Benchmarking Turbine Engine Fuel Systems for Performance

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Fuel System Evolution and Objectives

Turbine engine fuel systems have undergone significant evolution since their inception in the mid-20th century. Initially designed with basic mechanical components, these systems have transformed into sophisticated electromechanical networks that optimize fuel delivery, combustion efficiency, and overall engine performance. The progression from purely mechanical systems to digital electronic control units represents a fundamental shift in how fuel is managed within turbine engines.

The 1950s marked the beginning of modern turbine engine fuel systems with simple hydromechanical controls. By the 1970s, analog electronic components were integrated to enhance precision, followed by the introduction of Full Authority Digital Engine Control (FADEC) systems in the 1980s, which revolutionized fuel management capabilities. Recent advancements include adaptive control algorithms, predictive maintenance features, and real-time performance optimization technologies.

Current technological objectives in turbine engine fuel system development focus on several key areas. Efficiency improvement remains paramount, with goals to reduce specific fuel consumption by optimizing fuel-air ratios across all operating conditions. Environmental compliance has become increasingly important, driving innovations in fuel atomization and distribution to minimize emissions of nitrogen oxides, carbon monoxide, and unburned hydrocarbons.

Weight reduction represents another critical objective, with manufacturers pursuing lightweight materials and compact designs to improve the power-to-weight ratio of modern engines. Reliability enhancement through redundant systems, fault-tolerant architectures, and advanced diagnostics aims to minimize in-flight failures and maintenance requirements. Additionally, fuel flexibility has emerged as a significant goal, with systems being designed to accommodate alternative and sustainable aviation fuels without performance degradation.

The integration of advanced sensors and data analytics capabilities enables real-time performance monitoring and adjustment, supporting the trend toward condition-based maintenance rather than scheduled interventions. This shift promises to reduce operational costs while maintaining safety standards. Furthermore, thermal management has become increasingly sophisticated, with fuel systems now playing a dual role in cooling electronic components while maintaining optimal fuel temperatures for combustion efficiency.

As the industry moves toward more electric aircraft architectures, fuel system designers are exploring novel approaches to power generation and distribution, potentially reducing the parasitic losses associated with traditional hydraulic systems. These evolutionary trends collectively point toward increasingly intelligent, adaptive fuel systems capable of optimizing performance across diverse operating conditions while meeting stringent regulatory requirements.

The 1950s marked the beginning of modern turbine engine fuel systems with simple hydromechanical controls. By the 1970s, analog electronic components were integrated to enhance precision, followed by the introduction of Full Authority Digital Engine Control (FADEC) systems in the 1980s, which revolutionized fuel management capabilities. Recent advancements include adaptive control algorithms, predictive maintenance features, and real-time performance optimization technologies.

Current technological objectives in turbine engine fuel system development focus on several key areas. Efficiency improvement remains paramount, with goals to reduce specific fuel consumption by optimizing fuel-air ratios across all operating conditions. Environmental compliance has become increasingly important, driving innovations in fuel atomization and distribution to minimize emissions of nitrogen oxides, carbon monoxide, and unburned hydrocarbons.

Weight reduction represents another critical objective, with manufacturers pursuing lightweight materials and compact designs to improve the power-to-weight ratio of modern engines. Reliability enhancement through redundant systems, fault-tolerant architectures, and advanced diagnostics aims to minimize in-flight failures and maintenance requirements. Additionally, fuel flexibility has emerged as a significant goal, with systems being designed to accommodate alternative and sustainable aviation fuels without performance degradation.

The integration of advanced sensors and data analytics capabilities enables real-time performance monitoring and adjustment, supporting the trend toward condition-based maintenance rather than scheduled interventions. This shift promises to reduce operational costs while maintaining safety standards. Furthermore, thermal management has become increasingly sophisticated, with fuel systems now playing a dual role in cooling electronic components while maintaining optimal fuel temperatures for combustion efficiency.

As the industry moves toward more electric aircraft architectures, fuel system designers are exploring novel approaches to power generation and distribution, potentially reducing the parasitic losses associated with traditional hydraulic systems. These evolutionary trends collectively point toward increasingly intelligent, adaptive fuel systems capable of optimizing performance across diverse operating conditions while meeting stringent regulatory requirements.

Market Requirements for High-Performance Fuel Systems

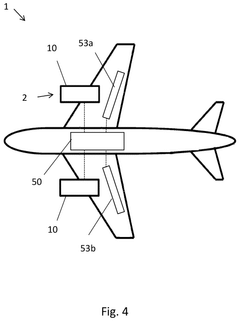

The global market for high-performance turbine engine fuel systems is experiencing significant growth driven by increasing demands for fuel efficiency, reduced emissions, and enhanced operational reliability. Aviation industry stakeholders, including commercial airlines, military organizations, and business jet operators, consistently emphasize the need for fuel systems that can deliver optimal performance under diverse operating conditions while meeting stringent regulatory requirements.

Primary market requirements center around fuel efficiency improvements, with operators seeking systems that can reduce fuel consumption by at least 5-10% compared to previous generation technologies. This demand is particularly acute in commercial aviation where fuel costs represent 20-30% of operational expenses. Military applications prioritize systems offering extended range capabilities and compatibility with alternative fuels to enhance operational flexibility and reduce logistical burdens.

