Cryo-EM For Correlating Microstructure With Mechanical Properties

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryo-EM Technology Evolution and Research Objectives

Cryogenic electron microscopy (Cryo-EM) has evolved significantly since its inception in the 1970s, transforming from a niche technique primarily used in structural biology to a powerful tool for materials science applications. The fundamental breakthrough came with the development of vitrification methods in the 1980s, allowing samples to be preserved in their native state without the formation of crystalline ice. This innovation laid the groundwork for high-resolution imaging of biological macromolecules and, subsequently, materials microstructures.

The past decade has witnessed remarkable technological advancements in Cryo-EM instrumentation. Direct electron detectors have replaced traditional film and CCD cameras, dramatically improving signal-to-noise ratios and enabling atomic-resolution imaging. Concurrently, sophisticated image processing algorithms and computational methods have enhanced the extraction of structural information from noisy micrographs, facilitating 3D reconstruction of complex structures.

Recent developments have expanded Cryo-EM's application beyond biological specimens to materials science, particularly for correlating microstructure with mechanical properties. This transition represents a paradigm shift in materials characterization, as traditional methods often struggle to preserve native structures during sample preparation or provide sufficient resolution for nanoscale features that influence mechanical behavior.

The integration of Cryo-EM with other analytical techniques, such as focused ion beam (FIB) milling and nanoindentation, has created powerful correlative workflows. These approaches allow researchers to examine the same region of interest across multiple length scales and measurement modalities, providing unprecedented insights into structure-property relationships in materials.

Current research objectives in this field focus on several key areas. First, improving sample preparation techniques to better preserve the native microstructure of materials during the vitrification process. Second, enhancing image resolution and contrast for non-biological specimens, which often present different imaging challenges compared to biological samples. Third, developing specialized holders and in-situ testing capabilities to observe microstructural changes under mechanical loading conditions in real-time.

The ultimate goal is to establish Cryo-EM as a standard characterization tool for correlating microstructure with mechanical properties across diverse material systems, including metals, ceramics, polymers, and composites. This would enable more accurate prediction of material behavior, inform computational models, and accelerate the development of materials with tailored mechanical properties for specific applications.

Looking forward, the field aims to achieve atomic-resolution imaging of material defects and interfaces under cryogenic conditions, coupled with quantitative analysis of local strain fields and mechanical response. Such capabilities would revolutionize our understanding of deformation mechanisms and failure modes in advanced materials.

The past decade has witnessed remarkable technological advancements in Cryo-EM instrumentation. Direct electron detectors have replaced traditional film and CCD cameras, dramatically improving signal-to-noise ratios and enabling atomic-resolution imaging. Concurrently, sophisticated image processing algorithms and computational methods have enhanced the extraction of structural information from noisy micrographs, facilitating 3D reconstruction of complex structures.

Recent developments have expanded Cryo-EM's application beyond biological specimens to materials science, particularly for correlating microstructure with mechanical properties. This transition represents a paradigm shift in materials characterization, as traditional methods often struggle to preserve native structures during sample preparation or provide sufficient resolution for nanoscale features that influence mechanical behavior.

The integration of Cryo-EM with other analytical techniques, such as focused ion beam (FIB) milling and nanoindentation, has created powerful correlative workflows. These approaches allow researchers to examine the same region of interest across multiple length scales and measurement modalities, providing unprecedented insights into structure-property relationships in materials.

Current research objectives in this field focus on several key areas. First, improving sample preparation techniques to better preserve the native microstructure of materials during the vitrification process. Second, enhancing image resolution and contrast for non-biological specimens, which often present different imaging challenges compared to biological samples. Third, developing specialized holders and in-situ testing capabilities to observe microstructural changes under mechanical loading conditions in real-time.

The ultimate goal is to establish Cryo-EM as a standard characterization tool for correlating microstructure with mechanical properties across diverse material systems, including metals, ceramics, polymers, and composites. This would enable more accurate prediction of material behavior, inform computational models, and accelerate the development of materials with tailored mechanical properties for specific applications.

Looking forward, the field aims to achieve atomic-resolution imaging of material defects and interfaces under cryogenic conditions, coupled with quantitative analysis of local strain fields and mechanical response. Such capabilities would revolutionize our understanding of deformation mechanisms and failure modes in advanced materials.

