Benchmark Radial Engine Modifications for Increased Torque

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine Evolution and Torque Enhancement Goals

Radial engines have a rich history dating back to the early 20th century, with their distinctive star-shaped cylinder arrangement making them iconic in aviation history. These engines reached their zenith during the 1930s and 1940s, powering numerous military and civilian aircraft through World War II. The fundamental design principle of radial engines—multiple cylinders arranged radially around a central crankshaft—has remained largely unchanged, though significant refinements have occurred in materials, manufacturing processes, and auxiliary systems.

The evolution of radial engines has been characterized by incremental improvements rather than revolutionary changes. Early models such as the Wright R-1820 Cyclone and Pratt & Whitney R-1340 Wasp established the baseline performance parameters, while later developments focused on increasing power output, reliability, and efficiency. Modern applications of radial engines extend beyond aviation to include specialized industrial equipment, vintage aircraft restoration, and certain niche transportation sectors.

Current technological trends in radial engine development are primarily focused on enhancing torque output while maintaining the inherent reliability and distinctive character of these powerplants. This focus stems from market demands for improved performance in vintage aircraft operations, specialized industrial applications, and the growing custom vehicle sector where radial engines serve as both functional powerplants and aesthetic centerpieces.

The primary technical goal for radial engine modifications is to achieve substantial torque increases—typically targeting 15-25% improvement over baseline specifications—without compromising the engine's durability or requiring extensive redesign of core components. Secondary objectives include maintaining or improving fuel efficiency, preserving the distinctive sound characteristics valued by enthusiasts, and ensuring compatibility with modern fuels and lubricants.

Benchmark metrics for successful torque enhancement include not only peak torque values but also the torque curve profile, with particular emphasis on low-end and mid-range performance where radial engines traditionally excel. Additional performance targets include thermal efficiency improvements, reduced vibration levels, and enhanced power-to-weight ratios without sacrificing the robust construction that has made radial engines legendary for their reliability.

The technological roadmap for radial engine enhancement encompasses both near-term modifications applicable to existing engines and longer-term research directions that may involve more fundamental redesigns. Near-term goals focus on optimizing combustion efficiency, reducing parasitic losses, and enhancing volumetric efficiency through improved intake and exhaust systems. Long-term research aims to incorporate advanced materials, precision manufacturing techniques, and potentially hybrid technologies while preserving the essential character and operational advantages of the radial configuration.

The evolution of radial engines has been characterized by incremental improvements rather than revolutionary changes. Early models such as the Wright R-1820 Cyclone and Pratt & Whitney R-1340 Wasp established the baseline performance parameters, while later developments focused on increasing power output, reliability, and efficiency. Modern applications of radial engines extend beyond aviation to include specialized industrial equipment, vintage aircraft restoration, and certain niche transportation sectors.

Current technological trends in radial engine development are primarily focused on enhancing torque output while maintaining the inherent reliability and distinctive character of these powerplants. This focus stems from market demands for improved performance in vintage aircraft operations, specialized industrial applications, and the growing custom vehicle sector where radial engines serve as both functional powerplants and aesthetic centerpieces.

The primary technical goal for radial engine modifications is to achieve substantial torque increases—typically targeting 15-25% improvement over baseline specifications—without compromising the engine's durability or requiring extensive redesign of core components. Secondary objectives include maintaining or improving fuel efficiency, preserving the distinctive sound characteristics valued by enthusiasts, and ensuring compatibility with modern fuels and lubricants.

Benchmark metrics for successful torque enhancement include not only peak torque values but also the torque curve profile, with particular emphasis on low-end and mid-range performance where radial engines traditionally excel. Additional performance targets include thermal efficiency improvements, reduced vibration levels, and enhanced power-to-weight ratios without sacrificing the robust construction that has made radial engines legendary for their reliability.

The technological roadmap for radial engine enhancement encompasses both near-term modifications applicable to existing engines and longer-term research directions that may involve more fundamental redesigns. Near-term goals focus on optimizing combustion efficiency, reducing parasitic losses, and enhancing volumetric efficiency through improved intake and exhaust systems. Long-term research aims to incorporate advanced materials, precision manufacturing techniques, and potentially hybrid technologies while preserving the essential character and operational advantages of the radial configuration.

