Case Studies: Cryo-EM Insights Into Battery Degradation

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryo-EM Battery Degradation Background and Objectives

Cryogenic electron microscopy (Cryo-EM) has emerged as a revolutionary analytical technique in materials science, particularly for understanding battery degradation mechanisms at the atomic and molecular levels. This technique, originally developed for biological specimen imaging, has evolved significantly over the past two decades to become an indispensable tool for battery research. The evolution of Cryo-EM technology has been marked by improvements in resolution capabilities, from nanometer to sub-angstrom levels, enabling unprecedented insights into battery material structures and interfaces.

The primary objective of applying Cryo-EM to battery degradation studies is to visualize and characterize the complex structural and chemical changes that occur during battery cycling. These changes, often invisible to conventional analytical methods, are critical determinants of battery performance, longevity, and safety. By preserving samples in their native state through vitrification, Cryo-EM overcomes limitations of traditional electron microscopy techniques that can introduce artifacts during sample preparation.

Recent technological advancements in Cryo-EM, including direct electron detectors, automated data collection, and sophisticated image processing algorithms, have dramatically enhanced our ability to study battery materials under near-operating conditions. These developments have coincided with growing global demand for high-performance energy storage solutions, particularly for electric vehicles and renewable energy integration, creating a perfect technological convergence.

The field has witnessed significant milestones, including the first high-resolution imaging of solid-electrolyte interphase (SEI) layers in 2017, visualization of lithium dendrite formation processes in 2019, and most recently, atomic-scale mapping of cathode-electrolyte interfaces in 2022. These achievements have transformed our understanding of degradation mechanisms from theoretical models to observable phenomena.

Current research trends are focusing on in situ and operando Cryo-EM techniques that allow real-time observation of dynamic processes during battery operation. This represents a shift from post-mortem analysis to dynamic studies that can directly correlate structural changes with electrochemical performance metrics. The ultimate technical goal is to develop predictive models of battery degradation based on fundamental mechanistic understanding rather than empirical observations.

The integration of Cryo-EM with complementary techniques such as X-ray diffraction, spectroscopic methods, and computational modeling is creating a multi-modal approach to battery research. This holistic strategy aims to bridge the gap between atomic-scale observations and device-level performance, establishing causal relationships between structural degradation and capacity fade, resistance increase, and other performance metrics that determine battery lifetime.

The primary objective of applying Cryo-EM to battery degradation studies is to visualize and characterize the complex structural and chemical changes that occur during battery cycling. These changes, often invisible to conventional analytical methods, are critical determinants of battery performance, longevity, and safety. By preserving samples in their native state through vitrification, Cryo-EM overcomes limitations of traditional electron microscopy techniques that can introduce artifacts during sample preparation.

Recent technological advancements in Cryo-EM, including direct electron detectors, automated data collection, and sophisticated image processing algorithms, have dramatically enhanced our ability to study battery materials under near-operating conditions. These developments have coincided with growing global demand for high-performance energy storage solutions, particularly for electric vehicles and renewable energy integration, creating a perfect technological convergence.

The field has witnessed significant milestones, including the first high-resolution imaging of solid-electrolyte interphase (SEI) layers in 2017, visualization of lithium dendrite formation processes in 2019, and most recently, atomic-scale mapping of cathode-electrolyte interfaces in 2022. These achievements have transformed our understanding of degradation mechanisms from theoretical models to observable phenomena.

Current research trends are focusing on in situ and operando Cryo-EM techniques that allow real-time observation of dynamic processes during battery operation. This represents a shift from post-mortem analysis to dynamic studies that can directly correlate structural changes with electrochemical performance metrics. The ultimate technical goal is to develop predictive models of battery degradation based on fundamental mechanistic understanding rather than empirical observations.

The integration of Cryo-EM with complementary techniques such as X-ray diffraction, spectroscopic methods, and computational modeling is creating a multi-modal approach to battery research. This holistic strategy aims to bridge the gap between atomic-scale observations and device-level performance, establishing causal relationships between structural degradation and capacity fade, resistance increase, and other performance metrics that determine battery lifetime.

Market Demand for Advanced Battery Degradation Analysis

The global battery market is experiencing unprecedented growth, with projections indicating a compound annual growth rate of 25% through 2030, primarily driven by electric vehicle adoption and renewable energy storage systems. Within this expanding market, there exists a critical and growing demand for advanced battery degradation analysis technologies, particularly those leveraging cutting-edge imaging techniques like cryo-electron microscopy (cryo-EM).

Battery manufacturers face mounting pressure to extend battery lifespans while maintaining safety and performance standards. This pressure stems from consumer expectations for longer-lasting devices, automotive industry demands for EV batteries with 10+ year warranties, and grid storage applications requiring decades of reliable operation. Consequently, the market for sophisticated degradation analysis tools is expanding rapidly, with industry analysts valuing this specialized segment at over $2 billion annually.

Cryo-EM technology represents a revolutionary approach to battery analysis, offering unprecedented insights into degradation mechanisms at the nanoscale level. The market demand for this technology is particularly strong in three key sectors: electric vehicle manufacturing, consumer electronics, and grid-scale energy storage. Each sector requires detailed understanding of different degradation pathways to optimize their specific battery chemistries and operating conditions.

