Cryo-EM For Structural Evolution During Electrochemical Cycling

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryo-EM Technology Background and Objectives

Cryo-electron microscopy (Cryo-EM) has emerged as a revolutionary technique in structural biology, enabling researchers to visualize biological macromolecules at near-atomic resolution. The application of this technology to study structural evolution during electrochemical cycling represents a significant advancement in materials science and energy storage research. This technological approach bridges the gap between theoretical models and practical observations of dynamic processes occurring in battery materials.

The evolution of Cryo-EM began in the 1980s with the development of vitrification techniques by Jacques Dubochet and colleagues, allowing biological samples to be preserved in their native state without the formation of ice crystals. The field experienced a "resolution revolution" around 2013 with the introduction of direct electron detectors and improved image processing algorithms, enabling unprecedented structural detail to be captured.

In recent years, the application of Cryo-EM has expanded beyond traditional biological samples to materials science, particularly in battery research. This cross-disciplinary application addresses the critical need to understand structural transformations in electrode materials during charge-discharge cycles, which directly impact battery performance, degradation mechanisms, and lifetime.

The primary technical objective of applying Cryo-EM to electrochemical cycling studies is to capture and analyze the dynamic structural changes occurring at the atomic and nanoscale levels during battery operation. This includes monitoring phase transformations, interfacial reactions, and degradation mechanisms in real-time or through strategic sampling at different stages of cycling.

Current technological trends indicate a growing integration of Cryo-EM with other analytical techniques such as spectroscopy and computational modeling to provide comprehensive insights into electrochemical processes. The development of in situ and operando Cryo-EM methodologies represents the frontier of this field, aiming to observe structural changes under actual operating conditions rather than post-mortem analysis.

The advancement of this technology is driven by the global push for improved energy storage solutions, particularly for electric vehicles and renewable energy integration. Understanding the fundamental mechanisms of battery operation at the atomic level is essential for designing next-generation energy storage systems with higher capacity, faster charging capabilities, and longer lifespans.

Technical goals for the continued development of Cryo-EM in electrochemical studies include improving temporal resolution to capture transient states during cycling, enhancing spatial resolution to better visualize atomic arrangements, and developing specialized sample preparation techniques that maintain the integrity of sensitive electrochemical interfaces while enabling high-quality imaging.

The evolution of Cryo-EM began in the 1980s with the development of vitrification techniques by Jacques Dubochet and colleagues, allowing biological samples to be preserved in their native state without the formation of ice crystals. The field experienced a "resolution revolution" around 2013 with the introduction of direct electron detectors and improved image processing algorithms, enabling unprecedented structural detail to be captured.

In recent years, the application of Cryo-EM has expanded beyond traditional biological samples to materials science, particularly in battery research. This cross-disciplinary application addresses the critical need to understand structural transformations in electrode materials during charge-discharge cycles, which directly impact battery performance, degradation mechanisms, and lifetime.

The primary technical objective of applying Cryo-EM to electrochemical cycling studies is to capture and analyze the dynamic structural changes occurring at the atomic and nanoscale levels during battery operation. This includes monitoring phase transformations, interfacial reactions, and degradation mechanisms in real-time or through strategic sampling at different stages of cycling.

Current technological trends indicate a growing integration of Cryo-EM with other analytical techniques such as spectroscopy and computational modeling to provide comprehensive insights into electrochemical processes. The development of in situ and operando Cryo-EM methodologies represents the frontier of this field, aiming to observe structural changes under actual operating conditions rather than post-mortem analysis.

The advancement of this technology is driven by the global push for improved energy storage solutions, particularly for electric vehicles and renewable energy integration. Understanding the fundamental mechanisms of battery operation at the atomic level is essential for designing next-generation energy storage systems with higher capacity, faster charging capabilities, and longer lifespans.

Technical goals for the continued development of Cryo-EM in electrochemical studies include improving temporal resolution to capture transient states during cycling, enhancing spatial resolution to better visualize atomic arrangements, and developing specialized sample preparation techniques that maintain the integrity of sensitive electrochemical interfaces while enabling high-quality imaging.

Market Applications in Battery Research and Development

Cryo-electron microscopy (Cryo-EM) has emerged as a revolutionary tool in battery research and development, offering unprecedented insights into structural evolution during electrochemical cycling. The battery market, valued at over $100 billion globally, is experiencing rapid growth driven by electric vehicles, renewable energy storage, and portable electronics. Within this expanding market, Cryo-EM technology addresses critical challenges in battery performance, longevity, and safety.