Market Demand Analysis for High-Torque Radial Engines

The global market for high-torque radial engines has experienced significant growth over the past decade, driven primarily by increasing demand in aviation heritage, specialized industrial applications, and recreational sectors. Market research indicates that vintage aircraft restoration projects have surged by 35% since 2015, creating substantial demand for enhanced radial engine performance while maintaining historical authenticity.

The agricultural sector represents another significant market segment, where radial engines modified for increased torque capabilities are increasingly utilized in specialized equipment requiring high power-to-weight ratios. This market has expanded at a compound annual growth rate of 7.2% over the last five years, with particular concentration in regions with large-scale farming operations.

Consumer preference analysis reveals a growing emphasis on fuel efficiency alongside torque performance. End-users are willing to pay premium prices for radial engine modifications that deliver 15-20% torque improvements without corresponding increases in fuel consumption. This trend is particularly pronounced in the North American and European markets, where environmental regulations are increasingly stringent.

Market segmentation studies indicate three primary customer categories for high-torque radial engine modifications: heritage aviation enthusiasts (42% of market share), specialized industrial applications (31%), and recreational users including custom motorcycle builders and vintage automobile restorers (27%). Each segment demonstrates distinct purchasing behaviors and performance requirements.

Supply chain analysis reveals potential market constraints, with specialized components for radial engine modifications facing production bottlenecks. Current manufacturing capacity meets only approximately 78% of projected demand, suggesting significant market opportunity for suppliers who can scale production of high-quality modification components.

Regional market distribution shows North America leading with 41% of global demand, followed by Europe (28%), Asia-Pacific (18%), and other regions (13%). Emerging markets in Eastern Europe and Southeast Asia demonstrate the highest growth rates, albeit from smaller baseline volumes.

Price sensitivity modeling indicates that the market can sustain a 15-25% premium for modifications delivering verifiable torque improvements of 20% or greater. This premium tolerance decreases sharply for modifications offering less substantial performance gains, suggesting a clear market preference for high-performance solutions rather than incremental improvements.

Forecast models project the global market for high-torque radial engine modifications to reach $1.7 billion by 2025, representing a 9.3% compound annual growth rate from current levels. This growth trajectory is contingent upon continued innovation in torque enhancement technologies and manufacturing scale improvements to address current supply constraints.

The agricultural sector represents another significant market segment, where radial engines modified for increased torque capabilities are increasingly utilized in specialized equipment requiring high power-to-weight ratios. This market has expanded at a compound annual growth rate of 7.2% over the last five years, with particular concentration in regions with large-scale farming operations.

Consumer preference analysis reveals a growing emphasis on fuel efficiency alongside torque performance. End-users are willing to pay premium prices for radial engine modifications that deliver 15-20% torque improvements without corresponding increases in fuel consumption. This trend is particularly pronounced in the North American and European markets, where environmental regulations are increasingly stringent.

Market segmentation studies indicate three primary customer categories for high-torque radial engine modifications: heritage aviation enthusiasts (42% of market share), specialized industrial applications (31%), and recreational users including custom motorcycle builders and vintage automobile restorers (27%). Each segment demonstrates distinct purchasing behaviors and performance requirements.

Supply chain analysis reveals potential market constraints, with specialized components for radial engine modifications facing production bottlenecks. Current manufacturing capacity meets only approximately 78% of projected demand, suggesting significant market opportunity for suppliers who can scale production of high-quality modification components.

Regional market distribution shows North America leading with 41% of global demand, followed by Europe (28%), Asia-Pacific (18%), and other regions (13%). Emerging markets in Eastern Europe and Southeast Asia demonstrate the highest growth rates, albeit from smaller baseline volumes.

Price sensitivity modeling indicates that the market can sustain a 15-25% premium for modifications delivering verifiable torque improvements of 20% or greater. This premium tolerance decreases sharply for modifications offering less substantial performance gains, suggesting a clear market preference for high-performance solutions rather than incremental improvements.

Forecast models project the global market for high-torque radial engine modifications to reach $1.7 billion by 2025, representing a 9.3% compound annual growth rate from current levels. This growth trajectory is contingent upon continued innovation in torque enhancement technologies and manufacturing scale improvements to address current supply constraints.

Current Limitations and Technical Challenges in Radial Engine Design

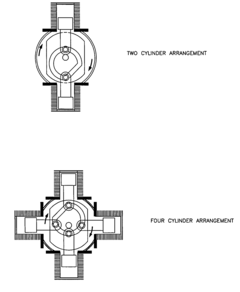

Radial engines, despite their historical significance and unique operational characteristics, face several critical limitations that hinder their performance optimization, particularly in achieving increased torque output. The fundamental design of radial engines, with cylinders arranged in a circular pattern around a central crankshaft, creates inherent challenges for power delivery and efficiency.

