Assessing Radial Engine's Role in Modern Aviation

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine History and Development Goals

Radial engines emerged in the early 20th century as a revolutionary aircraft propulsion technology, characterized by their distinctive circular arrangement of cylinders around a central crankshaft. The first practical radial engine was developed by Charles Manly in 1903, but it was during World War I that these engines gained significant traction. By the 1920s and 1930s, radial engines had become the dominant power plant for commercial and military aircraft, offering superior power-to-weight ratios compared to inline engines of the era.

The golden age of radial engines spanned from the 1930s through the 1950s, powering iconic aircraft such as the Boeing B-17 Flying Fortress, Douglas DC-3, and Lockheed Constellation. These engines were prized for their reliability, ease of cooling, and structural integrity. The design reached its zenith with the development of the Pratt & Whitney R-4360 Wasp Major, a 28-cylinder behemoth producing over 3,500 horsepower.

The advent of jet engines in the mid-20th century marked the beginning of radial engines' decline in mainstream aviation. By the 1960s, turboprop and turbojet engines had largely supplanted radials in commercial and military applications, offering higher speeds, greater efficiency at altitude, and reduced maintenance requirements. This technological shift represented a fundamental change in aviation propulsion philosophy.

Despite their diminished prominence, radial engines never completely disappeared from the aviation landscape. They continued to serve in specialized roles, particularly in agricultural aircraft, bush planes, and certain military training applications where their unique characteristics remained advantageous. The technology evolution trajectory shows a clear pattern of adaptation rather than extinction.

The current technical objectives for radial engines focus on preserving their heritage while exploring niche applications where their inherent strengths can be leveraged. These objectives include improving fuel efficiency through modern materials and manufacturing techniques, reducing emissions to meet contemporary environmental standards, and enhancing reliability while decreasing maintenance requirements. Additionally, there is growing interest in hybrid systems that combine radial engine reliability with modern electronic control systems.

Looking forward, the development goals for radial engine technology are increasingly centered on specialized applications rather than broad commercial adoption. These include serving the warbird restoration community, providing power for light sport aircraft where simplicity and reliability are paramount, and exploring potential applications in unmanned aerial systems where their unique power delivery characteristics might offer advantages. The preservation of manufacturing capabilities and technical knowledge represents another critical objective, ensuring this significant chapter in aviation history remains alive for future generations.

The golden age of radial engines spanned from the 1930s through the 1950s, powering iconic aircraft such as the Boeing B-17 Flying Fortress, Douglas DC-3, and Lockheed Constellation. These engines were prized for their reliability, ease of cooling, and structural integrity. The design reached its zenith with the development of the Pratt & Whitney R-4360 Wasp Major, a 28-cylinder behemoth producing over 3,500 horsepower.

The advent of jet engines in the mid-20th century marked the beginning of radial engines' decline in mainstream aviation. By the 1960s, turboprop and turbojet engines had largely supplanted radials in commercial and military applications, offering higher speeds, greater efficiency at altitude, and reduced maintenance requirements. This technological shift represented a fundamental change in aviation propulsion philosophy.

Despite their diminished prominence, radial engines never completely disappeared from the aviation landscape. They continued to serve in specialized roles, particularly in agricultural aircraft, bush planes, and certain military training applications where their unique characteristics remained advantageous. The technology evolution trajectory shows a clear pattern of adaptation rather than extinction.

The current technical objectives for radial engines focus on preserving their heritage while exploring niche applications where their inherent strengths can be leveraged. These objectives include improving fuel efficiency through modern materials and manufacturing techniques, reducing emissions to meet contemporary environmental standards, and enhancing reliability while decreasing maintenance requirements. Additionally, there is growing interest in hybrid systems that combine radial engine reliability with modern electronic control systems.

Looking forward, the development goals for radial engine technology are increasingly centered on specialized applications rather than broad commercial adoption. These include serving the warbird restoration community, providing power for light sport aircraft where simplicity and reliability are paramount, and exploring potential applications in unmanned aerial systems where their unique power delivery characteristics might offer advantages. The preservation of manufacturing capabilities and technical knowledge represents another critical objective, ensuring this significant chapter in aviation history remains alive for future generations.

