Cryo-EM In Situ Heating/Cooling Stage Techniques

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryo-EM Temperature Control Evolution and Objectives

Cryo-electron microscopy (Cryo-EM) has revolutionized structural biology by enabling the visualization of biological macromolecules in their near-native states. The evolution of temperature control in Cryo-EM represents a critical technological advancement that has significantly expanded the technique's capabilities and applications.

Initially, Cryo-EM relied solely on cryogenic temperatures (typically around -180°C using liquid nitrogen) to reduce radiation damage and preserve specimen structure. This approach, pioneered in the 1980s by Jacques Dubochet and colleagues, involved rapid freezing of samples in vitreous ice, allowing biological specimens to be imaged without crystallization artifacts.

The early temperature control systems were primarily focused on maintaining consistently low temperatures during sample preparation and imaging. These systems lacked the ability to dynamically adjust temperatures during observation, limiting researchers to static structural snapshots rather than capturing dynamic processes.

A significant technological shift occurred in the early 2000s with the development of more sophisticated temperature regulation systems. These advancements enabled better stability and reduced thermal drift, which was crucial for achieving higher resolution imaging. The introduction of automated liquid nitrogen delivery systems further improved temperature consistency during extended imaging sessions.

Recent years have witnessed a paradigm shift toward dynamic temperature control capabilities. The development of in situ heating and cooling stages represents a breakthrough that allows researchers to observe structural changes in biomolecules across a range of temperatures. These systems typically operate between -180°C and room temperature, with some advanced setups capable of reaching up to 100°C.

The primary objective of modern Cryo-EM temperature control technology is to enable time-resolved structural biology—capturing biomolecular dynamics and conformational changes triggered by temperature variations. This capability is particularly valuable for studying enzyme kinetics, protein folding pathways, and temperature-dependent molecular interactions.

Another key goal is to bridge the gap between cryogenic and physiological conditions. By developing systems that can gradually warm samples while imaging, researchers aim to observe how biomolecular structures transition between frozen and functional states, providing insights into their native behavior.

Looking forward, the field is moving toward more precise and localized temperature control, with emerging technologies aiming to create thermal gradients across samples or to rapidly cycle between temperature points. These capabilities would enable new experimental approaches for investigating temperature-sensitive biological processes at unprecedented resolution and temporal precision.

Initially, Cryo-EM relied solely on cryogenic temperatures (typically around -180°C using liquid nitrogen) to reduce radiation damage and preserve specimen structure. This approach, pioneered in the 1980s by Jacques Dubochet and colleagues, involved rapid freezing of samples in vitreous ice, allowing biological specimens to be imaged without crystallization artifacts.

The early temperature control systems were primarily focused on maintaining consistently low temperatures during sample preparation and imaging. These systems lacked the ability to dynamically adjust temperatures during observation, limiting researchers to static structural snapshots rather than capturing dynamic processes.

A significant technological shift occurred in the early 2000s with the development of more sophisticated temperature regulation systems. These advancements enabled better stability and reduced thermal drift, which was crucial for achieving higher resolution imaging. The introduction of automated liquid nitrogen delivery systems further improved temperature consistency during extended imaging sessions.

Recent years have witnessed a paradigm shift toward dynamic temperature control capabilities. The development of in situ heating and cooling stages represents a breakthrough that allows researchers to observe structural changes in biomolecules across a range of temperatures. These systems typically operate between -180°C and room temperature, with some advanced setups capable of reaching up to 100°C.

The primary objective of modern Cryo-EM temperature control technology is to enable time-resolved structural biology—capturing biomolecular dynamics and conformational changes triggered by temperature variations. This capability is particularly valuable for studying enzyme kinetics, protein folding pathways, and temperature-dependent molecular interactions.

Another key goal is to bridge the gap between cryogenic and physiological conditions. By developing systems that can gradually warm samples while imaging, researchers aim to observe how biomolecular structures transition between frozen and functional states, providing insights into their native behavior.

Looking forward, the field is moving toward more precise and localized temperature control, with emerging technologies aiming to create thermal gradients across samples or to rapidly cycle between temperature points. These capabilities would enable new experimental approaches for investigating temperature-sensitive biological processes at unprecedented resolution and temporal precision.

