GDI Engine Torque Mapping for Urban Applications

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Engine Torque Mapping Background and Objectives

Gasoline Direct Injection (GDI) engine technology has evolved significantly over the past three decades, transforming from a niche innovation to a mainstream powertrain solution. The development trajectory began in the late 1990s with rudimentary systems focused primarily on fuel economy improvements. By the mid-2000s, second-generation GDI systems emerged with enhanced injection pressure capabilities and more sophisticated control algorithms, enabling better combustion stability and emissions performance.

The current generation of GDI engines represents a convergence of multiple advanced technologies, including high-pressure fuel systems operating at 350+ bar, precision multi-pulse injection strategies, and integrated thermal management systems. This evolution has been driven by increasingly stringent emissions regulations worldwide, particularly in urban environments where air quality concerns are paramount.

Urban driving presents unique challenges for engine calibration due to its characteristic stop-start patterns, variable load demands, and thermal management complexities. Traditional torque mapping approaches developed for highway or standardized drive cycles often fail to optimize performance in these conditions, resulting in suboptimal fuel economy, elevated emissions, and compromised drivability in real-world urban scenarios.

The technical objective of GDI engine torque mapping for urban applications centers on developing precise, adaptive control strategies that can accurately predict and deliver the required engine torque across the highly variable conditions encountered in city driving. This involves creating multi-dimensional maps that account for transient operations, cold-start conditions, and the frequent load variations typical of urban environments.

Recent advancements in computational capabilities have enabled more sophisticated approaches to torque mapping, including physics-based models supplemented by machine learning algorithms that can adapt to changing conditions and driver behaviors. These hybrid approaches show promise in addressing the limitations of traditional lookup-table based calibration methods.

The industry is currently transitioning toward dynamic torque management systems that integrate real-time traffic data, topographical information, and predictive analytics to anticipate driving conditions. This forward-looking approach aims to optimize not just instantaneous performance but to manage energy flows across the entire urban journey, particularly important for hybrid GDI powertrains where the interplay between combustion engine and electric propulsion must be carefully orchestrated.

The ultimate goal of advanced torque mapping for urban GDI applications extends beyond conventional performance metrics to encompass broader sustainability objectives, including minimizing particulate emissions during cold starts and acceleration events, reducing CO2 output across diverse driving patterns, and ensuring consistent performance throughout the vehicle's lifecycle despite aging effects on components and sensors.

The current generation of GDI engines represents a convergence of multiple advanced technologies, including high-pressure fuel systems operating at 350+ bar, precision multi-pulse injection strategies, and integrated thermal management systems. This evolution has been driven by increasingly stringent emissions regulations worldwide, particularly in urban environments where air quality concerns are paramount.

Urban driving presents unique challenges for engine calibration due to its characteristic stop-start patterns, variable load demands, and thermal management complexities. Traditional torque mapping approaches developed for highway or standardized drive cycles often fail to optimize performance in these conditions, resulting in suboptimal fuel economy, elevated emissions, and compromised drivability in real-world urban scenarios.

The technical objective of GDI engine torque mapping for urban applications centers on developing precise, adaptive control strategies that can accurately predict and deliver the required engine torque across the highly variable conditions encountered in city driving. This involves creating multi-dimensional maps that account for transient operations, cold-start conditions, and the frequent load variations typical of urban environments.

Recent advancements in computational capabilities have enabled more sophisticated approaches to torque mapping, including physics-based models supplemented by machine learning algorithms that can adapt to changing conditions and driver behaviors. These hybrid approaches show promise in addressing the limitations of traditional lookup-table based calibration methods.

The industry is currently transitioning toward dynamic torque management systems that integrate real-time traffic data, topographical information, and predictive analytics to anticipate driving conditions. This forward-looking approach aims to optimize not just instantaneous performance but to manage energy flows across the entire urban journey, particularly important for hybrid GDI powertrains where the interplay between combustion engine and electric propulsion must be carefully orchestrated.

The ultimate goal of advanced torque mapping for urban GDI applications extends beyond conventional performance metrics to encompass broader sustainability objectives, including minimizing particulate emissions during cold starts and acceleration events, reducing CO2 output across diverse driving patterns, and ensuring consistent performance throughout the vehicle's lifecycle despite aging effects on components and sensors.

