Analyzing the performance of V16 engines in endurance competitions

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine Evolution

The V16 engine has a rich history in automotive engineering, with its evolution closely tied to the pursuit of power and performance in endurance racing. The development of V16 engines can be traced back to the early 20th century, with notable milestones occurring in the 1930s and 1940s. These engines were initially designed for luxury automobiles and racing cars, where their impressive power output and smooth operation were highly valued.

In the context of endurance competitions, the V16 engine's evolution has been marked by continuous improvements in power delivery, fuel efficiency, and reliability. Early V16 engines, such as those used in the Auto Union Type C racing cars of the 1930s, demonstrated the potential for high power output but often struggled with reliability issues during extended race durations. These challenges prompted engineers to focus on enhancing durability and thermal management in subsequent iterations.

The post-World War II era saw a decline in V16 engine development for automotive applications, as more compact and efficient engine configurations gained popularity. However, the lessons learned from V16 engines continued to influence the design of high-performance engines in motorsports. The emphasis shifted towards optimizing power-to-weight ratios and improving fuel consumption, which are critical factors in endurance racing.

In recent decades, advancements in materials science and manufacturing techniques have reignited interest in V16 engines for specialized applications. Modern V16 engines benefit from computer-aided design and simulation tools, allowing engineers to optimize combustion efficiency, reduce friction losses, and improve overall performance. These technological advancements have led to the development of V16 engines that can deliver exceptional power while meeting stringent emissions regulations.

The evolution of V16 engines in endurance competitions has also been influenced by changing regulations and the push for more sustainable racing practices. This has resulted in the exploration of hybrid V16 powertrains and the use of alternative fuels, aiming to maintain high performance while reducing environmental impact. These developments showcase the adaptability of the V16 configuration to meet evolving demands in motorsports.

Throughout its evolution, the V16 engine has remained a symbol of engineering prowess and a testament to the pursuit of ultimate performance in endurance racing. While not as common as other engine configurations in modern competitions, the legacy of V16 engines continues to inspire innovation in high-performance powertrains for endurance events.

In the context of endurance competitions, the V16 engine's evolution has been marked by continuous improvements in power delivery, fuel efficiency, and reliability. Early V16 engines, such as those used in the Auto Union Type C racing cars of the 1930s, demonstrated the potential for high power output but often struggled with reliability issues during extended race durations. These challenges prompted engineers to focus on enhancing durability and thermal management in subsequent iterations.

The post-World War II era saw a decline in V16 engine development for automotive applications, as more compact and efficient engine configurations gained popularity. However, the lessons learned from V16 engines continued to influence the design of high-performance engines in motorsports. The emphasis shifted towards optimizing power-to-weight ratios and improving fuel consumption, which are critical factors in endurance racing.

In recent decades, advancements in materials science and manufacturing techniques have reignited interest in V16 engines for specialized applications. Modern V16 engines benefit from computer-aided design and simulation tools, allowing engineers to optimize combustion efficiency, reduce friction losses, and improve overall performance. These technological advancements have led to the development of V16 engines that can deliver exceptional power while meeting stringent emissions regulations.

The evolution of V16 engines in endurance competitions has also been influenced by changing regulations and the push for more sustainable racing practices. This has resulted in the exploration of hybrid V16 powertrains and the use of alternative fuels, aiming to maintain high performance while reducing environmental impact. These developments showcase the adaptability of the V16 configuration to meet evolving demands in motorsports.

Throughout its evolution, the V16 engine has remained a symbol of engineering prowess and a testament to the pursuit of ultimate performance in endurance racing. While not as common as other engine configurations in modern competitions, the legacy of V16 engines continues to inspire innovation in high-performance powertrains for endurance events.

Endurance Racing Demands

Endurance racing presents unique challenges that push the limits of automotive engineering, particularly when it comes to high-performance engines like the V16. These competitions demand exceptional durability, reliability, and sustained performance over extended periods, often lasting 24 hours or more. The extreme conditions encountered during endurance races place immense stress on all vehicle components, with the engine being the most critical.

The primary demand in endurance racing is maintaining consistent power output over long durations. V16 engines, known for their high power-to-weight ratio, must be optimized to deliver steady performance without sacrificing reliability. This requires careful engineering to balance power output with fuel efficiency and component longevity. Heat management becomes a crucial factor, as sustained high-speed operation generates significant thermal stress on engine parts.