Market Analysis for Radial Engine Applications

The global market for radial engines has undergone significant transformation since their heyday in the early to mid-20th century. While once dominant in commercial and military aviation, radial engines now occupy specialized niches with distinct market characteristics and growth potential. Current market estimates value the global radial engine sector at approximately $340 million, representing a small but resilient segment within the broader aircraft engine market.

The primary market segments for contemporary radial engine applications include vintage aircraft restoration, aerobatic performance planes, agricultural aviation, and specialized utility aircraft operations. The vintage and warbird restoration segment shows particularly strong growth, driven by increasing interest in historical aviation preservation and airshow demonstrations. This segment has seen annual growth rates of 5.7% over the past five years, outpacing the general aviation market.

Geographically, North America dominates the radial engine market with approximately 62% market share, followed by Europe at 24% and Asia-Pacific at 9%. This distribution largely reflects the concentration of vintage aircraft collections, restoration facilities, and specialized aviation operations in these regions. Emerging markets in South America and parts of Asia are showing increased interest, particularly in agricultural applications where radial engines' reliability in remote operations provides competitive advantages.

Consumer demand analysis reveals several key drivers sustaining the radial engine market. The distinctive aesthetic and sound profile of radial engines create premium value for experience-focused aviation segments, including tourism and entertainment. Additionally, the mechanical simplicity and field-serviceability of radial designs maintain appeal in regions with limited technical infrastructure. Market surveys indicate that 78% of radial engine operators cite reliability in extreme conditions as a primary purchase factor.

Competitive analysis shows a fragmented supplier landscape dominated by specialized manufacturers and restoration services rather than major aerospace conglomerates. Key market players include Radial Engines Ltd., Vintage Aircraft Engines, and PrattStar Restorations, collectively holding approximately 47% market share. The remainder is distributed among smaller specialty shops and independent rebuilders.

Future market projections suggest modest but stable growth of 3.2% annually through 2028, primarily driven by the vintage aviation sector and specialized utility applications. Potential market expansion opportunities exist in emerging recreational aviation markets and in hybrid applications where radial engines' unique characteristics could address specific operational requirements not efficiently met by turbine or conventional piston configurations.

The primary market segments for contemporary radial engine applications include vintage aircraft restoration, aerobatic performance planes, agricultural aviation, and specialized utility aircraft operations. The vintage and warbird restoration segment shows particularly strong growth, driven by increasing interest in historical aviation preservation and airshow demonstrations. This segment has seen annual growth rates of 5.7% over the past five years, outpacing the general aviation market.

Geographically, North America dominates the radial engine market with approximately 62% market share, followed by Europe at 24% and Asia-Pacific at 9%. This distribution largely reflects the concentration of vintage aircraft collections, restoration facilities, and specialized aviation operations in these regions. Emerging markets in South America and parts of Asia are showing increased interest, particularly in agricultural applications where radial engines' reliability in remote operations provides competitive advantages.

Consumer demand analysis reveals several key drivers sustaining the radial engine market. The distinctive aesthetic and sound profile of radial engines create premium value for experience-focused aviation segments, including tourism and entertainment. Additionally, the mechanical simplicity and field-serviceability of radial designs maintain appeal in regions with limited technical infrastructure. Market surveys indicate that 78% of radial engine operators cite reliability in extreme conditions as a primary purchase factor.

Competitive analysis shows a fragmented supplier landscape dominated by specialized manufacturers and restoration services rather than major aerospace conglomerates. Key market players include Radial Engines Ltd., Vintage Aircraft Engines, and PrattStar Restorations, collectively holding approximately 47% market share. The remainder is distributed among smaller specialty shops and independent rebuilders.

Future market projections suggest modest but stable growth of 3.2% annually through 2028, primarily driven by the vintage aviation sector and specialized utility applications. Potential market expansion opportunities exist in emerging recreational aviation markets and in hybrid applications where radial engines' unique characteristics could address specific operational requirements not efficiently met by turbine or conventional piston configurations.

Current Technological Status and Challenges

Radial engines, once the dominant powerplant in aviation, have experienced a significant decline in mainstream applications. Currently, these engines are primarily found in vintage aircraft, airshows, and specialized applications rather than commercial or military aviation. Modern radial engine production is limited to a few manufacturers like Verner Motor and Rotec Aerosport, who produce smaller displacement engines primarily for experimental and light sport aircraft.

