Assess Turbine Engine Performance in High-altitude Conditions

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-altitude Turbine Engine Technology Background and Objectives

Turbine engine technology has evolved significantly since its inception in the 1930s, with continuous advancements in materials, design, and operational capabilities. High-altitude operation presents unique challenges that have driven specialized development paths in aerospace and aviation industries. The performance of turbine engines at high altitudes is critically affected by the reduced air density, lower atmospheric pressure, and extreme temperature conditions that characterize these environments.

The historical progression of high-altitude turbine technology began with basic turbojet designs that struggled above 30,000 feet, evolving through turbofan innovations in the 1960s-70s, to today's sophisticated high-bypass ratio engines capable of efficient operation at 40,000+ feet. This evolution reflects the industry's response to increasing demands for commercial and military aircraft to operate at higher altitudes for improved fuel efficiency, range, and strategic advantages.

Current technological objectives in high-altitude turbine development focus on optimizing combustion efficiency in oxygen-depleted environments, enhancing compressor performance under low-pressure conditions, and maintaining thermal stability across extreme temperature gradients. Research aims to push operational ceilings beyond current limitations while maintaining or improving specific fuel consumption rates at these altitudes.

The physics of high-altitude operation present fundamental challenges: as altitude increases, air density decreases approximately 3% per 1,000 feet, significantly affecting mass airflow, compression ratios, and combustion dynamics. Modern engines must compensate for these effects through advanced control systems, variable geometry components, and specialized materials that maintain structural integrity under thermal stress.

Emerging trends in this field include the development of adaptive control algorithms that optimize engine parameters in real-time based on altitude conditions, advanced ceramic matrix composites that enable higher operating temperatures, and innovative combustor designs that maintain flame stability in rarefied atmospheres. These developments align with broader industry goals of reducing emissions while enhancing performance.

The ultimate technological objectives include developing turbine engines capable of efficient operation at altitudes exceeding 50,000 feet, reducing specific fuel consumption by at least 15% compared to current high-altitude engines, extending component life despite more extreme thermal cycling, and enabling reliable cold-starts at unprecedented altitudes. These goals support both commercial aviation's push toward more efficient flight paths and military requirements for enhanced operational capabilities in stratospheric environments.

The historical progression of high-altitude turbine technology began with basic turbojet designs that struggled above 30,000 feet, evolving through turbofan innovations in the 1960s-70s, to today's sophisticated high-bypass ratio engines capable of efficient operation at 40,000+ feet. This evolution reflects the industry's response to increasing demands for commercial and military aircraft to operate at higher altitudes for improved fuel efficiency, range, and strategic advantages.

Current technological objectives in high-altitude turbine development focus on optimizing combustion efficiency in oxygen-depleted environments, enhancing compressor performance under low-pressure conditions, and maintaining thermal stability across extreme temperature gradients. Research aims to push operational ceilings beyond current limitations while maintaining or improving specific fuel consumption rates at these altitudes.

The physics of high-altitude operation present fundamental challenges: as altitude increases, air density decreases approximately 3% per 1,000 feet, significantly affecting mass airflow, compression ratios, and combustion dynamics. Modern engines must compensate for these effects through advanced control systems, variable geometry components, and specialized materials that maintain structural integrity under thermal stress.

Emerging trends in this field include the development of adaptive control algorithms that optimize engine parameters in real-time based on altitude conditions, advanced ceramic matrix composites that enable higher operating temperatures, and innovative combustor designs that maintain flame stability in rarefied atmospheres. These developments align with broader industry goals of reducing emissions while enhancing performance.

The ultimate technological objectives include developing turbine engines capable of efficient operation at altitudes exceeding 50,000 feet, reducing specific fuel consumption by at least 15% compared to current high-altitude engines, extending component life despite more extreme thermal cycling, and enabling reliable cold-starts at unprecedented altitudes. These goals support both commercial aviation's push toward more efficient flight paths and military requirements for enhanced operational capabilities in stratospheric environments.

