Assessing Radial Engine's Role in Aircraft Applications

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine Development History and Objectives

Radial engines emerged in the early 20th century as a revolutionary power solution for aircraft propulsion. The first practical radial engine design was developed by Charles Manly in 1903, featuring a five-cylinder configuration. However, it was during World War I that radial engines gained significant traction, with manufacturers like Gnome and Le Rhône pioneering rotary radial designs that offered impressive power-to-weight ratios crucial for military aircraft.

The 1920s and 1930s marked the golden age of radial engine development, with companies such as Pratt & Whitney and Wright Aeronautical introducing iconic models like the Wasp and Cyclone series. These engines featured multiple rows of cylinders, improved cooling systems, and enhanced reliability, enabling longer flights and heavier payloads. By the late 1930s, radial engines had reached outputs exceeding 2,000 horsepower, powering the most advanced aircraft of the era.

World War II accelerated radial engine evolution, pushing performance boundaries to meet military demands. Engineers focused on increasing power output while maintaining reliability under extreme conditions. The R-4360 Wasp Major, with its 28 cylinders arranged in four rows, represented the pinnacle of piston radial engine development, producing over 3,500 horsepower.

Post-war technological evolution saw jet engines gradually replacing radials in military and commercial aviation. However, radial engines maintained relevance in specific applications where their unique characteristics provided advantages. The primary objective of radial engine development shifted from pure performance gains to reliability, fuel efficiency, and specialized applications.

Contemporary radial engine development focuses on preserving historical technology while adapting it for modern requirements. Current objectives include integrating modern materials and manufacturing techniques to enhance traditional designs, developing hybrid systems that combine radial engine reliability with modern power delivery mechanisms, and exploring niche applications where radial engines offer distinct advantages over alternative power plants.

Looking forward, radial engine technology aims to balance historical engineering principles with contemporary demands. Objectives include reducing emissions through alternative fuel compatibility, implementing electronic engine management systems for improved efficiency, and developing lightweight variants using advanced materials. Additionally, there is growing interest in radial engines for unmanned aerial vehicles where their inherent reliability and simple maintenance requirements present valuable operational advantages.

The evolution of radial engine technology represents a fascinating trajectory of aviation engineering, from pioneering designs to specialized applications in modern aircraft systems, with clear development patterns that inform current research directions and future potential.

The 1920s and 1930s marked the golden age of radial engine development, with companies such as Pratt & Whitney and Wright Aeronautical introducing iconic models like the Wasp and Cyclone series. These engines featured multiple rows of cylinders, improved cooling systems, and enhanced reliability, enabling longer flights and heavier payloads. By the late 1930s, radial engines had reached outputs exceeding 2,000 horsepower, powering the most advanced aircraft of the era.

World War II accelerated radial engine evolution, pushing performance boundaries to meet military demands. Engineers focused on increasing power output while maintaining reliability under extreme conditions. The R-4360 Wasp Major, with its 28 cylinders arranged in four rows, represented the pinnacle of piston radial engine development, producing over 3,500 horsepower.

Post-war technological evolution saw jet engines gradually replacing radials in military and commercial aviation. However, radial engines maintained relevance in specific applications where their unique characteristics provided advantages. The primary objective of radial engine development shifted from pure performance gains to reliability, fuel efficiency, and specialized applications.

Contemporary radial engine development focuses on preserving historical technology while adapting it for modern requirements. Current objectives include integrating modern materials and manufacturing techniques to enhance traditional designs, developing hybrid systems that combine radial engine reliability with modern power delivery mechanisms, and exploring niche applications where radial engines offer distinct advantages over alternative power plants.

Looking forward, radial engine technology aims to balance historical engineering principles with contemporary demands. Objectives include reducing emissions through alternative fuel compatibility, implementing electronic engine management systems for improved efficiency, and developing lightweight variants using advanced materials. Additionally, there is growing interest in radial engines for unmanned aerial vehicles where their inherent reliability and simple maintenance requirements present valuable operational advantages.

The evolution of radial engine technology represents a fascinating trajectory of aviation engineering, from pioneering designs to specialized applications in modern aircraft systems, with clear development patterns that inform current research directions and future potential.