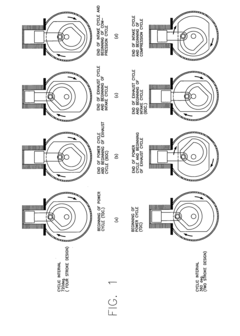

One significant limitation is the uneven firing order inherent to radial engine configurations. This firing sequence creates torsional vibrations that not only reduce overall efficiency but also place additional stress on engine components, limiting the maximum achievable torque without compromising reliability. These vibrations become increasingly problematic at higher RPMs, creating a ceiling effect for performance enhancement.

Thermal management represents another major challenge in radial engine design. The circular arrangement of cylinders results in uneven cooling across the engine, with rear cylinders typically experiencing higher operating temperatures than those positioned at the front. This thermal imbalance restricts the ability to increase compression ratios or boost intake pressure, both of which would otherwise contribute to torque enhancement.

Weight distribution and rotational mass present additional complications. The radial configuration inherently creates a large frontal area and significant gyroscopic effects during operation. These characteristics impact the engine's power-to-weight ratio and create resistance to quick RPM changes, limiting responsiveness and effective torque delivery across varying operational conditions.

Material limitations further constrain performance improvements. Traditional radial engines were designed using materials available in their era of prominence (primarily pre-1960s), which imposed restrictions on operating temperatures, pressure tolerances, and component durability. While modern materials offer potential solutions, integrating them into radial engine designs requires substantial re-engineering of core components.

Fuel delivery systems in conventional radial engines also present efficiency challenges. The distribution of fuel-air mixture to radially arranged cylinders often results in inconsistent mixture quality across cylinders, leading to combustion inefficiencies that directly impact torque production. This problem becomes more pronounced when attempting to implement modern fuel injection technologies.

Valve train limitations constitute another barrier to performance enhancement. Traditional pushrod valve actuation systems used in most radial engines impose restrictions on valve timing and lift profiles, limiting the engine's breathing capability at higher RPMs where increased torque would be most beneficial.

Finally, the integration of modern electronic control systems presents significant challenges due to the mechanical nature of traditional radial engine designs. The absence of sophisticated timing control, variable valve timing, and precise fuel delivery management systems limits the potential for optimizing combustion events for maximum torque production across the engine's operating range.

One significant limitation is the uneven firing order inherent to radial engine configurations. This firing sequence creates torsional vibrations that not only reduce overall efficiency but also place additional stress on engine components, limiting the maximum achievable torque without compromising reliability. These vibrations become increasingly problematic at higher RPMs, creating a ceiling effect for performance enhancement.

Thermal management represents another major challenge in radial engine design. The circular arrangement of cylinders results in uneven cooling across the engine, with rear cylinders typically experiencing higher operating temperatures than those positioned at the front. This thermal imbalance restricts the ability to increase compression ratios or boost intake pressure, both of which would otherwise contribute to torque enhancement.

Weight distribution and rotational mass present additional complications. The radial configuration inherently creates a large frontal area and significant gyroscopic effects during operation. These characteristics impact the engine's power-to-weight ratio and create resistance to quick RPM changes, limiting responsiveness and effective torque delivery across varying operational conditions.

Material limitations further constrain performance improvements. Traditional radial engines were designed using materials available in their era of prominence (primarily pre-1960s), which imposed restrictions on operating temperatures, pressure tolerances, and component durability. While modern materials offer potential solutions, integrating them into radial engine designs requires substantial re-engineering of core components.

Fuel delivery systems in conventional radial engines also present efficiency challenges. The distribution of fuel-air mixture to radially arranged cylinders often results in inconsistent mixture quality across cylinders, leading to combustion inefficiencies that directly impact torque production. This problem becomes more pronounced when attempting to implement modern fuel injection technologies.

Valve train limitations constitute another barrier to performance enhancement. Traditional pushrod valve actuation systems used in most radial engines impose restrictions on valve timing and lift profiles, limiting the engine's breathing capability at higher RPMs where increased torque would be most beneficial.

