Best Practices For Reporting Cryo-EM Methods In Materials Papers

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryo-EM in Materials Science: Background and Objectives

Cryogenic electron microscopy (Cryo-EM) has emerged as a revolutionary technique in materials science, enabling researchers to visualize and analyze materials at near-atomic resolution while preserving their native state. Originally developed for biological specimens, Cryo-EM has experienced significant technological advancements over the past two decades, transitioning from a specialized tool to an essential methodology in materials characterization.

The evolution of Cryo-EM in materials science has been driven by several key developments, including improved detector technology, enhanced computational methods for image processing, and refined sample preparation techniques. Direct electron detectors, introduced in the early 2010s, marked a pivotal moment in the field by dramatically improving signal-to-noise ratios and enabling higher resolution imaging of materials structures.

Concurrently, the development of sophisticated algorithms for image processing and 3D reconstruction has allowed researchers to extract meaningful structural information from noisy Cryo-EM data. These computational advances have been particularly important for materials science applications, where specimen heterogeneity and beam sensitivity often present significant challenges.

The primary objective of implementing standardized reporting practices for Cryo-EM methods in materials papers is to enhance reproducibility and reliability in the field. As Cryo-EM becomes increasingly prevalent in materials research, establishing clear guidelines for methodology reporting becomes essential for scientific progress and validation of results.

Current trends indicate a growing integration of Cryo-EM with complementary characterization techniques, creating multimodal approaches to materials analysis. This convergence of methodologies aims to provide more comprehensive insights into material properties and behaviors across different length scales and environmental conditions.

Looking forward, the field is moving toward automated data collection and processing workflows, which will further democratize access to Cryo-EM technology. Additionally, there is significant interest in developing in situ and operando Cryo-EM capabilities to observe materials under realistic operating conditions, particularly for energy materials and catalysts.

The technical goals for Cryo-EM in materials science include achieving consistent sub-angstrom resolution, developing protocols for challenging materials systems such as beam-sensitive or heterogeneous samples, and establishing quantitative analysis frameworks that can extract meaningful physical and chemical information from Cryo-EM data.

Ultimately, standardized reporting practices will facilitate knowledge transfer within the community, accelerate method development, and ensure that Cryo-EM continues to advance as a cornerstone technique in modern materials characterization.

The evolution of Cryo-EM in materials science has been driven by several key developments, including improved detector technology, enhanced computational methods for image processing, and refined sample preparation techniques. Direct electron detectors, introduced in the early 2010s, marked a pivotal moment in the field by dramatically improving signal-to-noise ratios and enabling higher resolution imaging of materials structures.

Concurrently, the development of sophisticated algorithms for image processing and 3D reconstruction has allowed researchers to extract meaningful structural information from noisy Cryo-EM data. These computational advances have been particularly important for materials science applications, where specimen heterogeneity and beam sensitivity often present significant challenges.

The primary objective of implementing standardized reporting practices for Cryo-EM methods in materials papers is to enhance reproducibility and reliability in the field. As Cryo-EM becomes increasingly prevalent in materials research, establishing clear guidelines for methodology reporting becomes essential for scientific progress and validation of results.

Current trends indicate a growing integration of Cryo-EM with complementary characterization techniques, creating multimodal approaches to materials analysis. This convergence of methodologies aims to provide more comprehensive insights into material properties and behaviors across different length scales and environmental conditions.

Looking forward, the field is moving toward automated data collection and processing workflows, which will further democratize access to Cryo-EM technology. Additionally, there is significant interest in developing in situ and operando Cryo-EM capabilities to observe materials under realistic operating conditions, particularly for energy materials and catalysts.

The technical goals for Cryo-EM in materials science include achieving consistent sub-angstrom resolution, developing protocols for challenging materials systems such as beam-sensitive or heterogeneous samples, and establishing quantitative analysis frameworks that can extract meaningful physical and chemical information from Cryo-EM data.

Ultimately, standardized reporting practices will facilitate knowledge transfer within the community, accelerate method development, and ensure that Cryo-EM continues to advance as a cornerstone technique in modern materials characterization.

Market Demand for Standardized Cryo-EM Reporting

The demand for standardized reporting in cryo-electron microscopy (cryo-EM) for materials science has grown significantly in recent years, driven by the increasing adoption of this powerful imaging technique across multiple industries. As cryo-EM transitions from a specialized tool primarily used in structural biology to a mainstream characterization method in materials science, the market need for consistent reporting protocols has become evident.

Research institutions, pharmaceutical companies, and materials manufacturers have expressed frustration with the current variability in cryo-EM methodological reporting. A recent survey conducted among materials scientists revealed that over 70% of researchers struggle to reproduce published cryo-EM results due to insufficient methodological details. This reproducibility crisis represents a substantial market pain point that standardization could address.

The pharmaceutical industry has emerged as a particularly vocal advocate for standardized reporting, as cryo-EM has become essential for drug discovery and development processes. With the global pharmaceutical R&D spending exceeding $180 billion annually, even marginal improvements in research efficiency through better reporting standards could translate to significant cost savings.