Aircraft Market Requirements Analysis

The global aircraft market demonstrates a complex interplay of requirements that directly impact the evaluation of radial engine applications. Current market analysis reveals a bifurcation between commercial aviation's push toward fuel efficiency and specialized sectors where radial engines maintain relevance. Commercial aviation, dominated by major manufacturers like Boeing and Airbus, prioritizes fuel economy, operational range, and reduced emissions—areas where modern turbofan and turboprop designs have decisively outperformed radial configurations.

Market data indicates that fuel efficiency remains the primary economic driver for commercial operators, with fuel costs representing 20-30% of operational expenses. This economic pressure has effectively eliminated radial engines from mainstream commercial aviation considerations, as their specific fuel consumption rates cannot compete with modern alternatives.

However, specialized market segments present different requirement profiles where radial engines maintain potential viability. The vintage and historical aircraft restoration market continues to grow steadily, with collectors and museums seeking authentic powerplants for heritage aircraft. This segment values historical accuracy and mechanical authenticity over operational efficiency, creating sustained demand for radial engine maintenance, rebuilding, and reproduction.

The agricultural aviation sector presents another potential application area, where the simplicity, reliability, and ease of field maintenance characteristic of radial designs align with operational requirements. These operators typically fly short missions with frequent maintenance opportunities, mitigating some of the radial engine's disadvantages.

Emerging markets in recreational aviation and specialized utility applications also demonstrate requirements that could accommodate radial engine characteristics. The bush plane market segment values robust reliability, simplicity of maintenance in remote locations, and the ability to operate on lower-grade fuels—all traditional strengths of radial configurations.

Market research further indicates growing interest in hybrid propulsion systems, where traditional combustion engines are paired with electric components. This emerging requirement could potentially create new niches where radial engines' power-to-weight characteristics might find application in specialized generator configurations.

Regional variations in market requirements also merit consideration. Developing aviation markets with limited maintenance infrastructure may value the mechanical simplicity and field-serviceability of radial designs, particularly in remote operations where advanced turbine maintenance facilities are unavailable.

The unmanned aerial vehicle (UAV) market segment presents another potential application area, with specific requirements for reliability, vibration characteristics, and power-to-weight ratios that might align with modernized radial engine designs in certain specialized applications.

Market data indicates that fuel efficiency remains the primary economic driver for commercial operators, with fuel costs representing 20-30% of operational expenses. This economic pressure has effectively eliminated radial engines from mainstream commercial aviation considerations, as their specific fuel consumption rates cannot compete with modern alternatives.

However, specialized market segments present different requirement profiles where radial engines maintain potential viability. The vintage and historical aircraft restoration market continues to grow steadily, with collectors and museums seeking authentic powerplants for heritage aircraft. This segment values historical accuracy and mechanical authenticity over operational efficiency, creating sustained demand for radial engine maintenance, rebuilding, and reproduction.

The agricultural aviation sector presents another potential application area, where the simplicity, reliability, and ease of field maintenance characteristic of radial designs align with operational requirements. These operators typically fly short missions with frequent maintenance opportunities, mitigating some of the radial engine's disadvantages.

Emerging markets in recreational aviation and specialized utility applications also demonstrate requirements that could accommodate radial engine characteristics. The bush plane market segment values robust reliability, simplicity of maintenance in remote locations, and the ability to operate on lower-grade fuels—all traditional strengths of radial configurations.

Market research further indicates growing interest in hybrid propulsion systems, where traditional combustion engines are paired with electric components. This emerging requirement could potentially create new niches where radial engines' power-to-weight characteristics might find application in specialized generator configurations.

Regional variations in market requirements also merit consideration. Developing aviation markets with limited maintenance infrastructure may value the mechanical simplicity and field-serviceability of radial designs, particularly in remote operations where advanced turbine maintenance facilities are unavailable.

The unmanned aerial vehicle (UAV) market segment presents another potential application area, with specific requirements for reliability, vibration characteristics, and power-to-weight ratios that might align with modernized radial engine designs in certain specialized applications.

Current Radial Engine Technology Landscape

Radial engines, despite being largely replaced by turbine engines in modern aviation, continue to maintain a presence in specific aircraft applications. Currently, the technology landscape for radial engines is characterized by a blend of legacy systems and modern adaptations. Traditional radial engine manufacturers like Pratt & Whitney, Wright Aeronautical, and Bristol have largely ceased production of new radial engines, with most existing units being maintained through specialized restoration services and parts manufacturing.