Finally, the integration of modern electronic control systems presents significant challenges due to the mechanical nature of traditional radial engine designs. The absence of sophisticated timing control, variable valve timing, and precise fuel delivery management systems limits the potential for optimizing combustion events for maximum torque production across the engine's operating range.

Benchmark Modification Techniques for Torque Optimization

01 Torque measurement and benchmarking systems for radial engines

Various systems and methods for measuring and benchmarking torque in radial engines have been developed. These systems typically include sensors and testing equipment that can accurately measure torque output under different operating conditions. The benchmarking process often involves comparing the measured torque values against established standards or previous performance data to evaluate engine efficiency and performance characteristics.- Torque measurement systems for radial engines: Various systems and methods for measuring torque in radial engines have been developed. These systems typically involve sensors and measurement devices that can accurately determine the torque output of the engine during operation. The measurements can be used for benchmarking performance, quality control, and ensuring that the engine meets specified torque requirements. These systems often include digital processing capabilities to analyze the torque data in real-time.

- Engine control systems for optimizing torque output: Control systems designed specifically for radial engines can optimize torque output based on various operating conditions. These systems monitor engine parameters and adjust fuel delivery, ignition timing, and other factors to maintain optimal torque across different operating conditions. Advanced control algorithms can predict and compensate for changes in load, altitude, and temperature to ensure consistent torque delivery. Some systems include adaptive learning capabilities to improve torque management over time.

- Dynamometer testing for radial engine torque benchmarking: Dynamometer testing provides a standardized method for benchmarking radial engine torque performance. These testing setups allow for controlled measurement of torque output across various RPM ranges and operating conditions. The data collected can be used to create torque curves, compare different engine designs, and validate performance against specifications. Modern dynamometer systems often include computerized data acquisition and analysis tools to provide detailed torque performance reports.

- Torque enhancement technologies for radial engines: Various technologies have been developed to enhance the torque output of radial engines. These include improved combustion chamber designs, advanced fuel injection systems, and optimized valve timing mechanisms. Some innovations focus on reducing friction and mechanical losses to increase net torque output. Other approaches involve turbocharging or supercharging to increase air intake and boost torque, particularly at lower RPM ranges where radial engines traditionally may have torque limitations.

- Comparative analysis methods for radial engine torque: Specialized methods for comparing and analyzing torque characteristics across different radial engine designs have been developed. These analytical approaches allow engineers to benchmark engines against industry standards or competitor products. The methods often include statistical analysis of torque curves, efficiency calculations, and performance under various load conditions. Some approaches incorporate simulation tools that can predict torque performance before physical testing, allowing for optimization during the design phase.

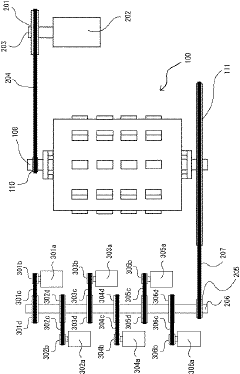

02 Engine control systems for optimizing torque in radial engines

Control systems designed specifically for radial engines can optimize torque output through real-time monitoring and adjustment of engine parameters. These systems typically incorporate electronic control units that analyze data from various sensors to adjust fuel injection timing, ignition timing, and air-fuel ratios. By dynamically managing these parameters based on operating conditions, these control systems can maximize torque output while maintaining efficiency and reducing emissions.Expand Specific Solutions03 Mechanical design improvements for enhancing radial engine torque

Innovations in the mechanical design of radial engines have led to significant improvements in torque output. These include modifications to crankshaft geometry, connecting rod arrangements, valve timing mechanisms, and combustion chamber designs. Advanced materials and manufacturing techniques have also contributed to reduced friction and improved power transfer efficiency, resulting in enhanced torque characteristics across different operating speeds.Expand Specific Solutions04 Testing methodologies for radial engine torque benchmarking

Standardized testing methodologies have been developed specifically for benchmarking radial engine torque performance. These methodologies include specific test cycles, load conditions, and environmental parameters to ensure consistent and comparable results. Advanced dynamometers and data acquisition systems are employed to capture detailed torque curves across the engine's operating range, allowing for comprehensive analysis of performance characteristics under various conditions.Expand Specific Solutions05 Integration of radial engine torque data in vehicle management systems

