How to Test GDI Engine Crankshaft Stability

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Engine Crankshaft Stability Testing Background and Objectives

Gasoline Direct Injection (GDI) engine technology has evolved significantly over the past three decades, revolutionizing internal combustion engine efficiency and performance. The crankshaft, as the central component translating reciprocating motion into rotational energy, faces unprecedented challenges in GDI systems due to higher combustion pressures and more precise timing requirements. Historical testing methodologies developed for port fuel injection engines have proven insufficient for evaluating the complex dynamics of GDI crankshafts under modern operating conditions.

The evolution of crankshaft stability testing parallels the advancement of engine technology itself. Early approaches focused primarily on static balance and material strength, while contemporary testing must address dynamic stability across variable load conditions, thermal expansion effects, and vibration characteristics specific to direct injection timing. Industry standards have progressively tightened as manufacturers push the boundaries of performance while meeting increasingly stringent emissions regulations.

Current technological trends indicate a shift toward integrated testing systems that simultaneously evaluate multiple crankshaft parameters under simulated real-world conditions. The emergence of digital twin modeling and real-time monitoring systems represents the cutting edge of crankshaft stability assessment, allowing engineers to predict failure modes before physical manifestation.

The primary objective of GDI crankshaft stability testing is to ensure operational reliability across the engine's entire performance envelope while maintaining precise injection timing critical for emissions control. Secondary objectives include optimizing NVH (Noise, Vibration, Harshness) characteristics, extending component lifespan, and identifying potential failure modes before production implementation.

Specific technical goals encompass quantifying torsional vibration under varying load conditions, measuring deflection at critical journal positions during operation, evaluating fatigue resistance under high-pressure combustion cycles, and assessing harmonic resonance characteristics across the RPM range. Additionally, modern testing aims to validate crankshaft performance with variable fuel qualities and injection patterns unique to GDI systems.

The technological trajectory suggests future testing will increasingly incorporate AI-driven predictive analytics, allowing for more sophisticated failure prediction and design optimization. Material science advancements are also driving changes in testing protocols as manufacturers explore composite materials and novel manufacturing techniques for crankshaft production.

Ultimately, comprehensive crankshaft stability testing represents a critical gateway between theoretical engine design and practical implementation, ensuring that the heart of GDI engines can withstand the demands of modern performance and efficiency requirements while maintaining the precision timing essential for direct injection systems.

The evolution of crankshaft stability testing parallels the advancement of engine technology itself. Early approaches focused primarily on static balance and material strength, while contemporary testing must address dynamic stability across variable load conditions, thermal expansion effects, and vibration characteristics specific to direct injection timing. Industry standards have progressively tightened as manufacturers push the boundaries of performance while meeting increasingly stringent emissions regulations.

Current technological trends indicate a shift toward integrated testing systems that simultaneously evaluate multiple crankshaft parameters under simulated real-world conditions. The emergence of digital twin modeling and real-time monitoring systems represents the cutting edge of crankshaft stability assessment, allowing engineers to predict failure modes before physical manifestation.

The primary objective of GDI crankshaft stability testing is to ensure operational reliability across the engine's entire performance envelope while maintaining precise injection timing critical for emissions control. Secondary objectives include optimizing NVH (Noise, Vibration, Harshness) characteristics, extending component lifespan, and identifying potential failure modes before production implementation.

Specific technical goals encompass quantifying torsional vibration under varying load conditions, measuring deflection at critical journal positions during operation, evaluating fatigue resistance under high-pressure combustion cycles, and assessing harmonic resonance characteristics across the RPM range. Additionally, modern testing aims to validate crankshaft performance with variable fuel qualities and injection patterns unique to GDI systems.

The technological trajectory suggests future testing will increasingly incorporate AI-driven predictive analytics, allowing for more sophisticated failure prediction and design optimization. Material science advancements are also driving changes in testing protocols as manufacturers explore composite materials and novel manufacturing techniques for crankshaft production.

Ultimately, comprehensive crankshaft stability testing represents a critical gateway between theoretical engine design and practical implementation, ensuring that the heart of GDI engines can withstand the demands of modern performance and efficiency requirements while maintaining the precision timing essential for direct injection systems.