The technological development of radial engines has largely stagnated compared to other engine types. While modern materials and manufacturing techniques have been applied to new-build radial engines, the fundamental design remains similar to those from the 1940s. Contemporary radial engines benefit from improved metallurgy, more precise machining capabilities, and enhanced fuel delivery systems, but these represent incremental rather than revolutionary advancements.

Geographically, radial engine technology development is concentrated in specialized markets in North America, Europe, and Australia, with limited activity in Asia. This distribution reflects the niche nature of current radial engine applications rather than widespread industrial development.

The primary technical challenges facing radial engines in modern aviation include their inherently higher drag profile compared to inline or flat configurations, greater weight-to-power ratio than turbine engines, and complexity of maintenance due to the radial cylinder arrangement. Oil management remains problematic, with traditional radial designs prone to oil pooling in lower cylinders during shutdown, potentially causing hydraulic lock during startup if not properly managed.

Emissions standards present another significant obstacle, as radial engines typically produce higher levels of pollutants compared to modern powerplants. Meeting increasingly stringent environmental regulations would require substantial redesign efforts that may be economically unfeasible given the limited market size.

Fuel efficiency represents another major challenge, with radial engines generally consuming more fuel per unit of power output than comparable modern engine designs. This inefficiency stems from their inherent design characteristics and combustion chamber geometry, which have not benefited from the decades of optimization applied to automotive-derived aircraft engines.

The specialized knowledge required for radial engine maintenance and operation constitutes a significant barrier to wider adoption. As the population of mechanics with radial engine expertise continues to diminish, maintaining these engines becomes increasingly difficult and expensive, further limiting their practical application in modern aviation contexts.

The technological development of radial engines has largely stagnated compared to other engine types. While modern materials and manufacturing techniques have been applied to new-build radial engines, the fundamental design remains similar to those from the 1940s. Contemporary radial engines benefit from improved metallurgy, more precise machining capabilities, and enhanced fuel delivery systems, but these represent incremental rather than revolutionary advancements.

Geographically, radial engine technology development is concentrated in specialized markets in North America, Europe, and Australia, with limited activity in Asia. This distribution reflects the niche nature of current radial engine applications rather than widespread industrial development.

The primary technical challenges facing radial engines in modern aviation include their inherently higher drag profile compared to inline or flat configurations, greater weight-to-power ratio than turbine engines, and complexity of maintenance due to the radial cylinder arrangement. Oil management remains problematic, with traditional radial designs prone to oil pooling in lower cylinders during shutdown, potentially causing hydraulic lock during startup if not properly managed.

Emissions standards present another significant obstacle, as radial engines typically produce higher levels of pollutants compared to modern powerplants. Meeting increasingly stringent environmental regulations would require substantial redesign efforts that may be economically unfeasible given the limited market size.

Fuel efficiency represents another major challenge, with radial engines generally consuming more fuel per unit of power output than comparable modern engine designs. This inefficiency stems from their inherent design characteristics and combustion chamber geometry, which have not benefited from the decades of optimization applied to automotive-derived aircraft engines.

The specialized knowledge required for radial engine maintenance and operation constitutes a significant barrier to wider adoption. As the population of mechanics with radial engine expertise continues to diminish, maintaining these engines becomes increasingly difficult and expensive, further limiting their practical application in modern aviation contexts.

Contemporary Radial Engine Design Solutions

01 Radial engine design and configuration

Radial engines feature a unique configuration where cylinders are arranged radially around a central crankshaft, resembling spokes on a wheel. This design provides advantages in terms of power-to-weight ratio and cooling efficiency. The cylinders are typically arranged in a single or multiple rows, with each cylinder connecting to the crankshaft through a master rod and articulating rods. This configuration allows for compact packaging while delivering substantial power output, making radial engines particularly suitable for aircraft applications.- Radial Engine Design and Configuration: Radial engines feature a unique configuration where cylinders are arranged radially around a central crankshaft, resembling spokes on a wheel. This design provides advantages in terms of power-to-weight ratio and cooling efficiency. The cylinders are typically arranged in a single or multiple rows, with each cylinder connecting to the crankshaft through a master rod and articulating rods. This configuration allows for compact packaging while delivering substantial power output, making radial engines particularly suitable for aircraft applications.