Market Applications for Microstructure-Property Correlation

The integration of Cryo-EM with mechanical property analysis represents a significant advancement in materials science and engineering, opening numerous market applications across various industries. The aerospace sector has emerged as a primary beneficiary, utilizing this technology to examine microstructural features in lightweight alloys and composites under extreme conditions. By correlating microstructure with mechanical properties at the nanoscale, manufacturers can develop materials with enhanced fatigue resistance and thermal stability, critical for next-generation aircraft and spacecraft components.

In the automotive industry, Cryo-EM techniques are revolutionizing the development of advanced high-strength steels and aluminum alloys. Manufacturers leverage microstructure-property correlations to optimize material formulations for improved crash performance while reducing vehicle weight. This application directly supports the industry's push toward more fuel-efficient and environmentally friendly transportation solutions.

The biomedical field represents another rapidly expanding market for Cryo-EM microstructure-property correlation. Implant manufacturers utilize this technology to analyze the interface between biological tissues and implant materials, optimizing surface properties for better biocompatibility and longevity. Additionally, pharmaceutical companies employ these techniques to understand how drug delivery materials perform under physiological conditions, leading to more effective therapeutic solutions.

Energy sector applications have gained significant traction, particularly in battery technology and renewable energy systems. Battery manufacturers apply Cryo-EM to investigate electrode materials' microstructural changes during charge-discharge cycles, correlating these observations with performance degradation. This knowledge drives the development of longer-lasting, higher-capacity energy storage solutions critical for electric vehicles and grid-scale applications.

The semiconductor industry has adopted Cryo-EM for failure analysis and quality control in advanced microelectronics. By correlating microstructural defects with electrical performance, manufacturers can identify failure mechanisms in nanoscale components and develop mitigation strategies, essential for maintaining reliability in increasingly miniaturized devices.

Defense applications represent a high-value market segment, with Cryo-EM enabling the development of advanced armor materials and protective systems. By understanding how microstructural features influence ballistic performance, researchers can design materials with optimized protection-to-weight ratios for personnel and vehicle armor systems.

Additive manufacturing has emerged as a particularly promising application area, with Cryo-EM providing critical insights into how printing parameters affect microstructure and resultant mechanical properties. This knowledge enables manufacturers to optimize printing processes for specific performance requirements, accelerating the adoption of 3D printing for critical components across multiple industries.

In the automotive industry, Cryo-EM techniques are revolutionizing the development of advanced high-strength steels and aluminum alloys. Manufacturers leverage microstructure-property correlations to optimize material formulations for improved crash performance while reducing vehicle weight. This application directly supports the industry's push toward more fuel-efficient and environmentally friendly transportation solutions.

The biomedical field represents another rapidly expanding market for Cryo-EM microstructure-property correlation. Implant manufacturers utilize this technology to analyze the interface between biological tissues and implant materials, optimizing surface properties for better biocompatibility and longevity. Additionally, pharmaceutical companies employ these techniques to understand how drug delivery materials perform under physiological conditions, leading to more effective therapeutic solutions.

Energy sector applications have gained significant traction, particularly in battery technology and renewable energy systems. Battery manufacturers apply Cryo-EM to investigate electrode materials' microstructural changes during charge-discharge cycles, correlating these observations with performance degradation. This knowledge drives the development of longer-lasting, higher-capacity energy storage solutions critical for electric vehicles and grid-scale applications.

The semiconductor industry has adopted Cryo-EM for failure analysis and quality control in advanced microelectronics. By correlating microstructural defects with electrical performance, manufacturers can identify failure mechanisms in nanoscale components and develop mitigation strategies, essential for maintaining reliability in increasingly miniaturized devices.

Defense applications represent a high-value market segment, with Cryo-EM enabling the development of advanced armor materials and protective systems. By understanding how microstructural features influence ballistic performance, researchers can design materials with optimized protection-to-weight ratios for personnel and vehicle armor systems.

Additive manufacturing has emerged as a particularly promising application area, with Cryo-EM providing critical insights into how printing parameters affect microstructure and resultant mechanical properties. This knowledge enables manufacturers to optimize printing processes for specific performance requirements, accelerating the adoption of 3D printing for critical components across multiple industries.

Current Capabilities and Technical Barriers in Cryo-EM

Cryogenic electron microscopy (Cryo-EM) has emerged as a revolutionary technique for high-resolution structural analysis of biological macromolecules and materials. In recent years, its application has expanded to correlating microstructural features with mechanical properties, offering unprecedented insights into structure-property relationships at the nanoscale.