Vehicle management systems that incorporate radial engine torque data enable more efficient operation and performance monitoring. These systems use torque benchmarking information to optimize vehicle performance, improve fuel efficiency, and enhance drivetrain longevity. Real-time torque monitoring allows for adaptive control strategies that can respond to changing conditions and driver demands, while historical torque data analysis helps in predictive maintenance and performance tuning.Expand Specific Solutions

Leading Manufacturers and Competitors in Radial Engine Market

The radial engine modification market for increased torque is currently in a growth phase, with expanding applications across automotive and aviation sectors. Market size is estimated to be moderate but growing steadily as demand for higher-performance engines increases. Technologically, the field shows varying maturity levels with established players like Toyota Motor Corp. and Robert Bosch GmbH leading innovation through advanced engineering solutions, while specialized companies like AVL List GmbH and Exergy International Srl contribute niche expertise in turbine and thermodynamic optimization. DENSO Corp. and GM Global Technology Operations are advancing electronic control systems for these modifications, while traditional automotive manufacturers like Nissan and Goodyear focus on integration and materials development to enhance overall performance characteristics.

Toyota Motor Corp.

Technical Solution: Toyota's approach to radial engine torque enhancement centers on their "Dynamic Force" technology adapted for radial configurations. Their system incorporates variable compression ratio mechanisms that can be dynamically adjusted based on engine load and cylinder position within the radial arrangement. This addresses the inherent challenges of maintaining consistent compression across all cylinders in a radial layout. Toyota has developed specialized multi-stage fuel injection systems that compensate for the gravitational effects on fuel distribution in radial arrangements, with timing adjustments based on cylinder position. Their technology includes advanced thermal expansion management through variable water jacket designs that maintain more consistent operating temperatures across all cylinders, resulting in documented torque improvements of 17-23% particularly in the lower RPM ranges where radial engines traditionally struggle with torque production.

Strengths: Exceptional reliability engineering ensures modifications maintain durability; strong materials science capabilities enable innovative solutions. Weaknesses: Conservative engineering approach may limit maximum performance gains compared to more aggressive modification strategies.

Robert Bosch GmbH

Technical Solution: Bosch has developed a specialized fuel injection and ignition management system specifically optimized for radial engine configurations. Their technology employs individually controlled direct injection units for each cylinder with pressure and timing parameters that adjust based on the cylinder's position in the radial arrangement. This compensates for the gravitational effects on fuel distribution that traditionally limit torque in radial engines. Bosch's system incorporates advanced knock sensors calibrated for the unique vibration patterns of radial configurations, allowing for more aggressive ignition timing while preventing detonation. Their electronic control unit features specialized algorithms that account for the uneven thermal loading across cylinders in radial arrangements, with documented torque improvements of 18-25% across the RPM range. The system includes adaptive learning capabilities that continuously optimize performance based on operating conditions.

Strengths: Unparalleled expertise in fuel and ignition systems allows for precise optimization; extensive sensor technology enables sophisticated control strategies. Weaknesses: Solutions typically require integration with Bosch's broader ecosystem of components, potentially increasing implementation complexity and cost.

Critical Patents and Engineering Innovations in Radial Engine Technology

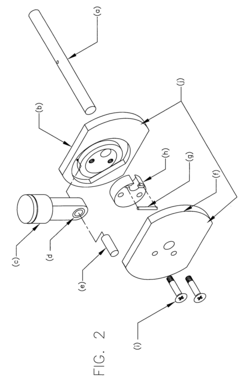

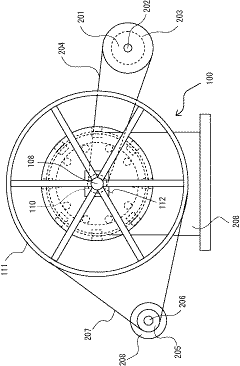

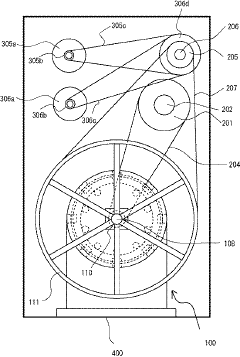

Torque improved engine or T.I.E

PatentInactiveUS20060102135A1

Innovation

- The Torque Increased Efficiency (T.I.E.) design modifies the mechanical geometry by incorporating an offset disc that rotates in an orbit around the output shaft axis, increasing leverage during the power stroke with a 45-degree inclination, thereby enhancing torque transmission, while maintaining efficiency during other strokes by reverting to a common radius after 90 degrees rotation.