Urban Mobility Market Requirements Analysis

The urban mobility landscape is undergoing significant transformation, driven by increasing urbanization, environmental concerns, and technological advancements. For GDI (Gasoline Direct Injection) Engine Torque Mapping applications in urban environments, market requirements are shaped by several critical factors that demand specialized optimization approaches.

Urban driving patterns differ substantially from highway or rural driving, characterized by frequent stop-start cycles, lower average speeds, and highly variable load demands. Market analysis indicates that vehicles operating in urban environments spend approximately 30% of their time idling and experience up to 40% more acceleration/deceleration events compared to highway driving. These conditions create unique challenges for engine performance optimization and fuel efficiency management.

Consumer expectations in urban mobility markets increasingly prioritize responsive acceleration at low speeds, minimal noise during frequent restarts, and optimal fuel economy during congested traffic conditions. Survey data from major metropolitan areas reveals that urban drivers rank smooth power delivery during stop-start situations as their third most important vehicle performance attribute, behind only fuel economy and overall reliability.

Regulatory pressures further shape market requirements for urban GDI applications. Major global cities have implemented or announced increasingly stringent emissions regulations, with many planning zero-emission zones by 2030. This regulatory landscape necessitates advanced torque mapping solutions that can minimize emissions during the challenging transient conditions typical of urban driving, particularly during cold starts and low-speed operation when catalytic converters may not be at optimal operating temperature.

Fleet operators in urban environments, including taxi services, delivery companies, and ride-sharing platforms, represent a significant market segment with specific requirements. These commercial users prioritize total cost of ownership, with particular emphasis on fuel consumption in urban conditions and maintenance intervals. Data from fleet management systems indicates that optimized torque mapping can reduce urban fuel consumption by 7-12% and extend maintenance intervals by reducing carbon buildup issues common in GDI engines during low-load urban operation.

The integration of connectivity and smart city infrastructure creates emerging requirements for GDI torque mapping systems. Real-time traffic data, predictive routing algorithms, and vehicle-to-infrastructure communication capabilities are enabling new approaches to dynamic engine management that can anticipate urban driving conditions and proactively optimize torque delivery for both efficiency and emissions control.

Consumer feedback analysis reveals growing expectations for seamless integration between powertrain performance and advanced driver assistance systems (ADAS) in urban environments, with particular emphasis on smooth, predictable torque delivery during semi-autonomous driving modes that are increasingly deployed in congested urban settings.

Urban driving patterns differ substantially from highway or rural driving, characterized by frequent stop-start cycles, lower average speeds, and highly variable load demands. Market analysis indicates that vehicles operating in urban environments spend approximately 30% of their time idling and experience up to 40% more acceleration/deceleration events compared to highway driving. These conditions create unique challenges for engine performance optimization and fuel efficiency management.

Consumer expectations in urban mobility markets increasingly prioritize responsive acceleration at low speeds, minimal noise during frequent restarts, and optimal fuel economy during congested traffic conditions. Survey data from major metropolitan areas reveals that urban drivers rank smooth power delivery during stop-start situations as their third most important vehicle performance attribute, behind only fuel economy and overall reliability.

Regulatory pressures further shape market requirements for urban GDI applications. Major global cities have implemented or announced increasingly stringent emissions regulations, with many planning zero-emission zones by 2030. This regulatory landscape necessitates advanced torque mapping solutions that can minimize emissions during the challenging transient conditions typical of urban driving, particularly during cold starts and low-speed operation when catalytic converters may not be at optimal operating temperature.

Fleet operators in urban environments, including taxi services, delivery companies, and ride-sharing platforms, represent a significant market segment with specific requirements. These commercial users prioritize total cost of ownership, with particular emphasis on fuel consumption in urban conditions and maintenance intervals. Data from fleet management systems indicates that optimized torque mapping can reduce urban fuel consumption by 7-12% and extend maintenance intervals by reducing carbon buildup issues common in GDI engines during low-load urban operation.

The integration of connectivity and smart city infrastructure creates emerging requirements for GDI torque mapping systems. Real-time traffic data, predictive routing algorithms, and vehicle-to-infrastructure communication capabilities are enabling new approaches to dynamic engine management that can anticipate urban driving conditions and proactively optimize torque delivery for both efficiency and emissions control.

Consumer feedback analysis reveals growing expectations for seamless integration between powertrain performance and advanced driver assistance systems (ADAS) in urban environments, with particular emphasis on smooth, predictable torque delivery during semi-autonomous driving modes that are increasingly deployed in congested urban settings.