The primary application of Cryo-EM in battery R&D lies in its ability to visualize electrode-electrolyte interfaces at atomic resolution during operation. This capability is particularly valuable for lithium-ion battery manufacturers seeking to understand degradation mechanisms and improve cycle life. Companies like Tesla, CATL, and Samsung SDI have begun incorporating Cryo-EM analysis into their development pipelines, resulting in batteries with enhanced energy density and longer operational lifespans.

Beyond lithium-ion technologies, Cryo-EM is proving instrumental in next-generation battery development. Solid-state battery research benefits significantly from Cryo-EM's ability to characterize interfacial phenomena and ion transport pathways. This application addresses a market segment projected to reach substantial growth as automotive manufacturers commit to solid-state technology roadmaps for future electric vehicles.

The energy storage sector represents another significant market application. Grid-scale storage systems require batteries with exceptional cycle stability and safety profiles. Cryo-EM enables researchers to observe structural changes during deep cycling and fast charging conditions, informing the design of more robust storage solutions for renewable energy integration.

Medical device batteries constitute a specialized but high-value application area. Implantable devices demand batteries with exceptional reliability and safety. Cryo-EM analysis helps manufacturers develop batteries that maintain structural integrity over thousands of cycles while meeting stringent biocompatibility requirements.

Consumer electronics manufacturers are also leveraging Cryo-EM insights to develop faster-charging batteries with higher energy density. This market segment is particularly sensitive to innovations that extend device usage time between charges while maintaining safety standards.

The analytical services market surrounding battery characterization has expanded to include specialized Cryo-EM facilities. Companies like Thermo Fisher Scientific and JEOL have developed dedicated instruments and workflows for battery research, creating a secondary market for equipment, software, and expertise in this specialized analytical technique.

The primary application of Cryo-EM in battery R&D lies in its ability to visualize electrode-electrolyte interfaces at atomic resolution during operation. This capability is particularly valuable for lithium-ion battery manufacturers seeking to understand degradation mechanisms and improve cycle life. Companies like Tesla, CATL, and Samsung SDI have begun incorporating Cryo-EM analysis into their development pipelines, resulting in batteries with enhanced energy density and longer operational lifespans.

Beyond lithium-ion technologies, Cryo-EM is proving instrumental in next-generation battery development. Solid-state battery research benefits significantly from Cryo-EM's ability to characterize interfacial phenomena and ion transport pathways. This application addresses a market segment projected to reach substantial growth as automotive manufacturers commit to solid-state technology roadmaps for future electric vehicles.

The energy storage sector represents another significant market application. Grid-scale storage systems require batteries with exceptional cycle stability and safety profiles. Cryo-EM enables researchers to observe structural changes during deep cycling and fast charging conditions, informing the design of more robust storage solutions for renewable energy integration.

Medical device batteries constitute a specialized but high-value application area. Implantable devices demand batteries with exceptional reliability and safety. Cryo-EM analysis helps manufacturers develop batteries that maintain structural integrity over thousands of cycles while meeting stringent biocompatibility requirements.

Consumer electronics manufacturers are also leveraging Cryo-EM insights to develop faster-charging batteries with higher energy density. This market segment is particularly sensitive to innovations that extend device usage time between charges while maintaining safety standards.

The analytical services market surrounding battery characterization has expanded to include specialized Cryo-EM facilities. Companies like Thermo Fisher Scientific and JEOL have developed dedicated instruments and workflows for battery research, creating a secondary market for equipment, software, and expertise in this specialized analytical technique.

Current Challenges in Electrochemical Imaging Techniques

Despite significant advancements in electrochemical energy storage technologies, current imaging techniques face substantial limitations when attempting to capture structural evolution during electrochemical cycling. Traditional electrochemical characterization methods provide valuable information about overall performance but fail to reveal the complex structural transformations occurring at the nanoscale during operation.

X-ray diffraction (XRD) techniques, while useful for crystalline phase identification, struggle with amorphous materials and lack the spatial resolution needed to observe localized structural changes. Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) offer high spatial resolution but typically require ex-situ sample preparation that may introduce artifacts and prevent real-time observation of dynamic processes.