Fuel efficiency is another key consideration in endurance racing. While V16 engines are capable of producing immense power, they must do so while conserving fuel to minimize pit stops. Engineers must develop advanced fuel injection systems and optimize combustion processes to extract maximum energy from each drop of fuel. This often involves sophisticated engine mapping and real-time adjustments to maintain optimal performance under varying race conditions.

Reliability is paramount in endurance racing, where a single mechanical failure can end a team's race. V16 engines must be designed with robust components capable of withstanding prolonged high-stress operation. This includes using advanced materials and manufacturing techniques to create stronger, lighter engine parts that can resist wear and fatigue over thousands of kilometers of racing.

Weight is a critical factor in endurance racing, affecting vehicle handling, tire wear, and fuel consumption. Despite their complexity, V16 engines must be engineered to be as lightweight as possible without compromising strength or reliability. This often involves the use of exotic materials and innovative design solutions to reduce mass while maintaining structural integrity.

Adaptability to changing race conditions is another crucial demand. Endurance races often span day and night, with varying temperatures and track conditions. V16 engines must be capable of performing consistently across this range of environments, requiring sophisticated cooling systems and flexible engine management strategies.

Lastly, the regulatory environment of endurance racing imposes additional demands on V16 engine design. Compliance with fuel consumption limits, noise regulations, and other technical rules requires careful engineering to maximize performance within the allowed parameters. This often leads to innovative solutions that push the boundaries of engine technology while adhering to strict guidelines.

The primary demand in endurance racing is maintaining consistent power output over long durations. V16 engines, known for their high power-to-weight ratio, must be optimized to deliver steady performance without sacrificing reliability. This requires careful engineering to balance power output with fuel efficiency and component longevity. Heat management becomes a crucial factor, as sustained high-speed operation generates significant thermal stress on engine parts.

Fuel efficiency is another key consideration in endurance racing. While V16 engines are capable of producing immense power, they must do so while conserving fuel to minimize pit stops. Engineers must develop advanced fuel injection systems and optimize combustion processes to extract maximum energy from each drop of fuel. This often involves sophisticated engine mapping and real-time adjustments to maintain optimal performance under varying race conditions.

Reliability is paramount in endurance racing, where a single mechanical failure can end a team's race. V16 engines must be designed with robust components capable of withstanding prolonged high-stress operation. This includes using advanced materials and manufacturing techniques to create stronger, lighter engine parts that can resist wear and fatigue over thousands of kilometers of racing.

Weight is a critical factor in endurance racing, affecting vehicle handling, tire wear, and fuel consumption. Despite their complexity, V16 engines must be engineered to be as lightweight as possible without compromising strength or reliability. This often involves the use of exotic materials and innovative design solutions to reduce mass while maintaining structural integrity.

Adaptability to changing race conditions is another crucial demand. Endurance races often span day and night, with varying temperatures and track conditions. V16 engines must be capable of performing consistently across this range of environments, requiring sophisticated cooling systems and flexible engine management strategies.

Lastly, the regulatory environment of endurance racing imposes additional demands on V16 engine design. Compliance with fuel consumption limits, noise regulations, and other technical rules requires careful engineering to maximize performance within the allowed parameters. This often leads to innovative solutions that push the boundaries of engine technology while adhering to strict guidelines.

V16 Technical Challenges

V16 engines, while impressive in their power output and engineering complexity, face significant technical challenges when deployed in endurance competitions. One of the primary issues is thermal management. The sheer size and power of these engines generate substantial heat, which can lead to performance degradation and potential failure over extended periods. Cooling systems must be exceptionally robust and efficient to maintain optimal operating temperatures across all 16 cylinders consistently.

Weight is another critical factor that poses challenges for V16 engines in endurance racing. These engines are inherently heavier than their smaller counterparts, which can negatively impact the overall vehicle dynamics and fuel efficiency. Engineers must employ advanced materials and design techniques to minimize weight without compromising structural integrity or performance.

Fuel consumption presents a significant hurdle for V16 engines in endurance events. The high cylinder count and large displacement typically result in greater fuel consumption compared to smaller engines. This necessitates larger fuel tanks or more frequent pit stops, both of which can adversely affect race strategy and overall competitiveness.

Reliability is a paramount concern in endurance racing, and V16 engines face unique challenges in this regard. The increased number of moving parts and complex systems elevate the risk of mechanical failure during extended operation. Ensuring consistent performance and durability across all 16 cylinders requires meticulous engineering and rigorous testing protocols.