Market Applications for In Situ Thermal Manipulation in Cryo-EM

The in situ thermal manipulation capabilities in cryo-electron microscopy (cryo-EM) have opened significant market opportunities across multiple sectors. The pharmaceutical industry represents one of the largest potential markets, where temperature-controlled observations of protein dynamics and drug-target interactions can dramatically accelerate drug discovery processes. Companies can observe structural changes in proteins at different temperatures, providing crucial insights into binding mechanisms and potentially reducing development timelines by months or years.

Materials science represents another substantial market, with manufacturers of advanced materials utilizing in situ thermal stages to observe phase transitions, crystallization processes, and thermal stability characteristics at the nanoscale. This capability is particularly valuable for developing high-performance polymers, semiconductors, and composite materials where temperature-dependent properties are critical to product performance.

The energy sector has embraced this technology for battery research and development, where observing electrode-electrolyte interfaces under varying thermal conditions helps optimize battery performance, safety, and longevity. Several major battery manufacturers have already incorporated cryo-EM with thermal manipulation capabilities into their R&D workflows, resulting in measurable improvements in energy density and cycle life.

Biotechnology companies are leveraging these techniques to study temperature-dependent cellular processes, membrane dynamics, and protein folding mechanisms. The ability to observe biomolecular assemblies under precisely controlled thermal conditions provides unprecedented insights into fundamental biological processes, creating opportunities for novel therapeutic approaches and biotechnological applications.

Academic research institutions represent a significant market segment, with universities and research centers investing in advanced cryo-EM facilities with thermal manipulation capabilities. This market is driven by competitive research grants and the need to maintain cutting-edge research infrastructure.

Semiconductor manufacturers utilize in situ thermal techniques to study temperature effects on nanoscale electronic components and materials, informing the development of more efficient and reliable microelectronics. The increasing miniaturization of electronic devices has made atomic-scale thermal behavior increasingly important to product performance and reliability.

The food science industry has begun exploring applications in studying temperature-dependent food structures, potentially leading to improved preservation techniques and novel food products with enhanced stability and texture properties. This emerging application area represents a growing market opportunity as food manufacturers seek scientific approaches to product innovation.

Materials science represents another substantial market, with manufacturers of advanced materials utilizing in situ thermal stages to observe phase transitions, crystallization processes, and thermal stability characteristics at the nanoscale. This capability is particularly valuable for developing high-performance polymers, semiconductors, and composite materials where temperature-dependent properties are critical to product performance.

The energy sector has embraced this technology for battery research and development, where observing electrode-electrolyte interfaces under varying thermal conditions helps optimize battery performance, safety, and longevity. Several major battery manufacturers have already incorporated cryo-EM with thermal manipulation capabilities into their R&D workflows, resulting in measurable improvements in energy density and cycle life.

Biotechnology companies are leveraging these techniques to study temperature-dependent cellular processes, membrane dynamics, and protein folding mechanisms. The ability to observe biomolecular assemblies under precisely controlled thermal conditions provides unprecedented insights into fundamental biological processes, creating opportunities for novel therapeutic approaches and biotechnological applications.

Academic research institutions represent a significant market segment, with universities and research centers investing in advanced cryo-EM facilities with thermal manipulation capabilities. This market is driven by competitive research grants and the need to maintain cutting-edge research infrastructure.

Semiconductor manufacturers utilize in situ thermal techniques to study temperature effects on nanoscale electronic components and materials, informing the development of more efficient and reliable microelectronics. The increasing miniaturization of electronic devices has made atomic-scale thermal behavior increasingly important to product performance and reliability.

The food science industry has begun exploring applications in studying temperature-dependent food structures, potentially leading to improved preservation techniques and novel food products with enhanced stability and texture properties. This emerging application area represents a growing market opportunity as food manufacturers seek scientific approaches to product innovation.

Current Challenges in Heating/Cooling Stage Development

The development of in situ heating and cooling stages for cryo-electron microscopy (cryo-EM) faces several significant technical challenges that impede their widespread implementation and optimal performance. One of the primary obstacles is thermal stability maintenance during experiments. Current stage designs struggle to provide uniform temperature distribution across the sample, resulting in thermal gradients that can compromise data quality and experimental reproducibility. These gradients often lead to specimen drift and deformation, particularly problematic when observing dynamic processes at atomic resolution.

Material selection presents another formidable challenge. Stage components must simultaneously satisfy contradictory requirements: excellent thermal conductivity for efficient temperature transfer, minimal thermal expansion to prevent mechanical instability, and low electron interaction to avoid compromising imaging quality. Currently available materials often represent compromises rather than optimal solutions, limiting stage performance across the full temperature range from cryogenic to elevated temperatures.