In-situ TEM techniques have emerged as promising alternatives, but they face significant challenges including limited electrochemical control, electron beam damage, and restricted viewing areas. These limitations often result in observations that may not accurately represent real-world battery operation conditions, creating a disconnect between laboratory findings and practical applications.

Atomic force microscopy (AFM) and scanning tunneling microscopy (STM) provide excellent surface characterization but cannot effectively probe subsurface structures critical to understanding electrochemical processes. This surface limitation significantly restricts their utility in comprehensively analyzing electrode materials during cycling.

Synchrotron-based techniques offer powerful capabilities but suffer from limited accessibility, high operational costs, and complex data interpretation requirements. These barriers restrict their widespread adoption for routine electrochemical research and development activities.

Current liquid-cell TEM approaches attempt to bridge some gaps but struggle with resolution degradation due to electron scattering in liquid environments. Additionally, the confined geometry of liquid cells often creates artificial electrochemical conditions that may not accurately reflect bulk behavior in commercial devices.

Perhaps most critically, existing techniques generally lack the capability to simultaneously capture both structural and chemical changes at high spatial and temporal resolution. This limitation prevents researchers from establishing clear structure-property-performance relationships essential for rational materials design.

The integration of data across multiple characterization techniques remains challenging, with inconsistencies in sample preparation, measurement conditions, and data processing creating barriers to developing comprehensive understanding of electrochemical systems. These challenges collectively highlight the urgent need for advanced imaging methodologies like cryo-EM that can preserve native structures while providing high-resolution insights into electrochemical processes.

X-ray diffraction (XRD) techniques, while useful for crystalline phase identification, struggle with amorphous materials and lack the spatial resolution needed to observe localized structural changes. Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) offer high spatial resolution but typically require ex-situ sample preparation that may introduce artifacts and prevent real-time observation of dynamic processes.

In-situ TEM techniques have emerged as promising alternatives, but they face significant challenges including limited electrochemical control, electron beam damage, and restricted viewing areas. These limitations often result in observations that may not accurately represent real-world battery operation conditions, creating a disconnect between laboratory findings and practical applications.

Atomic force microscopy (AFM) and scanning tunneling microscopy (STM) provide excellent surface characterization but cannot effectively probe subsurface structures critical to understanding electrochemical processes. This surface limitation significantly restricts their utility in comprehensively analyzing electrode materials during cycling.

Synchrotron-based techniques offer powerful capabilities but suffer from limited accessibility, high operational costs, and complex data interpretation requirements. These barriers restrict their widespread adoption for routine electrochemical research and development activities.

Current liquid-cell TEM approaches attempt to bridge some gaps but struggle with resolution degradation due to electron scattering in liquid environments. Additionally, the confined geometry of liquid cells often creates artificial electrochemical conditions that may not accurately reflect bulk behavior in commercial devices.

Perhaps most critically, existing techniques generally lack the capability to simultaneously capture both structural and chemical changes at high spatial and temporal resolution. This limitation prevents researchers from establishing clear structure-property-performance relationships essential for rational materials design.

The integration of data across multiple characterization techniques remains challenging, with inconsistencies in sample preparation, measurement conditions, and data processing creating barriers to developing comprehensive understanding of electrochemical systems. These challenges collectively highlight the urgent need for advanced imaging methodologies like cryo-EM that can preserve native structures while providing high-resolution insights into electrochemical processes.

Existing Cryo-EM Protocols for Battery Materials

01 Technical advancements in cryo-EM instrumentation

Innovations in cryo-EM hardware have significantly improved resolution capabilities and sample analysis. These advancements include enhanced electron detectors, more stable microscope platforms, and improved vacuum systems that reduce contamination. Modern cryo-EM instruments incorporate automated data collection systems and sophisticated optics that allow for higher resolution imaging of biological macromolecules in their native states.- Advancements in Cryo-EM hardware and instrumentation: Recent developments in Cryo-EM hardware have significantly improved resolution capabilities and data acquisition efficiency. These advancements include enhanced electron detectors, more stable microscope platforms, and automated specimen handling systems. The evolution of direct electron detectors has particularly revolutionized the field by enabling higher sensitivity and faster frame rates, which helps in reducing beam-induced motion and radiation damage to specimens.