Market Demand Analysis for Reliable GDI Engine Performance

The global automotive industry has witnessed a significant shift towards Gasoline Direct Injection (GDI) engines over the past decade, driven primarily by stringent emission regulations and consumer demand for fuel-efficient vehicles. Market research indicates that GDI engines now account for over 50% of new gasoline-powered vehicles worldwide, with projections showing continued growth through 2030.

Reliability concerns, particularly crankshaft stability issues, have emerged as critical factors influencing consumer purchasing decisions. Recent consumer satisfaction surveys reveal that engine reliability ranks among the top three considerations for vehicle purchases, with 78% of respondents citing long-term durability as "extremely important" in their decision-making process.

The aftermarket service sector has reported a substantial increase in GDI-related repairs, with crankshaft stability problems accounting for approximately 15% of major engine service requirements. This trend has created a robust demand for advanced testing methodologies that can predict and prevent such failures before they occur in production vehicles or during consumer use.

Automotive manufacturers face mounting pressure to extend warranty periods while simultaneously reducing warranty claim costs. The average cost of a major engine repair involving crankshaft replacement exceeds $3,000, creating significant financial incentives for manufacturers to implement comprehensive testing protocols during development and production phases.

Fleet operators and commercial vehicle users represent another significant market segment demanding reliable GDI performance. For these customers, vehicle downtime directly impacts operational efficiency and profitability, making preventative testing and early detection of potential crankshaft issues particularly valuable.

The rise of electric vehicles has paradoxically increased the importance of GDI engine reliability. As manufacturers allocate substantial R&D resources to electrification, ensuring the continued performance of conventional powertrains becomes crucial for maintaining brand reputation during this transitional period.

Emerging markets present substantial growth opportunities for GDI technology, but these regions often face challenging operating conditions including poor fuel quality and extreme temperature variations. These factors place additional stress on engine components, making crankshaft stability testing even more critical for vehicles destined for these markets.

Regulatory bodies worldwide continue to implement increasingly stringent durability requirements alongside emissions standards. The European Union's upcoming Euro 7 regulations and similar measures in North America and Asia will require manufacturers to demonstrate extended engine durability, creating additional demand for advanced testing methodologies focused on critical components like crankshafts.

Reliability concerns, particularly crankshaft stability issues, have emerged as critical factors influencing consumer purchasing decisions. Recent consumer satisfaction surveys reveal that engine reliability ranks among the top three considerations for vehicle purchases, with 78% of respondents citing long-term durability as "extremely important" in their decision-making process.

The aftermarket service sector has reported a substantial increase in GDI-related repairs, with crankshaft stability problems accounting for approximately 15% of major engine service requirements. This trend has created a robust demand for advanced testing methodologies that can predict and prevent such failures before they occur in production vehicles or during consumer use.

Automotive manufacturers face mounting pressure to extend warranty periods while simultaneously reducing warranty claim costs. The average cost of a major engine repair involving crankshaft replacement exceeds $3,000, creating significant financial incentives for manufacturers to implement comprehensive testing protocols during development and production phases.

Fleet operators and commercial vehicle users represent another significant market segment demanding reliable GDI performance. For these customers, vehicle downtime directly impacts operational efficiency and profitability, making preventative testing and early detection of potential crankshaft issues particularly valuable.

The rise of electric vehicles has paradoxically increased the importance of GDI engine reliability. As manufacturers allocate substantial R&D resources to electrification, ensuring the continued performance of conventional powertrains becomes crucial for maintaining brand reputation during this transitional period.

Emerging markets present substantial growth opportunities for GDI technology, but these regions often face challenging operating conditions including poor fuel quality and extreme temperature variations. These factors place additional stress on engine components, making crankshaft stability testing even more critical for vehicles destined for these markets.

Regulatory bodies worldwide continue to implement increasingly stringent durability requirements alongside emissions standards. The European Union's upcoming Euro 7 regulations and similar measures in North America and Asia will require manufacturers to demonstrate extended engine durability, creating additional demand for advanced testing methodologies focused on critical components like crankshafts.