The contemporary radial engine market primarily serves vintage aircraft restoration, aerobatic planes, and certain specialized applications where the unique characteristics of radial engines provide advantages. Modern radial engine technology has seen incremental improvements in materials science, with advanced alloys and composites enhancing durability while reducing weight. These improvements have addressed historical challenges such as oil consumption and thermal management, though not fundamentally altering the core design principles.

Electronically controlled ignition systems have replaced traditional magnetos in some applications, offering more precise timing and improved reliability. Fuel injection systems have also been adapted to some radial engines, providing better fuel economy and performance at varying altitudes compared to traditional carburetor systems. These modernizations represent evolutionary rather than revolutionary changes to the basic radial engine concept.

From a manufacturing perspective, computer-aided design and precision CNC machining have enabled more accurate production of replacement parts, addressing one of the key challenges in maintaining aging radial engine fleets. Several specialized companies now focus exclusively on providing parts and maintenance services for the existing radial engine market, ensuring continued operation of these engines despite their age.

Environmental considerations have prompted research into alternative fuels for radial engines, particularly as leaded aviation gasoline faces increasing regulatory pressure. Some operators have successfully adapted their radial engines to run on unleaded formulations or even biofuels, though these modifications often require careful adjustment of compression ratios and ignition timing.

The current technological landscape also includes a small but notable trend of new-production radial engines, primarily targeting the experimental aircraft market. Companies like Verner Motor and Rotec Engineering have developed modern radial engines incorporating contemporary manufacturing techniques and materials while maintaining the classic radial configuration. These engines typically offer power outputs ranging from 150 to 400 horsepower, filling a niche for builders seeking the distinctive sound, appearance, and operational characteristics of radial engines with improved reliability.

The contemporary radial engine market primarily serves vintage aircraft restoration, aerobatic planes, and certain specialized applications where the unique characteristics of radial engines provide advantages. Modern radial engine technology has seen incremental improvements in materials science, with advanced alloys and composites enhancing durability while reducing weight. These improvements have addressed historical challenges such as oil consumption and thermal management, though not fundamentally altering the core design principles.

Electronically controlled ignition systems have replaced traditional magnetos in some applications, offering more precise timing and improved reliability. Fuel injection systems have also been adapted to some radial engines, providing better fuel economy and performance at varying altitudes compared to traditional carburetor systems. These modernizations represent evolutionary rather than revolutionary changes to the basic radial engine concept.

From a manufacturing perspective, computer-aided design and precision CNC machining have enabled more accurate production of replacement parts, addressing one of the key challenges in maintaining aging radial engine fleets. Several specialized companies now focus exclusively on providing parts and maintenance services for the existing radial engine market, ensuring continued operation of these engines despite their age.

Environmental considerations have prompted research into alternative fuels for radial engines, particularly as leaded aviation gasoline faces increasing regulatory pressure. Some operators have successfully adapted their radial engines to run on unleaded formulations or even biofuels, though these modifications often require careful adjustment of compression ratios and ignition timing.

The current technological landscape also includes a small but notable trend of new-production radial engines, primarily targeting the experimental aircraft market. Companies like Verner Motor and Rotec Engineering have developed modern radial engines incorporating contemporary manufacturing techniques and materials while maintaining the classic radial configuration. These engines typically offer power outputs ranging from 150 to 400 horsepower, filling a niche for builders seeking the distinctive sound, appearance, and operational characteristics of radial engines with improved reliability.

Contemporary Radial Engine Design Solutions

01 Radial engine design and configuration

Radial engines feature a unique configuration where cylinders are arranged radially around a central crankshaft, resembling spokes on a wheel. This design provides advantages in terms of power-to-weight ratio and cooling efficiency. The cylinders are typically arranged in a single or multiple rows, with each cylinder containing pistons that connect to the central crankshaft through connecting rods. This configuration allows for compact packaging and efficient power delivery in various applications including aircraft and industrial equipment.- Radial engine design and configuration: Radial engines feature a unique configuration where cylinders are arranged radially around a central crankshaft, resembling spokes on a wheel. This design provides advantages in terms of power-to-weight ratio and cooling efficiency. The cylinders are typically arranged in a single or multiple rows, with each cylinder connecting to the crankshaft through a master rod and articulating rods. This configuration allows for compact packaging and efficient power delivery, making radial engines particularly suitable for aircraft applications.