- Computational methods and image processing techniques: Sophisticated computational algorithms have been developed to enhance Cryo-EM structural determination. These include advanced image processing techniques, 3D reconstruction methods, and machine learning approaches that improve signal-to-noise ratios and resolution. Software platforms now incorporate automated particle picking, classification, and refinement procedures that facilitate the processing of large datasets and enable the reconstruction of high-resolution structures from heterogeneous samples.

- Sample preparation innovations for Cryo-EM: Innovations in sample preparation techniques have addressed key challenges in Cryo-EM structural studies. These include methods for optimizing vitrification conditions, reducing preferred orientation of particles, and maintaining sample integrity during the freezing process. New grid technologies with improved surface properties and vitrification devices allow for better distribution of particles and thinner ice layers, which are critical for achieving high-resolution structural data.

- Integration of Cryo-EM with complementary techniques: The integration of Cryo-EM with other structural and functional techniques has expanded its applications and enhanced structural insights. Hybrid approaches combining Cryo-EM with X-ray crystallography, NMR spectroscopy, or mass spectrometry provide comprehensive structural information across different resolution ranges. Time-resolved Cryo-EM methods are also emerging, allowing visualization of dynamic structural changes and conformational states of macromolecular complexes.

- Applications of Cryo-EM in drug discovery and development: Cryo-EM has become an invaluable tool in pharmaceutical research and drug development processes. The ability to visualize drug-target interactions at near-atomic resolution provides crucial insights for structure-based drug design. Cryo-EM is increasingly used to study membrane proteins, large macromolecular complexes, and conformationally heterogeneous targets that are challenging for traditional structural biology methods, enabling the development of novel therapeutics for previously undruggable targets.

02 Sample preparation techniques for cryo-EM

Novel sample preparation methods have revolutionized cryo-EM structural analysis. These techniques include improved vitrification processes, grid preparation protocols that reduce preferred orientation issues, and methods to maintain sample integrity during freezing. Innovations in this area have enabled researchers to study increasingly complex biological structures with minimal artifacts, leading to more accurate structural determinations.Expand Specific Solutions03 Image processing and computational methods in cryo-EM

Advanced computational algorithms have transformed raw cryo-EM data into high-resolution structural models. These include machine learning approaches for particle picking, motion correction software that compensates for beam-induced movement, and sophisticated 3D reconstruction methods. The evolution of these computational tools has been crucial in achieving atomic-resolution structures from cryo-EM data, enabling researchers to visualize molecular details previously only accessible through X-ray crystallography.Expand Specific Solutions04 Integration of cryo-EM with other structural biology techniques

Hybrid approaches combining cryo-EM with complementary methods have enhanced structural understanding of complex biological systems. These integrative methods include correlative light and electron microscopy, cryo-electron tomography, and the combination of cryo-EM with mass spectrometry or X-ray crystallography data. Such multi-technique approaches provide comprehensive structural insights that would not be possible with any single method alone.Expand Specific Solutions05 Applications of cryo-EM in drug discovery and development

Cryo-EM has become an essential tool in pharmaceutical research, enabling structure-based drug design through detailed visualization of drug-target interactions. The technique allows researchers to observe conformational changes in proteins upon ligand binding and to study membrane proteins that are challenging targets for traditional structural methods. Recent advances have made it possible to use cryo-EM for fragment screening and hit optimization in drug discovery pipelines.Expand Specific Solutions

Leading Research Institutions and Industrial Partners

The Cryo-EM for structural evolution during electrochemical cycling market is in its growth phase, characterized by increasing adoption across research institutions and industry. The global market size is expanding rapidly, driven by the need for advanced battery research and development. Technologically, this field is maturing with significant contributions from academic institutions like Zhejiang University, Tsinghua University, and University of Washington, alongside commercial players such as FEI Co. (microscopy solutions provider) and Honda Motor Co. (end-user application in battery development). Research foundations including Wisconsin Alumni Research Foundation and The Regents of the University of California are actively patenting innovations, while specialized companies like MiTeGen LLC and Direct Electron LP are developing supporting technologies. The ecosystem demonstrates a collaborative environment between academia and industry, with varying levels of technological maturity across different application segments.