Current Challenges in Crankshaft Stability Testing

Testing the stability of crankshafts in Gasoline Direct Injection (GDI) engines presents significant challenges due to the complex nature of these advanced powertrain systems. Current testing methodologies often struggle to accurately simulate real-world conditions while maintaining precision and repeatability. One primary challenge is the increased mechanical stress that GDI engines place on crankshafts compared to traditional port fuel injection systems, requiring more sophisticated testing approaches.

The high-pressure fuel delivery system in GDI engines creates unique vibration patterns and stress distributions that conventional testing equipment may not adequately capture. Testing facilities frequently report difficulties in isolating crankshaft-specific instabilities from other engine component interactions, leading to potentially misleading test results and incomplete stability assessments.

Material limitations present another significant hurdle. As manufacturers push for lighter crankshafts to improve fuel efficiency, the reduced mass can introduce new resonance frequencies and stability concerns. Current testing protocols may not fully account for these emerging material properties, particularly in advanced alloys and composite materials being explored for next-generation GDI engines.

Data acquisition and analysis represent persistent challenges in crankshaft stability testing. The massive volumes of vibration, torque, and rotational data generated during comprehensive testing require sophisticated processing algorithms that many testing facilities have yet to fully implement. This data management gap often results in overlooked instability indicators or misinterpreted test results.

Temperature variation effects remain difficult to accurately replicate in laboratory settings. GDI engines operate across wider temperature ranges than traditional engines, and crankshaft stability can vary significantly across these thermal conditions. Current testing environments struggle to simulate these dynamic thermal cycles while maintaining consistent measurement parameters.

Standardization issues further complicate testing procedures. The automotive industry lacks universally accepted protocols specifically designed for GDI crankshaft stability assessment, resulting in inconsistent testing methodologies across manufacturers and research institutions. This hampers comparative analysis and slows the development of improved design standards.

Cost and time constraints also impact testing thoroughness. Comprehensive crankshaft stability testing requires significant resources, leading many manufacturers to rely on abbreviated testing protocols that may not reveal potential long-term stability issues. This economic pressure often results in testing compromises that could affect product reliability.

The high-pressure fuel delivery system in GDI engines creates unique vibration patterns and stress distributions that conventional testing equipment may not adequately capture. Testing facilities frequently report difficulties in isolating crankshaft-specific instabilities from other engine component interactions, leading to potentially misleading test results and incomplete stability assessments.

Material limitations present another significant hurdle. As manufacturers push for lighter crankshafts to improve fuel efficiency, the reduced mass can introduce new resonance frequencies and stability concerns. Current testing protocols may not fully account for these emerging material properties, particularly in advanced alloys and composite materials being explored for next-generation GDI engines.

Data acquisition and analysis represent persistent challenges in crankshaft stability testing. The massive volumes of vibration, torque, and rotational data generated during comprehensive testing require sophisticated processing algorithms that many testing facilities have yet to fully implement. This data management gap often results in overlooked instability indicators or misinterpreted test results.

Temperature variation effects remain difficult to accurately replicate in laboratory settings. GDI engines operate across wider temperature ranges than traditional engines, and crankshaft stability can vary significantly across these thermal conditions. Current testing environments struggle to simulate these dynamic thermal cycles while maintaining consistent measurement parameters.

Standardization issues further complicate testing procedures. The automotive industry lacks universally accepted protocols specifically designed for GDI crankshaft stability assessment, resulting in inconsistent testing methodologies across manufacturers and research institutions. This hampers comparative analysis and slows the development of improved design standards.

Cost and time constraints also impact testing thoroughness. Comprehensive crankshaft stability testing requires significant resources, leading many manufacturers to rely on abbreviated testing protocols that may not reveal potential long-term stability issues. This economic pressure often results in testing compromises that could affect product reliability.