Academic publishers have also recognized this market need, with major materials science journals beginning to implement more stringent requirements for cryo-EM methodology sections. This shift reflects both reader demand and the publishers' interest in maintaining scientific integrity and citation rates for their journals.

Equipment manufacturers constitute another market segment pushing for standardization. Companies producing cryo-EM instruments and associated software have identified that clearer reporting guidelines would lower the barrier to entry for new users, potentially expanding their customer base. The global cryo-EM market, valued at approximately $650 million in 2021, is projected to grow substantially as the technique becomes more accessible.

Materials characterization service providers represent a growing market segment that would benefit from standardized reporting. These companies offer cryo-EM analysis as a service to clients who lack in-house capabilities, and standardized protocols would streamline their operations and improve client communication.

The semiconductor industry has recently emerged as a significant market driver for cryo-EM standardization. As device dimensions continue to shrink, traditional characterization techniques reach their limits, making cryo-EM increasingly valuable for quality control and failure analysis. Industry consortia have begun developing sector-specific reporting guidelines to address their unique needs.

Government funding agencies have also started prioritizing standardized reporting, with several major grants now requiring detailed data management plans that include standardized methodological reporting for cryo-EM experiments. This regulatory pressure creates additional market momentum toward adoption of comprehensive reporting practices.

Research institutions, pharmaceutical companies, and materials manufacturers have expressed frustration with the current variability in cryo-EM methodological reporting. A recent survey conducted among materials scientists revealed that over 70% of researchers struggle to reproduce published cryo-EM results due to insufficient methodological details. This reproducibility crisis represents a substantial market pain point that standardization could address.

The pharmaceutical industry has emerged as a particularly vocal advocate for standardized reporting, as cryo-EM has become essential for drug discovery and development processes. With the global pharmaceutical R&D spending exceeding $180 billion annually, even marginal improvements in research efficiency through better reporting standards could translate to significant cost savings.

Academic publishers have also recognized this market need, with major materials science journals beginning to implement more stringent requirements for cryo-EM methodology sections. This shift reflects both reader demand and the publishers' interest in maintaining scientific integrity and citation rates for their journals.

Equipment manufacturers constitute another market segment pushing for standardization. Companies producing cryo-EM instruments and associated software have identified that clearer reporting guidelines would lower the barrier to entry for new users, potentially expanding their customer base. The global cryo-EM market, valued at approximately $650 million in 2021, is projected to grow substantially as the technique becomes more accessible.

Materials characterization service providers represent a growing market segment that would benefit from standardized reporting. These companies offer cryo-EM analysis as a service to clients who lack in-house capabilities, and standardized protocols would streamline their operations and improve client communication.

The semiconductor industry has recently emerged as a significant market driver for cryo-EM standardization. As device dimensions continue to shrink, traditional characterization techniques reach their limits, making cryo-EM increasingly valuable for quality control and failure analysis. Industry consortia have begun developing sector-specific reporting guidelines to address their unique needs.

Government funding agencies have also started prioritizing standardized reporting, with several major grants now requiring detailed data management plans that include standardized methodological reporting for cryo-EM experiments. This regulatory pressure creates additional market momentum toward adoption of comprehensive reporting practices.

Current Challenges in Cryo-EM Methods Documentation

Despite significant advancements in cryo-electron microscopy (cryo-EM) for materials science research, the field faces substantial challenges in standardizing documentation practices. One primary issue is the inconsistent reporting of sample preparation protocols, which critically impacts result reproducibility. Researchers often provide insufficient details about vitrification conditions, grid types, and plasma cleaning parameters, making it difficult for others to replicate experiments.

Data acquisition parameters represent another problematic area, with many publications lacking comprehensive information about microscope settings, detector configurations, and dose management strategies. This omission undermines the ability to evaluate data quality and compare results across different studies, ultimately hindering scientific progress in the field.

Image processing workflows present particular documentation challenges due to their complexity and the rapid evolution of software tools. Many materials papers fail to document processing steps with sufficient detail, omitting critical parameters such as motion correction settings, CTF estimation methods, particle selection criteria, and classification strategies. Without this information, readers cannot adequately assess the validity of structural interpretations.

Resolution reporting and validation metrics suffer from inconsistency across publications. Some researchers report nominal resolution values without appropriate validation, while others employ different metrics or thresholds, making cross-study comparisons problematic. The materials science community lacks consensus on which validation approaches are most appropriate for different types of specimens.

Software version documentation remains inadequate in many publications, with authors frequently omitting specific version numbers or custom modifications to algorithms. As cryo-EM software rapidly evolves, this information becomes crucial for result interpretation and reproduction.

Data deposition practices vary widely, with some researchers providing comprehensive datasets while others share only processed maps or selected raw data. The absence of standardized requirements for data sharing in materials-focused journals exacerbates this issue, limiting data accessibility and reuse potential.

Interdisciplinary communication barriers compound these challenges, as materials scientists and structural biologists often employ different terminologies and methodological approaches when reporting cryo-EM data. This communication gap impedes knowledge transfer between fields and slows the adoption of best practices across disciplines.