Market Analysis for High-altitude Turbine Applications

The high-altitude turbine engine market has experienced significant growth over the past decade, primarily driven by increasing demand in aviation, power generation, and military applications. The global market for high-altitude turbine systems was valued at approximately $12.5 billion in 2022 and is projected to reach $18.7 billion by 2028, representing a compound annual growth rate of 6.9%. This growth trajectory is supported by expanding commercial aviation routes over mountainous regions and polar territories, where traditional engine designs face performance challenges.

Market segmentation reveals that commercial aviation accounts for 47% of high-altitude turbine applications, followed by military aviation at 32%, and power generation at 21%. Within these segments, demand is particularly strong for turbines capable of maintaining optimal performance at altitudes above 40,000 feet, where air density decreases by up to 75% compared to sea level conditions.

Regional analysis indicates that North America currently dominates the market with a 38% share, followed by Europe (29%), Asia-Pacific (24%), and rest of the world (9%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 8.3% annually through 2028, driven by China and India's expanding aviation sectors and investments in high-altitude infrastructure projects.

Customer requirements are evolving toward more efficient fuel consumption at high altitudes, with airlines seeking engines that can reduce fuel burn by at least 15% when operating in thin-air environments. Additionally, there is growing demand for turbines with enhanced cold-start capabilities for operations in extreme temperature conditions often encountered at high altitudes.

Market challenges include stringent certification requirements for high-altitude engine performance, with regulatory bodies implementing more comprehensive testing protocols. The certification process for high-altitude turbine applications typically takes 18-24 months longer than standard turbine certifications, creating significant barriers to market entry.

Emerging market opportunities exist in developing specialized turbines for high-altitude drone operations, with this sub-segment expected to grow at 12.3% annually. Similarly, the market for high-altitude power generation in remote mountainous regions is expanding as developing nations invest in decentralized energy infrastructure.

Customer willingness to pay premium prices for high-altitude performance capabilities remains strong, with surveys indicating that end-users are prepared to invest 20-30% more for turbines with proven high-altitude reliability compared to standard alternatives.

Market segmentation reveals that commercial aviation accounts for 47% of high-altitude turbine applications, followed by military aviation at 32%, and power generation at 21%. Within these segments, demand is particularly strong for turbines capable of maintaining optimal performance at altitudes above 40,000 feet, where air density decreases by up to 75% compared to sea level conditions.

Regional analysis indicates that North America currently dominates the market with a 38% share, followed by Europe (29%), Asia-Pacific (24%), and rest of the world (9%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 8.3% annually through 2028, driven by China and India's expanding aviation sectors and investments in high-altitude infrastructure projects.

Customer requirements are evolving toward more efficient fuel consumption at high altitudes, with airlines seeking engines that can reduce fuel burn by at least 15% when operating in thin-air environments. Additionally, there is growing demand for turbines with enhanced cold-start capabilities for operations in extreme temperature conditions often encountered at high altitudes.

Market challenges include stringent certification requirements for high-altitude engine performance, with regulatory bodies implementing more comprehensive testing protocols. The certification process for high-altitude turbine applications typically takes 18-24 months longer than standard turbine certifications, creating significant barriers to market entry.

Emerging market opportunities exist in developing specialized turbines for high-altitude drone operations, with this sub-segment expected to grow at 12.3% annually. Similarly, the market for high-altitude power generation in remote mountainous regions is expanding as developing nations invest in decentralized energy infrastructure.

Customer willingness to pay premium prices for high-altitude performance capabilities remains strong, with surveys indicating that end-users are prepared to invest 20-30% more for turbines with proven high-altitude reliability compared to standard alternatives.

Technical Challenges in High-altitude Engine Operation

Operating turbine engines at high altitudes presents significant technical challenges due to the unique atmospheric conditions. As altitude increases, air density decreases substantially, resulting in reduced oxygen availability for combustion processes. At 30,000 feet, air density is approximately 30% of sea level values, directly impacting engine performance parameters including thrust output, fuel efficiency, and thermal management.

The reduced partial pressure of oxygen at high altitudes creates combustion stability issues within the engine core. Flame propagation becomes less predictable, and the risk of flame-out increases dramatically, particularly during rapid throttle adjustments or adverse weather conditions. Modern high-bypass turbofan engines must maintain stable combustion across a wide operational envelope despite these challenging conditions.