Current GDI Torque Mapping Challenges

Gasoline Direct Injection (GDI) engine torque mapping for urban applications faces several significant challenges that impede optimal performance and efficiency. The primary challenge lies in accurately modeling the complex relationship between multiple input parameters and torque output under the highly variable conditions characteristic of urban driving. Traditional mapping approaches often fail to capture the transient behaviors that dominate city driving scenarios, resulting in suboptimal engine performance and increased emissions.

The frequent stop-start patterns in urban environments create thermal management issues that affect torque delivery consistency. Cold-start conditions, which occur more frequently in urban driving, introduce additional variability in combustion efficiency and torque generation that is difficult to map accurately. Furthermore, the rapid transitions between different load conditions require sophisticated mapping strategies that can adapt quickly without compromising drivability or fuel economy.

Another significant challenge is the dimensional complexity of GDI torque maps. Modern GDI engines require multidimensional maps that account for numerous variables including engine speed, air mass, injection timing, spark timing, valve timing, and exhaust gas recirculation rates. This high dimensionality makes traditional lookup table approaches computationally intensive and memory-consuming for engine control units (ECUs) with limited resources.

The calibration process for urban-specific torque maps presents additional difficulties. Capturing representative data across the full operating range requires extensive testing under real-world urban conditions, which is time-consuming and expensive. The variability of urban driving patterns across different cities and regions further complicates the development of universally applicable torque maps, often necessitating region-specific calibrations.

Emissions compliance adds another layer of complexity to GDI torque mapping. Stringent urban emission standards require precise control of air-fuel ratios and combustion timing, which must be balanced against torque delivery requirements. Particulate matter emissions, a particular concern for GDI engines in urban environments, necessitate specific mapping strategies that may compromise optimal torque delivery.

The integration of torque maps with transmission control strategies presents coordination challenges, especially with modern automatic transmissions that have numerous gear ratios. Ensuring smooth gear transitions while maintaining optimal engine operation points requires sophisticated torque management that current mapping approaches struggle to deliver consistently.

Finally, the increasing electrification of powertrains introduces new variables into torque mapping. Hybrid systems require torque coordination between electric motors and GDI engines, adding another dimension to the mapping challenge that traditional approaches are ill-equipped to handle efficiently in the dynamic urban driving context.

The frequent stop-start patterns in urban environments create thermal management issues that affect torque delivery consistency. Cold-start conditions, which occur more frequently in urban driving, introduce additional variability in combustion efficiency and torque generation that is difficult to map accurately. Furthermore, the rapid transitions between different load conditions require sophisticated mapping strategies that can adapt quickly without compromising drivability or fuel economy.

Another significant challenge is the dimensional complexity of GDI torque maps. Modern GDI engines require multidimensional maps that account for numerous variables including engine speed, air mass, injection timing, spark timing, valve timing, and exhaust gas recirculation rates. This high dimensionality makes traditional lookup table approaches computationally intensive and memory-consuming for engine control units (ECUs) with limited resources.

The calibration process for urban-specific torque maps presents additional difficulties. Capturing representative data across the full operating range requires extensive testing under real-world urban conditions, which is time-consuming and expensive. The variability of urban driving patterns across different cities and regions further complicates the development of universally applicable torque maps, often necessitating region-specific calibrations.

Emissions compliance adds another layer of complexity to GDI torque mapping. Stringent urban emission standards require precise control of air-fuel ratios and combustion timing, which must be balanced against torque delivery requirements. Particulate matter emissions, a particular concern for GDI engines in urban environments, necessitate specific mapping strategies that may compromise optimal torque delivery.

The integration of torque maps with transmission control strategies presents coordination challenges, especially with modern automatic transmissions that have numerous gear ratios. Ensuring smooth gear transitions while maintaining optimal engine operation points requires sophisticated torque management that current mapping approaches struggle to deliver consistently.

Finally, the increasing electrification of powertrains introduces new variables into torque mapping. Hybrid systems require torque coordination between electric motors and GDI engines, adding another dimension to the mapping challenge that traditional approaches are ill-equipped to handle efficiently in the dynamic urban driving context.