Data acquisition parameters represent another problematic area, with many publications lacking comprehensive information about microscope settings, detector configurations, and dose management strategies. This omission undermines the ability to evaluate data quality and compare results across different studies, ultimately hindering scientific progress in the field.

Image processing workflows present particular documentation challenges due to their complexity and the rapid evolution of software tools. Many materials papers fail to document processing steps with sufficient detail, omitting critical parameters such as motion correction settings, CTF estimation methods, particle selection criteria, and classification strategies. Without this information, readers cannot adequately assess the validity of structural interpretations.

Resolution reporting and validation metrics suffer from inconsistency across publications. Some researchers report nominal resolution values without appropriate validation, while others employ different metrics or thresholds, making cross-study comparisons problematic. The materials science community lacks consensus on which validation approaches are most appropriate for different types of specimens.

Software version documentation remains inadequate in many publications, with authors frequently omitting specific version numbers or custom modifications to algorithms. As cryo-EM software rapidly evolves, this information becomes crucial for result interpretation and reproduction.

Data deposition practices vary widely, with some researchers providing comprehensive datasets while others share only processed maps or selected raw data. The absence of standardized requirements for data sharing in materials-focused journals exacerbates this issue, limiting data accessibility and reuse potential.

Interdisciplinary communication barriers compound these challenges, as materials scientists and structural biologists often employ different terminologies and methodological approaches when reporting cryo-EM data. This communication gap impedes knowledge transfer between fields and slows the adoption of best practices across disciplines.

Current Best Practices for Cryo-EM Methods Reporting

01 Image processing and analysis methods for Cryo-EM

Advanced computational methods for processing and analyzing cryo-electron microscopy images to enhance resolution and extract structural information. These techniques include image reconstruction algorithms, noise reduction, particle picking, and classification methods that improve the quality of 3D reconstructions from 2D projections. The methods enable researchers to achieve higher resolution structures and better interpret complex biological assemblies.- Data acquisition and processing methods in cryo-EM: Advanced methods for acquiring and processing cryo-EM data to improve resolution and accuracy. These techniques include specialized algorithms for image reconstruction, noise reduction, and signal enhancement. The methods focus on optimizing data collection parameters, implementing automated acquisition protocols, and developing computational approaches for extracting high-quality structural information from raw cryo-EM images.