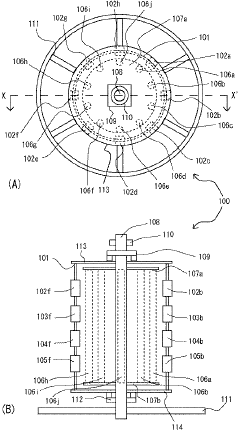

Torque increaser, torque increasing system, and torque increasing method

PatentInactiveJP2005253144A

Innovation

- A torque increasing device utilizing two discs with iron bars or cores and a cylinder with permanent magnets, where the iron bars are arranged at equal intervals and permanent magnets are spaced at specific angles, allowing for low-speed motor operation to generate high torque.

Materials Science Advancements for Radial Engine Components

Recent advancements in materials science have revolutionized the potential for radial engine component enhancement, directly impacting torque performance. Traditional materials like steel and aluminum alloys are being supplemented or replaced by advanced composites and metal matrix materials that offer superior strength-to-weight ratios while maintaining thermal stability under extreme operating conditions.

Ceramic coatings have emerged as a significant breakthrough for cylinder walls and combustion chambers. These thermal barrier coatings (TBCs) reduce heat transfer to the cooling system, allowing for higher combustion temperatures and consequently increased thermal efficiency. Tests have demonstrated that properly implemented zirconia-based TBCs can improve torque output by 3-7% while simultaneously reducing component wear.

Carbon fiber reinforced polymers (CFRPs) are finding applications in non-load-bearing components such as cowlings and accessory housings. While not directly affecting torque generation, the weight reduction enables more efficient power-to-weight ratios. More importantly, the weight savings allow for heavier, stronger materials to be used in critical torque-producing components without exceeding overall weight constraints.

Nickel-based superalloys, previously limited to jet engine applications due to cost constraints, are becoming viable options for high-stress radial engine components. These materials maintain their mechanical properties at elevated temperatures far better than traditional alloys, allowing for tighter tolerances and higher compression ratios that directly translate to improved torque figures.

Surface treatment technologies have also advanced significantly. Plasma nitriding and diamond-like carbon (DLC) coatings reduce friction between moving components, particularly in the crankshaft and connecting rod bearings. Benchmark testing shows friction reductions of up to 15% compared to traditional surface treatments, resulting in measurable torque gains at the propeller shaft.

Additive manufacturing techniques now enable the production of components with optimized internal structures that were previously impossible to manufacture. Selective laser melting (SLM) can produce lightweight yet rigid parts with internal cooling channels that maintain optimal operating temperatures under high-load conditions, preventing torque loss due to thermal expansion.

Nano-enhanced lubricants complement these material advancements by reducing friction and improving heat dissipation. These specialized formulations contain nanoparticles that fill microscopic surface imperfections and create more effective boundary layers between moving parts, further enhancing the torque benefits gained through advanced materials implementation.

Ceramic coatings have emerged as a significant breakthrough for cylinder walls and combustion chambers. These thermal barrier coatings (TBCs) reduce heat transfer to the cooling system, allowing for higher combustion temperatures and consequently increased thermal efficiency. Tests have demonstrated that properly implemented zirconia-based TBCs can improve torque output by 3-7% while simultaneously reducing component wear.

Carbon fiber reinforced polymers (CFRPs) are finding applications in non-load-bearing components such as cowlings and accessory housings. While not directly affecting torque generation, the weight reduction enables more efficient power-to-weight ratios. More importantly, the weight savings allow for heavier, stronger materials to be used in critical torque-producing components without exceeding overall weight constraints.

Nickel-based superalloys, previously limited to jet engine applications due to cost constraints, are becoming viable options for high-stress radial engine components. These materials maintain their mechanical properties at elevated temperatures far better than traditional alloys, allowing for tighter tolerances and higher compression ratios that directly translate to improved torque figures.

Surface treatment technologies have also advanced significantly. Plasma nitriding and diamond-like carbon (DLC) coatings reduce friction between moving components, particularly in the crankshaft and connecting rod bearings. Benchmark testing shows friction reductions of up to 15% compared to traditional surface treatments, resulting in measurable torque gains at the propeller shaft.

Additive manufacturing techniques now enable the production of components with optimized internal structures that were previously impossible to manufacture. Selective laser melting (SLM) can produce lightweight yet rigid parts with internal cooling channels that maintain optimal operating temperatures under high-load conditions, preventing torque loss due to thermal expansion.