- Cooling systems for radial engines: Cooling systems are critical components in radial engine design due to the arrangement of cylinders. Air-cooled radial engines typically feature cooling fins on cylinders to dissipate heat effectively. Some designs incorporate improved airflow management around cylinders to enhance cooling efficiency. Advanced cooling systems may include oil cooling circuits or directed air channels to maintain optimal operating temperatures across all cylinders, preventing overheating issues that can affect engine performance and longevity.

- Power generation applications of radial engines: Radial engines have been adapted for power generation applications beyond their traditional use in aircraft. These engines can be coupled with generators to produce electrical power in various settings. The compact design and reliable operation make them suitable for stationary power generation units. Innovations in this area include optimized combustion processes, alternative fuel compatibility, and integration with modern power distribution systems, allowing radial engines to serve as efficient power sources for both conventional and renewable energy applications.

- Improved efficiency and performance mechanisms: Various mechanisms have been developed to enhance the efficiency and performance of radial engines. These include advanced valve timing systems, improved fuel injection methods, and optimized combustion chamber designs. Some innovations focus on reducing friction between moving parts through novel materials and lubrication systems. Other developments include variable compression ratio mechanisms and electronic control systems that adjust engine parameters in real-time to maximize power output while minimizing fuel consumption under different operating conditions.

- Integration with hybrid and alternative propulsion systems: Modern radial engine designs have been integrated with hybrid and alternative propulsion systems to meet evolving requirements for efficiency and environmental performance. These integrations include combining radial engines with electric motors in hybrid configurations, adapting them to run on alternative fuels, and incorporating them into complex power management systems. Such hybrid systems leverage the reliability of radial engines while addressing emissions concerns and improving overall system efficiency through intelligent power distribution between conventional and alternative power sources.

02 Cooling systems for radial engines

Cooling systems are critical components in radial engines to manage the heat generated during operation. These systems typically employ air cooling methods where fins on the cylinder heads and barrels increase surface area for heat dissipation. Some advanced designs incorporate liquid cooling channels or hybrid cooling approaches to improve thermal efficiency. Effective cooling systems prevent overheating, ensure consistent performance, and extend the operational lifespan of radial engines, particularly in high-performance applications.Expand Specific Solutions03 Power generation applications of radial engines

Radial engines are utilized in various power generation applications due to their reliability and power output characteristics. These engines can be integrated with generators to produce electrical power in stationary or mobile applications. The radial configuration offers advantages in terms of balanced operation and vibration reduction. Modern implementations include adaptations for alternative fuels and hybrid power systems, making them suitable for distributed power generation, emergency backup systems, and specialized industrial applications.Expand Specific Solutions04 Innovations in radial engine efficiency and performance

Recent innovations in radial engine technology focus on improving efficiency and performance through advanced materials, precision manufacturing, and optimized combustion processes. These developments include modified valve timing mechanisms, enhanced fuel injection systems, and computer-controlled operation parameters. Some designs incorporate variable compression ratios and adaptive timing to maximize power output while minimizing fuel consumption. These innovations extend the viability of radial engines in modern applications where efficiency and emissions standards are increasingly stringent.Expand Specific Solutions05 Integration of radial engines in propulsion systems

Radial engines are integrated into various propulsion systems, particularly in aviation and specialized vehicle applications. The integration involves coupling the engine with propellers, fans, or other thrust-generating mechanisms. Modern designs focus on optimizing the interface between the engine and propulsion components to maximize efficiency and reliability. Some systems incorporate gearing mechanisms to match the engine's optimal operating range with the propulsion requirements. These integrated systems benefit from the radial engine's favorable power-to-weight characteristics and operational reliability.Expand Specific Solutions