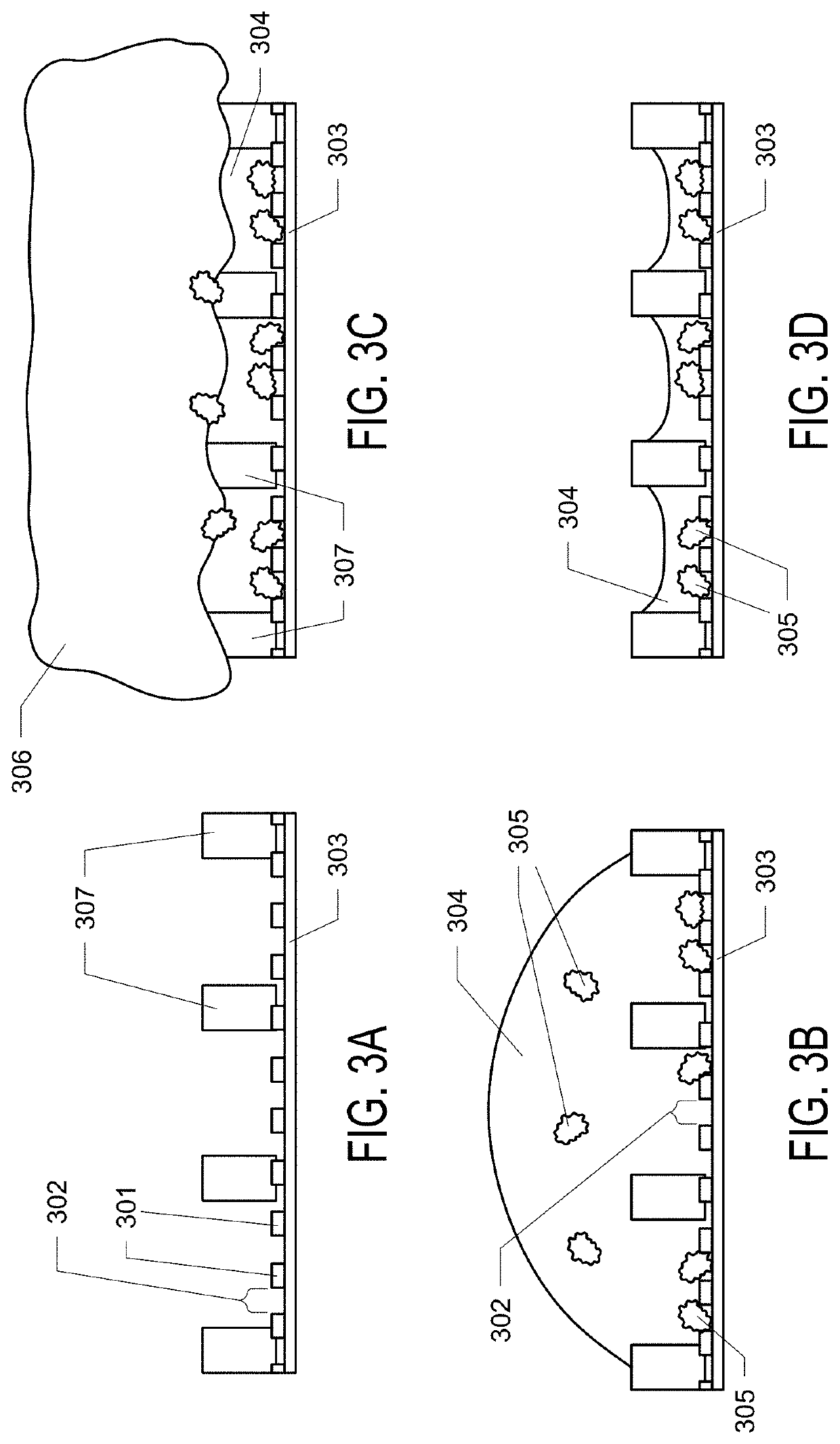

- Sample preparation techniques for cryo-EM: Innovative approaches for preparing biological samples for cryo-EM analysis. These techniques include methods for vitrification, grid preparation, and specimen handling that preserve the native structure of biological macromolecules. The approaches focus on minimizing artifacts, improving sample homogeneity, and enhancing the distribution of particles in different orientations to facilitate comprehensive structural analysis.

- Visualization and reporting tools for cryo-EM results: Specialized software and methodologies for visualizing and reporting cryo-EM structural data. These tools enable researchers to present complex 3D structural information in accessible formats, generate comprehensive reports of experimental conditions and results, and create standardized documentation for publication and data sharing. The approaches include interactive visualization interfaces, automated report generation, and methods for communicating uncertainty in structural models.

- Integration of cryo-EM with other analytical techniques: Methods for combining cryo-EM with complementary analytical approaches to enhance structural insights. These integrated approaches incorporate data from techniques such as X-ray crystallography, NMR spectroscopy, and mass spectrometry to validate and extend cryo-EM findings. The methods include computational frameworks for data fusion, correlation of structural information across different resolution scales, and protocols for comprehensive structural characterization.

- Automation and AI-assisted cryo-EM analysis: Advanced systems for automating cryo-EM workflows and implementing artificial intelligence to enhance data analysis. These approaches include machine learning algorithms for particle picking, classification, and model building, as well as automated systems for microscope operation and sample handling. The methods focus on increasing throughput, improving reproducibility, and enabling non-experts to obtain high-quality structural information from cryo-EM experiments.

02 Sample preparation techniques for Cryo-EM

Specialized methods for preparing biological specimens for cryogenic electron microscopy to preserve native structures. These techniques include vitrification protocols, grid preparation methods, and approaches to prevent ice contamination. Proper sample preparation is crucial for obtaining high-quality images and accurate structural information, as it maintains the specimen in a near-native state without crystalline ice formation.Expand Specific Solutions03 Data management and reporting systems for Cryo-EM

Comprehensive systems for managing, documenting, and reporting cryo-EM experimental data and results. These systems include standardized formats for data collection, storage solutions for large datasets, and structured reporting frameworks that ensure reproducibility and facilitate data sharing. The methods enable researchers to maintain detailed records of experimental conditions, processing parameters, and structural findings.Expand Specific Solutions04 Hardware innovations for Cryo-EM imaging

Technical advancements in cryo-EM instrumentation that improve imaging capabilities and data collection efficiency. These innovations include detector technologies, stage designs, and microscope components that enhance resolution, reduce beam-induced damage, and enable automated data acquisition. The hardware developments allow for faster throughput and better quality data collection in structural biology research.Expand Specific Solutions05 Integration of Cryo-EM with complementary techniques

Methods for combining cryo-EM with other structural and analytical techniques to provide comprehensive structural insights. These approaches integrate data from techniques such as X-ray crystallography, NMR spectroscopy, and computational modeling to validate and enhance structural information. The integrated methods enable researchers to overcome limitations of individual techniques and obtain more complete structural characterizations of biological systems.Expand Specific Solutions

Leading Institutions and Journals in Cryo-EM Materials Research

The cryo-electron microscopy (cryo-EM) field for materials science is currently in a rapid growth phase, with market size expanding significantly due to increasing applications in structural biology and materials characterization. The competitive landscape features established academic institutions (Tsinghua University, Peking University, University of Washington) collaborating with specialized equipment manufacturers (FEI Co., Quantifoil Micro Tools) and research centers (New York Structural Biology Center, Max Planck Society). Technical maturity varies across applications, with biological cryo-EM more advanced than materials science implementations. Leading companies like FEI (now part of Thermo Fisher) dominate instrumentation, while specialized grid manufacturers (MiTeGen, Quantifoil) control critical sample preparation technologies. The field is transitioning from method development to standardization, with increasing focus on establishing consistent reporting protocols for materials science applications.