Balancing and vibration control pose additional technical difficulties. The length of the V16 configuration can lead to torsional vibrations and harmonics that must be carefully managed to prevent fatigue and maintain smooth operation. Advanced crankshaft designs and vibration damping systems are crucial to mitigate these issues.

Lubrication systems for V16 engines must be exceptionally well-designed to ensure adequate oil flow to all components, particularly under the high-stress conditions of endurance racing. The extended length of the engine block and the number of bearings require innovative oil circulation and scavenging solutions to maintain proper lubrication throughout long-duration events.

Lastly, the complexity of V16 engines presents challenges in terms of maintenance and serviceability. The intricate nature of these powerplants often requires specialized tools and expertise for repairs and adjustments, which can be particularly problematic in the time-sensitive environment of endurance racing. Teams must develop efficient maintenance strategies and have highly skilled technicians to address any issues that arise during competition.

Weight is another critical factor that poses challenges for V16 engines in endurance racing. These engines are inherently heavier than their smaller counterparts, which can negatively impact the overall vehicle dynamics and fuel efficiency. Engineers must employ advanced materials and design techniques to minimize weight without compromising structural integrity or performance.

Fuel consumption presents a significant hurdle for V16 engines in endurance events. The high cylinder count and large displacement typically result in greater fuel consumption compared to smaller engines. This necessitates larger fuel tanks or more frequent pit stops, both of which can adversely affect race strategy and overall competitiveness.

Reliability is a paramount concern in endurance racing, and V16 engines face unique challenges in this regard. The increased number of moving parts and complex systems elevate the risk of mechanical failure during extended operation. Ensuring consistent performance and durability across all 16 cylinders requires meticulous engineering and rigorous testing protocols.

Balancing and vibration control pose additional technical difficulties. The length of the V16 configuration can lead to torsional vibrations and harmonics that must be carefully managed to prevent fatigue and maintain smooth operation. Advanced crankshaft designs and vibration damping systems are crucial to mitigate these issues.

Lubrication systems for V16 engines must be exceptionally well-designed to ensure adequate oil flow to all components, particularly under the high-stress conditions of endurance racing. The extended length of the engine block and the number of bearings require innovative oil circulation and scavenging solutions to maintain proper lubrication throughout long-duration events.

Lastly, the complexity of V16 engines presents challenges in terms of maintenance and serviceability. The intricate nature of these powerplants often requires specialized tools and expertise for repairs and adjustments, which can be particularly problematic in the time-sensitive environment of endurance racing. Teams must develop efficient maintenance strategies and have highly skilled technicians to address any issues that arise during competition.

Current V16 Solutions

01 Engine performance optimization

V16 engines can be optimized for performance through various methods, including advanced fuel injection systems, turbocharging, and electronic control units. These technologies help improve power output, fuel efficiency, and overall engine performance.- Engine design and optimization: V16 engine performance can be enhanced through advanced design and optimization techniques. This includes improving combustion efficiency, reducing friction, and optimizing valve timing. Computer-aided design and simulation tools are often used to refine engine components and overall architecture for maximum power output and fuel efficiency.

- Fuel injection and management systems: Advanced fuel injection and management systems play a crucial role in V16 engine performance. These systems precisely control fuel delivery, timing, and mixture for optimal combustion. Electronic control units (ECUs) and sophisticated sensors are employed to continuously adjust engine parameters based on operating conditions, enhancing power output and fuel economy.

- Turbocharging and supercharging: Forced induction techniques such as turbocharging and supercharging are commonly used to boost V16 engine performance. These systems increase the amount of air and fuel that can be combusted, resulting in higher power output. Advanced designs may incorporate variable geometry turbochargers or electric superchargers for improved responsiveness across the engine's rev range.

- Materials and manufacturing techniques: The use of advanced materials and manufacturing techniques can significantly improve V16 engine performance. Lightweight alloys, composite materials, and precision manufacturing processes help reduce engine weight while increasing strength and durability. These improvements allow for higher operating temperatures and pressures, contributing to increased power output and efficiency.

- Engine monitoring and diagnostics: Sophisticated engine monitoring and diagnostic systems are essential for maintaining optimal V16 engine performance. These systems use various sensors and data analysis techniques to continuously monitor engine parameters, detect potential issues, and optimize performance in real-time. Advanced diagnostics can predict maintenance needs and prevent performance degradation over time.