Direct Electron, L P

Technical Solution: Direct Electron has developed specialized direct detection camera systems optimized for cryo-EM applications in battery research, particularly for tracking structural evolution during electrochemical cycling. Their DE-series cameras feature electron-counting technology with exceptional detective quantum efficiency (DQE) and modulation transfer function (MTF), enabling high-resolution imaging of beam-sensitive battery materials with minimal electron dose[2]. The company's proprietary event-driven readout architecture allows for dose fractionation and drift correction, critical for capturing transient structural states during dynamic electrochemical processes. Direct Electron has also developed specialized software solutions for automated data acquisition and processing specifically tailored to time-resolved cryo-EM studies of battery materials[4]. Their technology enables researchers to visualize the formation and evolution of solid-electrolyte interphase (SEI) layers, lithium dendrite growth, and structural transformations in electrode materials at near-atomic resolution during cycling, providing unprecedented insights into degradation mechanisms and failure modes in battery systems.

Strengths: Superior detector sensitivity allows for lower electron doses, reducing beam damage to sensitive battery materials. High frame rates enable time-resolved imaging of rapid structural changes during cycling events. Weaknesses: Integration challenges with some existing microscope systems may require additional hardware modifications. Software solutions, while powerful, have steep learning curves for new users in the battery research field.

FEI Co.

Technical Solution: FEI Co. has developed advanced cryo-electron microscopy (cryo-EM) solutions specifically optimized for tracking structural evolution during electrochemical cycling. Their technology integrates specialized sample holders that maintain cryogenic temperatures while allowing for in situ electrochemical operations. FEI's Titan Krios platform, equipped with direct electron detectors and phase plates, achieves sub-2Å resolution imaging of battery materials during cycling processes[1]. Their proprietary workflow includes flash-freezing techniques that capture transient structural states at precise points during charge-discharge cycles, preserving the native hydrated state of electrochemical interfaces. FEI has also pioneered correlative techniques that combine cryo-EM with spectroscopic methods, enabling simultaneous structural and chemical characterization of electrode-electrolyte interfaces during cycling[3]. Their automated data acquisition systems allow for time-resolved studies that track structural evolution across multiple cycles, providing insights into degradation mechanisms and performance limitations in battery materials.

Strengths: Superior resolution capabilities with sub-2Å imaging allows visualization of atomic-level structural changes during cycling. Integrated sample preparation workflow preserves native states of electrochemical interfaces. Weaknesses: High equipment costs limit accessibility, and sample preparation remains challenging for certain battery materials. Limited field of view may miss larger-scale structural evolutions across electrode materials.

Key Innovations in Sample Preparation and Data Processing

Means and methods for time-resolved sampling

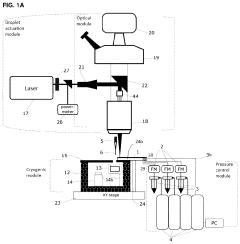

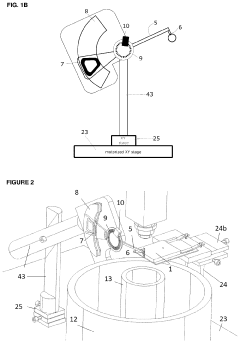

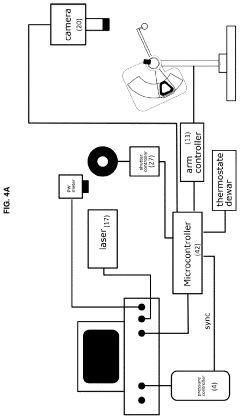

PatentPendingUS20240085288A1

Innovation

- A microfluidic chip with a droplet-on-demand system for fast mixing and controlled droplet generation, combined with a plunger module for rapid vitrification, allowing for low sample consumption and precise control over reaction delay times, enabling millisecond time-resolution sampling.

