-700 per service. MPFI systems generally avoid this issue as fuel spray helps clean intake valves during normal operation.

From an emissions compliance perspective, GDI provides manufacturers with advantages in meeting increasingly stringent regulations. The reduced CO2 emissions from improved fuel efficiency help automakers meet fleet average requirements, potentially saving millions in regulatory compliance costs or penalties. However, GDI systems typically produce higher particulate matter emissions, necessitating additional filtration systems costing $100-200 per vehicle.

The total cost of ownership analysis indicates that despite higher initial and maintenance costs, GDI systems generally provide net economic benefits over a vehicle's lifetime in markets with higher fuel prices or stricter emissions regulations. In regions with lower fuel costs, the economic advantage diminishes significantly.

For manufacturers, the transition to GDI technology requires substantial capital investment in production facilities, estimated at $50-100 million per production line. This investment includes retooling, worker training, and quality control systems specific to higher-precision GDI components.

Market analysis shows consumers are increasingly willing to pay premium prices for vehicles with better fuel economy, with surveys indicating 65% of new car buyers consider fuel efficiency "very important" in purchasing decisions. This market preference helps offset the higher production costs of GDI technology through improved sales performance and brand positioning.

Initial manufacturing costs for GDI systems are approximately 5-10% higher than traditional MPFI systems due to the need for higher-pressure fuel pumps, more precise injectors, and more sophisticated engine control units. This translates to an additional $200-500 per vehicle in production costs, which manufacturers typically pass on to consumers.

However, the long-term operational economics present a different picture. GDI engines demonstrate 10-15% better fuel efficiency compared to MPFI counterparts, resulting in estimated savings of $300-600 annually for average drivers (15,000 miles/year) at current fuel prices. This efficiency advantage means the higher initial investment can be recouped within 1-2 years of vehicle operation.

Maintenance considerations also factor into the equation. GDI systems are more prone to carbon buildup on intake valves, potentially requiring specialized cleaning procedures every 30,000-50,000 miles at costs ranging from $300-700 per service. MPFI systems generally avoid this issue as fuel spray helps clean intake valves during normal operation.

From an emissions compliance perspective, GDI provides manufacturers with advantages in meeting increasingly stringent regulations. The reduced CO2 emissions from improved fuel efficiency help automakers meet fleet average requirements, potentially saving millions in regulatory compliance costs or penalties. However, GDI systems typically produce higher particulate matter emissions, necessitating additional filtration systems costing $100-200 per vehicle.

The total cost of ownership analysis indicates that despite higher initial and maintenance costs, GDI systems generally provide net economic benefits over a vehicle's lifetime in markets with higher fuel prices or stricter emissions regulations. In regions with lower fuel costs, the economic advantage diminishes significantly.

For manufacturers, the transition to GDI technology requires substantial capital investment in production facilities, estimated at $50-100 million per production line. This investment includes retooling, worker training, and quality control systems specific to higher-precision GDI components.

Market analysis shows consumers are increasingly willing to pay premium prices for vehicles with better fuel economy, with surveys indicating 65% of new car buyers consider fuel efficiency "very important" in purchasing decisions. This market preference helps offset the higher production costs of GDI technology through improved sales performance and brand positioning.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!