02 Combustion efficiency improvements

Enhancing combustion efficiency in V16 engines involves optimizing cylinder design, valve timing, and fuel mixture ratios. Advanced combustion chamber designs and precise control of air-fuel mixtures can lead to increased power output and reduced emissions.Expand Specific Solutions03 Cooling and thermal management

Effective cooling and thermal management are crucial for V16 engine performance. Advanced cooling systems, including liquid cooling and oil cooling techniques, help maintain optimal operating temperatures and prevent overheating, ensuring consistent performance and longevity.Expand Specific Solutions04 Engine control and monitoring systems

Sophisticated engine control and monitoring systems play a vital role in V16 engine performance. These systems utilize sensors, actuators, and advanced algorithms to optimize engine parameters in real-time, ensuring peak performance under various operating conditions.Expand Specific Solutions05 Materials and manufacturing techniques

The use of advanced materials and manufacturing techniques can significantly improve V16 engine performance. Lightweight alloys, composite materials, and precision manufacturing processes contribute to reduced engine weight, improved strength, and enhanced overall performance.Expand Specific Solutions

Key V16 Manufacturers

The competition landscape for V16 engines in endurance racing is characterized by a mature market with limited growth potential. Major players like Ford Global Technologies, Toyota Motor Corp., and Honda Motor Co. are investing in research and development to enhance engine performance and reliability. The market size remains relatively small, catering to niche high-performance applications. Technological advancements focus on improving fuel efficiency, power output, and durability. Companies such as AVL List GmbH and Shell Internationale Research Maatschappij BV contribute to the development of advanced lubricants and testing systems, further refining V16 engine capabilities for endurance competitions.

Ford Global Technologies LLC

Technical Solution: Ford has developed advanced V16 engine technologies for endurance competitions, focusing on optimizing power output and fuel efficiency. Their V16 engine design incorporates innovative cooling systems to manage high temperatures during extended racing periods. Ford's engine features a lightweight aluminum block with plasma-coated cylinder liners, reducing friction and improving heat dissipation[1]. The company has also implemented advanced fuel injection systems and variable valve timing to enhance performance across a wide RPM range. Ford's V16 engine utilizes a dry sump lubrication system to ensure consistent oil pressure during high-G cornering and acceleration, critical for endurance racing[3]. Additionally, they have integrated sophisticated engine management systems to monitor and adjust performance parameters in real-time, ensuring optimal efficiency throughout long races[5].

Strengths: Extensive experience in motorsport, advanced cooling technology, and real-time performance optimization. Weaknesses: Higher fuel consumption compared to smaller engines, increased complexity leading to potential reliability issues in extended races.

AVL List GmbH

Technical Solution: AVL List GmbH has developed a comprehensive approach to analyzing V16 engine performance in endurance competitions. Their methodology combines advanced simulation tools with real-world testing to optimize engine design and performance. AVL's V16 engine analysis focuses on thermal management, using computational fluid dynamics (CFD) to model heat distribution and develop efficient cooling strategies[2]. They have created a high-fidelity digital twin of the V16 engine, allowing for rapid iteration and testing of different configurations without the need for physical prototypes[4]. AVL's approach also includes advanced combustion analysis, utilizing optical engines and laser-induced fluorescence to study fuel mixture formation and combustion processes in real-time[6]. This data is then used to fine-tune injection timing and valve actuation for maximum efficiency and power output.

Strengths: Cutting-edge simulation capabilities, comprehensive testing methodologies, and expertise in thermal management. Weaknesses: Reliance on complex software systems, potentially higher development costs compared to traditional methods.

V16 Innovations Analysis

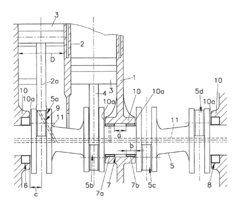

Combustion engine, in particular for racing vehicles

PatentInactiveEP2469108A1

Innovation

- The engine employs roller bearings for the first and third main bearings and a plain bearing for the second main bearing, with the option of using two slide bearings for increased rigidity, and a divided bearing design for ease of assembly, along with oil supply via drilled ducts to minimize lubricating oil usage.

Method for the assessment of the dispersing capacity of new or used lubricating compositions and of additives for lubricating compositions

PatentWO2021205360A1

Innovation

- A laboratory-based method using optical microscopy and lacunarity analysis to quantify the dispersing capacity of lubricating compositions and additives, involving the preparation of carbonaceous particulate dispersions and image processing to determine the degree of dispersion, allowing for high-speed, low-cost, and reproducible assessments.