Institute of Biophysics of Chinese Academy of Sciences

Technical Solution: The Institute of Biophysics of Chinese Academy of Sciences has developed comprehensive cryo-EM methodological protocols specifically tailored for materials science applications. Their approach emphasizes rigorous sample preparation techniques including controlled vitrification processes that preserve native structures of materials at atomic resolution. They pioneered the use of graphene-oxide supports for improved background contrast and reduced beam-induced motion during imaging. Their methodological framework includes detailed reporting standards covering microscope parameters (voltage, dose rate, total exposure), detector specifications (pixel size, frame rate), and processing workflows with validation metrics. The institute has established a standardized data management system that ensures complete experimental reproducibility through comprehensive metadata recording. Their protocols specifically address the challenges of beam-sensitive materials through dose-fractionation strategies and frame alignment algorithms optimized for inorganic specimens. The institute also developed specialized image processing pipelines that account for the unique contrast mechanisms in materials samples compared to biological specimens.

Strengths: Their methodologies excel at preserving structural integrity of beam-sensitive materials while achieving high resolution. Their standardized reporting framework ensures experimental reproducibility across different research groups. Weaknesses: Their protocols may require specialized equipment not universally available, and the comprehensive reporting standards can be time-consuming to implement for routine analyses.

FEI Co.

Technical Solution: FEI Co. (now part of Thermo Fisher Scientific) has developed an integrated cryo-EM workflow solution specifically designed for materials science applications. Their approach combines specialized hardware innovations with comprehensive reporting protocols. The company's Titan Krios and Talos microscope platforms have been adapted with materials-specific holders and stage designs that minimize thermal drift—critical for high-resolution materials analysis. Their workflow incorporates automated data collection software (EPU) modified to handle the unique contrast properties of materials specimens, with specialized acquisition parameters that balance beam damage against resolution requirements. FEI's reporting framework emphasizes quantitative documentation of microscope alignment procedures, including coma-free alignment verification and energy filter calibration specifics. Their methodology includes detailed protocols for reporting beam conditions (convergence angle, beam current density) that affect materials differently than biological samples. The company has also developed materials-specific processing workflows that incorporate appropriate CTF correction models accounting for the higher atomic numbers typically found in materials specimens compared to biological samples.

Strengths: Their integrated hardware-software solutions provide end-to-end consistency in data collection and reporting. Their automated workflows reduce user variability, enhancing reproducibility across different operators and facilities. Weaknesses: Their proprietary systems may create vendor lock-in, and their reporting standards may be overly optimized for their own hardware ecosystem rather than being universally applicable.