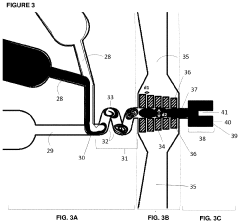

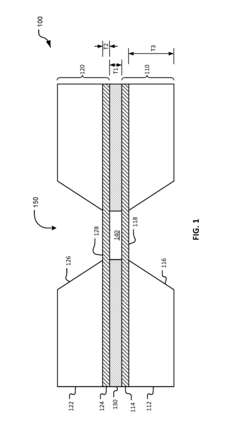

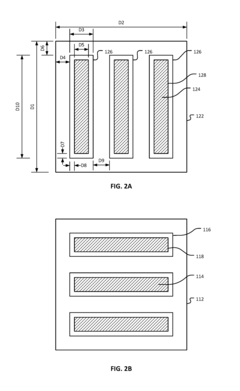

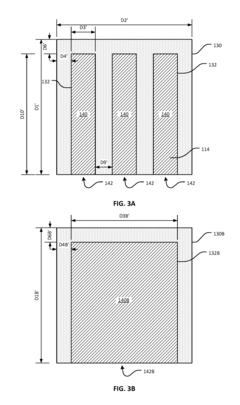

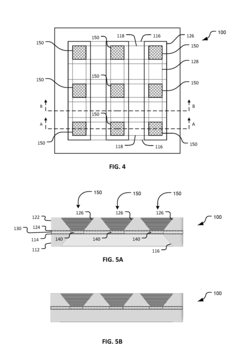

Thin-ice grid assembly for cryo-electron microscopy

PatentInactiveUS20160351374A1

Innovation

- A grid assembly for cryo-EM is developed, comprising two support members with electron-transparent layers and a rigid spacer layer, allowing precise control of ice thickness between them, enabling consistent vitrification and efficient imaging.

Safety and Environmental Considerations

The implementation of Cryo-EM for structural evolution studies during electrochemical cycling necessitates careful consideration of safety protocols and environmental impacts. Laboratory environments utilizing cryogenic electron microscopy involve handling of potentially hazardous materials, including liquid nitrogen and various chemical electrolytes, which require stringent safety measures. Personnel must be adequately trained in cryogen handling procedures to prevent cold burns, asphyxiation risks in confined spaces, and potential pressure build-up hazards in storage containers.

Environmental considerations extend beyond immediate laboratory safety to the broader ecological footprint of Cryo-EM operations. The significant energy consumption required for maintaining ultra-low temperatures in electron microscopes contributes to carbon emissions, particularly in regions dependent on fossil fuel energy sources. Additionally, the disposal of spent electrolytes and battery materials examined during electrochemical cycling studies must adhere to strict waste management protocols to prevent soil and water contamination.

Regulatory compliance represents another critical dimension, with varying standards across different jurisdictions governing the handling of cryogenic materials, chemical waste disposal, and laboratory emissions. Research institutions and commercial entities employing Cryo-EM technology must navigate these regulatory frameworks while maintaining operational efficiency and scientific productivity.

The sustainability aspect of Cryo-EM research in battery development presents both challenges and opportunities. While the technology itself consumes considerable resources, its application in developing more efficient energy storage solutions could yield net environmental benefits through improved battery performance and longevity. Researchers are increasingly exploring methods to reduce the environmental impact of Cryo-EM operations, including energy recovery systems, optimized sample preparation techniques that minimize chemical usage, and shared facility models that maximize instrument utilization.

Risk assessment and mitigation strategies form an integral component of Cryo-EM implementation. Comprehensive protocols should address potential failure scenarios, including power outages affecting cryogen containment systems, sample contamination events, and equipment malfunctions. Emergency response procedures must be clearly documented and regularly practiced to ensure prompt and effective action in case of incidents.

The ethical dimensions of safety and environmental considerations extend to transparency in reporting potential hazards associated with new battery materials discovered through Cryo-EM research. Scientists bear responsibility for communicating not only the performance benefits but also any safety or environmental concerns identified during structural evolution studies, ensuring that subsequent commercial applications incorporate appropriate safeguards.

Environmental considerations extend beyond immediate laboratory safety to the broader ecological footprint of Cryo-EM operations. The significant energy consumption required for maintaining ultra-low temperatures in electron microscopes contributes to carbon emissions, particularly in regions dependent on fossil fuel energy sources. Additionally, the disposal of spent electrolytes and battery materials examined during electrochemical cycling studies must adhere to strict waste management protocols to prevent soil and water contamination.

Regulatory compliance represents another critical dimension, with varying standards across different jurisdictions governing the handling of cryogenic materials, chemical waste disposal, and laboratory emissions. Research institutions and commercial entities employing Cryo-EM technology must navigate these regulatory frameworks while maintaining operational efficiency and scientific productivity.

The sustainability aspect of Cryo-EM research in battery development presents both challenges and opportunities. While the technology itself consumes considerable resources, its application in developing more efficient energy storage solutions could yield net environmental benefits through improved battery performance and longevity. Researchers are increasingly exploring methods to reduce the environmental impact of Cryo-EM operations, including energy recovery systems, optimized sample preparation techniques that minimize chemical usage, and shared facility models that maximize instrument utilization.