Fuel Efficiency Impact

The fuel efficiency impact of V16 engines in endurance competitions is a critical factor that significantly influences their overall performance and competitiveness. These large, powerful engines are known for their high output and smooth operation, but they also face challenges in terms of fuel consumption, especially in long-duration races where efficiency becomes paramount.

V16 engines, with their 16 cylinders arranged in a V-configuration, inherently consume more fuel than smaller engines due to their increased displacement and number of combustion chambers. This higher fuel consumption can lead to more frequent pit stops for refueling, potentially offsetting the power advantages these engines offer. In endurance races, where every second counts, the time lost during additional pit stops can be a significant disadvantage.

However, advancements in engine technology have led to improvements in fuel efficiency for V16 engines. Modern fuel injection systems, variable valve timing, and advanced engine management systems have helped optimize fuel delivery and combustion processes. These technologies allow for more precise control over the air-fuel mixture, resulting in better fuel economy without sacrificing power output.

The use of lightweight materials in engine construction has also contributed to improved fuel efficiency. Reduced engine weight not only enhances overall vehicle performance but also decreases the energy required to propel the vehicle, thus lowering fuel consumption. Additionally, aerodynamic improvements in vehicle design help reduce drag, further enhancing fuel efficiency during high-speed endurance racing.

Despite these advancements, V16 engines still face challenges in matching the fuel efficiency of smaller engine configurations. Teams employing V16 engines in endurance competitions must carefully balance the power advantages against the potential fuel efficiency drawbacks. Strategies such as fuel mapping, where engine performance is optimized for different race stages, and advanced energy recovery systems can help mitigate some of the fuel consumption issues.

The impact of fuel efficiency on race strategy cannot be overstated. Teams must consider factors such as fuel load, which affects vehicle weight and handling, and the frequency of pit stops. In some cases, the superior power output of a V16 engine may compensate for the additional fuel stops by allowing for faster lap times or better overtaking capabilities. However, in races where fuel efficiency is a critical factor, teams may opt for smaller, more fuel-efficient engine configurations.

In conclusion, while V16 engines offer impressive power and performance characteristics, their fuel efficiency impact in endurance competitions remains a significant consideration. The ongoing development of engine technologies and race strategies continues to address these challenges, aiming to strike an optimal balance between power output and fuel consumption in the demanding world of endurance racing.

V16 engines, with their 16 cylinders arranged in a V-configuration, inherently consume more fuel than smaller engines due to their increased displacement and number of combustion chambers. This higher fuel consumption can lead to more frequent pit stops for refueling, potentially offsetting the power advantages these engines offer. In endurance races, where every second counts, the time lost during additional pit stops can be a significant disadvantage.

However, advancements in engine technology have led to improvements in fuel efficiency for V16 engines. Modern fuel injection systems, variable valve timing, and advanced engine management systems have helped optimize fuel delivery and combustion processes. These technologies allow for more precise control over the air-fuel mixture, resulting in better fuel economy without sacrificing power output.

The use of lightweight materials in engine construction has also contributed to improved fuel efficiency. Reduced engine weight not only enhances overall vehicle performance but also decreases the energy required to propel the vehicle, thus lowering fuel consumption. Additionally, aerodynamic improvements in vehicle design help reduce drag, further enhancing fuel efficiency during high-speed endurance racing.

Despite these advancements, V16 engines still face challenges in matching the fuel efficiency of smaller engine configurations. Teams employing V16 engines in endurance competitions must carefully balance the power advantages against the potential fuel efficiency drawbacks. Strategies such as fuel mapping, where engine performance is optimized for different race stages, and advanced energy recovery systems can help mitigate some of the fuel consumption issues.

The impact of fuel efficiency on race strategy cannot be overstated. Teams must consider factors such as fuel load, which affects vehicle weight and handling, and the frequency of pit stops. In some cases, the superior power output of a V16 engine may compensate for the additional fuel stops by allowing for faster lap times or better overtaking capabilities. However, in races where fuel efficiency is a critical factor, teams may opt for smaller, more fuel-efficient engine configurations.

In conclusion, while V16 engines offer impressive power and performance characteristics, their fuel efficiency impact in endurance competitions remains a significant consideration. The ongoing development of engine technologies and race strategies continues to address these challenges, aiming to strike an optimal balance between power output and fuel consumption in the demanding world of endurance racing.