Regulatory factors are further accelerating market demand. Stringent safety standards in automotive and aviation industries necessitate comprehensive degradation analysis throughout product development cycles. Additionally, emerging sustainability regulations requiring battery recycling and second-life applications create demand for precise assessment of battery health and remaining useful life.

The economic implications of battery degradation are substantial, with premature failure costs estimated at billions annually across industries. This economic pressure creates willingness among manufacturers to invest in advanced analytical technologies that can identify degradation mechanisms earlier and more accurately than conventional methods.

Research institutions and battery development laboratories represent another significant market segment, with increasing research budgets allocated specifically for advanced characterization techniques. The academic-industrial partnership model is becoming prevalent, with universities developing fundamental cryo-EM methodologies while industry partners fund application-specific implementations.

Geographically, market demand is concentrated in regions with established battery manufacturing ecosystems: East Asia (particularly Japan, South Korea, and China), North America, and Western Europe. However, emerging battery production hubs in Southeast Asia and Eastern Europe are rapidly increasing their analytical capabilities, representing new growth markets for advanced degradation analysis technologies.

Battery manufacturers face mounting pressure to extend battery lifespans while maintaining safety and performance standards. This pressure stems from consumer expectations for longer-lasting devices, automotive industry demands for EV batteries with 10+ year warranties, and grid storage applications requiring decades of reliable operation. Consequently, the market for sophisticated degradation analysis tools is expanding rapidly, with industry analysts valuing this specialized segment at over $2 billion annually.

Cryo-EM technology represents a revolutionary approach to battery analysis, offering unprecedented insights into degradation mechanisms at the nanoscale level. The market demand for this technology is particularly strong in three key sectors: electric vehicle manufacturing, consumer electronics, and grid-scale energy storage. Each sector requires detailed understanding of different degradation pathways to optimize their specific battery chemistries and operating conditions.

Regulatory factors are further accelerating market demand. Stringent safety standards in automotive and aviation industries necessitate comprehensive degradation analysis throughout product development cycles. Additionally, emerging sustainability regulations requiring battery recycling and second-life applications create demand for precise assessment of battery health and remaining useful life.

The economic implications of battery degradation are substantial, with premature failure costs estimated at billions annually across industries. This economic pressure creates willingness among manufacturers to invest in advanced analytical technologies that can identify degradation mechanisms earlier and more accurately than conventional methods.

Research institutions and battery development laboratories represent another significant market segment, with increasing research budgets allocated specifically for advanced characterization techniques. The academic-industrial partnership model is becoming prevalent, with universities developing fundamental cryo-EM methodologies while industry partners fund application-specific implementations.

Geographically, market demand is concentrated in regions with established battery manufacturing ecosystems: East Asia (particularly Japan, South Korea, and China), North America, and Western Europe. However, emerging battery production hubs in Southeast Asia and Eastern Europe are rapidly increasing their analytical capabilities, representing new growth markets for advanced degradation analysis technologies.

Current State and Challenges in Battery Imaging Technologies

Battery imaging technologies have evolved significantly over the past decades, yet they continue to face substantial challenges in providing comprehensive insights into degradation mechanisms. Currently, several imaging techniques dominate the landscape, each with distinct capabilities and limitations. Scanning Electron Microscopy (SEM) offers high-resolution surface imaging but struggles with internal structure visualization. Transmission Electron Microscopy (TEM) provides atomic-level resolution but requires extremely thin samples, limiting its application for intact battery components.

X-ray tomography has emerged as a powerful non-destructive technique, allowing three-dimensional visualization of battery internals across multiple length scales. However, it faces resolution limitations when examining nanoscale features critical to understanding degradation pathways. Focused Ion Beam-SEM (FIB-SEM) enables 3D reconstruction with nanometer resolution but is inherently destructive and time-consuming, making dynamic studies challenging.

Cryo-electron microscopy (Cryo-EM) represents a revolutionary advancement, preserving battery materials in their native state by flash-freezing samples. This technique has recently demonstrated unprecedented capabilities in visualizing the solid-electrolyte interphase (SEI) layer and lithium dendrite formation. Nevertheless, sample preparation remains exceptionally challenging, requiring specialized equipment and expertise not widely available in battery research facilities.

A significant technical hurdle across all imaging modalities is the beam sensitivity of battery materials. Electron and X-ray beams can induce artifacts or damage the very structures being studied, particularly organic components in electrolytes and SEI layers. This creates a fundamental paradox: higher resolution typically requires more intense beam exposure, potentially compromising sample integrity.

In-situ and operando imaging capabilities remain limited despite their critical importance. Current technologies struggle to maintain resolution while accommodating the environmental conditions necessary for battery operation. The development of specialized electrochemical cells compatible with various imaging techniques has progressed, but trade-offs between electrochemical performance and imaging quality persist.

Data processing presents another significant challenge. Advanced imaging techniques generate massive datasets requiring sophisticated algorithms for reconstruction, segmentation, and analysis. Machine learning approaches show promise but require extensive training datasets that are not yet widely available for battery systems.

Correlative imaging—combining multiple techniques to overcome individual limitations—is increasingly recognized as essential but faces practical implementation challenges. Workflows for efficiently transferring samples between instruments while maintaining sample integrity remain underdeveloped, limiting the potential of this approach.