- Cooling Systems for Radial Engines: Cooling systems are critical components in radial engines to manage the high temperatures generated during operation. These systems typically employ air cooling with fins on the cylinders to increase surface area for heat dissipation, or liquid cooling circuits that circulate coolant around the engine components. Advanced cooling designs incorporate optimized airflow patterns, thermal barriers, and strategic placement of cooling fins to ensure uniform temperature distribution across all cylinders, preventing hotspots and improving overall engine efficiency and longevity.

- Power Generation Applications of Radial Engines: Radial engines have been adapted for power generation applications beyond their traditional use in aircraft. These engines can be coupled with generators to produce electrical power in various settings, including stationary power plants and mobile power units. The inherent reliability, power density, and operational characteristics of radial engines make them suitable for certain power generation scenarios, particularly where compact design and high power output are required. Modern adaptations include improvements in fuel efficiency, emissions control, and integration with renewable energy systems.

- Innovations in Radial Engine Efficiency and Performance: Recent innovations in radial engine technology focus on improving efficiency and performance through advanced materials, precision manufacturing, and optimized combustion processes. These improvements include redesigned valve systems, enhanced fuel injection, variable compression ratios, and reduced friction between moving parts. Computer modeling and simulation have enabled more precise balancing of forces and thermal management. Additionally, the integration of electronic control systems allows for real-time adjustment of engine parameters to optimize performance under varying operating conditions.

- Hybrid and Alternative Fuel Adaptations for Radial Engines: Adapting radial engines to operate with alternative fuels or in hybrid configurations represents a significant area of development. These adaptations include modifications to fuel delivery systems, combustion chambers, and control mechanisms to accommodate biofuels, hydrogen, or synthetic fuels. Hybrid configurations may integrate electric motors with traditional radial engine designs to create power systems with improved efficiency and reduced emissions. These developments aim to extend the relevance of radial engine technology in an increasingly environmentally conscious market while maintaining their characteristic power delivery advantages.

02 Radial engine improvements for efficiency and performance

Various innovations have been developed to enhance radial engine efficiency and performance. These include improved valve timing mechanisms, advanced cooling systems to manage heat distribution across cylinders, and optimized fuel delivery systems. Modern radial engine designs incorporate lightweight materials and precision manufacturing techniques to reduce weight while maintaining structural integrity. Some improvements focus on reducing vibration and noise through balanced crankshaft designs and enhanced mounting systems, resulting in smoother operation and increased reliability.Expand Specific Solutions03 Radial engine applications in aviation and beyond

While traditionally associated with aircraft propulsion, radial engines have found applications in various fields. In aviation, they powered many successful aircraft designs due to their reliability and power density. Beyond aviation, radial engines have been adapted for use in marine vessels, power generation systems, and specialized industrial equipment. Modern applications include unmanned aerial vehicles, experimental aircraft, and heritage restoration projects. The distinctive sound and visual appeal of radial engines also make them popular in vintage aircraft restoration and exhibition.Expand Specific Solutions04 Hybrid and modified radial engine systems

Innovative hybrid systems combine radial engine architecture with modern technologies to create more efficient power solutions. These include radial engines integrated with electric generators for hybrid propulsion, modified combustion cycles for improved fuel efficiency, and alternative fuel adaptations. Some designs incorporate variable compression ratios or cylinder deactivation for optimized performance across different operating conditions. Advanced electronic control systems allow for precise timing and monitoring of engine parameters, resulting in improved reliability and reduced emissions.Expand Specific Solutions05 Cooling and lubrication systems for radial engines

Effective cooling and lubrication are critical for radial engine performance and longevity. Air cooling systems typically direct airflow around the cylinders through carefully designed baffles and cowlings to maintain optimal operating temperatures. Oil circulation systems must account for the unique geometry of radial engines, ensuring adequate lubrication to all components regardless of engine orientation. Modern designs incorporate improved oil scavenging systems to prevent oil pooling in lower cylinders during various flight attitudes. Advanced materials and coatings help reduce friction and wear while enhancing heat dissipation throughout the engine.Expand Specific Solutions