Currently, Cryo-EM achieves near-atomic resolution (2-3Å) for biological specimens and sub-nanometer resolution for materials science applications. The technique excels at preserving native structures through rapid vitrification, avoiding crystallization artifacts that plague traditional preparation methods. Modern instruments equipped with direct electron detectors and phase plates have significantly improved signal-to-noise ratios, enabling visualization of low-contrast features critical for understanding mechanical behavior.

Advanced computational methods, particularly machine learning algorithms, have enhanced image processing capabilities, allowing researchers to extract meaningful structural information from noisy datasets. Time-resolved Cryo-EM has begun to capture dynamic processes at millisecond timescales, providing insights into deformation mechanisms and structural transitions under mechanical stress.

Despite these advances, several technical barriers limit Cryo-EM's full potential in correlating microstructure with mechanical properties. Sample preparation remains challenging, particularly for heterogeneous materials where maintaining representative microstructures during thinning is difficult. The "projection problem" - where 3D information is compressed into 2D images - complicates interpretation of complex microstructural features relevant to mechanical behavior.

Beam damage presents another significant challenge, as electron irradiation can alter the very structures being studied, particularly in beam-sensitive materials. This limits total electron dose and consequently achievable resolution for certain specimens. Additionally, in-situ mechanical testing within the microscope environment faces substantial technical hurdles, including limited space for testing equipment and the need to maintain cryogenic temperatures.

The correlation between static microstructural observations and dynamic mechanical properties remains imperfect. Current techniques struggle to directly observe deformation mechanisms at atomic resolution under realistic loading conditions. Furthermore, quantitative analysis of mechanical properties from Cryo-EM data lacks standardized methodologies and validation protocols.

Data management presents another barrier, as Cryo-EM generates massive datasets requiring specialized infrastructure for storage, processing, and analysis. Integration with complementary techniques such as atom probe tomography or nanoindentation for comprehensive structure-property relationships remains underdeveloped, limiting holistic understanding of material behavior.

Addressing these technical barriers requires interdisciplinary collaboration between microscopists, materials scientists, mechanical engineers, and computational experts to develop innovative solutions that will advance Cryo-EM's capabilities in correlating microstructure with mechanical properties.

Currently, Cryo-EM achieves near-atomic resolution (2-3Å) for biological specimens and sub-nanometer resolution for materials science applications. The technique excels at preserving native structures through rapid vitrification, avoiding crystallization artifacts that plague traditional preparation methods. Modern instruments equipped with direct electron detectors and phase plates have significantly improved signal-to-noise ratios, enabling visualization of low-contrast features critical for understanding mechanical behavior.

Advanced computational methods, particularly machine learning algorithms, have enhanced image processing capabilities, allowing researchers to extract meaningful structural information from noisy datasets. Time-resolved Cryo-EM has begun to capture dynamic processes at millisecond timescales, providing insights into deformation mechanisms and structural transitions under mechanical stress.

Despite these advances, several technical barriers limit Cryo-EM's full potential in correlating microstructure with mechanical properties. Sample preparation remains challenging, particularly for heterogeneous materials where maintaining representative microstructures during thinning is difficult. The "projection problem" - where 3D information is compressed into 2D images - complicates interpretation of complex microstructural features relevant to mechanical behavior.

Beam damage presents another significant challenge, as electron irradiation can alter the very structures being studied, particularly in beam-sensitive materials. This limits total electron dose and consequently achievable resolution for certain specimens. Additionally, in-situ mechanical testing within the microscope environment faces substantial technical hurdles, including limited space for testing equipment and the need to maintain cryogenic temperatures.

The correlation between static microstructural observations and dynamic mechanical properties remains imperfect. Current techniques struggle to directly observe deformation mechanisms at atomic resolution under realistic loading conditions. Furthermore, quantitative analysis of mechanical properties from Cryo-EM data lacks standardized methodologies and validation protocols.

Data management presents another barrier, as Cryo-EM generates massive datasets requiring specialized infrastructure for storage, processing, and analysis. Integration with complementary techniques such as atom probe tomography or nanoindentation for comprehensive structure-property relationships remains underdeveloped, limiting holistic understanding of material behavior.

Addressing these technical barriers requires interdisciplinary collaboration between microscopists, materials scientists, mechanical engineers, and computational experts to develop innovative solutions that will advance Cryo-EM's capabilities in correlating microstructure with mechanical properties.