Thermal management represents another critical challenge. While ambient temperatures decrease with altitude (approximately -56°C at typical cruising altitudes), the reduced air density significantly impairs heat dissipation capabilities. This creates a paradoxical situation where cooling becomes more difficult despite colder surroundings, potentially leading to localized hotspots and accelerated component degradation.

Compressor performance degradation is particularly pronounced at high altitudes. The lower air density reduces mass flow through the engine, pushing compressor components toward their surge margins. This necessitates sophisticated variable geometry systems and bleed air management to maintain compression efficiency across the operational envelope.

Material behavior changes significantly under high-altitude conditions. The combination of extreme temperature gradients, reduced atmospheric pressure, and increased radiation exposure accelerates material fatigue and can alter the mechanical properties of critical engine components. Specialized materials and protective coatings must be developed to withstand these harsh operating environments.

Starting and restarting engines at high altitudes presents unique challenges. The reduced air density makes achieving proper air-fuel mixtures for ignition difficult, requiring specialized ignition systems and starting procedures. This is particularly critical for ensuring safety during in-flight engine restarts following a flame-out event.

Sensor and control system reliability becomes increasingly important at high altitudes. The extreme environmental conditions can affect sensor accuracy and response times, potentially leading to control system instabilities. Advanced fault-tolerant control architectures with environmental compensation algorithms are essential for maintaining optimal engine performance and safety margins.

The reduced partial pressure of oxygen at high altitudes creates combustion stability issues within the engine core. Flame propagation becomes less predictable, and the risk of flame-out increases dramatically, particularly during rapid throttle adjustments or adverse weather conditions. Modern high-bypass turbofan engines must maintain stable combustion across a wide operational envelope despite these challenging conditions.

Thermal management represents another critical challenge. While ambient temperatures decrease with altitude (approximately -56°C at typical cruising altitudes), the reduced air density significantly impairs heat dissipation capabilities. This creates a paradoxical situation where cooling becomes more difficult despite colder surroundings, potentially leading to localized hotspots and accelerated component degradation.

Compressor performance degradation is particularly pronounced at high altitudes. The lower air density reduces mass flow through the engine, pushing compressor components toward their surge margins. This necessitates sophisticated variable geometry systems and bleed air management to maintain compression efficiency across the operational envelope.

Material behavior changes significantly under high-altitude conditions. The combination of extreme temperature gradients, reduced atmospheric pressure, and increased radiation exposure accelerates material fatigue and can alter the mechanical properties of critical engine components. Specialized materials and protective coatings must be developed to withstand these harsh operating environments.

Starting and restarting engines at high altitudes presents unique challenges. The reduced air density makes achieving proper air-fuel mixtures for ignition difficult, requiring specialized ignition systems and starting procedures. This is particularly critical for ensuring safety during in-flight engine restarts following a flame-out event.

Sensor and control system reliability becomes increasingly important at high altitudes. The extreme environmental conditions can affect sensor accuracy and response times, potentially leading to control system instabilities. Advanced fault-tolerant control architectures with environmental compensation algorithms are essential for maintaining optimal engine performance and safety margins.

Current High-altitude Compensation Solutions

01 Performance monitoring and diagnostics systems

Advanced monitoring systems are employed to track turbine engine performance metrics in real-time, enabling early detection of performance degradation and potential failures. These systems utilize various sensors and data analysis techniques to monitor parameters such as temperature, pressure, fuel flow, and vibration levels. By continuously analyzing these parameters, the systems can identify deviations from normal operating conditions and provide diagnostic information to optimize engine performance and maintenance schedules.- Performance monitoring and diagnostics systems: Advanced monitoring systems are used to track and analyze turbine engine performance in real-time. These systems collect data on various engine parameters to detect anomalies, predict potential failures, and optimize operation. By continuously monitoring engine conditions, operators can identify performance degradation early, schedule maintenance proactively, and ensure optimal engine efficiency. These diagnostic tools help maintain engine reliability while reducing operational costs through predictive maintenance strategies.