Established Crankshaft Stability Testing Protocols

01 Crankshaft balancing mechanisms for GDI engines

Various balancing mechanisms are employed in GDI engines to enhance crankshaft stability. These include counterweights, balance shafts, and optimized bearing designs that reduce vibration and improve overall engine performance. The balanced crankshaft design helps minimize stress on engine components, reduces noise, and extends engine life while maintaining smooth operation at various RPM ranges.- Crankshaft balancing mechanisms for GDI engines: Various balancing mechanisms are employed in GDI engines to enhance crankshaft stability. These include counterweights, balance shafts, and harmonic dampers that help reduce vibration and improve engine performance. The balanced crankshaft design minimizes stress on bearings and other engine components, leading to increased durability and reduced noise during operation.

- Material innovations for crankshaft durability: Advanced materials and manufacturing techniques are used to improve crankshaft stability in GDI engines. These include high-strength alloys, forged steel with specific heat treatments, and composite materials that provide better strength-to-weight ratios. These material innovations help withstand the higher combustion pressures characteristic of GDI engines while maintaining dimensional stability under thermal stress.

- Bearing design optimization for GDI crankshafts: Specialized bearing designs are implemented to support GDI engine crankshafts and enhance stability. These include improved main bearings with optimized oil flow channels, thrust bearings to control axial movement, and connecting rod bearings designed to handle higher loads. The bearing systems incorporate advanced lubrication technologies to reduce friction and wear under the high-pressure conditions of GDI operation.

- Vibration dampening systems for GDI crankshafts: Specialized vibration dampening systems are integrated into GDI engines to improve crankshaft stability. These systems include torsional vibration dampers, dual-mass flywheels, and elastomeric isolators that absorb and dissipate harmful vibrations. By reducing torsional vibrations and resonance effects, these systems extend crankshaft life and improve overall engine performance and refinement.

- Structural reinforcement techniques for crankshaft stability: Various structural reinforcement techniques are employed to enhance crankshaft stability in GDI engines. These include optimized web designs, fillet rolling to strengthen stress points, cross-drilling for weight reduction while maintaining strength, and specialized heat treatment processes. These structural improvements help the crankshaft withstand the higher combustion pressures and operating speeds of GDI engines without compromising durability.

02 Material innovations for GDI engine crankshafts

Advanced materials and manufacturing techniques are used to improve the stability and durability of crankshafts in GDI engines. These include high-strength alloys, composite materials, and specialized heat treatments that enhance the mechanical properties of the crankshaft. These material innovations help the crankshaft withstand higher combustion pressures typical in GDI engines while maintaining dimensional stability under thermal stress.Expand Specific Solutions03 Vibration dampening systems for GDI crankshafts

Specialized vibration dampening systems are integrated into GDI engines to improve crankshaft stability. These systems include harmonic balancers, torsional vibration dampers, and fluid-filled dampening mechanisms that absorb and dissipate vibrations. By reducing torsional vibrations, these systems prevent resonance conditions that could lead to crankshaft failure and improve overall engine refinement.Expand Specific Solutions04 Bearing and lubrication systems for GDI crankshaft stability

Enhanced bearing designs and lubrication systems are crucial for maintaining GDI crankshaft stability. These include precision-engineered main bearings, optimized oil flow channels, and specialized lubricants that reduce friction and wear. Advanced oil pressure management systems ensure proper lubrication under varying engine loads, which is particularly important for GDI engines that operate with higher mechanical stresses.Expand Specific Solutions05 Integrated sensor and control systems for crankshaft monitoring

Modern GDI engines incorporate advanced sensor and control systems to monitor crankshaft stability in real-time. These systems include position sensors, vibration monitors, and electronic control units that can detect abnormal crankshaft behavior. The data collected allows for adaptive engine management strategies that can adjust timing and fuel delivery to maintain optimal crankshaft stability under varying operating conditions.Expand Specific Solutions