Temperature transition speed and control precision remain significant hurdles. Existing systems typically offer either rapid temperature changes with poor stability or excellent stability with slow transition rates. This limitation restricts researchers' ability to capture fast dynamic processes at precise temperature points, particularly important for studying phase transitions or temperature-dependent biological reactions at the molecular level.

Vacuum compatibility issues further complicate stage design. Components must maintain their structural and functional integrity under high vacuum conditions while simultaneously managing thermal transfer. Many conventional heating and cooling mechanisms perform poorly in vacuum environments, necessitating complex engineering solutions that often increase system bulk and reduce reliability.

Integration with existing microscope systems poses substantial engineering challenges. The limited space within the microscope column constrains stage dimensions, while electromagnetic interference from heating elements can disrupt the electron beam path and imaging systems. These constraints often force compromises in stage functionality or microscope performance.

Sample viability during temperature manipulation represents a critical biological challenge. Rapid temperature changes can induce ice crystallization in biological samples or cause structural damage to sensitive specimens. Current technologies struggle to balance the need for temperature control with sample preservation, particularly when transitioning between cryogenic and ambient or elevated temperatures.

Finally, data acquisition synchronization with temperature changes presents significant technical difficulties. Coordinating precise temperature control with automated imaging sequences requires sophisticated software integration that is not yet standardized across different microscope platforms and stage manufacturers, limiting experimental reproducibility and data comparability between research groups.

Material selection presents another formidable challenge. Stage components must simultaneously satisfy contradictory requirements: excellent thermal conductivity for efficient temperature transfer, minimal thermal expansion to prevent mechanical instability, and low electron interaction to avoid compromising imaging quality. Currently available materials often represent compromises rather than optimal solutions, limiting stage performance across the full temperature range from cryogenic to elevated temperatures.

Temperature transition speed and control precision remain significant hurdles. Existing systems typically offer either rapid temperature changes with poor stability or excellent stability with slow transition rates. This limitation restricts researchers' ability to capture fast dynamic processes at precise temperature points, particularly important for studying phase transitions or temperature-dependent biological reactions at the molecular level.

Vacuum compatibility issues further complicate stage design. Components must maintain their structural and functional integrity under high vacuum conditions while simultaneously managing thermal transfer. Many conventional heating and cooling mechanisms perform poorly in vacuum environments, necessitating complex engineering solutions that often increase system bulk and reduce reliability.

Integration with existing microscope systems poses substantial engineering challenges. The limited space within the microscope column constrains stage dimensions, while electromagnetic interference from heating elements can disrupt the electron beam path and imaging systems. These constraints often force compromises in stage functionality or microscope performance.

Sample viability during temperature manipulation represents a critical biological challenge. Rapid temperature changes can induce ice crystallization in biological samples or cause structural damage to sensitive specimens. Current technologies struggle to balance the need for temperature control with sample preservation, particularly when transitioning between cryogenic and ambient or elevated temperatures.

Finally, data acquisition synchronization with temperature changes presents significant technical difficulties. Coordinating precise temperature control with automated imaging sequences requires sophisticated software integration that is not yet standardized across different microscope platforms and stage manufacturers, limiting experimental reproducibility and data comparability between research groups.

Contemporary Heating/Cooling Stage Design Solutions

01 Temperature control systems for cryo-EM stages

Advanced temperature control systems are essential for cryo-electron microscopy (cryo-EM) stages to maintain precise thermal conditions during imaging. These systems typically include temperature sensors, feedback controllers, and heating/cooling elements that work together to achieve stable temperatures ranging from cryogenic to elevated levels. The precise control allows researchers to observe structural changes in specimens at different temperatures while minimizing thermal drift and ensuring high-resolution imaging.- Temperature control systems for cryo-EM stages: Advanced temperature control systems are essential for cryo-electron microscopy (cryo-EM) stages to maintain precise thermal conditions during imaging. These systems typically include thermal sensors, feedback controllers, and heating/cooling elements that work together to achieve stable temperatures. The temperature control can be programmed to maintain constant conditions or to follow specific thermal profiles, allowing researchers to observe structural changes in specimens at different temperatures while minimizing drift and thermal noise.