Key Technical Parameters and Metadata Requirements

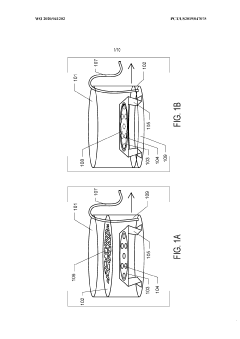

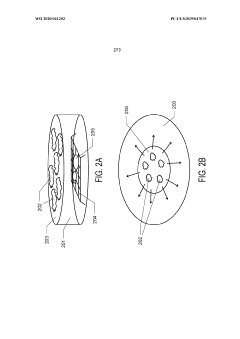

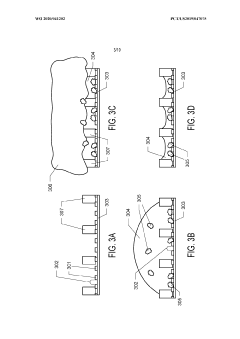

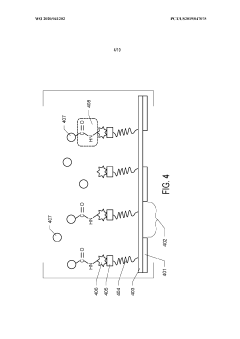

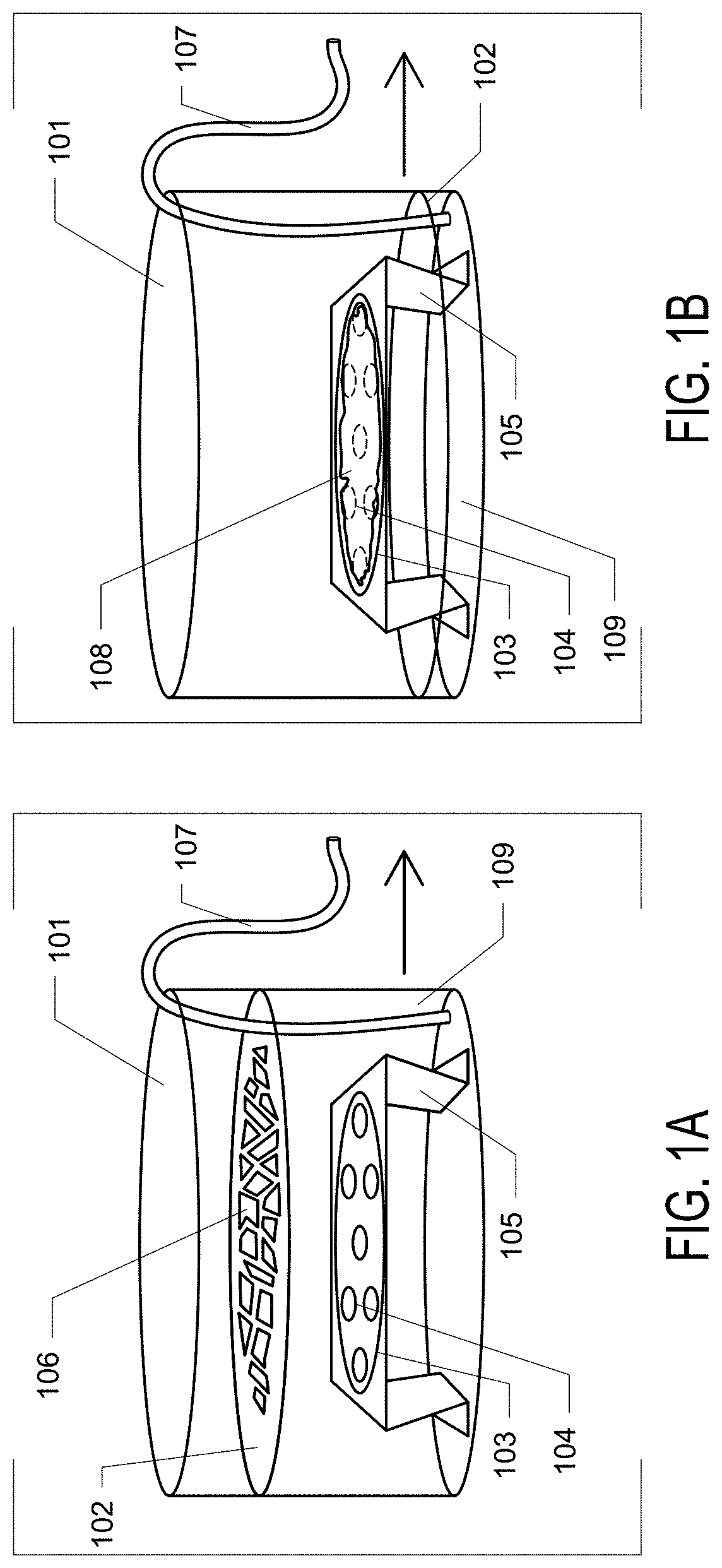

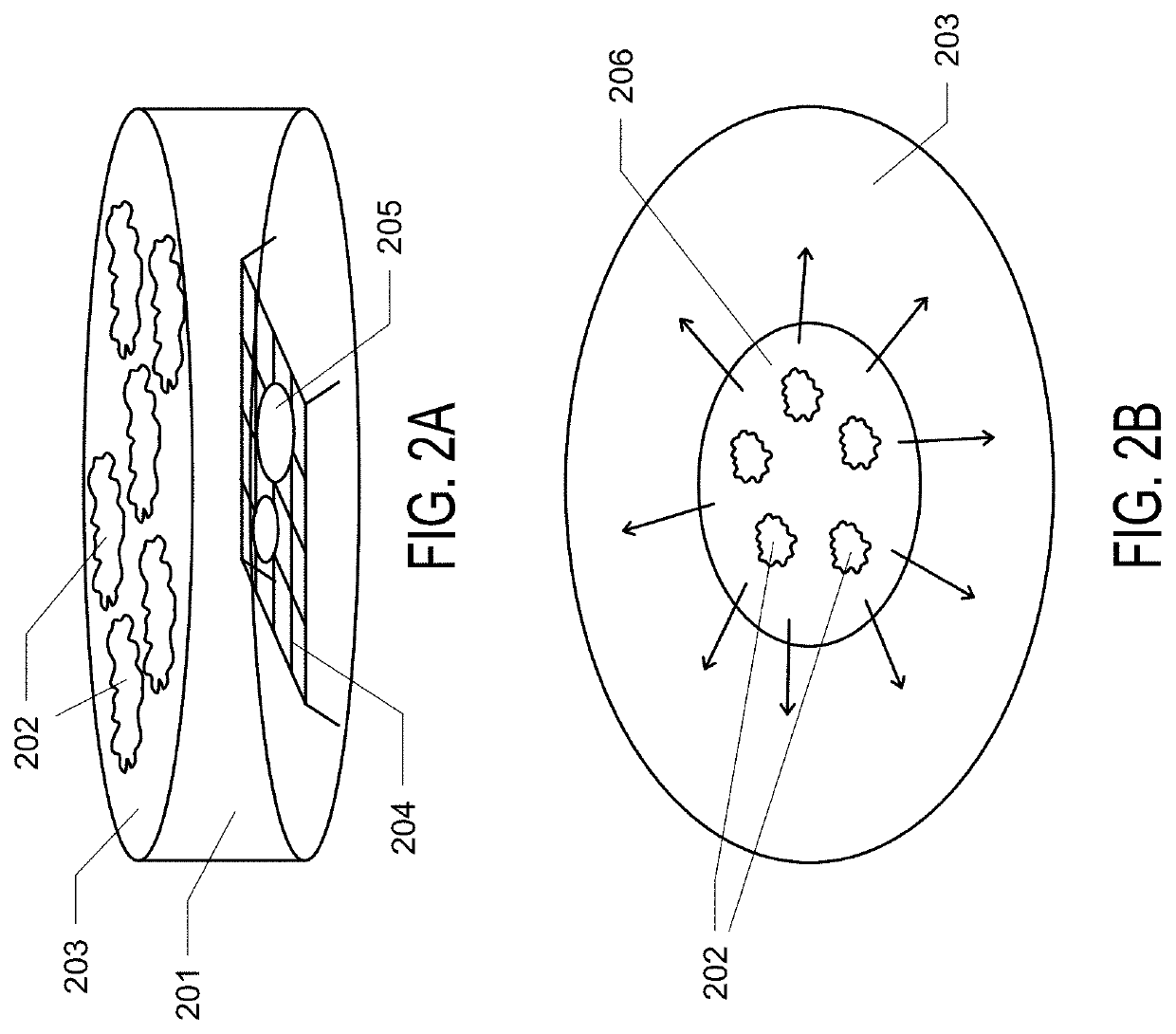

Graphene oxide affinity sample grids for cryo-em

PatentWO2020041202A1

Innovation

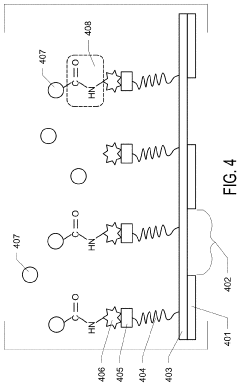

- The use of graphene oxide affinity grids with functionalized surfaces, including polyethylene glycol spacers, to immobilize samples away from the air-water interface and substrate interactions, enabling diverse target species capture and storage, and facilitating high-quality sample preparation for cryo-EM imaging.

Graphene Oxide Affinity Sample Grids for Cyro-EM

PatentActiveUS20210310910A1

Innovation

- The use of graphene oxide films functionalized with various chemistries for immobilizing diverse target species on cryo-EM grids, combined with polyethylene glycol linkers to position samples optimally away from the air-water interface and substrate, enabling efficient and versatile sample preparation for high-quality cryo-EM imaging.

Data Reproducibility and Validation Protocols

Reproducibility and validation are critical components in cryo-electron microscopy (cryo-EM) research for materials science. The field currently faces significant challenges in standardizing protocols that ensure experimental results can be independently verified and reproduced. A comprehensive data reproducibility framework must include detailed documentation of sample preparation, imaging conditions, data processing workflows, and validation metrics.

Sample preparation protocols require meticulous documentation, including grid type, plasma cleaning parameters, vitrification conditions, and storage methods. These factors significantly impact ice thickness, particle distribution, and ultimately, the quality of collected data. Researchers should report quantitative measurements such as ice thickness gradients and particle concentration to enable others to replicate their experimental conditions.

Data acquisition parameters must be thoroughly documented, including microscope model, detector specifications, beam energy, dose rate, and frame collection strategy. The total electron dose should be reported alongside the dose per frame and exposure time, as these parameters directly influence radiation damage and resolution limits. Additionally, calibration procedures for pixel size and magnification should be explicitly stated, as these measurements impact the accuracy of structural determinations.