Reliability metrics have become increasingly stringent, with customers expecting mean time between failures (MTBF) exceeding 10,000 operating hours for critical fuel system components. This requirement stems from the substantial costs associated with unscheduled maintenance and operational disruptions, which can reach millions of dollars per incident for commercial carriers.

Environmental compliance represents another crucial market demand, with regulatory frameworks such as ICAO's CORSIA and regional emission standards driving requirements for fuel systems that can support lower-carbon operations. Systems capable of handling sustainable aviation fuels (SAF) with minimal modifications are gaining competitive advantage as the industry pursues carbon reduction targets.

Weight reduction continues to be a significant market requirement, with OEMs and operators seeking fuel system components that contribute to overall aircraft weight reduction while maintaining structural integrity and performance. The market values solutions that can achieve 15-20% weight reduction compared to conventional systems without compromising safety or durability.

Adaptability to extreme operating conditions has emerged as a critical requirement, particularly for military applications and commercial routes in challenging environments. Systems must maintain consistent performance across temperature ranges from -65°F to +160°F and at altitudes exceeding 40,000 feet, while handling variations in fuel quality encountered in global operations.

Integration capabilities with advanced engine control systems and health monitoring technologies represent growing market requirements, as operators seek comprehensive solutions that enable predictive maintenance and real-time performance optimization. The ability to provide accurate fuel flow data to engine control systems can improve overall engine efficiency by 2-3%, representing significant operational cost savings over an aircraft's service life.

Primary market requirements center around fuel efficiency improvements, with operators seeking systems that can reduce fuel consumption by at least 5-10% compared to previous generation technologies. This demand is particularly acute in commercial aviation where fuel costs represent 20-30% of operational expenses. Military applications prioritize systems offering extended range capabilities and compatibility with alternative fuels to enhance operational flexibility and reduce logistical burdens.

Reliability metrics have become increasingly stringent, with customers expecting mean time between failures (MTBF) exceeding 10,000 operating hours for critical fuel system components. This requirement stems from the substantial costs associated with unscheduled maintenance and operational disruptions, which can reach millions of dollars per incident for commercial carriers.

Environmental compliance represents another crucial market demand, with regulatory frameworks such as ICAO's CORSIA and regional emission standards driving requirements for fuel systems that can support lower-carbon operations. Systems capable of handling sustainable aviation fuels (SAF) with minimal modifications are gaining competitive advantage as the industry pursues carbon reduction targets.

Weight reduction continues to be a significant market requirement, with OEMs and operators seeking fuel system components that contribute to overall aircraft weight reduction while maintaining structural integrity and performance. The market values solutions that can achieve 15-20% weight reduction compared to conventional systems without compromising safety or durability.

Adaptability to extreme operating conditions has emerged as a critical requirement, particularly for military applications and commercial routes in challenging environments. Systems must maintain consistent performance across temperature ranges from -65°F to +160°F and at altitudes exceeding 40,000 feet, while handling variations in fuel quality encountered in global operations.

Integration capabilities with advanced engine control systems and health monitoring technologies represent growing market requirements, as operators seek comprehensive solutions that enable predictive maintenance and real-time performance optimization. The ability to provide accurate fuel flow data to engine control systems can improve overall engine efficiency by 2-3%, representing significant operational cost savings over an aircraft's service life.

Current Fuel System Technologies and Barriers

Current turbine engine fuel systems predominantly employ pressure-atomizing fuel injectors, which break fuel into fine droplets for efficient combustion. These systems typically operate at pressures ranging from 100 to 1000 psi, depending on engine size and application. Modern fuel systems incorporate electronic control units (ECUs) that precisely regulate fuel flow based on multiple sensor inputs, enabling real-time adjustments to maintain optimal air-fuel ratios across various operating conditions.

Advanced fuel metering technologies have evolved significantly, with hydromechanical systems gradually giving way to Full Authority Digital Engine Control (FADEC) systems. These digital systems offer superior precision, reliability, and adaptability, allowing for fuel flow modulation with accuracy levels of ±1% or better. Contemporary fuel pumps have also improved, with high-pressure positive displacement pumps achieving efficiencies of 85-90% while maintaining consistent performance across wide temperature ranges from -40°C to +150°C.

Despite these advancements, several significant barriers impede further performance improvements. Fuel coking remains a persistent challenge, particularly in high-temperature environments where fuel acts as a heat sink before combustion. Carbon deposits form on injector surfaces at temperatures exceeding 150°C, progressively degrading spray patterns and reducing combustion efficiency by up to 5-8% before maintenance is required.

Material limitations present another substantial barrier. Current alloys and sealing materials struggle to maintain integrity under the combined stresses of high pressure, temperature cycling, and exposure to various fuel contaminants. This constrains operational parameters and necessitates more frequent maintenance intervals, typically every 3,000-5,000 operating hours for commercial applications.

Weight and space constraints pose additional challenges, particularly in aerospace applications where every kilogram matters. Current fuel system components typically constitute 3-7% of total engine weight, creating a constant trade-off between system robustness and weight minimization efforts.