- In situ heating mechanisms for cryo-EM: In situ heating mechanisms for cryo-EM enable researchers to observe dynamic structural changes in specimens as temperature increases. These mechanisms typically incorporate resistive heating elements, infrared heating, or Peltier devices integrated directly into the sample holder or stage. The heating systems are designed to provide uniform temperature distribution across the sample while minimizing electromagnetic interference with the electron beam. Some advanced designs allow for rapid temperature changes with minimal thermal drift, enabling time-resolved studies of temperature-dependent processes.

- Cooling technologies for cryo-EM sample preservation: Specialized cooling technologies are crucial for maintaining samples at cryogenic temperatures during electron microscopy imaging. These systems typically use liquid nitrogen or helium circulation, thermoelectric cooling, or multi-stage refrigeration to achieve temperatures as low as -180°C. Advanced designs incorporate thermal shields, vacuum insulation, and anti-contamination measures to prevent ice formation and sample degradation. The cooling systems are engineered to minimize vibration and electromagnetic interference while providing stable temperature conditions for extended imaging sessions.

- Integrated temperature monitoring and feedback systems: Integrated temperature monitoring and feedback systems are essential components of cryo-EM heating/cooling stages. These systems utilize high-precision temperature sensors placed strategically near the sample to provide real-time temperature data. Advanced control algorithms process this data to adjust heating or cooling elements, maintaining the desired temperature with minimal fluctuation. Some systems incorporate multiple sensing points to ensure temperature uniformity across the sample and can detect and compensate for environmental variations or beam-induced heating effects.

- Sample holders with integrated thermal management: Specialized sample holders with integrated thermal management capabilities are designed for in situ heating and cooling experiments in cryo-EM. These holders feature miniaturized heating/cooling elements, temperature sensors, and thermal insulation directly integrated into the holder structure. The design minimizes thermal mass while maximizing thermal conductivity to the sample, allowing for rapid temperature changes with minimal drift. Some advanced holders incorporate microfluidic channels for liquid cooling or multiple electrical contacts for resistive heating, enabling precise control of sample temperature during imaging.

02 In situ heating mechanisms for cryo-EM

In situ heating mechanisms enable researchers to observe dynamic structural changes in specimens as temperature increases from cryogenic conditions. These mechanisms incorporate resistive heating elements, infrared heating, or Peltier devices directly into the specimen holder or stage. The heating systems are designed to provide uniform temperature distribution across the sample while minimizing electromagnetic interference with the electron beam, allowing for real-time observation of temperature-dependent transformations in biological or material samples.Expand Specific Solutions03 Cooling systems for maintaining cryogenic temperatures

Specialized cooling systems are crucial for maintaining samples at cryogenic temperatures during cryo-EM imaging. These systems typically utilize liquid nitrogen or helium circulation, thermoelectric cooling, or gas-flow cooling mechanisms to achieve temperatures below -150°C. Advanced designs incorporate thermal shields, vacuum insulation, and efficient heat exchangers to minimize temperature fluctuations and prevent ice contamination, ensuring sample integrity during extended imaging sessions.Expand Specific Solutions04 Temperature gradient control for dynamic experiments

Temperature gradient control systems allow researchers to create controlled thermal gradients across samples or to rapidly change temperatures for dynamic experiments. These systems incorporate multiple heating/cooling zones with independent temperature controllers, enabling spatial temperature variations or programmed temperature ramps. Such capabilities are valuable for studying phase transitions, reaction kinetics, or thermal behavior of materials at the nanoscale while maintaining imaging capabilities throughout the temperature change process.Expand Specific Solutions05 Integration of temperature control with other environmental parameters

Advanced cryo-EM systems integrate temperature control with other environmental parameters such as humidity, gas composition, or pressure. These integrated systems allow for complex in situ experiments where multiple environmental factors can be manipulated simultaneously while maintaining imaging capabilities. The integration often involves specialized specimen holders with multiple feedthroughs for sensors and control systems, enabling researchers to study samples under conditions that more closely mimic their natural environment or specific experimental requirements.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Cryo-EM Thermal Stages

Cryo-EM in situ heating/cooling stage techniques are currently in a growth phase, with an expanding market driven by increasing demand for advanced microscopy solutions in materials science and life sciences. The technology is maturing rapidly, with key players including FEI Co. (microscopy innovation leader), IBM (advanced research capabilities), and Oxford University Innovation (academic research commercialization). Specialized companies like Xiamen Chip-nova Technology and VeriCold Technologies are developing niche solutions for temperature-controlled sample environments. Academic institutions such as Tsinghua University, Zhejiang University, and Wisconsin Alumni Research Foundation are advancing fundamental research. The competitive landscape features both established scientific instrument manufacturers and emerging specialized technology providers, with collaboration between industry and academia accelerating technological development and commercialization.