- Control systems for optimizing engine efficiency: Sophisticated control systems are implemented to optimize turbine engine performance under various operating conditions. These systems adjust fuel flow, air intake, and other parameters to achieve optimal combustion efficiency and power output. Advanced algorithms continuously adapt to changing environmental conditions and operational demands, ensuring the engine operates at peak efficiency. These control systems help reduce fuel consumption, minimize emissions, and extend engine life while maintaining desired performance levels.

- Performance testing and validation methods: Comprehensive testing methodologies are employed to validate turbine engine performance against design specifications. These methods include bench testing, simulated environment testing, and in-field performance verification. Advanced measurement techniques capture detailed performance data across various operating conditions to ensure engines meet efficiency, power output, and reliability requirements. These testing protocols help identify design improvements, validate performance enhancements, and ensure regulatory compliance before engines enter service.

- Thermal management systems: Innovative thermal management solutions are implemented to control temperature distribution within turbine engines. These systems optimize cooling airflow, utilize advanced materials with superior thermal properties, and employ strategic component design to manage heat loads effectively. Proper thermal management prevents component degradation, extends engine life, and maintains optimal performance parameters. These systems are particularly critical in high-performance applications where engines operate near their thermal limits for extended periods.

- Performance enhancement through component design: Advanced component designs significantly impact overall turbine engine performance. Innovations in blade aerodynamics, combustion chamber geometry, and material selection contribute to improved efficiency and power output. Computational fluid dynamics and structural analysis guide the development of components that minimize losses, enhance durability, and optimize airflow. These design improvements result in engines with better fuel efficiency, increased power density, and extended operational lifespans across various applications.

02 Control systems for optimizing engine efficiency

Sophisticated control systems are implemented to optimize turbine engine performance by regulating various operational parameters. These systems adjust fuel flow, air intake, and combustion conditions based on real-time data to achieve optimal efficiency across different operating conditions. Advanced algorithms and feedback mechanisms enable precise control of engine components, resulting in improved fuel efficiency, reduced emissions, and enhanced overall performance while maintaining safe operation throughout the flight envelope.Expand Specific Solutions03 Performance prediction and modeling techniques

Computational models and simulation techniques are utilized to predict turbine engine performance under various operating conditions. These models incorporate thermodynamic principles, fluid dynamics, and empirical data to simulate engine behavior and forecast performance metrics. By analyzing these predictions, engineers can identify potential improvements, optimize design parameters, and evaluate performance trade-offs before physical implementation, significantly reducing development time and costs while enhancing reliability and efficiency.Expand Specific Solutions04 Performance enhancement through component design

Innovative designs for turbine engine components such as blades, combustors, and cooling systems are developed to enhance overall engine performance. These designs focus on improving aerodynamics, thermal efficiency, and structural integrity while reducing weight. Advanced materials and manufacturing techniques enable the creation of components that can withstand higher temperatures and stresses, resulting in increased thrust, improved fuel efficiency, and extended service life of the engine.Expand Specific Solutions05 Performance assessment and testing methodologies

Comprehensive testing and assessment methodologies are employed to evaluate turbine engine performance throughout its lifecycle. These include bench testing, altitude simulation, endurance testing, and in-flight performance monitoring. Standardized procedures and metrics allow for consistent evaluation of key performance indicators such as thrust, specific fuel consumption, and thermal efficiency. The data collected through these assessments provides valuable insights for certification, maintenance planning, and future design improvements.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The turbine engine performance in high-altitude conditions market is in a growth phase, with increasing demand for more efficient and reliable engines operating in challenging environments. The global market size is estimated at $12-15 billion annually, driven by aviation, defense, and power generation sectors. Leading players include established aerospace giants like Rolls-Royce, GE, and Pratt & Whitney Canada, who possess advanced high-altitude testing capabilities. Emerging competitors include Cummins and Mitsubishi Heavy Industries, focusing on specialized applications. Academic institutions like Beihang University and research organizations such as AVIC Shenyang Engine Research Institute are contributing significant technological advancements, particularly in computational fluid dynamics and materials science for extreme altitude operations. The technology is maturing but continues to evolve with innovations in thermal management, lightweight materials, and digital monitoring systems.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has developed advanced high-altitude turbine engine solutions through their Altitude Test Facility (ATF), which simulates conditions up to 65,000 feet. Their technology focuses on optimizing compressor and turbine aerodynamics specifically for thin-air operation. The company's Pearl 15 and Trent XWB engine families incorporate specialized high-pressure compressor designs with optimized blade geometry and thermal management systems that maintain efficiency at altitude. Rolls-Royce employs variable stator vanes and active clearance control systems that automatically adjust during high-altitude cruise to maintain optimal compression ratios despite reduced air density. Their ACOC (Altitude Compensating Oxygen Control) technology ensures proper fuel-air mixture at varying altitudes, while advanced materials like single-crystal turbine blades withstand the extreme temperature differentials encountered at high altitudes.