Emissions regulations represent an evolving barrier, with increasingly stringent standards requiring more sophisticated fuel delivery systems. Current technologies struggle to simultaneously optimize for NOx, CO, and particulate emissions across all operating conditions, particularly during transient operations where fuel-air mixing becomes less predictable.

Lastly, alternative fuel compatibility presents a growing challenge. While conventional fuel systems are optimized for traditional hydrocarbon fuels, the industry's shift toward sustainable aviation fuels (SAFs) and hydrogen introduces new variables in viscosity, lubricity, and energy density that current systems are not fully equipped to handle efficiently.

Advanced fuel metering technologies have evolved significantly, with hydromechanical systems gradually giving way to Full Authority Digital Engine Control (FADEC) systems. These digital systems offer superior precision, reliability, and adaptability, allowing for fuel flow modulation with accuracy levels of ±1% or better. Contemporary fuel pumps have also improved, with high-pressure positive displacement pumps achieving efficiencies of 85-90% while maintaining consistent performance across wide temperature ranges from -40°C to +150°C.

Despite these advancements, several significant barriers impede further performance improvements. Fuel coking remains a persistent challenge, particularly in high-temperature environments where fuel acts as a heat sink before combustion. Carbon deposits form on injector surfaces at temperatures exceeding 150°C, progressively degrading spray patterns and reducing combustion efficiency by up to 5-8% before maintenance is required.

Material limitations present another substantial barrier. Current alloys and sealing materials struggle to maintain integrity under the combined stresses of high pressure, temperature cycling, and exposure to various fuel contaminants. This constrains operational parameters and necessitates more frequent maintenance intervals, typically every 3,000-5,000 operating hours for commercial applications.

Weight and space constraints pose additional challenges, particularly in aerospace applications where every kilogram matters. Current fuel system components typically constitute 3-7% of total engine weight, creating a constant trade-off between system robustness and weight minimization efforts.

Emissions regulations represent an evolving barrier, with increasingly stringent standards requiring more sophisticated fuel delivery systems. Current technologies struggle to simultaneously optimize for NOx, CO, and particulate emissions across all operating conditions, particularly during transient operations where fuel-air mixing becomes less predictable.

Lastly, alternative fuel compatibility presents a growing challenge. While conventional fuel systems are optimized for traditional hydrocarbon fuels, the industry's shift toward sustainable aviation fuels (SAFs) and hydrogen introduces new variables in viscosity, lubricity, and energy density that current systems are not fully equipped to handle efficiently.

State-of-the-Art Fuel System Performance Solutions

01 Fuel delivery and control systems

Advanced fuel delivery and control systems are critical for turbine engine performance. These systems include precision fuel metering devices, electronic control units, and integrated sensors that monitor and adjust fuel flow based on engine operating conditions. Improved fuel delivery systems ensure optimal combustion efficiency, reduce fuel consumption, and enhance overall engine performance across various operating conditions.- Fuel delivery and control systems: Advanced fuel delivery and control systems are essential for optimizing turbine engine performance. These systems include precision fuel metering devices, electronic control units, and integrated sensors that monitor and adjust fuel flow based on operating conditions. Modern systems incorporate adaptive algorithms to maintain optimal fuel-air ratios across various flight regimes, improving both efficiency and power output while reducing emissions.

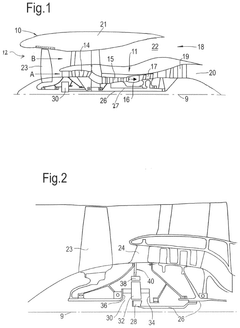

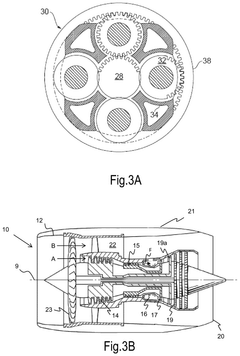

- Fuel atomization and combustion efficiency: Effective fuel atomization is critical for combustion efficiency in turbine engines. Specialized nozzle designs and fuel injectors create optimal droplet size distribution, ensuring proper mixing with air and complete combustion. Advanced atomization techniques include swirl-type injectors, air-blast atomizers, and pressure-atomizing systems that function effectively across varying engine operating conditions, resulting in improved thermal efficiency and reduced fuel consumption.

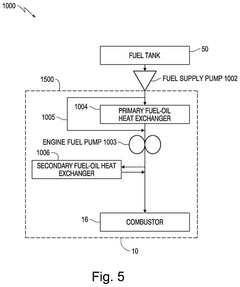

- Fuel system thermal management: Thermal management within turbine engine fuel systems is crucial for maintaining performance and preventing vapor lock or coking. Heat exchangers and fuel recirculation systems help regulate fuel temperature before combustion. Some designs use fuel as a cooling medium for engine oil or electronic components before routing it to combustion chambers, creating an integrated thermal management approach that improves overall system efficiency while ensuring reliable operation across extreme temperature ranges.

- Fuel filtration and contamination control: Effective filtration and contamination control systems are essential for preventing fuel system malfunctions and extending engine life. Multi-stage filtration systems remove particulates, water, and other contaminants that could damage precision components or disrupt combustion. Advanced systems incorporate water separators, magnetic filters for metallic particles, and condition monitoring capabilities that alert operators to potential contamination issues before they affect engine performance.