FEI Co.

Technical Solution: FEI Co. (now part of Thermo Fisher Scientific) has developed advanced in situ heating and cooling stages for cryo-electron microscopy that enable dynamic observation of structural changes in biological and materials samples. Their technology incorporates microelectromechanical systems (MEMS)-based heating elements with precise temperature control from cryogenic temperatures (-196°C) up to 1000°C. The system features specialized thermal isolation to minimize thermal drift and maintain sample stability during temperature transitions. FEI's solution includes integrated liquid nitrogen cooling systems with automated temperature regulation and specialized sample holders that minimize contamination risks during temperature changes. Their platforms are compatible with both single-particle analysis and tomography workflows, allowing researchers to capture structural dynamics across multiple temperature points with minimal beam-induced damage[1][3]. The technology enables direct visualization of phase transitions, protein conformational changes, and material transformations in near-native environments.

Strengths: Superior thermal stability with drift compensation algorithms that maintain nanometer-level precision during temperature changes; seamless integration with existing TEM systems; high-resolution imaging capabilities even during dynamic temperature transitions. Weaknesses: Complex setup requiring specialized training; higher cost compared to conventional stages; potential for increased ice contamination during extended heating/cooling cycles.

International Business Machines Corp.

Technical Solution: IBM has pioneered cryo-EM in situ heating/cooling stage technology through their development of the "Molecular Microscope" platform. This system incorporates proprietary temperature control mechanisms that allow precise manipulation of sample temperatures from -180°C to 100°C with stability within 0.1°C. IBM's approach utilizes advanced materials science to create thermally conductive yet electrically insulating sample supports that minimize thermal gradients across specimens. Their technology features a closed-loop feedback system that continuously monitors and adjusts temperature parameters in real-time, compensating for electron beam-induced heating effects. The system incorporates specialized anti-contamination devices and vacuum management protocols to maintain sample integrity during temperature transitions[2]. IBM has also developed complementary software tools that enable automated data collection across temperature series, with algorithms specifically designed to account for thermal drift and specimen movement during heating/cooling cycles[5]. This integrated hardware-software solution enables researchers to track molecular conformational changes as a function of temperature with unprecedented precision.

Strengths: Exceptional temperature stability and precision control; sophisticated software integration for automated experimental protocols; advanced drift correction algorithms. Weaknesses: Proprietary system with limited compatibility with third-party equipment; higher initial investment costs; requires specialized technical expertise for optimal operation and maintenance.

Breakthrough Technologies in Temperature-Controlled Specimen Holders

Means and methods for time-resolved sampling

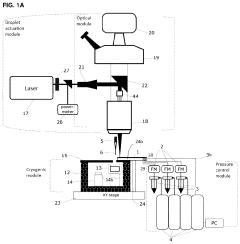

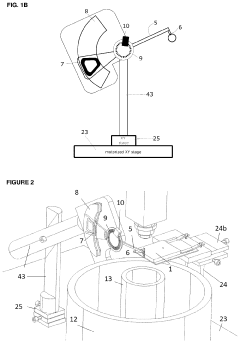

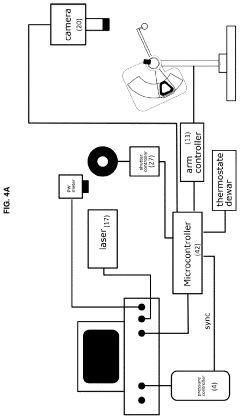

PatentPendingUS20240085288A1

Innovation

- A microfluidic chip with a droplet-on-demand system for fast mixing and controlled droplet generation, combined with a plunger module for rapid vitrification, allowing for low sample consumption and precise control over reaction delay times, enabling millisecond time-resolution sampling.

Device and method for cryogenic electron microscopy sample preparation

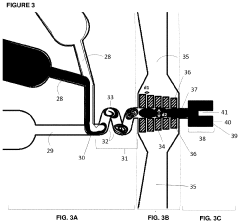

PatentWO2024080868A1

Innovation

- A cryo-EM sample preparation device with dual applicators and gas outlets for precise and automated deposition and removal of sample materials on a grid, combined with a cooling bath and image capturing apparatus for real-time monitoring, allowing for rapid mixing and vitrification of samples on a millisecond timescale.