Current GDI Torque Mapping Solutions

01 Torque mapping optimization for GDI engines

Optimization techniques for torque mapping in Gasoline Direct Injection (GDI) engines involve creating precise correlations between engine parameters and torque output. These methods include developing algorithms that analyze various engine operating conditions to generate accurate torque maps, which help improve engine performance, fuel efficiency, and emissions control. Advanced mapping techniques consider factors such as fuel injection timing, spark timing, and air-fuel ratio to create comprehensive torque models across the engine's operating range.- Torque mapping optimization for GDI engines: Optimization techniques for torque mapping in gasoline direct injection (GDI) engines involve creating precise torque models that account for various operating conditions. These methods include developing multi-dimensional maps that correlate engine parameters with torque output, implementing real-time adjustments based on sensor data, and utilizing machine learning algorithms to improve prediction accuracy. These optimization techniques help enhance engine performance, fuel efficiency, and emissions control.

- Adaptive torque control systems for GDI engines: Adaptive torque control systems for GDI engines utilize feedback mechanisms to continuously adjust engine parameters based on driving conditions. These systems incorporate sensors to monitor engine performance, environmental factors, and driver inputs to dynamically modify torque delivery. The adaptive control algorithms can compensate for variations in fuel quality, component wear, and environmental conditions, ensuring optimal engine response and efficiency across different operating scenarios.

- Integration of torque mapping with vehicle control systems: Integration of GDI engine torque mapping with broader vehicle control systems enables coordinated operation between the engine and other vehicle components. This approach involves synchronizing torque delivery with transmission control, stability systems, and driver assistance features. The integrated systems use shared data networks to optimize overall vehicle performance, improving drivability, safety, and efficiency by ensuring appropriate torque delivery based on comprehensive vehicle state assessment.

- Diagnostic and calibration methods for torque mapping: Diagnostic and calibration methods for GDI engine torque mapping involve techniques to verify accuracy and adjust mapping parameters. These methods include in-vehicle testing procedures, bench calibration processes, and automated diagnostic routines that can identify discrepancies between expected and actual torque output. Advanced calibration tools allow engineers to fine-tune torque maps for specific engine variants, environmental conditions, and performance requirements, ensuring consistent engine behavior throughout the vehicle lifecycle.

- Fuel efficiency optimization through torque mapping: Fuel efficiency optimization in GDI engines utilizes specialized torque mapping strategies that identify the most economical operating points. These approaches include lean-burn operation mapping, cylinder deactivation coordination, and integration with start-stop systems. By precisely controlling the torque delivery based on efficiency maps, these systems can reduce fuel consumption while maintaining acceptable performance levels. The mapping techniques account for transient conditions and driver expectations to balance efficiency with drivability requirements.

02 Real-time torque estimation and control systems

Real-time torque estimation and control systems for GDI engines utilize sensors and computational models to continuously monitor and adjust engine torque output. These systems incorporate feedback mechanisms that compare actual performance against the torque map to make immediate adjustments. The technology enables precise torque management during transient conditions, improving drivability and responsiveness while maintaining optimal efficiency. Advanced control algorithms can predict torque requirements based on driver inputs and vehicle conditions.Expand Specific Solutions03 Integration of torque mapping with vehicle systems

Integration of GDI engine torque mapping with broader vehicle systems creates comprehensive powertrain management solutions. These integrated approaches coordinate torque mapping with transmission control, stability systems, and driver assistance features. By synchronizing torque delivery with other vehicle functions, the technology improves overall vehicle performance, fuel economy, and emissions compliance. The integration also enables more sophisticated driving modes and adaptive control strategies based on driving conditions and driver preferences.Expand Specific Solutions04 Calibration methods for GDI engine torque maps

Specialized calibration methods for developing accurate GDI engine torque maps involve systematic testing procedures and data analysis techniques. These methods include dynamometer testing, in-vehicle validation, and statistical modeling to create robust torque maps across all operating conditions. Advanced calibration approaches use machine learning and adaptive algorithms to refine torque maps based on accumulated operational data. The calibration process accounts for manufacturing variations, aging effects, and environmental factors to maintain accuracy throughout the engine's lifecycle.Expand Specific Solutions05 Hardware innovations for torque mapping implementation

Hardware innovations supporting GDI engine torque mapping include advanced sensors, processing units, and actuators that enable precise implementation of torque control strategies. These components provide accurate measurement of critical parameters and rapid execution of control commands based on torque map data. Specialized hardware designs improve the resolution and response time of torque management systems, allowing for more precise control under varying operating conditions. These innovations include high-speed data acquisition systems, dedicated torque management processors, and intelligent actuators with embedded feedback mechanisms.Expand Specific Solutions