- Alternative fuel compatibility and performance: Modern turbine engine fuel systems are increasingly designed to accommodate alternative and sustainable fuels while maintaining performance standards. These systems feature components resistant to the different chemical properties of biofuels, hydrogen, or synthetic fuels. Adaptive control systems can adjust fuel delivery parameters based on fuel composition, ensuring consistent performance and emissions control regardless of the specific fuel blend being used.

02 Fuel injection and atomization technologies

Fuel injection and atomization technologies play a crucial role in turbine engine performance. These technologies focus on optimizing the spray pattern, droplet size, and distribution of fuel in the combustion chamber. Advanced injector designs improve fuel-air mixing, enhance combustion efficiency, and reduce emissions. Innovations in this area include multi-point injection systems, pressure-swirl atomizers, and air-blast atomizers that function effectively across various engine operating conditions.Expand Specific Solutions03 Fuel system thermal management

Thermal management systems for turbine engine fuel systems are essential for maintaining optimal performance. These systems regulate fuel temperature to prevent coking, vapor lock, and other temperature-related issues that can affect fuel flow and combustion efficiency. Heat exchangers, cooling circuits, and thermal barriers are employed to manage heat transfer between the fuel system and other engine components, ensuring reliable operation across a wide range of operating conditions.Expand Specific Solutions04 Alternative and multi-fuel compatibility

Modern turbine engine fuel systems are designed to accommodate alternative and multiple fuel types. These systems incorporate adaptive components that can adjust to variations in fuel properties such as viscosity, energy content, and combustion characteristics. Flexible fuel systems enable engines to operate efficiently with conventional jet fuels, biofuels, synthetic fuels, or blends, enhancing operational flexibility while maintaining performance standards and reducing environmental impact.Expand Specific Solutions05 Fuel system monitoring and diagnostics

Advanced monitoring and diagnostic capabilities for turbine engine fuel systems enable real-time performance assessment and predictive maintenance. These systems utilize sensors, data analytics, and machine learning algorithms to detect anomalies, predict potential failures, and optimize fuel system operation. Continuous monitoring of parameters such as pressure, temperature, flow rate, and fuel quality helps maintain optimal engine performance, extend component life, and reduce unscheduled maintenance events.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The turbine engine fuel systems benchmarking landscape is currently in a growth phase, with the market expected to reach significant expansion due to increasing demand for fuel-efficient propulsion systems. Major players like General Electric, Rolls-Royce, and RTX Corp dominate with established technological expertise, while companies such as Honeywell International and Safran Aircraft Engines are making substantial innovations in performance optimization. The technology maturity varies across applications, with aerospace implementations being most advanced. Research institutions like Southwest Research Institute and Beihang University are contributing to technological advancements through collaborative projects with industry leaders. Competition is intensifying as automotive players like Hyundai and Ford enter the space with cross-industry applications of turbine fuel system technologies.

General Electric Company

Technical Solution: General Electric has developed advanced fuel system benchmarking technologies for turbine engines through their Digital Twin approach. Their system utilizes high-fidelity computational fluid dynamics (CFD) modeling combined with real-time sensor networks to create comprehensive digital representations of fuel system performance. GE's benchmarking methodology incorporates machine learning algorithms that analyze operational data across various environmental conditions, enabling predictive maintenance and performance optimization. Their TAPS (Twin Annular Premixing Swirler) fuel injection system demonstrates up to 30% reduction in NOx emissions while maintaining combustion stability[1]. GE's benchmarking platform integrates with their broader Predix industrial IoT ecosystem, allowing for continuous monitoring of key performance indicators such as fuel flow uniformity, atomization quality, and combustion efficiency across their entire turbine engine portfolio[3].

Strengths: Comprehensive integration with digital twin technology enables predictive analytics and real-time optimization. Extensive operational data from global fleet provides robust benchmarking baselines. Weaknesses: System complexity requires significant computational resources and specialized expertise to implement and maintain. Higher initial implementation costs compared to traditional benchmarking methods.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has pioneered the Intelligent Engine concept for benchmarking turbine fuel systems, combining physical testing with advanced simulation capabilities. Their approach utilizes a network of over 5,000 sensors per engine that monitor fuel system parameters at microsecond intervals[2]. The company's proprietary FOCAL (Fuel Optimization and Control Analysis Laboratory) system enables precise measurement of fuel distribution, atomization characteristics, and combustion dynamics across various operating conditions. Rolls-Royce implements a multi-phase benchmarking methodology that incorporates both component-level and system-level performance metrics, allowing for isolation of specific fuel system elements for targeted optimization. Their advanced test facilities can simulate altitude conditions from sea level to 45,000 feet and temperatures from -60°C to +130°C to evaluate fuel system performance across the entire flight envelope[5]. The benchmarking data feeds into their IntelligentEngine ecosystem, enabling continuous improvement of fuel efficiency and emissions performance.

Strengths: Exceptional sensor density provides highly granular performance data. Comprehensive environmental simulation capabilities enable thorough testing across all operating conditions. Weaknesses: High implementation costs for full-scale testing infrastructure. Requires significant expertise to interpret complex multivariable data sets and translate into actionable improvements.