Processing workflows represent another critical area requiring standardization. Materials papers should include comprehensive descriptions of motion correction, CTF estimation, particle picking strategies, and classification methods. Software packages and version numbers must be specified, along with key parameters used during processing. Importantly, researchers should provide access to raw data and processing scripts through public repositories to enable independent verification.

Validation protocols should incorporate resolution assessment using multiple metrics beyond the conventional Fourier Shell Correlation (FSC). These include local resolution estimation, map-to-model validation, and tilt-pair analysis where appropriate. For materials applications specifically, researchers should validate structural models against known physical and chemical constraints of the material system under investigation. Quantitative assessments of model quality, including bond lengths, angles, and Ramachandran statistics for protein components, provide additional validation metrics.

Data deposition in public repositories such as the Electron Microscopy Data Bank (EMDB) and Protein Data Bank (PDB) should be mandatory for publication. These submissions should include raw micrographs, particle stacks, maps at various processing stages, and final models with associated validation reports. The implementation of standardized reporting templates would significantly enhance reproducibility across the field.

Sample preparation protocols require meticulous documentation, including grid type, plasma cleaning parameters, vitrification conditions, and storage methods. These factors significantly impact ice thickness, particle distribution, and ultimately, the quality of collected data. Researchers should report quantitative measurements such as ice thickness gradients and particle concentration to enable others to replicate their experimental conditions.

Data acquisition parameters must be thoroughly documented, including microscope model, detector specifications, beam energy, dose rate, and frame collection strategy. The total electron dose should be reported alongside the dose per frame and exposure time, as these parameters directly influence radiation damage and resolution limits. Additionally, calibration procedures for pixel size and magnification should be explicitly stated, as these measurements impact the accuracy of structural determinations.