X-ray tomography has emerged as a powerful non-destructive technique, allowing three-dimensional visualization of battery internals across multiple length scales. However, it faces resolution limitations when examining nanoscale features critical to understanding degradation pathways. Focused Ion Beam-SEM (FIB-SEM) enables 3D reconstruction with nanometer resolution but is inherently destructive and time-consuming, making dynamic studies challenging.

Cryo-electron microscopy (Cryo-EM) represents a revolutionary advancement, preserving battery materials in their native state by flash-freezing samples. This technique has recently demonstrated unprecedented capabilities in visualizing the solid-electrolyte interphase (SEI) layer and lithium dendrite formation. Nevertheless, sample preparation remains exceptionally challenging, requiring specialized equipment and expertise not widely available in battery research facilities.

A significant technical hurdle across all imaging modalities is the beam sensitivity of battery materials. Electron and X-ray beams can induce artifacts or damage the very structures being studied, particularly organic components in electrolytes and SEI layers. This creates a fundamental paradox: higher resolution typically requires more intense beam exposure, potentially compromising sample integrity.

In-situ and operando imaging capabilities remain limited despite their critical importance. Current technologies struggle to maintain resolution while accommodating the environmental conditions necessary for battery operation. The development of specialized electrochemical cells compatible with various imaging techniques has progressed, but trade-offs between electrochemical performance and imaging quality persist.

Data processing presents another significant challenge. Advanced imaging techniques generate massive datasets requiring sophisticated algorithms for reconstruction, segmentation, and analysis. Machine learning approaches show promise but require extensive training datasets that are not yet widely available for battery systems.

Correlative imaging—combining multiple techniques to overcome individual limitations—is increasingly recognized as essential but faces practical implementation challenges. Workflows for efficiently transferring samples between instruments while maintaining sample integrity remain underdeveloped, limiting the potential of this approach.

Existing Cryo-EM Methodologies for Battery Degradation Studies

01 Cryo-EM techniques for battery material characterization

Cryogenic electron microscopy (Cryo-EM) techniques are used to characterize battery materials at the atomic and molecular level. By freezing samples to cryogenic temperatures, researchers can preserve the native structure of battery components and observe them in their near-natural state. This approach allows for high-resolution imaging of electrode materials, electrolyte interfaces, and degradation products without introducing artifacts that might occur at room temperature. These techniques help in understanding the fundamental mechanisms of battery operation and failure.- Cryo-EM techniques for battery material characterization: Cryogenic electron microscopy (Cryo-EM) techniques are used to characterize battery materials at the atomic and molecular level. By freezing battery samples to cryogenic temperatures, researchers can preserve their native state and minimize beam damage during imaging. This allows for high-resolution visualization of battery components, including electrode materials, electrolyte interfaces, and degradation products, providing insights into battery performance and failure mechanisms.

- In-situ monitoring of battery degradation processes: In-situ Cryo-EM techniques enable real-time observation of battery degradation processes during cycling. By maintaining batteries in operating conditions while imaging at cryogenic temperatures, researchers can capture dynamic changes in electrode morphology, solid-electrolyte interphase (SEI) formation, and lithium dendrite growth. This approach provides valuable information about degradation mechanisms that occur during battery operation, helping to develop strategies to mitigate capacity fade and extend battery life.

- Analysis of solid-electrolyte interphase formation: Cryo-EM enables detailed analysis of the solid-electrolyte interphase (SEI) layer, which forms on battery electrodes during cycling and significantly impacts battery performance and degradation. By preserving the delicate SEI structure through cryogenic freezing, researchers can study its composition, morphology, and evolution over time. This information is crucial for understanding how the SEI contributes to battery degradation and for developing electrolyte formulations that promote stable SEI formation.

- Lithium dendrite growth investigation: Cryo-EM techniques are employed to investigate lithium dendrite formation and growth, a major cause of battery degradation and safety issues. By imaging at cryogenic temperatures, researchers can preserve the native structure of lithium dendrites and study their nucleation, growth patterns, and interaction with the electrolyte and separator. This knowledge helps in developing strategies to suppress dendrite formation and improve battery safety and longevity.

- Machine learning integration with Cryo-EM for battery analysis: Advanced machine learning algorithms are being integrated with Cryo-EM data analysis to enhance the understanding of battery degradation mechanisms. These computational approaches help process and interpret the complex image data generated by Cryo-EM, enabling automated identification of degradation patterns, prediction of failure modes, and optimization of battery materials and designs. The combination of Cryo-EM imaging and machine learning accelerates the development of more durable and efficient battery technologies.