Critical Patents and Technical Literature Analysis

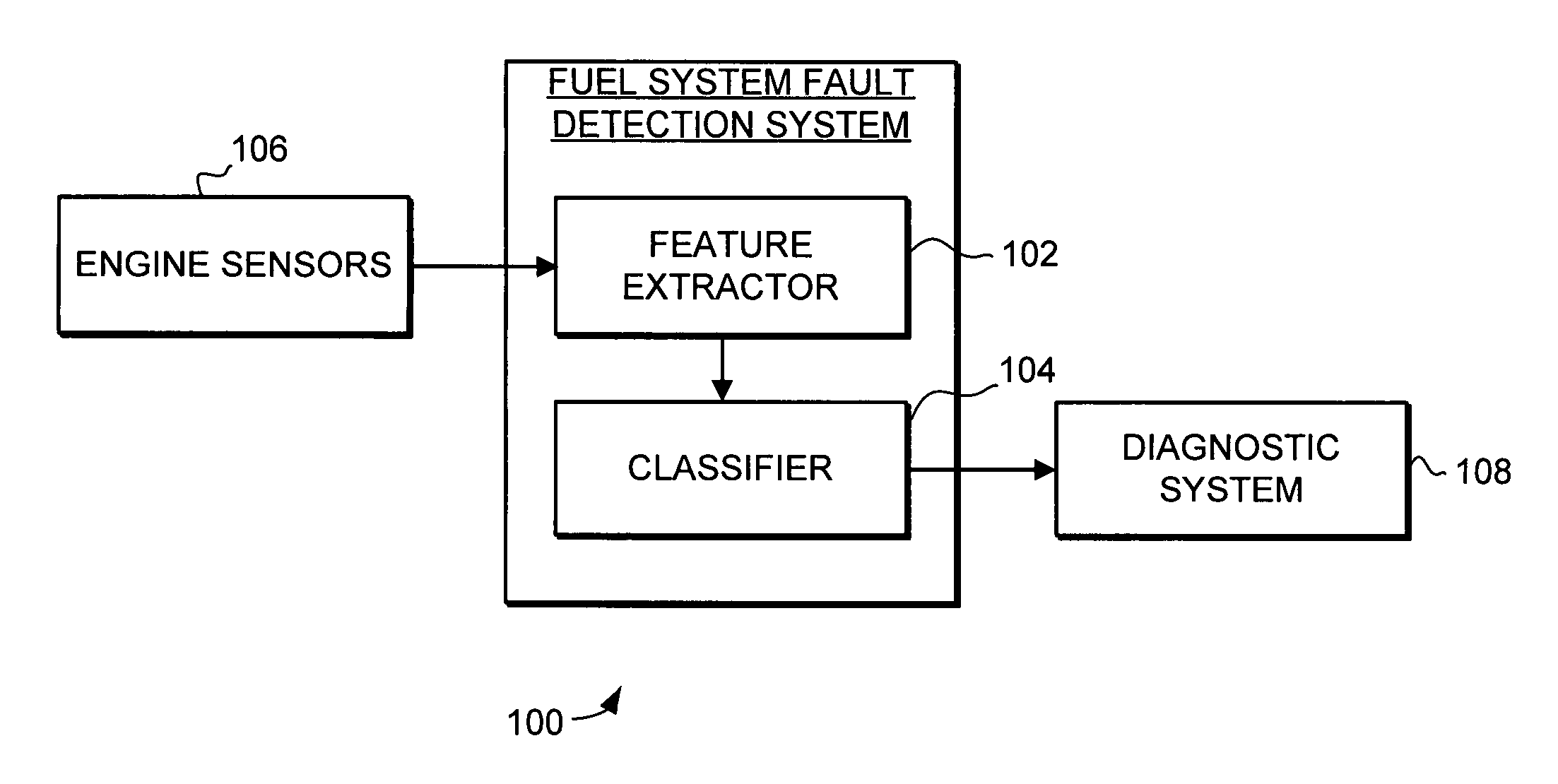

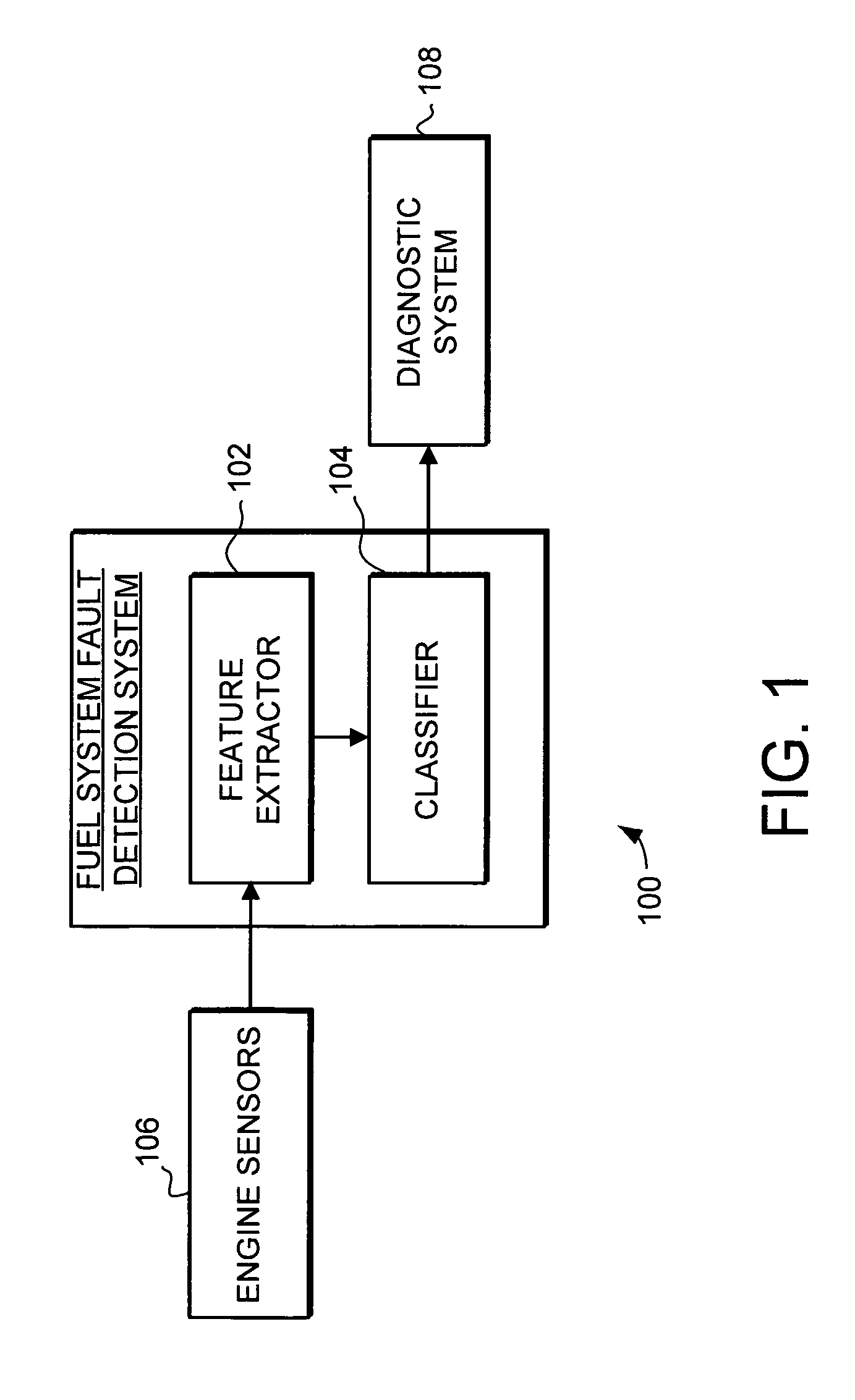

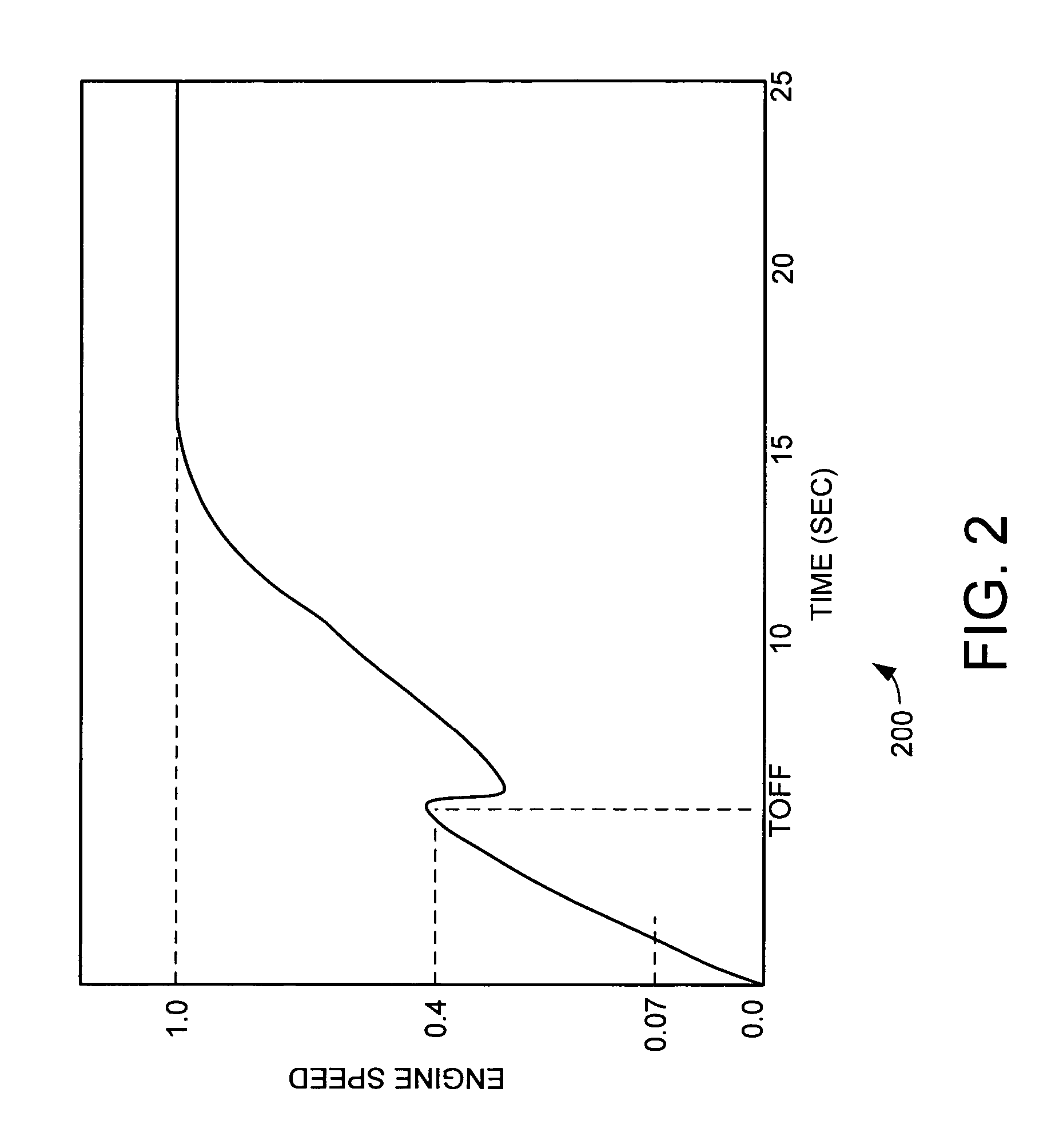

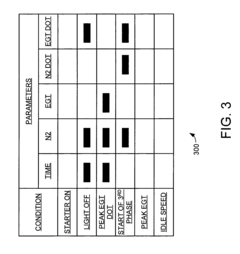

Fault detection system and method for turbine engine fuel systems

PatentInactiveUS7693643B2

Innovation

- A fault detection system that collects and analyzes turbine sensor data using a feature extractor to reduce data dimensions and a classifier to identify anomalies, specifically applicable to the hydro-mechanical assembly (HMA) of turbine engines, employing statistical analysis and techniques like principal component analysis (PCA) and fuzzy clustering to efficiently detect fuel system issues.

Gas turbine performance

PatentPendingUS20240318600A1

Innovation

- A fuel management system for gas turbine engines that includes two fuel-oil heat exchangers, a fuel pump located between them, and a recirculation valve to control fuel flow and temperature, allowing for optimized fuel properties by transferring heat and adjusting fuel viscosity and flow rates based on engine conditions.

Environmental Regulations Impact on Fuel System Design

Environmental regulations have become increasingly stringent in the aviation industry, significantly impacting turbine engine fuel system design and performance benchmarking. The International Civil Aviation Organization (ICAO) has established progressive emissions standards through its Committee on Aviation Environmental Protection (CAEP), with each iteration imposing stricter limits on nitrogen oxides (NOx), carbon monoxide (CO), unburned hydrocarbons (UHC), and particulate matter emissions.