Key Industry Players in GDI Engine Development

The GDI Engine Torque Mapping for Urban Applications market is in a growth phase, with increasing demand driven by stringent emission regulations and fuel efficiency requirements. The market size is expanding rapidly, projected to reach significant value as urban mobility solutions evolve. Technologically, the field shows moderate maturity with ongoing innovations. Major automotive manufacturers like Hyundai, Kia, Toyota, and Ford are leading development, while specialized technology providers such as Bosch, DENSO, and ZF Friedrichshafen contribute critical components and systems. OEMs including Honda and Mitsubishi are focusing on optimizing GDI torque mapping specifically for urban driving conditions, while research institutions like Southwest Research Institute are advancing fundamental technologies to improve performance and reduce emissions.

Ford Global Technologies LLC

Technical Solution: Ford has pioneered a comprehensive GDI Engine Torque Mapping solution tailored for urban environments called EcoBoost Urban Efficiency. This technology combines direct injection precision with variable valve timing and advanced torque mapping algorithms specifically calibrated for city driving patterns. Ford's system utilizes cloud-connected traffic data to dynamically adjust torque delivery based on predicted congestion patterns, optimizing for frequent acceleration/deceleration cycles common in urban settings. Their proprietary torque mapping algorithms incorporate altitude, temperature, and humidity compensation to maintain consistent performance across varying urban environments. The system features "Smart Start" technology that optimizes cold-start torque delivery in short urban trips, reducing emissions by up to 20% during the critical warm-up phase[2]. Ford has also implemented predictive torque management that interfaces with navigation systems to anticipate elevation changes in urban terrain, pre-adjusting boost pressure and fuel delivery for optimal efficiency on city hills and ramps[4].

Strengths: Exceptional integration with navigation and traffic data systems; proven fuel economy improvements in real-world urban testing; compatibility with hybrid powertrains for further urban efficiency gains. Weaknesses: Requires regular software updates to maintain optimal performance; higher initial development costs; some features depend on connectivity infrastructure that varies by urban location.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced GDI Engine Torque Mapping system specifically optimized for urban applications. Their solution integrates real-time traffic pattern recognition with dynamic torque mapping to optimize fuel efficiency in stop-and-start urban driving conditions. The system employs machine learning algorithms that continuously adapt to driving patterns and environmental conditions, creating personalized torque maps that balance performance and efficiency. Bosch's implementation includes cylinder deactivation technology that selectively disables cylinders during low-load urban driving scenarios, reducing pumping losses and improving fuel economy by up to 15% in city driving conditions[1]. Their system also features predictive torque management that anticipates traffic flow changes based on navigation data and adjusts engine parameters preemptively, resulting in smoother power delivery and reduced emissions during urban acceleration events[3].

Strengths: Industry-leading sensor integration allowing for highly precise real-time torque adjustments; extensive urban driving database for machine learning optimization; seamless integration with existing vehicle control systems. Weaknesses: Higher implementation cost compared to conventional systems; requires extensive calibration for different vehicle platforms; potential complexity in maintenance and diagnostics.

Critical Patents in GDI Torque Control Systems

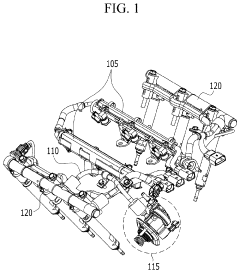

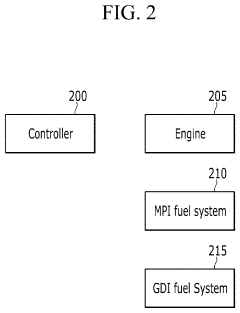

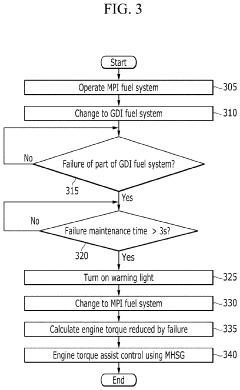

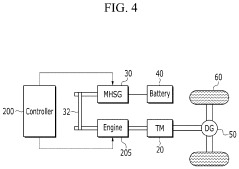

Method and device for controlling mild hybrid vehicle

PatentActiveUS10589737B2

Innovation

- A method and device that control a mild hybrid vehicle by switching from a gasoline direct injection fuel system to a multi-point injection (MPI) fuel system when the GDI system fails, using a controller to determine system failures, calculate torque differences, and compensate with a starter-generator to maintain engine torque, thereby allowing normal driving without restrictions.