Leading Manufacturers and Testing Equipment Providers

The GDI engine crankshaft stability testing market is currently in a growth phase, driven by increasing demands for fuel-efficient engines and stricter emission regulations. The market size is expanding globally, particularly in automotive manufacturing regions across Asia, Europe, and North America. From a technological maturity perspective, established automotive giants like Ford, Toyota, Hyundai, and Porsche lead with advanced testing methodologies, while specialized companies such as Weichai Power, Shanghai Marine Crankshaft, and Continental Automotive contribute significant innovations. Chinese educational institutions including Jilin University and Tianjin University are emerging as important research centers, collaborating with manufacturers to develop next-generation testing protocols. The competitive landscape features both traditional OEMs and specialized engineering firms developing proprietary testing technologies to address the complex dynamics of GDI crankshaft performance.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive GDI engine crankshaft stability testing system that combines both dynamic and static testing methodologies. Their approach utilizes advanced vibration analysis with multi-point sensors placed strategically along the crankshaft to detect torsional vibrations during operation. The system incorporates real-time monitoring technology that can detect micro-level deformations under various load conditions. Ford's testing protocol includes specialized high-speed imaging cameras capturing crankshaft behavior at up to 10,000 frames per second, allowing engineers to visualize deflection patterns invisible to conventional methods. Additionally, they employ proprietary algorithms that analyze frequency response data to identify potential failure points before they manifest in physical damage. The company has integrated these technologies into both development testing and production quality control processes.

Strengths: Comprehensive integration of multiple testing technologies provides holistic assessment of crankshaft stability. Their system can detect issues earlier than many conventional methods. Weaknesses: The complex multi-sensor setup requires significant calibration time and specialized expertise to interpret results accurately.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered an innovative approach to GDI engine crankshaft stability testing through their "Total Harmonic Distortion Analysis" methodology. This system utilizes precision torque measurement devices installed at both ends of the crankshaft to calculate torsional vibration characteristics across the entire RPM range. Their testing protocol incorporates specialized strain gauges with temperature compensation that can operate reliably in high-temperature engine environments. Toyota's system is notable for its integration with their broader engine management diagnostics, allowing for correlation between crankshaft stability issues and other engine parameters. The company has developed proprietary software that creates detailed 3D models of crankshaft behavior under various load conditions, enabling engineers to visualize stress concentrations and potential failure points. This approach has reportedly reduced development time for new engine designs by approximately 30% while improving reliability metrics.

Strengths: Highly integrated with overall engine development process, providing contextual data beyond isolated crankshaft measurements. Their temperature-compensated sensors deliver reliable data even under extreme operating conditions. Weaknesses: System requires extensive baseline data for each engine family to establish meaningful comparative analysis, making it less flexible for testing prototype designs.

Key Technologies in Modern Crankshaft Stability Assessment

Evaluation of the delivery and effectiveness of engine performance chemicals and products

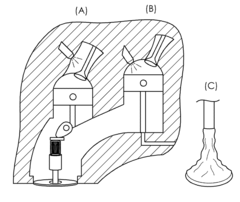

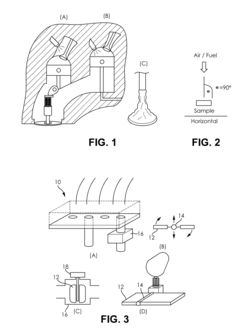

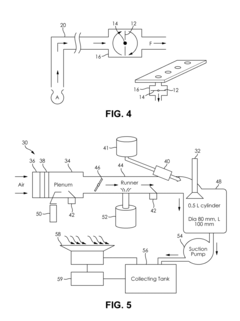

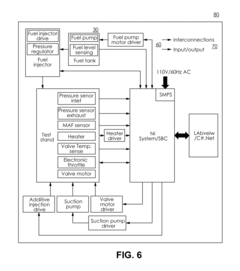

PatentActiveUS20170114716A1

Innovation

- A method and system for evaluating the delivery and effectiveness of engine performance chemicals and products for reducing intake valve deposits, utilizing a controlled environment with simulated engine conditions to quantify improvements, including adjustable parameters like air-fuel ratio, temperature, and oscillation frequency, and employing three approaches to introduce cleaners: airstream addition, suction-based distribution, and fuel additive application.