These regulations have driven fundamental changes in fuel system architecture, particularly in fuel atomization and distribution components. Modern fuel nozzles must now achieve finer atomization patterns while maintaining operational stability across diverse flight conditions. This requirement has led to the development of multi-point injection systems that optimize fuel-air mixing to minimize pollutant formation during combustion processes.

The European Union's Emissions Trading System (EU ETS) and the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) have established market-based mechanisms that effectively place a price on carbon emissions. These economic instruments have accelerated the adoption of more efficient fuel metering systems capable of precise fuel delivery across all operational regimes, directly influencing performance benchmarking parameters.

Sulfur content regulations have necessitated modifications to fuel system materials and filtration technologies. Traditional elastomers and sealing components must now demonstrate compatibility with ultra-low sulfur fuels while maintaining durability under extreme operating conditions. This has prompted the development of advanced filtration systems that can remove contaminants without restricting fuel flow or increasing system pressure drops.

The emergence of sustainable aviation fuels (SAFs) presents additional challenges for fuel system design. These alternative fuels often exhibit different viscosity profiles, energy densities, and material compatibility characteristics compared to conventional jet fuels. Consequently, fuel systems must now demonstrate adaptability across a broader range of fuel properties while maintaining certification standards for performance and reliability.

Noise regulations have indirectly influenced fuel system design through their impact on combustion dynamics. Fuel delivery systems must now support combustion patterns that minimize acoustic resonance while maintaining thermal efficiency. This has led to the development of variable geometry fuel injectors that can adjust spray patterns based on operational conditions.

Regional variations in environmental regulations create additional complexity for global manufacturers. The California Air Resources Board (CARB) standards often exceed federal requirements, while emerging markets may implement unique regulatory frameworks. This regulatory diversity necessitates modular fuel system designs that can be adapted to meet specific regional requirements without compromising core performance metrics.

These regulations have driven fundamental changes in fuel system architecture, particularly in fuel atomization and distribution components. Modern fuel nozzles must now achieve finer atomization patterns while maintaining operational stability across diverse flight conditions. This requirement has led to the development of multi-point injection systems that optimize fuel-air mixing to minimize pollutant formation during combustion processes.

The European Union's Emissions Trading System (EU ETS) and the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) have established market-based mechanisms that effectively place a price on carbon emissions. These economic instruments have accelerated the adoption of more efficient fuel metering systems capable of precise fuel delivery across all operational regimes, directly influencing performance benchmarking parameters.