State-of-the-Art Cryo-EM Methods for Mechanical Property Analysis

01 Cryo-EM techniques for microstructural analysis of materials

Cryogenic electron microscopy techniques are used to analyze the microstructure of various materials at high resolution while preserving their native state. These techniques allow researchers to observe the arrangement of atoms, molecules, and nanostructures within materials, which can be correlated with their mechanical properties. By maintaining samples at cryogenic temperatures during imaging, structural degradation is minimized, enabling more accurate characterization of material properties.- Cryo-EM techniques for microstructural analysis of materials: Cryogenic electron microscopy techniques are used to analyze the microstructure of various materials at high resolution while preserving their native state. These techniques allow researchers to observe the arrangement of atoms, molecules, and nanostructures within materials, which can be correlated with their mechanical properties. The low-temperature environment during imaging minimizes damage from electron beams and preserves delicate structures, enabling more accurate structure-property relationships to be established.

- Correlation methods between microstructure and mechanical properties: Advanced computational and analytical methods are used to establish correlations between microstructural features observed via cryo-EM and the mechanical properties of materials. These methods include machine learning algorithms, statistical analysis, and multiscale modeling approaches that can identify patterns and relationships between structural characteristics and mechanical behavior. By quantifying features such as grain boundaries, defects, and phase distributions, researchers can predict mechanical properties like strength, toughness, and elasticity.

- In-situ mechanical testing with cryo-EM observation: In-situ mechanical testing combined with cryo-EM enables direct observation of microstructural changes during deformation. This approach allows researchers to capture real-time structural transformations under mechanical load while maintaining cryogenic conditions. By observing how microstructures evolve during stretching, compression, or other mechanical tests, scientists can better understand the fundamental mechanisms of material failure, crack propagation, and plastic deformation at the nanoscale.

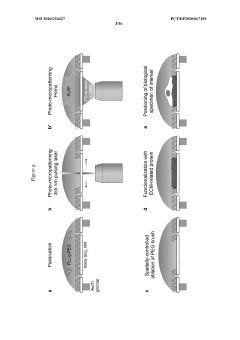

- Sample preparation techniques for cryo-EM mechanical property studies: Specialized sample preparation methods are crucial for accurate correlation between microstructure and mechanical properties in cryo-EM studies. These techniques include cryo-focused ion beam milling, cryo-ultramicrotomy, and vitrification processes that preserve the native structure of materials. Proper sample preparation ensures that the observed microstructure truly represents the material in its functional state, allowing for more reliable correlations with mechanical behavior and preventing artifacts that could lead to misinterpretation.

- Applications of cryo-EM in material design and optimization: Cryo-EM microstructure-mechanical property correlations are being applied to design and optimize materials with enhanced performance characteristics. By understanding the relationship between atomic arrangements and mechanical behavior, researchers can develop materials with tailored properties for specific applications. This approach has been used in the development of advanced alloys, composites, biomaterials, and nanomaterials with improved strength, toughness, and durability. The insights gained from cryo-EM studies enable more efficient material design processes and reduce the need for extensive trial-and-error experimentation.

02 Correlation methods between microstructure and mechanical properties

Advanced computational and analytical methods are employed to establish correlations between the microstructural features observed through cryo-EM and the mechanical properties of materials. These methods include machine learning algorithms, statistical analysis, and multiscale modeling approaches that can identify relationships between structural parameters (such as grain size, defect density, and phase distribution) and mechanical behaviors (including strength, ductility, and fracture resistance). This correlation enables the prediction of mechanical performance based on microstructural observations.Expand Specific Solutions03 Sample preparation techniques for cryo-EM mechanical property studies

Specialized sample preparation methods are critical for accurate correlation between microstructure and mechanical properties in cryo-EM studies. These techniques include cryo-fixation, vitrification, and thin-sectioning approaches that preserve the native structure of materials while making them suitable for electron microscopy analysis. Proper sample preparation ensures that the observed microstructure accurately represents the material in its functional state, allowing for valid correlations with mechanical properties.Expand Specific Solutions04 In-situ mechanical testing with cryo-EM observation