02 Analysis of solid-electrolyte interphase (SEI) formation and degradation

Cryo-EM enables detailed analysis of the solid-electrolyte interphase (SEI) layer, which forms on battery electrodes during cycling. This layer is critical to battery performance and longevity but is challenging to study due to its sensitivity to environmental conditions. By using cryogenic techniques, researchers can preserve the native structure of the SEI and analyze its composition, morphology, and evolution during battery cycling. This information helps in understanding how the SEI contributes to battery degradation and in developing strategies to optimize its properties for improved battery performance.Expand Specific Solutions03 In-situ and operando Cryo-EM for dynamic degradation studies

In-situ and operando Cryo-EM techniques allow researchers to observe battery degradation processes in real-time while the battery is operating. By combining cryogenic sample preparation with specialized holders and experimental setups, it's possible to capture dynamic changes in electrode materials, electrolyte distribution, and interfacial reactions during charge-discharge cycles. These techniques provide insights into degradation mechanisms that cannot be obtained through post-mortem analysis, helping to identify critical failure modes and develop mitigation strategies.Expand Specific Solutions04 Lithium dendrite formation and growth monitoring

Cryo-EM is particularly valuable for studying lithium dendrite formation and growth, which is a major cause of battery failure and safety concerns. The cryogenic conditions preserve the delicate structure of lithium metal and its surrounding electrolyte environment. High-resolution imaging reveals how dendrites nucleate, grow, and penetrate through the separator, potentially causing short circuits. This understanding helps in developing strategies to suppress dendrite formation, such as electrolyte additives, structured current collectors, or artificial SEI layers.Expand Specific Solutions05 Machine learning integration with Cryo-EM for degradation prediction

Advanced data analysis and machine learning techniques are being integrated with Cryo-EM imaging to enhance battery degradation studies. These computational approaches help process the large datasets generated by Cryo-EM and extract meaningful patterns related to degradation mechanisms. Machine learning algorithms can identify subtle structural changes that precede failure, predict degradation pathways, and suggest optimization strategies. This combination of high-resolution imaging and computational analysis accelerates the development of more durable battery materials and designs.Expand Specific Solutions

Key Players in Cryo-EM Battery Analysis Industry

The cryo-electron microscopy (cryo-EM) battery degradation research field is currently in a growth phase, with the market expected to reach significant expansion as battery technology becomes increasingly critical for electric vehicles and energy storage systems. Major automotive manufacturers (Toyota, Hyundai, Kia) and battery producers (LG Energy Solution, Samsung SDI, LG Chem) are heavily investing in this technology to address battery performance and longevity challenges. Research institutions like University of Michigan and Ulsan National Institute collaborate with industry leaders to advance understanding of degradation mechanisms at the nanoscale. The technology is approaching maturity with companies like Siemens, Bosch, and Panasonic integrating cryo-EM insights into battery design processes, while emerging players from China such as Shanghai Mek Sheng Energy Technology are rapidly entering the field with innovative diagnostic approaches.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution在Cryo-EM应用于电池研究方面投入了大量资源,建立了专门的先进材料表征中心。他们的技术方案结合了冷冻电镜与其他先进表征技术,如X射线断层扫描和中子散射,形成了多模态分析平台。特别是,他们开发了专门的样品制备工艺,能够从实际使用过的商业电池中提取样品进行Cryo-EM分析,保持其原始微观结构。该公司的研究重点是理解高镍正极材料(如NMC811)在快充条件下的降解机制,通过Cryo-EM观察到了纳米级裂纹的形成和传播过程。他们还开发了专门的图像分析软件,能够自动识别和量化电池材料中的缺陷和相变,大大提高了分析效率。这些技术已经应用于他们的新一代电池开发,特别是针对电动汽车市场的高能量密度电池。

优势:将基础研究与商业产品开发紧密结合,拥有从材料发现到产品制造的完整产业链。技术应用场景明确,针对实际电池问题。劣势:研究成果多为专有技术,公开发表的学术文献相对有限,可能限制了与学术界的合作深度。

The Regents of the University of Michigan

Technical Solution: 密歇根大学在Cryo-EM应用于电池研究领域处于领先地位,开发了专门的样品制备技术来保持电池材料在电子束下的稳定性。他们的研究团队使用冷冻电镜技术实现了对锂离子电池正极材料纳米结构的原位观察,特别是在充放电循环过程中的结构演变。该团队开发了创新的"液体电池单元",允许在电池操作条件下进行实时成像,捕捉到了以前无法观察到的降解机制,如晶格畸变和相变过程。他们还将Cryo-EM与计算模拟相结合,建立了电池材料降解的多尺度模型,为新一代电池材料设计提供了指导。

优势:拥有世界级的冷冻电镜设施和专业技术团队,样品制备技术先进,能够保持电池材料在电子束下的稳定性。与材料科学和计算模拟团队紧密合作,形成了完整的研究生态系统。劣势:作为学术机构,技术商业化能力有限,需要与工业合作伙伴合作将研究成果转化为实际应用。