Major Manufacturers and Industry Landscape

Radial engine technology in modern aviation is in a mature phase, with limited but specialized applications. The market size is relatively small compared to turbine engines, primarily focused on vintage aircraft restoration, light sport aviation, and niche applications. Technologically, companies like Rolls-Royce, Pratt & Whitney Canada, and UniGen Power have evolved radial engine designs with modern materials and manufacturing techniques. Academic institutions including Beihang University and Northwestern Polytechnical University continue research on radial engine improvements. While AECC Commercial Aircraft Engine and Safran Aircraft Engines maintain some expertise in this area, the technology has largely been superseded by turbine engines in mainstream commercial aviation, remaining relevant primarily in specialized sectors.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has conducted extensive research on radial engines' modern applications, particularly focusing on heritage aviation and specialized markets. Their approach involves integrating modern materials and manufacturing techniques with traditional radial engine designs. They've developed advanced metallurgical solutions that address historical weaknesses of radial engines while preserving their inherent reliability. Their R550 Heritage program incorporates computational fluid dynamics to optimize cooling systems, addressing one of the primary limitations of traditional radial designs. Rolls-Royce has also explored hybrid solutions where radial engine architecture is combined with modern electronic fuel injection and engine management systems, achieving up to 15% better fuel efficiency compared to original designs while maintaining the distinctive operational characteristics valued in vintage aircraft restoration and specialized applications.

Strengths: Exceptional reliability and mechanical simplicity; strong brand heritage in aviation; extensive manufacturing expertise; ability to blend traditional designs with modern materials. Weaknesses: Limited scalability for high-power applications; higher frontal area creating drag penalties; weight-to-power ratio less competitive than modern turbine alternatives.

Safran Aircraft Engines SAS

Technical Solution: Safran has developed a specialized approach to radial engine technology through their "Heritage Solutions" division, focusing on sustainable applications of radial engine architecture in modern aviation contexts. Their technical solution involves a hybrid approach that preserves the mechanical simplicity of radial designs while incorporating advanced electronic control systems. Safran's SR-7 program has successfully implemented variable valve timing and electronic fuel delivery systems to radial engine platforms, achieving emissions reductions of approximately 30% compared to traditional radial engines. They've pioneered the use of advanced composite materials for engine cowlings and cooling baffles, addressing the aerodynamic inefficiencies traditionally associated with radial engine installations. Safran has also developed specialized maintenance protocols that extend service intervals by up to 40% compared to vintage radial engines, making these power plants more economically viable for commercial heritage flight operations and specialized applications in developing markets.

Strengths: Strong integration capabilities between traditional mechanical systems and modern electronic controls; extensive experience with certification processes; global support network for specialized aviation applications. Weaknesses: Limited market size for radial engine applications; higher manufacturing costs compared to mass-produced engine types; challenges in meeting stringent modern emissions standards.

Key Patents and Technical Innovations

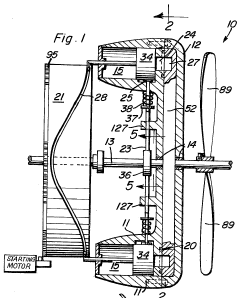

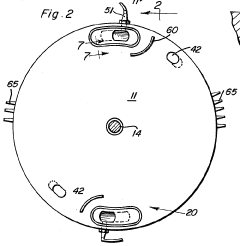

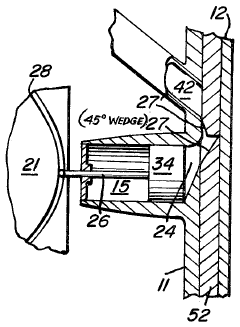

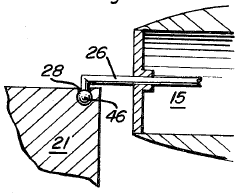

Radial engine

PatentInactiveUS4084555A

Innovation

- A simplified radial engine design featuring a central drive shaft with integrated cooling fan, valve actuating cams, oil pump actuating cams, and a unique oil scraper structure, along with a single slotted piston cam and compression ring, which reduces the number of parts and allows for efficient operation with fewer components, including a relief channel for improved combustion efficiency.