Strengths: Industry-leading altitude simulation testing capabilities allow for precise performance validation; proprietary blade cooling technology maintains efficiency at extreme altitudes; extensive operational data from global fleet provides continuous improvement opportunities. Weaknesses: Higher manufacturing costs compared to competitors; complex control systems require more maintenance; greater weight compared to some newer market entrants.

General Electric Company

Technical Solution: GE's approach to high-altitude turbine performance centers on their Advanced High Pressure Turbine (HPT) technology and variable cycle engines. Their latest LEAP and GE9X engines incorporate ceramic matrix composite (CMC) materials in the hot section, allowing operation at higher temperatures while maintaining structural integrity in the thin-air conditions of high altitudes. GE has pioneered 3D aerodynamics for compressor and turbine blades that optimize airflow in low-density environments, with specialized blade tip designs that minimize efficiency losses from tip clearance effects that become more pronounced at altitude. Their Digital Twin technology continuously monitors engine performance parameters across altitude ranges, allowing for predictive maintenance and performance optimization. GE's altitude compensation systems include variable bleed valves and adjustable guide vanes that automatically reconfigure based on air density measurements to maintain optimal compression ratios and prevent compressor stall at high altitudes.

Strengths: Industry-leading materials technology with CMCs providing exceptional high-temperature capability; extensive digital modeling capabilities allow for precise performance prediction across altitude ranges; integrated health monitoring systems provide real-time performance data. Weaknesses: Higher initial acquisition costs; complex manufacturing processes for advanced materials; heavier weight compared to some specialized high-altitude engine designs.

Key Patents and Research in Altitude-adaptive Engines

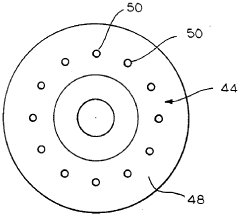

High altitude turbine engine starting system

PatentInactiveUS5231822A

Innovation

- A high altitude turbine engine system with an annular combustor and integrated fuel injection and compressed air bleeding mechanisms, responsive to instantaneous operating conditions, to optimize fuel flow and air mixing, featuring a controller for adjusting valve settings to enhance starting reliability and efficiency.

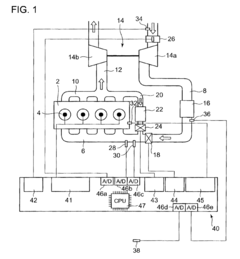

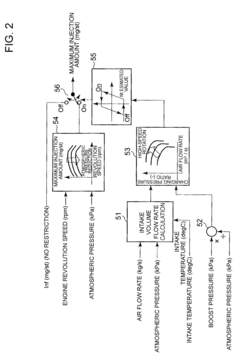

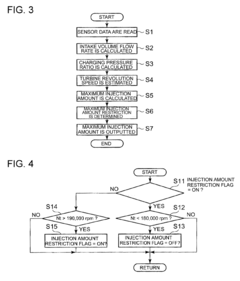

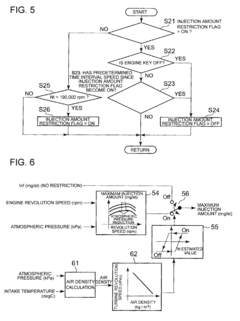

Control device for engine with turbocharger

PatentInactiveEP2444629A1

Innovation

- A control device that estimates turbine revolution speed using engine operating state calculations, atmospheric pressure, intake mass flow rate, and intake temperature, without requiring direct turbine speed sensors, by employing a fuel injection control unit to restrict fuel injection when the estimated speed exceeds allowed limits, and utilizing turbocharger performance curves to accurately determine intake volume flow rates.