Critical Insights from Cryo-EM Battery Case Studies

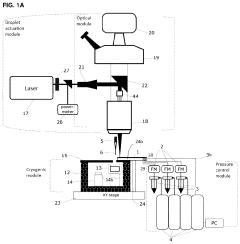

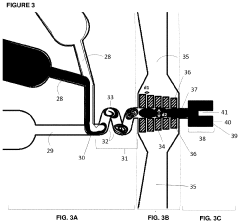

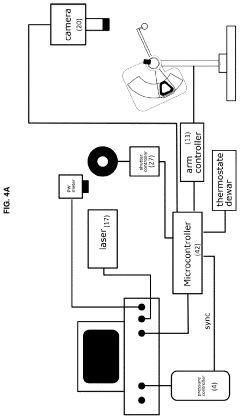

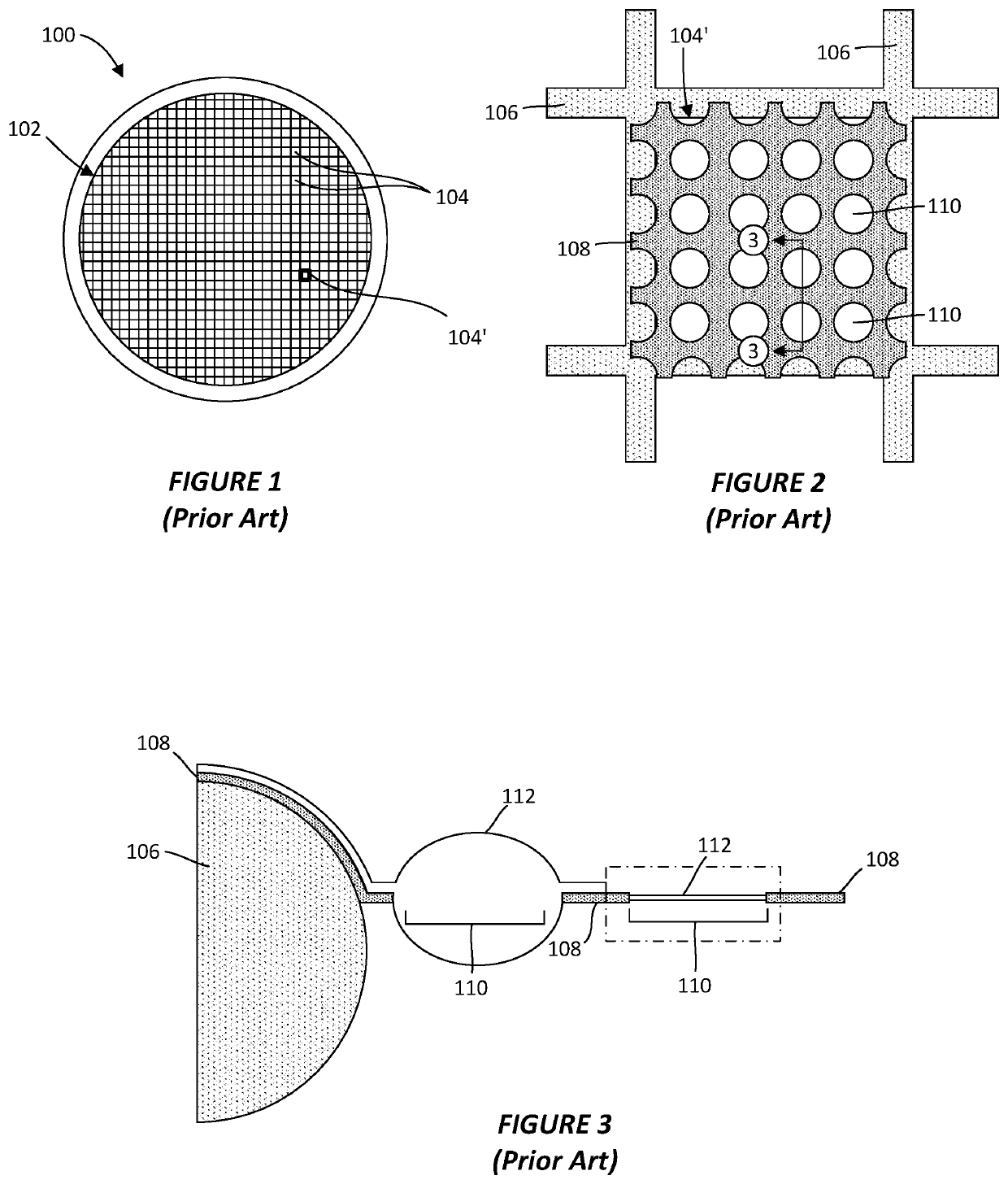

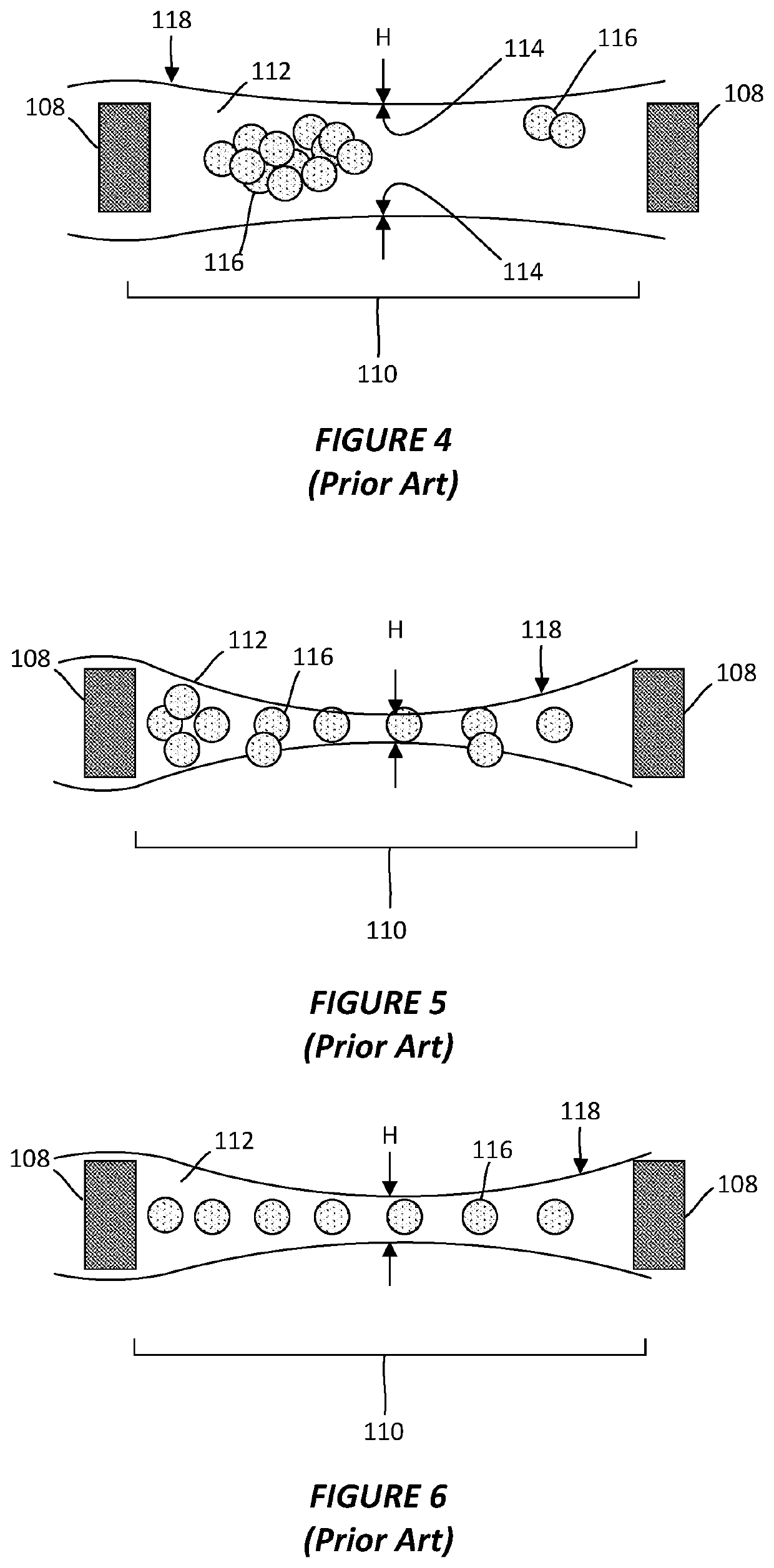

Means and methods for time-resolved sampling

PatentPendingUS20240085288A1

Innovation

- A microfluidic chip with a droplet-on-demand system for fast mixing and controlled droplet generation, combined with a plunger module for rapid vitrification, allowing for low sample consumption and precise control over reaction delay times, enabling millisecond time-resolution sampling.