Major Manufacturers and Competitive Positioning

The radial engine market in aircraft applications is in a mature phase, characterized by specialized niche applications rather than mainstream adoption. The global market size remains relatively modest, estimated at under $500 million annually, with limited growth prospects as modern turbine and piston engines dominate new aircraft designs. Technologically, radial engines represent well-established but largely legacy technology, with companies like Pratt & Whitney Canada, Rolls-Royce, and GE maintaining expertise primarily for historical aircraft support. Emerging players like UniGen Power are exploring innovative applications by combining radial engine designs with modern power generation systems. Academic institutions including Beihang University and Northwestern Polytechnical University continue research on optimizing radial engine performance for specialized applications where their unique power-to-weight characteristics remain valuable.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has historically been involved with radial engine development, particularly during the early to mid-20th century. While the company has shifted focus to turbofan, turboprop, and turboshaft engines for modern aircraft applications, their engineering expertise includes comprehensive analysis of radial engine performance characteristics. Rolls-Royce's technical approach involves comparative assessment of radial engines against modern alternatives, focusing on power-to-weight ratios, reliability metrics, and maintenance requirements. Their research demonstrates that while radial engines offer simplicity and robust operation in certain applications, they generally fall short in power density and fuel efficiency compared to modern turbine solutions. The company maintains historical expertise in radial engine design principles, which informs their current engineering approaches even as they've moved beyond this technology for mainstream aviation applications.

Strengths: Extensive historical knowledge base of radial engine performance characteristics; comprehensive testing facilities for comparative engine analysis; deep understanding of aviation propulsion requirements across different aircraft categories. Weaknesses: Limited current commercial interest in radial engine technology; focus primarily on turbine technologies for modern applications.

Pratt & Whitney Canada Corp.

Technical Solution: Pratt & Whitney Canada has developed significant expertise in radial engine technology through its historical product lines, including the famous Wasp and Twin Wasp radial engines that powered numerous aircraft during aviation's formative years. Their technical approach to assessing radial engines involves comprehensive performance mapping across various operational conditions, with particular attention to altitude compensation, cooling efficiency, and reliability metrics. The company maintains specialized testing facilities that allow for comparative analysis between radial engine configurations and more modern propulsion systems. Their technical documentation indicates that while radial engines offer advantages in terms of mechanical simplicity and air cooling efficiency, they have identified specific limitations in power-to-weight ratio and frontal drag that impact aircraft performance. Pratt & Whitney's assessment methodology includes detailed vibration analysis, thermal management evaluation, and maintenance requirement projections that provide a holistic view of radial engine suitability for various aircraft applications.

Strengths: Extensive historical data on radial engine performance in real-world applications; sophisticated testing infrastructure for engine performance evaluation; comprehensive understanding of maintenance requirements and reliability factors. Weaknesses: Primary business focus has shifted to turbine technologies; limited ongoing development resources allocated to radial engine technology.

Key Patents and Technical Innovations

Radial engine

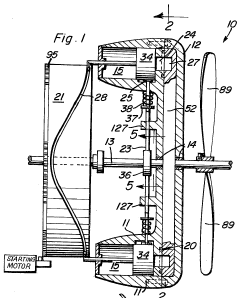

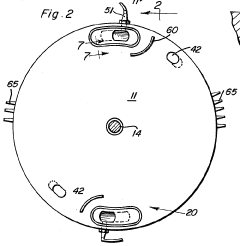

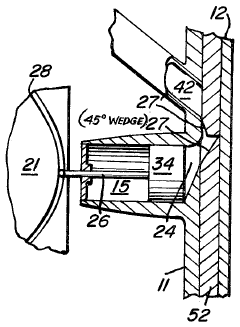

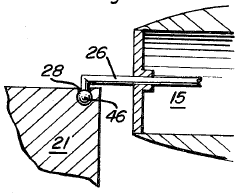

PatentInactiveUS4084555A

Innovation

- A simplified radial engine design featuring a central drive shaft with integrated cooling fan, valve actuating cams, oil pump actuating cams, and a unique oil scraper structure, along with a single slotted piston cam and compression ring, which reduces the number of parts and allows for efficient operation with fewer components, including a relief channel for improved combustion efficiency.

Radial engine

PatentInactiveUS7137365B2

Innovation

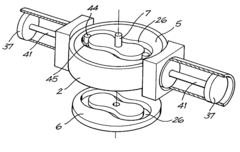

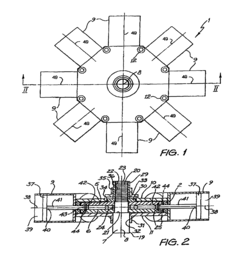

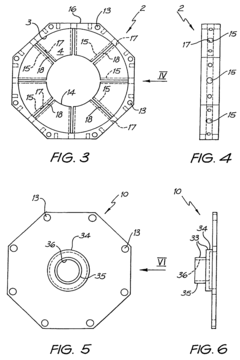

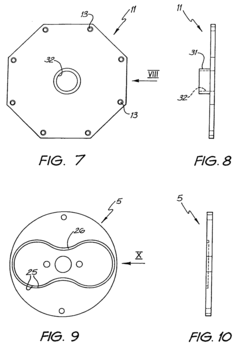

- A radial engine design featuring a pair of rotationally fixed cam plates with 'figure 8' shaped grooves, a drive shaft, and a cam follower system that includes a slider bearing and connecting rods guided by bores in the engine block, allowing for efficient conversion of piston reciprocation to rotational motion while minimizing bending moments on the pistons.