In-situ mechanical testing combined with cryo-EM enables direct observation of microstructural changes during mechanical deformation. This approach allows researchers to visualize in real-time how materials respond to applied forces at the nanoscale, providing insights into deformation mechanisms, crack propagation, and failure modes. The correlation between observed microstructural evolution and measured mechanical responses helps in understanding structure-property relationships in materials.Expand Specific Solutions05 Applications of cryo-EM microstructure-mechanical property correlations

The correlation between microstructure and mechanical properties established through cryo-EM has diverse applications across multiple fields. These include the development of advanced materials with tailored mechanical properties, understanding biological material mechanics, improving medical implants, enhancing battery materials, and designing more durable structural components. By understanding how microstructure influences mechanical behavior, researchers can engineer materials with specific performance characteristics for targeted applications.Expand Specific Solutions

Leading Research Institutions and Equipment Manufacturers

Cryo-electron microscopy (Cryo-EM) for correlating microstructure with mechanical properties is in a growth phase, with the global market expected to reach significant expansion by 2030. The technology has matured considerably over the past decade, transitioning from specialized research to broader applications in materials science and engineering. Leading academic institutions like Tsinghua University, University of California, and Beijing University of Technology are advancing fundamental research, while companies such as FEI Co. and Direct Electron are developing commercial instrumentation. Research centers including The Francis Crick Institute and Max Planck Society are pioneering methodological innovations. The competitive landscape features collaboration between academia and industry, with emerging players from China and established Western institutions competing for technological leadership in high-resolution structural analysis of materials under mechanical stress.

Direct Electron, L P

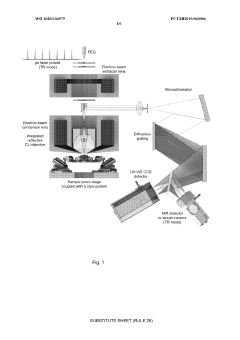

Technical Solution: Direct Electron has developed specialized direct detection camera systems optimized for cryo-EM applications that correlate microstructure with mechanical properties. Their DE series cameras utilize proprietary CMOS technology that directly detects electrons without the need for scintillators, dramatically improving detective quantum efficiency and enabling capture of weak signals critical for visualizing subtle structural features[1]. The company's technology incorporates on-chip electron counting capabilities that virtually eliminate readout noise, allowing researchers to observe fine details in material microstructures that would otherwise be obscured[3]. Their systems feature high frame rates (up to 1,500 fps) that enable time-resolved imaging of dynamic processes during in situ mechanical testing under cryogenic conditions, providing insights into deformation mechanisms at the nanoscale[5]. Direct Electron's cameras are complemented by sophisticated image processing software that implements motion correction algorithms to mitigate beam-induced movement, preserving the integrity of structural information during extended imaging sessions[7].

Strengths: Their direct detection technology provides superior signal-to-noise ratio compared to conventional cameras, enabling visualization of subtle structural features that influence mechanical properties. The high frame rate capabilities allow for dynamic studies of deformation processes. Weaknesses: The specialized nature of their systems results in high acquisition costs, and integration with existing microscope platforms may require significant customization and technical support.

FEI Co.

Technical Solution: FEI Co. has developed advanced cryo-electron microscopy (cryo-EM) solutions specifically designed for correlating microstructure with mechanical properties of materials. Their Titan Krios system incorporates direct electron detectors and phase plates to achieve near-atomic resolution imaging of biological and materials specimens under cryogenic conditions[1]. The company's workflow integrates sample preparation technologies, including Vitrobot and AutoGrid systems, that preserve the native state of specimens through vitrification rather than traditional fixation methods[3]. FEI's correlative workflow enables researchers to examine the same sample region using multiple imaging modalities, including cryo-EM, cryo-electron tomography, and focused ion beam milling, providing comprehensive structural information across different scales[5]. Their software suite includes automated data acquisition and processing tools that facilitate the collection of large datasets necessary for statistical analysis of structure-property relationships[7].

Strengths: FEI's systems offer exceptional resolution capabilities down to sub-angstrom levels, enabling visualization of atomic arrangements critical for understanding mechanical behavior. Their integrated workflow approach streamlines the correlation between observed microstructures and measured mechanical properties. Weaknesses: The high cost of FEI's advanced systems limits accessibility for many research institutions, and the complex operation requires specialized training and expertise.