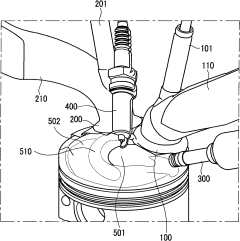

Gasoline direct injection engine

PatentInactiveCN102086818A

Innovation

- A gasoline direct injection engine is designed. A first cavity and a second cavity are formed on the piston head. The first cavity is located at the intake valve, and the second cavity is located at the exhaust valve. The volume ratio of the combustion chamber is controlled through different heights, and the injection The injector injects fuel directly into the combustion chamber, and part of the fuel returns to the spark plug, forming stratified combustion.

Environmental Impact of GDI Engine Testing Procedures

The environmental impact of GDI (Gasoline Direct Injection) engine testing procedures, particularly those focused on crankshaft stability assessment, represents a growing concern in the automotive industry. These testing methodologies, while essential for ensuring engine reliability and performance, generate significant environmental footprints that warrant careful consideration and mitigation strategies.

Traditional crankshaft stability testing procedures often involve extended engine operation under various load conditions, resulting in substantial fuel consumption and emissions. A typical comprehensive crankshaft stability test may consume between 50-100 liters of fuel, producing approximately 115-230 kg of CO2 emissions per test cycle. Additionally, these tests generate other pollutants including nitrogen oxides (NOx), particulate matter (PM), and volatile organic compounds (VOCs) that contribute to air quality degradation.

Water consumption represents another environmental concern in GDI engine testing. Cooling systems utilized during extended high-load stability tests can consume 200-500 liters of water per test cycle. This water often becomes contaminated with oils and chemicals, requiring specialized treatment before discharge, further increasing the environmental burden of testing operations.

Noise pollution constitutes a frequently overlooked environmental impact of crankshaft stability testing. High-speed rotation tests can generate noise levels exceeding 100 dB, potentially affecting surrounding communities and ecosystems if proper sound insulation measures are not implemented in testing facilities.

Recent advancements in testing methodologies have begun addressing these environmental concerns. Virtual simulation technologies can reduce physical testing requirements by up to 40%, significantly decreasing associated emissions and resource consumption. Hybrid testing approaches that combine limited physical testing with advanced modeling have demonstrated emission reductions of 25-35% compared to traditional methods while maintaining testing accuracy.

Closed-loop testing systems represent another promising development, enabling the recapture and recycling of up to 80% of water used in cooling systems. Similarly, energy recovery systems can harness power generated during load testing, potentially offsetting 15-20% of the energy consumed during test procedures.

Regulatory frameworks increasingly recognize these environmental impacts, with several jurisdictions implementing specific requirements for testing facility emissions and resource consumption. The International Organization for Standardization (ISO) has developed standards specifically addressing environmental management in automotive testing facilities, providing a framework for continuous improvement in environmental performance.

Traditional crankshaft stability testing procedures often involve extended engine operation under various load conditions, resulting in substantial fuel consumption and emissions. A typical comprehensive crankshaft stability test may consume between 50-100 liters of fuel, producing approximately 115-230 kg of CO2 emissions per test cycle. Additionally, these tests generate other pollutants including nitrogen oxides (NOx), particulate matter (PM), and volatile organic compounds (VOCs) that contribute to air quality degradation.

Water consumption represents another environmental concern in GDI engine testing. Cooling systems utilized during extended high-load stability tests can consume 200-500 liters of water per test cycle. This water often becomes contaminated with oils and chemicals, requiring specialized treatment before discharge, further increasing the environmental burden of testing operations.

Noise pollution constitutes a frequently overlooked environmental impact of crankshaft stability testing. High-speed rotation tests can generate noise levels exceeding 100 dB, potentially affecting surrounding communities and ecosystems if proper sound insulation measures are not implemented in testing facilities.

Recent advancements in testing methodologies have begun addressing these environmental concerns. Virtual simulation technologies can reduce physical testing requirements by up to 40%, significantly decreasing associated emissions and resource consumption. Hybrid testing approaches that combine limited physical testing with advanced modeling have demonstrated emission reductions of 25-35% compared to traditional methods while maintaining testing accuracy.

Closed-loop testing systems represent another promising development, enabling the recapture and recycling of up to 80% of water used in cooling systems. Similarly, energy recovery systems can harness power generated during load testing, potentially offsetting 15-20% of the energy consumed during test procedures.