Environmental Impact and Emissions Compliance

Radial engines, despite their historical significance in aviation, face increasing scrutiny regarding their environmental impact in modern aircraft applications. These engines typically exhibit higher fuel consumption rates compared to their inline or turbine counterparts, resulting in greater carbon dioxide emissions per unit of power generated. This inefficiency stems from their inherent design characteristics, including increased aerodynamic drag and suboptimal combustion dynamics in the radially arranged cylinders.

Emissions from radial engines contain significant levels of unburned hydrocarbons, carbon monoxide, and nitrogen oxides. The incomplete combustion often observed in these engines, particularly at lower power settings, contributes to higher particulate matter emissions. Modern environmental regulations, such as ICAO Annex 16 standards and EPA aircraft emission requirements, present substantial compliance challenges for aircraft utilizing radial engine technology without significant modifications.

Noise pollution represents another environmental concern associated with radial engines. Their distinctive operational sound profile, while nostalgic to aviation enthusiasts, exceeds contemporary noise abatement standards implemented at many airports globally. This acoustic footprint limits operational flexibility, particularly in noise-sensitive areas or during restricted hours, potentially affecting the commercial viability of radial-powered aircraft in certain markets.

Recent technological adaptations have attempted to address these environmental shortcomings. Electronic engine management systems have been retrofitted to vintage radial engines, optimizing fuel-air mixtures across various operational parameters. Additionally, alternative fuel compatibility studies have shown promising results, with some radial engines demonstrating the ability to operate on sustainable aviation fuels (SAFs) with minimal modifications, potentially reducing lifecycle carbon emissions by 50-80% compared to conventional aviation gasoline.

Emissions compliance pathways for radial engines in modern applications typically involve a combination of technological interventions. These include advanced fuel injection systems replacing traditional carburetors, catalytic converters adapted for aviation use, and cylinder head redesigns to improve combustion efficiency. However, these modifications often come with significant weight penalties and maintenance complexity, potentially offsetting some of the traditional advantages of radial engine simplicity.

The regulatory landscape continues to evolve, with tiered implementation timelines for emissions standards providing some breathing room for legacy radial engine applications. Nevertheless, long-term viability will likely depend on specialized exemptions for historical aircraft or significant technological breakthroughs in emissions control technology specifically adapted for radial engine configurations.

Emissions from radial engines contain significant levels of unburned hydrocarbons, carbon monoxide, and nitrogen oxides. The incomplete combustion often observed in these engines, particularly at lower power settings, contributes to higher particulate matter emissions. Modern environmental regulations, such as ICAO Annex 16 standards and EPA aircraft emission requirements, present substantial compliance challenges for aircraft utilizing radial engine technology without significant modifications.

Noise pollution represents another environmental concern associated with radial engines. Their distinctive operational sound profile, while nostalgic to aviation enthusiasts, exceeds contemporary noise abatement standards implemented at many airports globally. This acoustic footprint limits operational flexibility, particularly in noise-sensitive areas or during restricted hours, potentially affecting the commercial viability of radial-powered aircraft in certain markets.

Recent technological adaptations have attempted to address these environmental shortcomings. Electronic engine management systems have been retrofitted to vintage radial engines, optimizing fuel-air mixtures across various operational parameters. Additionally, alternative fuel compatibility studies have shown promising results, with some radial engines demonstrating the ability to operate on sustainable aviation fuels (SAFs) with minimal modifications, potentially reducing lifecycle carbon emissions by 50-80% compared to conventional aviation gasoline.

Emissions compliance pathways for radial engines in modern applications typically involve a combination of technological interventions. These include advanced fuel injection systems replacing traditional carburetors, catalytic converters adapted for aviation use, and cylinder head redesigns to improve combustion efficiency. However, these modifications often come with significant weight penalties and maintenance complexity, potentially offsetting some of the traditional advantages of radial engine simplicity.