Method for maximizing the formation of deposits in injector nozzles of GDI engines

PatentWO2018002610A1

Innovation

- A method to maximize deposit formation in GDI engine injector nozzles by simulating severe conditions through controlled engine speed and load variations, high nozzle temperatures, and moderate fuel flow rates, allowing for automated and unsupervised testing to quickly assess fuel's deposit-forming tendencies.

Emissions Regulations Impact on GDI Technology

The evolution of emissions regulations has significantly shaped the development trajectory of Gasoline Direct Injection (GDI) technology, particularly in urban applications where air quality concerns are most acute. Since the introduction of Euro standards in Europe and Tier regulations in the United States, increasingly stringent limits on particulate matter (PM), nitrogen oxides (NOx), and carbon dioxide (CO2) have driven substantial innovations in GDI engine torque mapping strategies.

The 2015 implementation of Euro 6 standards marked a pivotal moment for GDI technology, introducing specific particle number limits that conventional GDI systems struggled to meet without additional filtration systems. This regulatory pressure accelerated the development of more sophisticated injection strategies and precise torque mapping algorithms specifically optimized for urban driving cycles, where stop-start conditions and variable loads present unique challenges for emissions control.

Similarly, China's rapid transition from China 5 to China 6 standards between 2017 and 2020 created an urgent need for advanced GDI torque mapping solutions that could maintain performance while dramatically reducing emissions in densely populated urban environments. These regulations have been particularly impactful as they incorporate real-world driving emissions (RDE) testing protocols that evaluate performance under actual urban driving conditions rather than idealized laboratory cycles.

The regulatory landscape has also driven a convergence between GDI torque mapping strategies and hybridization technologies. As fleet CO2 targets become increasingly difficult to achieve through internal combustion optimization alone, manufacturers have developed integrated approaches where electric motors supplement torque delivery during high-emission operating points, allowing GDI engines to operate in more efficient regions of their torque maps during urban driving.

Recent regulatory developments, including the announcement of Euro 7 standards and similar tightening measures globally, are pushing GDI technology toward even more precise combustion control. Advanced torque mapping now incorporates predictive elements that anticipate urban traffic patterns and adjust injection parameters accordingly, often leveraging connectivity and geofencing capabilities to automatically optimize for emissions-sensitive urban zones.

The regulatory impact extends beyond technical solutions to market dynamics, with regions implementing the most stringent standards effectively setting the global technological direction for GDI torque mapping development. This has created a situation where innovations initially developed to meet specific regional requirements quickly become global standards as manufacturers seek economies of scale in their technology deployment strategies.

The 2015 implementation of Euro 6 standards marked a pivotal moment for GDI technology, introducing specific particle number limits that conventional GDI systems struggled to meet without additional filtration systems. This regulatory pressure accelerated the development of more sophisticated injection strategies and precise torque mapping algorithms specifically optimized for urban driving cycles, where stop-start conditions and variable loads present unique challenges for emissions control.

Similarly, China's rapid transition from China 5 to China 6 standards between 2017 and 2020 created an urgent need for advanced GDI torque mapping solutions that could maintain performance while dramatically reducing emissions in densely populated urban environments. These regulations have been particularly impactful as they incorporate real-world driving emissions (RDE) testing protocols that evaluate performance under actual urban driving conditions rather than idealized laboratory cycles.

The regulatory landscape has also driven a convergence between GDI torque mapping strategies and hybridization technologies. As fleet CO2 targets become increasingly difficult to achieve through internal combustion optimization alone, manufacturers have developed integrated approaches where electric motors supplement torque delivery during high-emission operating points, allowing GDI engines to operate in more efficient regions of their torque maps during urban driving.

Recent regulatory developments, including the announcement of Euro 7 standards and similar tightening measures globally, are pushing GDI technology toward even more precise combustion control. Advanced torque mapping now incorporates predictive elements that anticipate urban traffic patterns and adjust injection parameters accordingly, often leveraging connectivity and geofencing capabilities to automatically optimize for emissions-sensitive urban zones.