Regulatory Considerations

Regulatory considerations play a crucial role in the development and implementation of V16 engines in endurance competitions. These regulations are designed to ensure fair competition, maintain safety standards, and promote technological innovation within specified parameters.

One of the primary regulatory aspects for V16 engines in endurance racing is the limitation on engine displacement. Governing bodies often set maximum displacement limits to level the playing field and prevent excessive power advantages. For V16 engines, these limits may be more restrictive compared to engines with fewer cylinders, necessitating innovative design solutions to maximize performance within the allowed parameters.

Fuel efficiency regulations are another critical factor in endurance competitions. With races lasting for extended periods, fuel consumption becomes a significant consideration. Regulatory bodies may impose restrictions on fuel tank capacity or mandate the use of specific fuel types. These regulations encourage manufacturers to develop more efficient V16 engines, balancing power output with fuel economy.

Emissions standards are increasingly important in motorsports, including endurance racing. V16 engines must comply with stringent emissions regulations, which may vary depending on the competition and jurisdiction. This necessitates the integration of advanced exhaust aftertreatment systems and the optimization of combustion processes to minimize harmful emissions while maintaining performance.

Weight restrictions are also a key regulatory consideration for V16 engines in endurance racing. The inherent complexity and size of V16 engines can present challenges in meeting weight limits imposed by regulatory bodies. Engineers must employ lightweight materials and innovative design techniques to reduce engine weight without compromising durability or performance.

Noise regulations are another important aspect, particularly for endurance races that may run through populated areas or during nighttime hours. V16 engines, with their distinctive sound profile, must be designed to meet specified decibel limits while maintaining their performance characteristics. This often involves the development of sophisticated exhaust systems and sound-dampening technologies.

Durability and reliability standards are crucial in endurance racing regulations. V16 engines must demonstrate the ability to perform consistently over extended periods without failure. Regulatory bodies may impose mandatory inspection intervals or component life limits to ensure safety and fair competition. This drives the development of robust engine designs and advanced materials capable of withstanding the rigors of endurance racing.

In conclusion, regulatory considerations for V16 engines in endurance competitions encompass a wide range of factors, from performance limitations to environmental concerns. These regulations shape the development and implementation of V16 engines, driving innovation while ensuring fair and safe competition.

One of the primary regulatory aspects for V16 engines in endurance racing is the limitation on engine displacement. Governing bodies often set maximum displacement limits to level the playing field and prevent excessive power advantages. For V16 engines, these limits may be more restrictive compared to engines with fewer cylinders, necessitating innovative design solutions to maximize performance within the allowed parameters.

Fuel efficiency regulations are another critical factor in endurance competitions. With races lasting for extended periods, fuel consumption becomes a significant consideration. Regulatory bodies may impose restrictions on fuel tank capacity or mandate the use of specific fuel types. These regulations encourage manufacturers to develop more efficient V16 engines, balancing power output with fuel economy.

Emissions standards are increasingly important in motorsports, including endurance racing. V16 engines must comply with stringent emissions regulations, which may vary depending on the competition and jurisdiction. This necessitates the integration of advanced exhaust aftertreatment systems and the optimization of combustion processes to minimize harmful emissions while maintaining performance.

Weight restrictions are also a key regulatory consideration for V16 engines in endurance racing. The inherent complexity and size of V16 engines can present challenges in meeting weight limits imposed by regulatory bodies. Engineers must employ lightweight materials and innovative design techniques to reduce engine weight without compromising durability or performance.

Noise regulations are another important aspect, particularly for endurance races that may run through populated areas or during nighttime hours. V16 engines, with their distinctive sound profile, must be designed to meet specified decibel limits while maintaining their performance characteristics. This often involves the development of sophisticated exhaust systems and sound-dampening technologies.

Durability and reliability standards are crucial in endurance racing regulations. V16 engines must demonstrate the ability to perform consistently over extended periods without failure. Regulatory bodies may impose mandatory inspection intervals or component life limits to ensure safety and fair competition. This drives the development of robust engine designs and advanced materials capable of withstanding the rigors of endurance racing.

In conclusion, regulatory considerations for V16 engines in endurance competitions encompass a wide range of factors, from performance limitations to environmental concerns. These regulations shape the development and implementation of V16 engines, driving innovation while ensuring fair and safe competition.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!