Risk assessment and mitigation strategies form an integral component of Cryo-EM implementation. Comprehensive protocols should address potential failure scenarios, including power outages affecting cryogen containment systems, sample contamination events, and equipment malfunctions. Emergency response procedures must be clearly documented and regularly practiced to ensure prompt and effective action in case of incidents.

The ethical dimensions of safety and environmental considerations extend to transparency in reporting potential hazards associated with new battery materials discovered through Cryo-EM research. Scientists bear responsibility for communicating not only the performance benefits but also any safety or environmental concerns identified during structural evolution studies, ensuring that subsequent commercial applications incorporate appropriate safeguards.

Scalability and Integration with Computational Methods

The scalability of cryo-electron microscopy (cryo-EM) techniques for monitoring structural evolution during electrochemical cycling presents both significant challenges and opportunities. Current cryo-EM implementations often require specialized facilities and expertise, limiting widespread adoption across research institutions. The high capital costs associated with cryo-EM equipment—typically ranging from $5-10 million for state-of-the-art systems—create substantial barriers to entry for many research groups interested in battery materials characterization.

Integration with computational methods represents a critical frontier for advancing cryo-EM applications in electrochemical systems. Machine learning algorithms are increasingly being deployed to enhance image processing capabilities, allowing for more efficient identification and classification of structural features across large datasets. These computational approaches can significantly reduce the manual analysis time required for interpreting complex structural changes occurring during battery cycling.

Molecular dynamics simulations coupled with cryo-EM data provide powerful insights by bridging experimental observations with theoretical models. This integration enables researchers to validate structural hypotheses and predict behavior under conditions that may be difficult to capture experimentally. Density functional theory (DFT) calculations further complement cryo-EM findings by elucidating electronic structure changes associated with observed morphological transformations.

Cloud-based computing platforms are emerging as solutions to the computational demands of cryo-EM data processing. These platforms enable distributed processing of terabyte-scale datasets generated during in situ electrochemical experiments. Several commercial and open-source software packages now offer specialized tools for cryo-EM data analysis in materials science applications, though further development is needed for electrochemical-specific workflows.

The development of automated sample preparation systems represents another avenue for improving scalability. Current methods often require time-consuming manual preparation steps that introduce variability between samples. Robotics-assisted sample preparation could standardize these processes, enabling higher throughput and more consistent results across experiments.

Looking forward, the integration of cryo-EM with other characterization techniques through correlative microscopy approaches offers promising pathways for comprehensive material analysis. Combining cryo-EM structural data with spectroscopic methods (such as XPS or EELS) provides complementary chemical information that enhances understanding of degradation mechanisms in battery materials. This multi-modal approach will likely become standard practice as the field advances toward more holistic characterization methodologies.

Integration with computational methods represents a critical frontier for advancing cryo-EM applications in electrochemical systems. Machine learning algorithms are increasingly being deployed to enhance image processing capabilities, allowing for more efficient identification and classification of structural features across large datasets. These computational approaches can significantly reduce the manual analysis time required for interpreting complex structural changes occurring during battery cycling.

Molecular dynamics simulations coupled with cryo-EM data provide powerful insights by bridging experimental observations with theoretical models. This integration enables researchers to validate structural hypotheses and predict behavior under conditions that may be difficult to capture experimentally. Density functional theory (DFT) calculations further complement cryo-EM findings by elucidating electronic structure changes associated with observed morphological transformations.

Cloud-based computing platforms are emerging as solutions to the computational demands of cryo-EM data processing. These platforms enable distributed processing of terabyte-scale datasets generated during in situ electrochemical experiments. Several commercial and open-source software packages now offer specialized tools for cryo-EM data analysis in materials science applications, though further development is needed for electrochemical-specific workflows.

The development of automated sample preparation systems represents another avenue for improving scalability. Current methods often require time-consuming manual preparation steps that introduce variability between samples. Robotics-assisted sample preparation could standardize these processes, enabling higher throughput and more consistent results across experiments.

Looking forward, the integration of cryo-EM with other characterization techniques through correlative microscopy approaches offers promising pathways for comprehensive material analysis. Combining cryo-EM structural data with spectroscopic methods (such as XPS or EELS) provides complementary chemical information that enhances understanding of degradation mechanisms in battery materials. This multi-modal approach will likely become standard practice as the field advances toward more holistic characterization methodologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!