Sulfur content regulations have necessitated modifications to fuel system materials and filtration technologies. Traditional elastomers and sealing components must now demonstrate compatibility with ultra-low sulfur fuels while maintaining durability under extreme operating conditions. This has prompted the development of advanced filtration systems that can remove contaminants without restricting fuel flow or increasing system pressure drops.

The emergence of sustainable aviation fuels (SAFs) presents additional challenges for fuel system design. These alternative fuels often exhibit different viscosity profiles, energy densities, and material compatibility characteristics compared to conventional jet fuels. Consequently, fuel systems must now demonstrate adaptability across a broader range of fuel properties while maintaining certification standards for performance and reliability.

Noise regulations have indirectly influenced fuel system design through their impact on combustion dynamics. Fuel delivery systems must now support combustion patterns that minimize acoustic resonance while maintaining thermal efficiency. This has led to the development of variable geometry fuel injectors that can adjust spray patterns based on operational conditions.

Regional variations in environmental regulations create additional complexity for global manufacturers. The California Air Resources Board (CARB) standards often exceed federal requirements, while emerging markets may implement unique regulatory frameworks. This regulatory diversity necessitates modular fuel system designs that can be adapted to meet specific regional requirements without compromising core performance metrics.

Reliability and Safety Standards Compliance Framework

Compliance with reliability and safety standards is paramount in turbine engine fuel systems, as these systems operate in high-stress environments where failures can lead to catastrophic consequences. The regulatory landscape governing these systems is complex and multifaceted, encompassing international aviation authorities, military specifications, and industry best practices.

The primary regulatory bodies overseeing turbine engine fuel systems include the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and International Civil Aviation Organization (ICAO). These organizations establish minimum performance requirements through standards such as FAR Part 33 (Airworthiness Standards: Aircraft Engines) and EASA CS-E (Certification Specifications for Engines). Military applications follow additional stringent requirements outlined in MIL-STD-810 for environmental testing and MIL-E-5007 for engine performance.

Reliability assessment methodologies for fuel systems typically incorporate Failure Mode and Effects Analysis (FMEA), Fault Tree Analysis (FTA), and Mean Time Between Failure (MTBF) calculations. These analytical approaches help identify potential failure points and establish quantitative reliability metrics. Modern compliance frameworks increasingly emphasize prognostic health monitoring systems that can detect degradation before critical failures occur.

Safety certification processes require extensive testing regimes, including environmental exposure tests (temperature extremes, vibration, humidity), contamination resistance validation, and electromagnetic interference assessments. Fuel system components must demonstrate resilience against common failure modes such as fuel coking, filter clogging, and pump cavitation under all operating conditions.

Documentation requirements constitute a significant aspect of compliance, with manufacturers needing to maintain comprehensive records of design specifications, test results, material certifications, and maintenance procedures. These records form the basis for initial certification and continued airworthiness directives throughout the system's operational life.

Risk management frameworks have evolved to incorporate probabilistic risk assessment techniques that quantify the likelihood and consequences of various failure scenarios. These assessments inform design decisions and establish acceptable risk thresholds for different operational contexts, from commercial aviation to military applications.

Emerging trends in compliance frameworks include increased emphasis on cybersecurity considerations for digitally controlled fuel systems, sustainability requirements for alternative fuel compatibility, and harmonization of international standards to reduce regulatory complexity for global manufacturers. These evolving requirements necessitate adaptive compliance strategies that anticipate regulatory developments while maintaining focus on fundamental safety principles.

The primary regulatory bodies overseeing turbine engine fuel systems include the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and International Civil Aviation Organization (ICAO). These organizations establish minimum performance requirements through standards such as FAR Part 33 (Airworthiness Standards: Aircraft Engines) and EASA CS-E (Certification Specifications for Engines). Military applications follow additional stringent requirements outlined in MIL-STD-810 for environmental testing and MIL-E-5007 for engine performance.

Reliability assessment methodologies for fuel systems typically incorporate Failure Mode and Effects Analysis (FMEA), Fault Tree Analysis (FTA), and Mean Time Between Failure (MTBF) calculations. These analytical approaches help identify potential failure points and establish quantitative reliability metrics. Modern compliance frameworks increasingly emphasize prognostic health monitoring systems that can detect degradation before critical failures occur.

Safety certification processes require extensive testing regimes, including environmental exposure tests (temperature extremes, vibration, humidity), contamination resistance validation, and electromagnetic interference assessments. Fuel system components must demonstrate resilience against common failure modes such as fuel coking, filter clogging, and pump cavitation under all operating conditions.

Documentation requirements constitute a significant aspect of compliance, with manufacturers needing to maintain comprehensive records of design specifications, test results, material certifications, and maintenance procedures. These records form the basis for initial certification and continued airworthiness directives throughout the system's operational life.

Risk management frameworks have evolved to incorporate probabilistic risk assessment techniques that quantify the likelihood and consequences of various failure scenarios. These assessments inform design decisions and establish acceptable risk thresholds for different operational contexts, from commercial aviation to military applications.

Emerging trends in compliance frameworks include increased emphasis on cybersecurity considerations for digitally controlled fuel systems, sustainability requirements for alternative fuel compatibility, and harmonization of international standards to reduce regulatory complexity for global manufacturers. These evolving requirements necessitate adaptive compliance strategies that anticipate regulatory developments while maintaining focus on fundamental safety principles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!