Materials Science Considerations for Thermal Stability

The thermal stability of materials is a critical factor in the development and application of Cryo-EM in situ heating/cooling stage techniques. These stages must maintain structural integrity across extreme temperature ranges, typically from liquid nitrogen temperatures (-196°C) to several hundred degrees Celsius. The materials selected for stage construction must exhibit minimal thermal expansion coefficients to prevent dimensional changes that could compromise imaging precision or damage sensitive biological specimens.

Metal alloys such as Invar (64% iron, 36% nickel) have gained prominence in cryo-EM stage design due to their remarkably low thermal expansion properties. This characteristic ensures dimensional stability during temperature transitions, which is essential for maintaining focus and preventing drift during high-resolution imaging. Additionally, thermally conductive ceramics like aluminum nitride and silicon carbide offer excellent thermal management capabilities while providing electrical insulation properties necessary for electron microscopy environments.

Thermal gradients present significant challenges in stage design, as uneven heating or cooling can induce mechanical stress, leading to specimen deformation or stage warping. Advanced computational fluid dynamics modeling has become instrumental in predicting these thermal behaviors, allowing engineers to optimize heat distribution pathways and minimize gradient-induced artifacts. Recent innovations include the integration of microfluidic channels within stage components to ensure uniform temperature distribution.

Material fatigue considerations are particularly relevant for in situ stages designed for cyclic temperature experiments. Repeated thermal cycling between cryogenic and elevated temperatures accelerates material degradation through mechanisms such as thermal shock, creep, and stress relaxation. Research indicates that nanostructured materials and advanced composites can offer superior resistance to these fatigue mechanisms, extending the operational lifespan of heating/cooling stages.

Surface treatments and coatings have emerged as essential elements in cryo-EM stage design. Hydrophobic coatings prevent ice contamination at low temperatures, while specialized thermal barrier coatings can isolate sensitive components from extreme temperatures. Diamond-like carbon coatings provide exceptional wear resistance and thermal conductivity, protecting stage surfaces from beam-induced damage while facilitating efficient heat transfer.

The interface between different materials in multi-component stages requires careful engineering to accommodate differential thermal expansion. Techniques such as compliant layer bonding and gradient material transitions have been developed to mitigate stress concentration at these interfaces. Recent advances in additive manufacturing have enabled the production of functionally graded materials with spatially varying thermal properties, offering new possibilities for optimized thermal management in next-generation cryo-EM stages.

Metal alloys such as Invar (64% iron, 36% nickel) have gained prominence in cryo-EM stage design due to their remarkably low thermal expansion properties. This characteristic ensures dimensional stability during temperature transitions, which is essential for maintaining focus and preventing drift during high-resolution imaging. Additionally, thermally conductive ceramics like aluminum nitride and silicon carbide offer excellent thermal management capabilities while providing electrical insulation properties necessary for electron microscopy environments.

Thermal gradients present significant challenges in stage design, as uneven heating or cooling can induce mechanical stress, leading to specimen deformation or stage warping. Advanced computational fluid dynamics modeling has become instrumental in predicting these thermal behaviors, allowing engineers to optimize heat distribution pathways and minimize gradient-induced artifacts. Recent innovations include the integration of microfluidic channels within stage components to ensure uniform temperature distribution.

Material fatigue considerations are particularly relevant for in situ stages designed for cyclic temperature experiments. Repeated thermal cycling between cryogenic and elevated temperatures accelerates material degradation through mechanisms such as thermal shock, creep, and stress relaxation. Research indicates that nanostructured materials and advanced composites can offer superior resistance to these fatigue mechanisms, extending the operational lifespan of heating/cooling stages.

Surface treatments and coatings have emerged as essential elements in cryo-EM stage design. Hydrophobic coatings prevent ice contamination at low temperatures, while specialized thermal barrier coatings can isolate sensitive components from extreme temperatures. Diamond-like carbon coatings provide exceptional wear resistance and thermal conductivity, protecting stage surfaces from beam-induced damage while facilitating efficient heat transfer.