Processing workflows represent another critical area requiring standardization. Materials papers should include comprehensive descriptions of motion correction, CTF estimation, particle picking strategies, and classification methods. Software packages and version numbers must be specified, along with key parameters used during processing. Importantly, researchers should provide access to raw data and processing scripts through public repositories to enable independent verification.

Validation protocols should incorporate resolution assessment using multiple metrics beyond the conventional Fourier Shell Correlation (FSC). These include local resolution estimation, map-to-model validation, and tilt-pair analysis where appropriate. For materials applications specifically, researchers should validate structural models against known physical and chemical constraints of the material system under investigation. Quantitative assessments of model quality, including bond lengths, angles, and Ramachandran statistics for protein components, provide additional validation metrics.

Data deposition in public repositories such as the Electron Microscopy Data Bank (EMDB) and Protein Data Bank (PDB) should be mandatory for publication. These submissions should include raw micrographs, particle stacks, maps at various processing stages, and final models with associated validation reports. The implementation of standardized reporting templates would significantly enhance reproducibility across the field.

International Standardization Efforts for Cryo-EM Reporting

The global cryo-electron microscopy (cryo-EM) community has recognized the critical need for standardized reporting protocols to ensure reproducibility and reliability of research findings in materials science. Several international organizations have spearheaded efforts to establish comprehensive guidelines for cryo-EM data reporting, including the International Union of Crystallography (IUCr), the Electron Microscopy Society of America (EMSA), and the European Microscopy Society (EMS).

In 2018, the IUCr established a commission specifically focused on electron crystallography, which has been instrumental in developing preliminary reporting standards for cryo-EM in materials research. Their guidelines emphasize detailed documentation of sample preparation methods, imaging conditions, and data processing workflows. These efforts have been complemented by the work of the CryoEM Global Resources Consortium, which brings together experts from North America, Europe, and Asia to harmonize reporting practices.

The EMDataBank, an international repository for cryo-EM data, has implemented validation tools that enforce certain reporting requirements when researchers deposit their structural data. This has significantly improved the consistency of metadata reporting across the field. Additionally, the Worldwide Protein Data Bank (wwPDB) has extended its validation framework to include cryo-EM specific metrics, providing researchers with standardized tools to assess data quality.

Journal publishers have also played a crucial role in standardization efforts. Nature journals, Science, and specialized publications like Journal of Structural Biology have adopted increasingly stringent requirements for cryo-EM method reporting in materials papers. These requirements typically include mandatory reporting of resolution metrics, sample vitrification parameters, and detailed image processing workflows.

The Materials Research Society (MRS) and the International Federation of Societies for Microscopy (IFSM) have jointly established working groups dedicated to developing consensus guidelines for cryo-EM reporting in materials science. Their recommendations emphasize the importance of reporting beam-sensitive sample handling procedures and dose-fractionation strategies, which are particularly relevant for materials applications.

Recent international workshops, including the 2022 Cryo-EM Data Management Summit and the 2023 International Conference on Electron Cryomicroscopy of Materials, have further advanced standardization efforts by bringing together stakeholders from academia, industry, and publishing. These forums have facilitated the exchange of best practices and the development of community-endorsed reporting templates that are gaining widespread adoption.

In 2018, the IUCr established a commission specifically focused on electron crystallography, which has been instrumental in developing preliminary reporting standards for cryo-EM in materials research. Their guidelines emphasize detailed documentation of sample preparation methods, imaging conditions, and data processing workflows. These efforts have been complemented by the work of the CryoEM Global Resources Consortium, which brings together experts from North America, Europe, and Asia to harmonize reporting practices.

The EMDataBank, an international repository for cryo-EM data, has implemented validation tools that enforce certain reporting requirements when researchers deposit their structural data. This has significantly improved the consistency of metadata reporting across the field. Additionally, the Worldwide Protein Data Bank (wwPDB) has extended its validation framework to include cryo-EM specific metrics, providing researchers with standardized tools to assess data quality.

Journal publishers have also played a crucial role in standardization efforts. Nature journals, Science, and specialized publications like Journal of Structural Biology have adopted increasingly stringent requirements for cryo-EM method reporting in materials papers. These requirements typically include mandatory reporting of resolution metrics, sample vitrification parameters, and detailed image processing workflows.

The Materials Research Society (MRS) and the International Federation of Societies for Microscopy (IFSM) have jointly established working groups dedicated to developing consensus guidelines for cryo-EM reporting in materials science. Their recommendations emphasize the importance of reporting beam-sensitive sample handling procedures and dose-fractionation strategies, which are particularly relevant for materials applications.

Recent international workshops, including the 2022 Cryo-EM Data Management Summit and the 2023 International Conference on Electron Cryomicroscopy of Materials, have further advanced standardization efforts by bringing together stakeholders from academia, industry, and publishing. These forums have facilitated the exchange of best practices and the development of community-endorsed reporting templates that are gaining widespread adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!