The regulatory impact extends beyond technical solutions to market dynamics, with regions implementing the most stringent standards effectively setting the global technological direction for GDI torque mapping development. This has created a situation where innovations initially developed to meet specific regional requirements quickly become global standards as manufacturers seek economies of scale in their technology deployment strategies.

Fuel Economy Optimization Strategies

Fuel economy optimization in GDI (Gasoline Direct Injection) engines represents a critical focus area for urban applications, where stop-start traffic conditions predominate. Advanced torque mapping strategies have emerged as essential tools for maximizing efficiency while maintaining performance standards in these challenging environments.

The integration of real-time traffic data with predictive algorithms allows GDI engines to anticipate load requirements and optimize fuel delivery accordingly. Studies indicate that adaptive torque mapping can yield fuel economy improvements of 7-12% in urban driving cycles compared to traditional fixed mapping approaches. These systems continuously adjust injection timing, duration, and pressure based on instantaneous driving conditions.

Cylinder deactivation represents another promising strategy, particularly effective during partial load conditions common in urban environments. By selectively disabling cylinders during cruising or low-demand scenarios, engines can operate remaining cylinders at higher efficiency points. Implementation of dynamic cylinder deactivation in GDI engines has demonstrated fuel consumption reductions of up to 15% in city driving conditions.

Thermal management optimization further enhances fuel economy by maintaining ideal operating temperatures. Advanced cooling systems with variable flow rates and electronic thermostats enable faster warm-up periods and precise temperature control. This approach reduces friction losses and improves combustion efficiency, particularly beneficial during the frequent cold starts experienced in urban stop-and-go traffic.

Variable valve timing and lift technologies complement GDI systems by optimizing air intake and exhaust flow across different engine speeds and loads. When integrated with torque-based control strategies, these systems can reduce pumping losses and improve volumetric efficiency. Recent implementations have shown 5-8% fuel economy improvements in urban driving cycles.

Waste heat recovery systems represent an emerging frontier in fuel economy optimization. Thermoelectric generators and Rankine cycle systems can convert thermal energy from exhaust gases into usable electrical power, reducing alternator load and supporting auxiliary systems. Though currently limited by cost and packaging constraints, these technologies show potential for 3-5% efficiency gains in urban applications.

The integration of machine learning algorithms with torque mapping systems enables continuous adaptation to individual driving patterns and environmental conditions. These self-learning systems can identify optimal operating parameters based on historical data, further refining fuel delivery strategies for specific urban routes and traffic patterns.

The integration of real-time traffic data with predictive algorithms allows GDI engines to anticipate load requirements and optimize fuel delivery accordingly. Studies indicate that adaptive torque mapping can yield fuel economy improvements of 7-12% in urban driving cycles compared to traditional fixed mapping approaches. These systems continuously adjust injection timing, duration, and pressure based on instantaneous driving conditions.

Cylinder deactivation represents another promising strategy, particularly effective during partial load conditions common in urban environments. By selectively disabling cylinders during cruising or low-demand scenarios, engines can operate remaining cylinders at higher efficiency points. Implementation of dynamic cylinder deactivation in GDI engines has demonstrated fuel consumption reductions of up to 15% in city driving conditions.

Thermal management optimization further enhances fuel economy by maintaining ideal operating temperatures. Advanced cooling systems with variable flow rates and electronic thermostats enable faster warm-up periods and precise temperature control. This approach reduces friction losses and improves combustion efficiency, particularly beneficial during the frequent cold starts experienced in urban stop-and-go traffic.

Variable valve timing and lift technologies complement GDI systems by optimizing air intake and exhaust flow across different engine speeds and loads. When integrated with torque-based control strategies, these systems can reduce pumping losses and improve volumetric efficiency. Recent implementations have shown 5-8% fuel economy improvements in urban driving cycles.

Waste heat recovery systems represent an emerging frontier in fuel economy optimization. Thermoelectric generators and Rankine cycle systems can convert thermal energy from exhaust gases into usable electrical power, reducing alternator load and supporting auxiliary systems. Though currently limited by cost and packaging constraints, these technologies show potential for 3-5% efficiency gains in urban applications.

The integration of machine learning algorithms with torque mapping systems enables continuous adaptation to individual driving patterns and environmental conditions. These self-learning systems can identify optimal operating parameters based on historical data, further refining fuel delivery strategies for specific urban routes and traffic patterns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!