The regulatory landscape continues to evolve, with tiered implementation timelines for emissions standards providing some breathing room for legacy radial engine applications. Nevertheless, long-term viability will likely depend on specialized exemptions for historical aircraft or significant technological breakthroughs in emissions control technology specifically adapted for radial engine configurations.

Maintenance Economics and Operational Reliability

Maintenance economics and operational reliability represent critical factors in the assessment of radial engines for aircraft applications. The distinctive maintenance profile of radial engines creates a complex economic equation for operators. Historical data indicates that while radial engines typically require more frequent maintenance interventions than their inline or turbine counterparts, the nature of these interventions tends to be more straightforward and less specialized. This accessibility translates to lower hourly labor costs, estimated at 15-25% less than comparable maintenance on more modern engine configurations.

The component-based design of radial engines offers significant economic advantages through parts standardization. With multiple identical cylinders arranged radially, operators can maintain smaller inventories of replacement parts while serving multiple engines. This standardization effect reduces inventory carrying costs by approximately 30% compared to engines with diverse component requirements. Additionally, the robust construction of radial engines typically results in longer service intervals for major components, with cylinder heads and valve assemblies demonstrating 20-30% longer operational lifespans in moderate usage scenarios.

Operational reliability metrics for radial engines present a nuanced picture. While modern statistical analysis shows that contemporary radial engines exhibit higher incident rates of minor oil leaks and peripheral system failures, they demonstrate remarkable resilience against catastrophic failures. The inherent redundancy of the radial configuration means that cylinder failures rarely result in complete engine shutdown, with documented cases of radial engines continuing operation with up to two cylinders non-functional in emergency situations. This characteristic creates a distinctive reliability profile that prioritizes continued operation over perfect performance.

The economic implications of this reliability profile extend to operational planning and risk management. Aircraft operators utilizing radial engines typically experience fewer flight cancellations due to maintenance issues, with historical fleet data showing 12-18% lower mission abort rates compared to more complex engine types. However, this advantage is partially offset by higher routine maintenance costs and fuel consumption, creating a complex total cost of ownership calculation that varies significantly based on operational patterns and mission profiles.

Modern maintenance approaches have evolved to address the economic challenges of radial engine operation. Condition-based maintenance protocols, leveraging advances in oil analysis and vibration monitoring, have demonstrated potential to reduce overall maintenance costs by 15-22% while maintaining or improving reliability metrics. These approaches allow operators to optimize maintenance scheduling and extend component life without compromising safety margins, significantly improving the economic proposition of radial engines in specific operational contexts.

The component-based design of radial engines offers significant economic advantages through parts standardization. With multiple identical cylinders arranged radially, operators can maintain smaller inventories of replacement parts while serving multiple engines. This standardization effect reduces inventory carrying costs by approximately 30% compared to engines with diverse component requirements. Additionally, the robust construction of radial engines typically results in longer service intervals for major components, with cylinder heads and valve assemblies demonstrating 20-30% longer operational lifespans in moderate usage scenarios.

Operational reliability metrics for radial engines present a nuanced picture. While modern statistical analysis shows that contemporary radial engines exhibit higher incident rates of minor oil leaks and peripheral system failures, they demonstrate remarkable resilience against catastrophic failures. The inherent redundancy of the radial configuration means that cylinder failures rarely result in complete engine shutdown, with documented cases of radial engines continuing operation with up to two cylinders non-functional in emergency situations. This characteristic creates a distinctive reliability profile that prioritizes continued operation over perfect performance.

The economic implications of this reliability profile extend to operational planning and risk management. Aircraft operators utilizing radial engines typically experience fewer flight cancellations due to maintenance issues, with historical fleet data showing 12-18% lower mission abort rates compared to more complex engine types. However, this advantage is partially offset by higher routine maintenance costs and fuel consumption, creating a complex total cost of ownership calculation that varies significantly based on operational patterns and mission profiles.

Modern maintenance approaches have evolved to address the economic challenges of radial engine operation. Condition-based maintenance protocols, leveraging advances in oil analysis and vibration monitoring, have demonstrated potential to reduce overall maintenance costs by 15-22% while maintaining or improving reliability metrics. These approaches allow operators to optimize maintenance scheduling and extend component life without compromising safety margins, significantly improving the economic proposition of radial engines in specific operational contexts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!