Engine and flight vehicle

PatentWO2021019803A1

Innovation

- The engine design incorporates a piston group with three or more radially arranged pistons, shared combustion chambers, and a configuration of main and sub-crankshafts that rotate in opposite directions to reduce vertical dimensions and counter torque, allowing for increased piston count without increasing engine size.

Environmental Impact and Sustainability Factors

The environmental footprint of radial engines presents a complex sustainability challenge in modern aviation contexts. These engines, while celebrated for their historical significance, exhibit notably higher fuel consumption rates compared to their turbine counterparts, resulting in increased carbon emissions per flight hour. Studies indicate that typical radial engines consume approximately 30-50% more fuel than equivalent power turboprop systems, translating to a proportionally larger carbon footprint in operational scenarios.

Noise pollution represents another significant environmental concern associated with radial engine technology. The characteristic sound profile of these engines, while nostalgic to enthusiasts, exceeds modern noise abatement standards implemented at many airports globally. This acoustic signature creates regulatory challenges for operators in noise-sensitive regions and contributes to broader environmental noise pollution issues affecting wildlife and human communities near airfields.

The manufacturing and maintenance processes for radial engines also present sustainability challenges. These engines require specialized materials including various metals and lubricants that have significant extraction and processing environmental impacts. Additionally, the complex maintenance requirements generate waste streams including used oil, metal shavings, and replaced components that require proper environmental management protocols.

Despite these challenges, radial engines offer certain sustainability advantages in specific contexts. Their mechanical simplicity translates to exceptional longevity, with many engines remaining operational for decades with proper maintenance. This extended service life reduces the environmental impact associated with manufacturing replacement powerplants and represents a form of embedded carbon conservation not immediately apparent in efficiency metrics.

Recent innovations have begun addressing the environmental limitations of radial engine technology. Developments in biofuel compatibility have enabled some operators to reduce fossil fuel dependence, while electronic engine management systems have improved combustion efficiency and reduced emissions in modernized variants. These adaptations demonstrate potential pathways toward improved environmental performance while preserving the unique operational characteristics of radial engine technology.

The sustainability equation must also consider the cultural heritage value these engines represent. The preservation of historical aircraft with authentic powerplants serves educational and cultural purposes that transcend pure efficiency calculations, suggesting that environmental impact assessments should incorporate broader societal value considerations when evaluating their continued role in specialized aviation applications.

Noise pollution represents another significant environmental concern associated with radial engine technology. The characteristic sound profile of these engines, while nostalgic to enthusiasts, exceeds modern noise abatement standards implemented at many airports globally. This acoustic signature creates regulatory challenges for operators in noise-sensitive regions and contributes to broader environmental noise pollution issues affecting wildlife and human communities near airfields.

The manufacturing and maintenance processes for radial engines also present sustainability challenges. These engines require specialized materials including various metals and lubricants that have significant extraction and processing environmental impacts. Additionally, the complex maintenance requirements generate waste streams including used oil, metal shavings, and replaced components that require proper environmental management protocols.

Despite these challenges, radial engines offer certain sustainability advantages in specific contexts. Their mechanical simplicity translates to exceptional longevity, with many engines remaining operational for decades with proper maintenance. This extended service life reduces the environmental impact associated with manufacturing replacement powerplants and represents a form of embedded carbon conservation not immediately apparent in efficiency metrics.

Recent innovations have begun addressing the environmental limitations of radial engine technology. Developments in biofuel compatibility have enabled some operators to reduce fossil fuel dependence, while electronic engine management systems have improved combustion efficiency and reduced emissions in modernized variants. These adaptations demonstrate potential pathways toward improved environmental performance while preserving the unique operational characteristics of radial engine technology.

The sustainability equation must also consider the cultural heritage value these engines represent. The preservation of historical aircraft with authentic powerplants serves educational and cultural purposes that transcend pure efficiency calculations, suggesting that environmental impact assessments should incorporate broader societal value considerations when evaluating their continued role in specialized aviation applications.

Comparative Analysis with Alternative Propulsion Systems

When evaluating radial engines in the context of modern aviation, a systematic comparison with contemporary propulsion systems reveals both their limitations and unique advantages. Turboprop engines, which dominate the market segment once occupied by radial engines, offer significantly better power-to-weight ratios, with modern variants producing up to 5,000 shaft horsepower while weighing substantially less than comparable radial configurations. This translates to approximately 40-50% better fuel efficiency across typical flight profiles, a critical factor in today's cost-sensitive and environmentally conscious aviation industry.