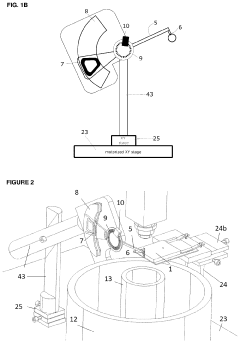

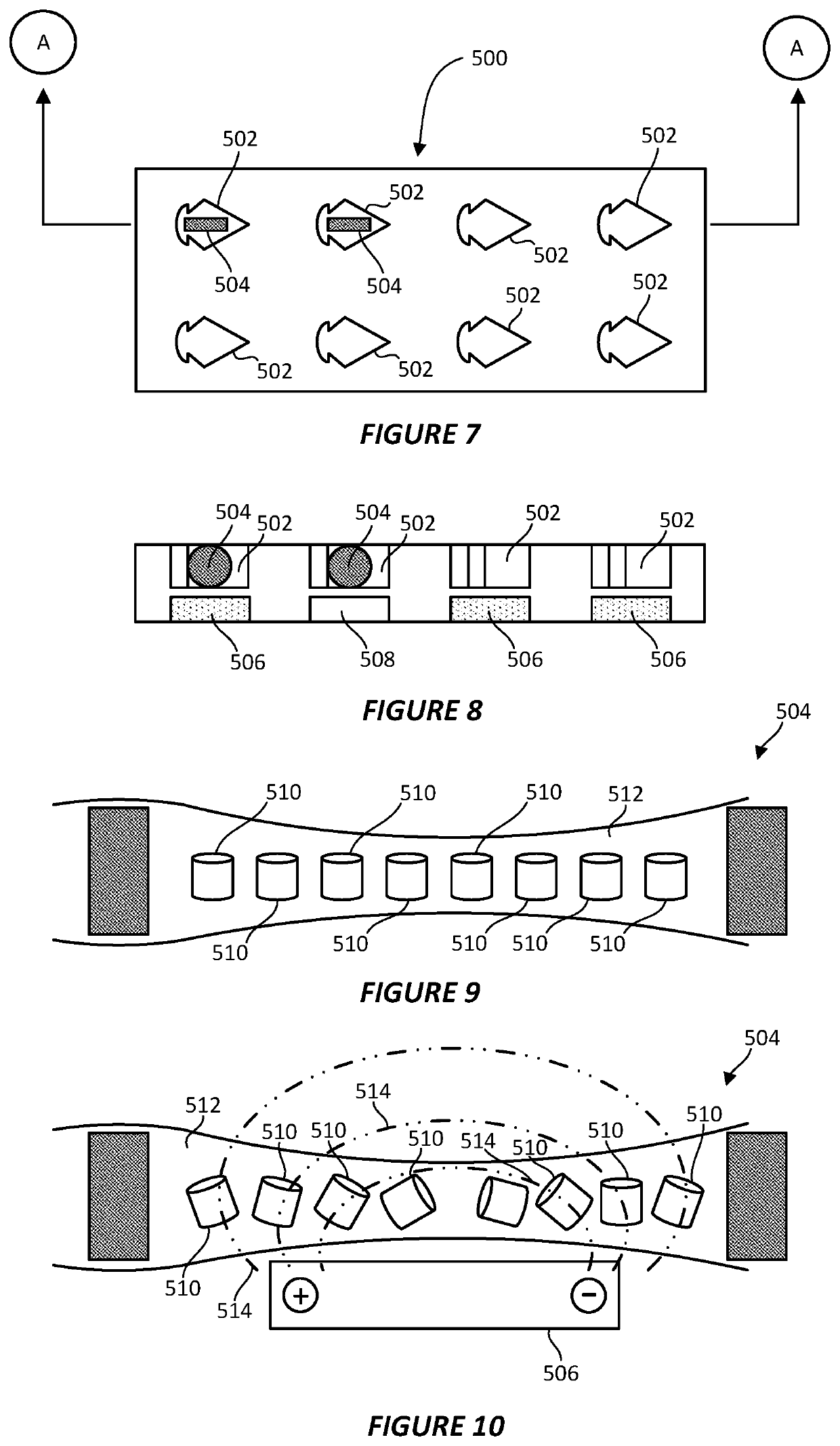

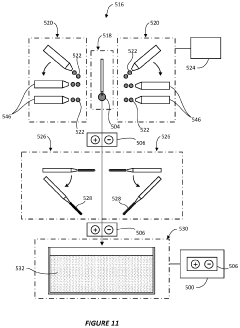

System and method for preparing CRYO-em grids

PatentActiveUS20200363301A1

Innovation

- A method and apparatus that utilize an electromagnetic field (EMF) to re-orient proteins and a system with a sample shaping element and cryogenic vitrifying element to deposit, thin, and vitrify samples on cryo-EM grids, allowing for precise control over sample thickness and orientation, and incorporating a storage device to further randomize protein orientations post-vitrification.

Environmental Impact of Battery Lifecycle Optimization

The environmental implications of battery lifecycle optimization have become increasingly significant as the global adoption of battery technologies continues to accelerate. Cryo-electron microscopy (Cryo-EM) insights into battery degradation mechanisms provide crucial knowledge that can be leveraged to minimize environmental impacts throughout the battery lifecycle. By understanding degradation at the atomic and molecular levels, manufacturers can design batteries with extended lifespans, reducing the frequency of replacement and associated resource consumption.

Battery production involves energy-intensive processes and the extraction of finite mineral resources, including lithium, cobalt, and nickel. These extraction activities often result in habitat destruction, water pollution, and significant carbon emissions. Cryo-EM studies reveal how electrode materials degrade during cycling, enabling the development of more durable materials that require less frequent mining operations and reduce overall environmental footprint.

The operational phase of batteries presents another environmental consideration. Degradation mechanisms identified through Cryo-EM, such as solid-electrolyte interphase (SEI) formation and lithium plating, directly impact energy efficiency. Optimizing these processes based on Cryo-EM insights can enhance energy conversion efficiency, reducing the electricity required for charging and consequently lowering associated carbon emissions from power generation.

End-of-life management represents perhaps the most visible environmental challenge in the battery lifecycle. Current recycling processes recover only a fraction of valuable materials, with significant portions ending up in landfills. Cryo-EM analyses of aged batteries provide detailed information about material transformations, potentially enabling more targeted and efficient recycling technologies that can recover a higher percentage of critical materials.

The environmental benefits of applying Cryo-EM insights extend beyond direct battery improvements. By enabling the development of fast-charging protocols that minimize degradation, these technologies can facilitate greater adoption of renewable energy storage solutions. This transition supports broader decarbonization efforts by providing reliable storage for intermittent renewable energy sources like solar and wind power.

Quantitative lifecycle assessments indicate that extending battery lifespan through degradation-informed design can reduce environmental impact by 20-30% compared to conventional approaches. Furthermore, improved recycling techniques based on Cryo-EM understanding of material transformations could potentially recover up to 95% of critical materials, significantly reducing the need for environmentally damaging mining operations.

Battery production involves energy-intensive processes and the extraction of finite mineral resources, including lithium, cobalt, and nickel. These extraction activities often result in habitat destruction, water pollution, and significant carbon emissions. Cryo-EM studies reveal how electrode materials degrade during cycling, enabling the development of more durable materials that require less frequent mining operations and reduce overall environmental footprint.