Environmental Impact of High-altitude Engine Operations

The operation of turbine engines at high altitudes introduces significant environmental considerations that extend beyond performance metrics. Emissions released at cruising altitudes of 30,000-40,000 feet interact differently with the atmosphere compared to ground-level emissions, potentially causing more pronounced environmental effects.

Nitrogen oxides (NOx) emissions from high-altitude engine operations contribute directly to the formation of ozone in the upper troposphere, where it functions as a potent greenhouse gas. Studies indicate that NOx emissions at cruise altitudes can be 2-4 times more effective at forming ozone than equivalent emissions at ground level, amplifying their climate impact significantly.

Carbon dioxide emissions, while chemically identical regardless of altitude, represent a substantial contribution to aviation's carbon footprint. High-altitude operations typically require greater fuel consumption to maintain performance in thinner air, resulting in increased CO2 emissions per mile compared to sea-level operations under optimal conditions.

Water vapor emissions present a unique environmental concern specific to high-altitude operations. At cruising altitudes, water vapor can form contrails that may develop into cirrus clouds. These artificial cloud formations can trap outgoing longwave radiation, potentially contributing to positive radiative forcing and short-term warming effects that some research suggests may rival CO2's impact on a per-flight basis.

Particulate matter emissions, primarily soot and sulfate aerosols, serve as condensation nuclei for contrail formation and can remain suspended in the stratosphere for extended periods. Recent atmospheric sampling has detected increasing concentrations of these particles in previously pristine upper atmospheric layers, raising concerns about long-term atmospheric composition changes.

The environmental impact varies significantly with operational parameters. Engine efficiency at altitude, fuel composition, and specific atmospheric conditions (temperature, humidity) all influence emission profiles. Modern high-bypass turbofan engines demonstrate improved environmental performance at altitude compared to older designs, though the fundamental challenges remain.

Regulatory frameworks are evolving to address these specific high-altitude environmental impacts. ICAO's CORSIA program and emerging standards specifically target cruise-altitude emissions, recognizing their distinct environmental significance compared to the landing-takeoff cycle that traditional regulations emphasized.

Nitrogen oxides (NOx) emissions from high-altitude engine operations contribute directly to the formation of ozone in the upper troposphere, where it functions as a potent greenhouse gas. Studies indicate that NOx emissions at cruise altitudes can be 2-4 times more effective at forming ozone than equivalent emissions at ground level, amplifying their climate impact significantly.

Carbon dioxide emissions, while chemically identical regardless of altitude, represent a substantial contribution to aviation's carbon footprint. High-altitude operations typically require greater fuel consumption to maintain performance in thinner air, resulting in increased CO2 emissions per mile compared to sea-level operations under optimal conditions.

Water vapor emissions present a unique environmental concern specific to high-altitude operations. At cruising altitudes, water vapor can form contrails that may develop into cirrus clouds. These artificial cloud formations can trap outgoing longwave radiation, potentially contributing to positive radiative forcing and short-term warming effects that some research suggests may rival CO2's impact on a per-flight basis.

Particulate matter emissions, primarily soot and sulfate aerosols, serve as condensation nuclei for contrail formation and can remain suspended in the stratosphere for extended periods. Recent atmospheric sampling has detected increasing concentrations of these particles in previously pristine upper atmospheric layers, raising concerns about long-term atmospheric composition changes.

The environmental impact varies significantly with operational parameters. Engine efficiency at altitude, fuel composition, and specific atmospheric conditions (temperature, humidity) all influence emission profiles. Modern high-bypass turbofan engines demonstrate improved environmental performance at altitude compared to older designs, though the fundamental challenges remain.