Regulatory frameworks increasingly recognize these environmental impacts, with several jurisdictions implementing specific requirements for testing facility emissions and resource consumption. The International Organization for Standardization (ISO) has developed standards specifically addressing environmental management in automotive testing facilities, providing a framework for continuous improvement in environmental performance.

Regulatory Standards for Engine Component Reliability

The regulatory landscape for engine component reliability, particularly for GDI engine crankshafts, is governed by stringent international and regional standards that manufacturers must adhere to. ISO 16750 series provides comprehensive guidelines for testing automotive components under various environmental conditions, with specific sections addressing mechanical vibration and shock resistance critical for crankshaft stability assessment. The SAE J1349 standard establishes protocols for engine power testing, indirectly influencing crankshaft performance evaluation methodologies.

In the United States, the National Highway Traffic Safety Administration (NHTSA) enforces Federal Motor Vehicle Safety Standards (FMVSS) that include durability requirements for critical engine components. The Environmental Protection Agency (EPA) regulations on emissions indirectly impact crankshaft testing, as unstable crankshafts can lead to combustion inefficiencies and increased emissions. Similarly, the European Union's Regulation (EC) No 715/2007 on emissions standards necessitates thorough component testing to ensure long-term compliance.

The Chinese GB/T 18488 standard specifically addresses engine reliability testing procedures, with detailed protocols for crankshaft stability assessment under various operating conditions. Japan's JASO standards, particularly JASO M328, provide specific guidelines for engine component durability testing with emphasis on vibration resistance and fatigue life.

Industry-specific standards such as ASTM A247 govern the metallurgical quality of crankshaft materials, while ISO 1940 sets balancing requirements for rotating equipment including crankshafts. These standards specify acceptable vibration limits and testing methodologies to ensure operational stability throughout the component's service life.

Regulatory compliance documentation typically requires manufacturers to maintain detailed records of testing procedures, results, and failure analyses. This documentation must demonstrate adherence to minimum performance thresholds across various operating conditions, including extreme temperature ranges, high-speed operation, and prolonged full-load scenarios.

The trend in regulatory standards is moving toward more stringent requirements for durability testing, with increasing emphasis on accelerated life testing methodologies that can predict long-term reliability within shorter test cycles. Additionally, there is growing regulatory focus on standardizing test procedures for new engine technologies, including specific protocols for GDI engine components that face unique stresses due to higher combustion pressures and temperatures.

In the United States, the National Highway Traffic Safety Administration (NHTSA) enforces Federal Motor Vehicle Safety Standards (FMVSS) that include durability requirements for critical engine components. The Environmental Protection Agency (EPA) regulations on emissions indirectly impact crankshaft testing, as unstable crankshafts can lead to combustion inefficiencies and increased emissions. Similarly, the European Union's Regulation (EC) No 715/2007 on emissions standards necessitates thorough component testing to ensure long-term compliance.

The Chinese GB/T 18488 standard specifically addresses engine reliability testing procedures, with detailed protocols for crankshaft stability assessment under various operating conditions. Japan's JASO standards, particularly JASO M328, provide specific guidelines for engine component durability testing with emphasis on vibration resistance and fatigue life.

Industry-specific standards such as ASTM A247 govern the metallurgical quality of crankshaft materials, while ISO 1940 sets balancing requirements for rotating equipment including crankshafts. These standards specify acceptable vibration limits and testing methodologies to ensure operational stability throughout the component's service life.

Regulatory compliance documentation typically requires manufacturers to maintain detailed records of testing procedures, results, and failure analyses. This documentation must demonstrate adherence to minimum performance thresholds across various operating conditions, including extreme temperature ranges, high-speed operation, and prolonged full-load scenarios.

The trend in regulatory standards is moving toward more stringent requirements for durability testing, with increasing emphasis on accelerated life testing methodologies that can predict long-term reliability within shorter test cycles. Additionally, there is growing regulatory focus on standardizing test procedures for new engine technologies, including specific protocols for GDI engine components that face unique stresses due to higher combustion pressures and temperatures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!