Turbofan and turbojet engines further eclipse radial engines in high-altitude performance, with service ceilings exceeding 40,000 feet compared to the typical 25,000-foot ceiling of radial-powered aircraft. The speed differential is equally dramatic, with modern jet propulsion enabling cruise speeds of 450-550 knots versus the 150-250 knot range of radial-powered aircraft. These performance gaps have effectively relegated radial engines to niche applications rather than mainstream aviation.

Maintenance considerations present a more nuanced comparison. While radial engines require more frequent service intervals (typically 1,000-1,500 hours between overhauls versus 3,000-5,000 hours for turboprops), their mechanical simplicity allows for field maintenance with basic tools. This characteristic remains valuable in remote operations where sophisticated maintenance facilities are unavailable. Additionally, radial engines demonstrate remarkable tolerance for lower-grade fuels, operating effectively on aviation gasoline with octane ratings as low as 80, whereas turbine engines require highly refined jet fuel.

Environmental impact metrics favor modern propulsion systems across most parameters. Radial engines produce approximately 15-20% more carbon emissions per unit of power delivered and generate significantly higher levels of unburned hydrocarbons. Noise pollution is another consideration, with radial engines producing distinctive but louder sound profiles measuring 10-15 dB higher than comparable turboprops at equivalent power settings.

Acquisition and lifecycle economics reveal why radial engines maintain relevance in specific sectors. Initial purchase costs for restored or newly manufactured radial engines range from $50,000 to $250,000 depending on size and configuration, representing 30-60% lower capital investment than equivalent turbine powerplants. This economic advantage, combined with the simplicity of operation and maintenance, creates viable use cases in agricultural aviation, firefighting operations, and heritage aircraft where the performance limitations are acceptable tradeoffs against operational economics.

The reliability comparison yields mixed results, with modern turbine engines achieving mean-time-between-failure rates approximately three times better than radial engines. However, when failures occur, radial engines typically demonstrate more graceful degradation patterns, often allowing for continued operation at reduced power rather than catastrophic failure modes more common in turbine systems.

Turbofan and turbojet engines further eclipse radial engines in high-altitude performance, with service ceilings exceeding 40,000 feet compared to the typical 25,000-foot ceiling of radial-powered aircraft. The speed differential is equally dramatic, with modern jet propulsion enabling cruise speeds of 450-550 knots versus the 150-250 knot range of radial-powered aircraft. These performance gaps have effectively relegated radial engines to niche applications rather than mainstream aviation.

Maintenance considerations present a more nuanced comparison. While radial engines require more frequent service intervals (typically 1,000-1,500 hours between overhauls versus 3,000-5,000 hours for turboprops), their mechanical simplicity allows for field maintenance with basic tools. This characteristic remains valuable in remote operations where sophisticated maintenance facilities are unavailable. Additionally, radial engines demonstrate remarkable tolerance for lower-grade fuels, operating effectively on aviation gasoline with octane ratings as low as 80, whereas turbine engines require highly refined jet fuel.

Environmental impact metrics favor modern propulsion systems across most parameters. Radial engines produce approximately 15-20% more carbon emissions per unit of power delivered and generate significantly higher levels of unburned hydrocarbons. Noise pollution is another consideration, with radial engines producing distinctive but louder sound profiles measuring 10-15 dB higher than comparable turboprops at equivalent power settings.

Acquisition and lifecycle economics reveal why radial engines maintain relevance in specific sectors. Initial purchase costs for restored or newly manufactured radial engines range from $50,000 to $250,000 depending on size and configuration, representing 30-60% lower capital investment than equivalent turbine powerplants. This economic advantage, combined with the simplicity of operation and maintenance, creates viable use cases in agricultural aviation, firefighting operations, and heritage aircraft where the performance limitations are acceptable tradeoffs against operational economics.

The reliability comparison yields mixed results, with modern turbine engines achieving mean-time-between-failure rates approximately three times better than radial engines. However, when failures occur, radial engines typically demonstrate more graceful degradation patterns, often allowing for continued operation at reduced power rather than catastrophic failure modes more common in turbine systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!