The operational phase of batteries presents another environmental consideration. Degradation mechanisms identified through Cryo-EM, such as solid-electrolyte interphase (SEI) formation and lithium plating, directly impact energy efficiency. Optimizing these processes based on Cryo-EM insights can enhance energy conversion efficiency, reducing the electricity required for charging and consequently lowering associated carbon emissions from power generation.

End-of-life management represents perhaps the most visible environmental challenge in the battery lifecycle. Current recycling processes recover only a fraction of valuable materials, with significant portions ending up in landfills. Cryo-EM analyses of aged batteries provide detailed information about material transformations, potentially enabling more targeted and efficient recycling technologies that can recover a higher percentage of critical materials.

The environmental benefits of applying Cryo-EM insights extend beyond direct battery improvements. By enabling the development of fast-charging protocols that minimize degradation, these technologies can facilitate greater adoption of renewable energy storage solutions. This transition supports broader decarbonization efforts by providing reliable storage for intermittent renewable energy sources like solar and wind power.

Quantitative lifecycle assessments indicate that extending battery lifespan through degradation-informed design can reduce environmental impact by 20-30% compared to conventional approaches. Furthermore, improved recycling techniques based on Cryo-EM understanding of material transformations could potentially recover up to 95% of critical materials, significantly reducing the need for environmentally damaging mining operations.

Interdisciplinary Applications of Cryo-EM in Energy Storage

Cryo-electron microscopy (cryo-EM) has emerged as a revolutionary analytical technique in energy storage research, particularly in understanding battery degradation mechanisms. This interdisciplinary application bridges materials science, electrochemistry, and advanced microscopy to provide unprecedented insights into energy storage systems at the atomic and molecular levels.

The integration of cryo-EM into battery research represents a significant methodological advancement. Traditional characterization techniques often fail to capture the dynamic processes occurring within battery materials during cycling. Cryo-EM addresses this limitation by rapidly freezing samples, preserving their native state and allowing researchers to observe transient phases and interfaces that would otherwise be altered during conventional sample preparation.

Several landmark studies have demonstrated the power of cryo-EM in revealing degradation mechanisms in lithium-ion batteries. Researchers have successfully visualized the formation and evolution of solid-electrolyte interphase (SEI) layers, a critical component affecting battery performance and longevity. These studies have identified previously unknown nanostructures and chemical compositions within the SEI, providing crucial information for designing more stable interfaces.

Beyond lithium-ion systems, cryo-EM has been instrumental in advancing next-generation battery technologies. In lithium-sulfur batteries, it has enabled direct observation of polysulfide formation and dissolution processes. For solid-state batteries, cryo-EM has revealed interfacial phenomena between solid electrolytes and electrodes that contribute to resistance increase and capacity fade over time.

The cross-disciplinary nature of cryo-EM applications extends to supercapacitors and fuel cells, where researchers have gained insights into electrode-electrolyte interactions and catalyst degradation mechanisms. This versatility demonstrates how techniques originally developed for biological sciences can be adapted to solve critical challenges in energy materials research.

Collaborative efforts between microscopy specialists and battery researchers have led to methodological innovations specific to energy storage materials. These include specialized sample holders, in situ and operando capabilities, and advanced image processing algorithms tailored to battery materials' unique characteristics.

As computational methods advance alongside experimental techniques, the combination of cryo-EM data with molecular dynamics simulations and machine learning approaches is creating a powerful platform for predictive battery design. This synergy enables researchers to not only observe degradation processes but also model and predict how material modifications might improve performance and durability in next-generation energy storage systems.

The integration of cryo-EM into battery research represents a significant methodological advancement. Traditional characterization techniques often fail to capture the dynamic processes occurring within battery materials during cycling. Cryo-EM addresses this limitation by rapidly freezing samples, preserving their native state and allowing researchers to observe transient phases and interfaces that would otherwise be altered during conventional sample preparation.

Several landmark studies have demonstrated the power of cryo-EM in revealing degradation mechanisms in lithium-ion batteries. Researchers have successfully visualized the formation and evolution of solid-electrolyte interphase (SEI) layers, a critical component affecting battery performance and longevity. These studies have identified previously unknown nanostructures and chemical compositions within the SEI, providing crucial information for designing more stable interfaces.

Beyond lithium-ion systems, cryo-EM has been instrumental in advancing next-generation battery technologies. In lithium-sulfur batteries, it has enabled direct observation of polysulfide formation and dissolution processes. For solid-state batteries, cryo-EM has revealed interfacial phenomena between solid electrolytes and electrodes that contribute to resistance increase and capacity fade over time.

The cross-disciplinary nature of cryo-EM applications extends to supercapacitors and fuel cells, where researchers have gained insights into electrode-electrolyte interactions and catalyst degradation mechanisms. This versatility demonstrates how techniques originally developed for biological sciences can be adapted to solve critical challenges in energy materials research.

Collaborative efforts between microscopy specialists and battery researchers have led to methodological innovations specific to energy storage materials. These include specialized sample holders, in situ and operando capabilities, and advanced image processing algorithms tailored to battery materials' unique characteristics.

As computational methods advance alongside experimental techniques, the combination of cryo-EM data with molecular dynamics simulations and machine learning approaches is creating a powerful platform for predictive battery design. This synergy enables researchers to not only observe degradation processes but also model and predict how material modifications might improve performance and durability in next-generation energy storage systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!