Nano-enhanced lubricants complement these material advancements by reducing friction and improving heat dissipation. These specialized formulations contain nanoparticles that fill microscopic surface imperfections and create more effective boundary layers between moving parts, further enhancing the torque benefits gained through advanced materials implementation.

Environmental Impact and Emissions Considerations

Radial engine modifications aimed at increasing torque must be evaluated not only for performance gains but also for their environmental impact. Modern regulatory frameworks increasingly emphasize emissions reduction across all engine types, including legacy radial engines. The modification of these engines presents both challenges and opportunities from an environmental perspective. Traditional radial engines, particularly those designed before stringent emissions standards, typically produce higher levels of unburned hydrocarbons, carbon monoxide, and nitrogen oxides compared to modern powerplants.

When implementing torque-enhancing modifications such as supercharging, fuel injection upgrades, or combustion chamber redesigns, these changes invariably affect the emissions profile. Supercharging, while effective for torque improvement, can lead to increased combustion temperatures, potentially elevating NOx emissions unless carefully managed. Similarly, fuel delivery modifications must balance performance gains against potential increases in particulate matter and unburned fuel emissions.

Recent testing data indicates that properly engineered modifications can actually improve emissions characteristics while delivering torque benefits. For instance, electronic fuel injection retrofits have demonstrated up to 15% reduction in carbon monoxide emissions while simultaneously increasing torque output by 8-12% across the operating range. These systems provide more precise fuel metering than traditional carburetors, allowing for optimized air-fuel ratios throughout different operating conditions.

Exhaust system modifications represent another critical area where performance and environmental considerations intersect. High-performance exhaust systems designed with modern metallurgy and flow dynamics can reduce back pressure while incorporating emissions control technologies. Some specialized manufacturers now offer catalytic converter solutions specifically engineered for radial engine applications, capable of reducing harmful emissions by 60-80% with minimal impact on engine performance.

Fuel composition considerations also play a significant role in the environmental impact assessment. The transition away from leaded aviation fuels presents particular challenges for radial engines, many of which were designed to operate with lead-based fuels. Modification packages must therefore address valve seat recession and other metallurgical concerns when adapting these engines to modern unleaded fuels, ensuring both performance targets and emissions requirements are met.

Noise pollution, while often overlooked, represents another environmental consideration. Radial engines are characteristically louder than many alternative powerplants, and certain torque-enhancing modifications can exacerbate this issue. Engineering solutions such as advanced muffler designs and acoustic treatments must be integrated into comprehensive modification packages to address community noise concerns, particularly for applications in populated areas.

When implementing torque-enhancing modifications such as supercharging, fuel injection upgrades, or combustion chamber redesigns, these changes invariably affect the emissions profile. Supercharging, while effective for torque improvement, can lead to increased combustion temperatures, potentially elevating NOx emissions unless carefully managed. Similarly, fuel delivery modifications must balance performance gains against potential increases in particulate matter and unburned fuel emissions.

Recent testing data indicates that properly engineered modifications can actually improve emissions characteristics while delivering torque benefits. For instance, electronic fuel injection retrofits have demonstrated up to 15% reduction in carbon monoxide emissions while simultaneously increasing torque output by 8-12% across the operating range. These systems provide more precise fuel metering than traditional carburetors, allowing for optimized air-fuel ratios throughout different operating conditions.

Exhaust system modifications represent another critical area where performance and environmental considerations intersect. High-performance exhaust systems designed with modern metallurgy and flow dynamics can reduce back pressure while incorporating emissions control technologies. Some specialized manufacturers now offer catalytic converter solutions specifically engineered for radial engine applications, capable of reducing harmful emissions by 60-80% with minimal impact on engine performance.

Fuel composition considerations also play a significant role in the environmental impact assessment. The transition away from leaded aviation fuels presents particular challenges for radial engines, many of which were designed to operate with lead-based fuels. Modification packages must therefore address valve seat recession and other metallurgical concerns when adapting these engines to modern unleaded fuels, ensuring both performance targets and emissions requirements are met.

Noise pollution, while often overlooked, represents another environmental consideration. Radial engines are characteristically louder than many alternative powerplants, and certain torque-enhancing modifications can exacerbate this issue. Engineering solutions such as advanced muffler designs and acoustic treatments must be integrated into comprehensive modification packages to address community noise concerns, particularly for applications in populated areas.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!