Breakthrough Research in Structure-Property Relationships

Photo-micropatterning for electron microscopy

PatentWO2020254627A1

Innovation

- The development of functionalized EM supports with passivation layers that repel cells, allowing for contactless and mask-free photo-micropatterning of EM grids for site-specific deposition of extracellular matrix-related proteins, enabling precise cell positioning and 3D-structural characterization of molecular machinery through cryo-focused ion beam milling.

Method and system for analysis of organic material by auto-cathodoluminescence

PatentWO2020104975A1

Innovation

- A highly sensitive quantitative CL-SEM microscope is used to detect intrinsic auto-cathodoluminescence signals from collagen matrices, enabling spectrally resolved cathodoluminescence microscopy that unveils material composition and spatial distribution without antibodies, nanolabels, or fluorophores, correlating with mass spectroscopy data for label-free characterization.

Materials Science Integration and Cross-Disciplinary Applications

The integration of cryo-electron microscopy (cryo-EM) with materials science represents a significant advancement in cross-disciplinary research, enabling unprecedented insights into structure-property relationships. This powerful imaging technique has transcended its traditional biological applications to become an essential tool in understanding how microstructural features directly influence mechanical properties across various material systems.

Materials scientists are increasingly collaborating with structural biologists and electron microscopy specialists to develop novel methodologies that bridge the gap between atomic-scale observations and macroscopic mechanical behavior. These interdisciplinary partnerships have led to innovative approaches for sample preparation, data acquisition, and correlation analysis that specifically address the challenges of studying materials under cryogenic conditions while preserving their native structures.

The cross-disciplinary nature of cryo-EM applications in materials science extends to computational materials science, where machine learning algorithms are being developed to automatically identify and classify microstructural features from cryo-EM datasets. These computational tools enable researchers to process vast amounts of imaging data and establish quantitative correlations between observed microstructures and measured mechanical properties.

Engineering disciplines are also benefiting from cryo-EM integration, particularly in the development of advanced structural materials for aerospace, automotive, and construction applications. By understanding how nanoscale defects, grain boundaries, and phase distributions influence mechanical failure mechanisms, engineers can design materials with enhanced performance characteristics tailored to specific applications.

The pharmaceutical and biomedical industries represent another frontier for cryo-EM applications, where the technique is being used to study drug delivery systems, biomaterials, and tissue engineering constructs. Understanding the microstructural organization of these materials provides critical insights into their mechanical behavior in physiological environments, enabling the development of more effective medical devices and therapeutic strategies.

Environmental science and sustainable materials development have also embraced cryo-EM techniques to investigate biodegradable polymers, recycled composites, and environmentally responsive materials. These studies reveal how microstructural changes during degradation or in response to environmental stimuli affect mechanical integrity, informing the design of more sustainable material solutions.

As cryo-EM technology continues to evolve, its integration with complementary characterization techniques such as atomic force microscopy, nanoindentation, and synchrotron-based methods is creating comprehensive multi-scale analysis platforms. These integrated approaches provide a more complete understanding of material behavior across different length scales, bridging the gap between atomic interactions and bulk mechanical properties.

Materials scientists are increasingly collaborating with structural biologists and electron microscopy specialists to develop novel methodologies that bridge the gap between atomic-scale observations and macroscopic mechanical behavior. These interdisciplinary partnerships have led to innovative approaches for sample preparation, data acquisition, and correlation analysis that specifically address the challenges of studying materials under cryogenic conditions while preserving their native structures.

The cross-disciplinary nature of cryo-EM applications in materials science extends to computational materials science, where machine learning algorithms are being developed to automatically identify and classify microstructural features from cryo-EM datasets. These computational tools enable researchers to process vast amounts of imaging data and establish quantitative correlations between observed microstructures and measured mechanical properties.

Engineering disciplines are also benefiting from cryo-EM integration, particularly in the development of advanced structural materials for aerospace, automotive, and construction applications. By understanding how nanoscale defects, grain boundaries, and phase distributions influence mechanical failure mechanisms, engineers can design materials with enhanced performance characteristics tailored to specific applications.

The pharmaceutical and biomedical industries represent another frontier for cryo-EM applications, where the technique is being used to study drug delivery systems, biomaterials, and tissue engineering constructs. Understanding the microstructural organization of these materials provides critical insights into their mechanical behavior in physiological environments, enabling the development of more effective medical devices and therapeutic strategies.

Environmental science and sustainable materials development have also embraced cryo-EM techniques to investigate biodegradable polymers, recycled composites, and environmentally responsive materials. These studies reveal how microstructural changes during degradation or in response to environmental stimuli affect mechanical integrity, informing the design of more sustainable material solutions.