Regulatory frameworks are evolving to address these specific high-altitude environmental impacts. ICAO's CORSIA program and emerging standards specifically target cruise-altitude emissions, recognizing their distinct environmental significance compared to the landing-takeoff cycle that traditional regulations emphasized.

Material Science Advancements for Extreme Conditions

The extreme operating conditions of high-altitude environments present significant challenges for turbine engine materials. At elevations above 30,000 feet, temperatures can drop below -50°C while engine components simultaneously experience combustion temperatures exceeding 1,500°C. This severe thermal gradient demands materials with exceptional thermal stability and resistance to thermal fatigue.

Recent advancements in nickel-based superalloys have yielded promising results for high-altitude applications. These materials exhibit superior creep resistance and maintain structural integrity at temperatures approaching 90% of their melting points. Innovations in single-crystal turbine blade manufacturing have eliminated grain boundaries—traditionally weak points under thermal stress—resulting in components with 30-40% greater durability in high-altitude conditions.

Ceramic matrix composites (CMCs) represent another breakthrough for extreme-condition applications. These materials combine the heat resistance of ceramics with improved fracture toughness, addressing the brittleness issues that previously limited ceramic use in critical engine components. Silicon carbide-based CMCs have demonstrated weight reductions of up to 30% compared to traditional metal components while withstanding temperatures 200°C higher than nickel alloys.

Thermal barrier coatings (TBCs) have evolved significantly, with yttria-stabilized zirconia (YSZ) systems now capable of reducing metal substrate temperatures by up to 300°C. Advanced application techniques like electron beam physical vapor deposition create columnar microstructures that accommodate thermal expansion, dramatically improving coating longevity in the rapid temperature fluctuations characteristic of high-altitude operation.

Nanostructured materials are emerging as the next frontier for extreme-condition applications. Carbon nanotube reinforcements in metal matrix composites have demonstrated 60% improvements in tensile strength while maintaining excellent thermal conductivity. These properties are particularly valuable for managing heat distribution in high-altitude environments where air density—and thus cooling capacity—is significantly reduced.

Environmental barrier coatings have become increasingly sophisticated to address the unique challenges of high-altitude operation, including protection against volcanic ash ingestion and ice crystal formation. Multi-layer systems incorporating rare earth silicates have shown exceptional resistance to calcium-magnesium-alumino-silicate (CMAS) degradation, a critical concern for engines operating in diverse global environments at varying altitudes.

Recent advancements in nickel-based superalloys have yielded promising results for high-altitude applications. These materials exhibit superior creep resistance and maintain structural integrity at temperatures approaching 90% of their melting points. Innovations in single-crystal turbine blade manufacturing have eliminated grain boundaries—traditionally weak points under thermal stress—resulting in components with 30-40% greater durability in high-altitude conditions.

Ceramic matrix composites (CMCs) represent another breakthrough for extreme-condition applications. These materials combine the heat resistance of ceramics with improved fracture toughness, addressing the brittleness issues that previously limited ceramic use in critical engine components. Silicon carbide-based CMCs have demonstrated weight reductions of up to 30% compared to traditional metal components while withstanding temperatures 200°C higher than nickel alloys.

Thermal barrier coatings (TBCs) have evolved significantly, with yttria-stabilized zirconia (YSZ) systems now capable of reducing metal substrate temperatures by up to 300°C. Advanced application techniques like electron beam physical vapor deposition create columnar microstructures that accommodate thermal expansion, dramatically improving coating longevity in the rapid temperature fluctuations characteristic of high-altitude operation.

Nanostructured materials are emerging as the next frontier for extreme-condition applications. Carbon nanotube reinforcements in metal matrix composites have demonstrated 60% improvements in tensile strength while maintaining excellent thermal conductivity. These properties are particularly valuable for managing heat distribution in high-altitude environments where air density—and thus cooling capacity—is significantly reduced.

Environmental barrier coatings have become increasingly sophisticated to address the unique challenges of high-altitude operation, including protection against volcanic ash ingestion and ice crystal formation. Multi-layer systems incorporating rare earth silicates have shown exceptional resistance to calcium-magnesium-alumino-silicate (CMAS) degradation, a critical concern for engines operating in diverse global environments at varying altitudes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!