The interface between different materials in multi-component stages requires careful engineering to accommodate differential thermal expansion. Techniques such as compliant layer bonding and gradient material transitions have been developed to mitigate stress concentration at these interfaces. Recent advances in additive manufacturing have enabled the production of functionally graded materials with spatially varying thermal properties, offering new possibilities for optimized thermal management in next-generation cryo-EM stages.

Sample Preservation Techniques During Temperature Transitions

Sample preservation during temperature transitions represents a critical challenge in cryo-electron microscopy (cryo-EM) in situ heating/cooling stage techniques. The integrity of biological specimens must be maintained throughout temperature changes to ensure accurate structural analysis and meaningful experimental outcomes.

Traditional preservation methods often struggle with ice crystal formation during cooling processes, which can severely damage cellular ultrastructure. Recent advancements have introduced vitrification techniques that rapidly cool samples to cryogenic temperatures (-150°C to -196°C) at rates exceeding 10,000°C/second, preventing destructive ice crystal formation and preserving samples in a glass-like amorphous state.

For heating transitions, researchers have developed specialized protocols utilizing controlled warming rates to minimize thermal stress. Gradual temperature ramping at 1-5°C per minute has shown significant improvement in maintaining structural integrity compared to rapid heating. Additionally, the incorporation of cryoprotectants such as glycerol, DMSO, and trehalose has demonstrated enhanced sample stability during temperature fluctuations by modifying water behavior and reducing ice nucleation.

Advanced sample holders featuring thin carbon films and specialized grids with minimal thermal mass facilitate more uniform temperature distribution across specimens. These innovations reduce thermal gradients that could otherwise create mechanical stress and structural deformation. Gold-based grids have gained popularity due to their excellent thermal conductivity properties, ensuring more consistent temperature control throughout the sample.

Environmental control systems have evolved to maintain optimal humidity levels during temperature transitions. Humidity-controlled chambers prevent dehydration or condensation issues that commonly occur during warming phases. These systems typically maintain relative humidity between 80-95% to preserve hydration states of biological specimens.

Real-time monitoring technologies now allow researchers to observe structural changes during temperature transitions. Integrated sensors capable of measuring local temperature with sub-degree precision provide crucial feedback for preservation protocols. This monitoring capability has enabled the development of adaptive cooling/heating algorithms that adjust rates based on sample response, significantly improving preservation outcomes.

The field continues to advance with the development of hybrid preservation approaches combining chemical fixation with physical preservation techniques. These methods show particular promise for complex biological assemblies and cellular structures that are traditionally challenging to preserve during temperature transitions in cryo-EM studies.

Traditional preservation methods often struggle with ice crystal formation during cooling processes, which can severely damage cellular ultrastructure. Recent advancements have introduced vitrification techniques that rapidly cool samples to cryogenic temperatures (-150°C to -196°C) at rates exceeding 10,000°C/second, preventing destructive ice crystal formation and preserving samples in a glass-like amorphous state.

For heating transitions, researchers have developed specialized protocols utilizing controlled warming rates to minimize thermal stress. Gradual temperature ramping at 1-5°C per minute has shown significant improvement in maintaining structural integrity compared to rapid heating. Additionally, the incorporation of cryoprotectants such as glycerol, DMSO, and trehalose has demonstrated enhanced sample stability during temperature fluctuations by modifying water behavior and reducing ice nucleation.

Advanced sample holders featuring thin carbon films and specialized grids with minimal thermal mass facilitate more uniform temperature distribution across specimens. These innovations reduce thermal gradients that could otherwise create mechanical stress and structural deformation. Gold-based grids have gained popularity due to their excellent thermal conductivity properties, ensuring more consistent temperature control throughout the sample.

Environmental control systems have evolved to maintain optimal humidity levels during temperature transitions. Humidity-controlled chambers prevent dehydration or condensation issues that commonly occur during warming phases. These systems typically maintain relative humidity between 80-95% to preserve hydration states of biological specimens.

Real-time monitoring technologies now allow researchers to observe structural changes during temperature transitions. Integrated sensors capable of measuring local temperature with sub-degree precision provide crucial feedback for preservation protocols. This monitoring capability has enabled the development of adaptive cooling/heating algorithms that adjust rates based on sample response, significantly improving preservation outcomes.

The field continues to advance with the development of hybrid preservation approaches combining chemical fixation with physical preservation techniques. These methods show particular promise for complex biological assemblies and cellular structures that are traditionally challenging to preserve during temperature transitions in cryo-EM studies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!