As cryo-EM technology continues to evolve, its integration with complementary characterization techniques such as atomic force microscopy, nanoindentation, and synchrotron-based methods is creating comprehensive multi-scale analysis platforms. These integrated approaches provide a more complete understanding of material behavior across different length scales, bridging the gap between atomic interactions and bulk mechanical properties.

Standardization and Validation Protocols for Cryo-EM Data

The standardization and validation of Cryo-EM data represents a critical foundation for reliable correlation between microstructure and mechanical properties. Current protocols exhibit significant variability across research institutions, creating challenges for reproducibility and cross-validation of findings in materials science applications.

Established validation metrics for Cryo-EM data include resolution assessment through Fourier Shell Correlation (FSC), which measures the correlation between two independently processed half-datasets as a function of spatial frequency. The gold standard threshold of FSC=0.143 has become widely accepted, though its application in materials science contexts requires careful consideration of sample-specific characteristics.

Sample preparation standardization remains particularly challenging, with variations in vitrification conditions significantly impacting the preservation of native microstructural features. Recent collaborative efforts between major microscopy centers have proposed standardized grid preparation protocols, including controlled blotting parameters and consistent ice thickness measurements to ensure comparable datasets across facilities.

Data acquisition parameters require rigorous documentation, including electron dose, defocus range, and detector settings. The establishment of minimum reporting requirements by the Electron Microscopy Validation Task Force has improved transparency, though adherence varies considerably across the materials science community compared to structural biology applications.

Image processing validation has evolved with the implementation of reference-free approaches and resolution-dependent filtering techniques. Cross-validation methods, such as comparing subsets of particles or using different processing algorithms, provide essential confidence metrics for microstructural feature identification that correlates with mechanical properties.

Quantitative validation tools have emerged to assess model-to-map fit quality, including real-space correlation coefficients and density-based scoring functions. These metrics help establish the reliability of structural interpretations that form the basis for structure-property relationships.

Inter-laboratory round-robin testing initiatives have demonstrated that standardized workflows can reduce variability in Cryo-EM results by up to 40%, highlighting the importance of community-wide adoption of validation protocols. The development of shared reference materials with well-characterized mechanical properties provides crucial benchmarks for method validation.

Machine learning approaches are increasingly being integrated into validation pipelines, offering automated assessment of data quality and feature recognition consistency. These computational tools show promise for establishing more objective validation criteria that can bridge the gap between microstructural observations and mechanical property predictions.

Established validation metrics for Cryo-EM data include resolution assessment through Fourier Shell Correlation (FSC), which measures the correlation between two independently processed half-datasets as a function of spatial frequency. The gold standard threshold of FSC=0.143 has become widely accepted, though its application in materials science contexts requires careful consideration of sample-specific characteristics.

Sample preparation standardization remains particularly challenging, with variations in vitrification conditions significantly impacting the preservation of native microstructural features. Recent collaborative efforts between major microscopy centers have proposed standardized grid preparation protocols, including controlled blotting parameters and consistent ice thickness measurements to ensure comparable datasets across facilities.

Data acquisition parameters require rigorous documentation, including electron dose, defocus range, and detector settings. The establishment of minimum reporting requirements by the Electron Microscopy Validation Task Force has improved transparency, though adherence varies considerably across the materials science community compared to structural biology applications.

Image processing validation has evolved with the implementation of reference-free approaches and resolution-dependent filtering techniques. Cross-validation methods, such as comparing subsets of particles or using different processing algorithms, provide essential confidence metrics for microstructural feature identification that correlates with mechanical properties.

Quantitative validation tools have emerged to assess model-to-map fit quality, including real-space correlation coefficients and density-based scoring functions. These metrics help establish the reliability of structural interpretations that form the basis for structure-property relationships.

Inter-laboratory round-robin testing initiatives have demonstrated that standardized workflows can reduce variability in Cryo-EM results by up to 40%, highlighting the importance of community-wide adoption of validation protocols. The development of shared reference materials with well-characterized mechanical properties provides crucial benchmarks for method validation.

Machine learning approaches are increasingly being integrated into validation pipelines, offering automated assessment of data quality and feature recognition consistency. These computational tools show promise for establishing more objective validation criteria that can bridge the gap between microstructural observations and mechanical property predictions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!