Cryo-EM For Monitoring Polymer Crosslinking And Curing

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryo-EM Technology Background and Objectives

Cryogenic electron microscopy (Cryo-EM) has emerged as a revolutionary technique in structural biology, enabling researchers to visualize biological macromolecules at near-atomic resolution. Originally developed in the 1980s, this technology has undergone significant advancements over the past four decades, culminating in the 2017 Nobel Prize in Chemistry awarded to Jacques Dubochet, Joachim Frank, and Richard Henderson for their pioneering contributions to the field.

The application of Cryo-EM to polymer science represents a novel extension of this powerful imaging technology. Traditional polymer characterization methods such as differential scanning calorimetry (DSC), rheology, and spectroscopic techniques provide valuable but indirect information about crosslinking and curing processes. These conventional approaches often fail to capture the nanoscale structural changes occurring during polymer network formation.

Cryo-EM offers unique advantages for monitoring polymer crosslinking and curing by enabling direct visualization of structural transformations at the molecular level. By rapidly freezing polymer samples at different stages of the curing process, researchers can create a series of "molecular snapshots" that reveal the progressive formation of crosslinks and the evolution of network architecture.

The technical evolution of Cryo-EM has been marked by several breakthrough innovations, including the development of direct electron detectors, improved sample preparation methods, and advanced image processing algorithms. These advancements have dramatically enhanced resolution capabilities from nanometer to sub-nanometer and even angstrom levels, making it possible to observe fine details of polymer structures previously inaccessible to researchers.

Recent developments in time-resolved Cryo-EM techniques have further expanded the potential for studying dynamic processes such as polymer curing. By implementing sophisticated sample vitrification methods with precise timing control, researchers can now capture transient states during crosslinking reactions, providing unprecedented insights into reaction kinetics and mechanisms.

The primary objective of applying Cryo-EM to polymer crosslinking and curing is to establish a comprehensive understanding of the relationship between processing conditions, molecular structure, and final material properties. This knowledge is crucial for the rational design of advanced polymer materials with tailored characteristics for applications ranging from aerospace composites to biomedical implants.

Additional technical goals include developing standardized protocols for sample preparation specific to polymer systems, optimizing image acquisition parameters for non-biological specimens, and creating specialized computational tools for analyzing polymer network structures. These methodological advances will be essential for transforming Cryo-EM from a primarily biological technique into a versatile tool for materials science research.

The application of Cryo-EM to polymer science represents a novel extension of this powerful imaging technology. Traditional polymer characterization methods such as differential scanning calorimetry (DSC), rheology, and spectroscopic techniques provide valuable but indirect information about crosslinking and curing processes. These conventional approaches often fail to capture the nanoscale structural changes occurring during polymer network formation.

Cryo-EM offers unique advantages for monitoring polymer crosslinking and curing by enabling direct visualization of structural transformations at the molecular level. By rapidly freezing polymer samples at different stages of the curing process, researchers can create a series of "molecular snapshots" that reveal the progressive formation of crosslinks and the evolution of network architecture.

The technical evolution of Cryo-EM has been marked by several breakthrough innovations, including the development of direct electron detectors, improved sample preparation methods, and advanced image processing algorithms. These advancements have dramatically enhanced resolution capabilities from nanometer to sub-nanometer and even angstrom levels, making it possible to observe fine details of polymer structures previously inaccessible to researchers.

Recent developments in time-resolved Cryo-EM techniques have further expanded the potential for studying dynamic processes such as polymer curing. By implementing sophisticated sample vitrification methods with precise timing control, researchers can now capture transient states during crosslinking reactions, providing unprecedented insights into reaction kinetics and mechanisms.

The primary objective of applying Cryo-EM to polymer crosslinking and curing is to establish a comprehensive understanding of the relationship between processing conditions, molecular structure, and final material properties. This knowledge is crucial for the rational design of advanced polymer materials with tailored characteristics for applications ranging from aerospace composites to biomedical implants.

Additional technical goals include developing standardized protocols for sample preparation specific to polymer systems, optimizing image acquisition parameters for non-biological specimens, and creating specialized computational tools for analyzing polymer network structures. These methodological advances will be essential for transforming Cryo-EM from a primarily biological technique into a versatile tool for materials science research.

Market Applications for Polymer Crosslinking Monitoring

The polymer industry has witnessed significant growth in demand for advanced monitoring techniques, particularly for crosslinking and curing processes. The application of Cryo-Electron Microscopy (Cryo-EM) for monitoring polymer crosslinking represents a revolutionary approach with substantial market potential across multiple sectors.

In the aerospace industry, high-performance polymer composites require precise crosslinking control to ensure structural integrity under extreme conditions. Cryo-EM monitoring enables manufacturers to verify crosslinking uniformity in critical components, potentially reducing failure rates by enhancing quality control processes. This application segment is projected to grow substantially as aerospace manufacturers increasingly adopt advanced materials for fuel efficiency and performance improvements.

The automotive sector represents another significant market opportunity, particularly with the transition toward electric vehicles. Battery encapsulants and thermal management systems utilize specialized polymers whose performance depends on optimal crosslinking. Cryo-EM monitoring can help manufacturers achieve consistent battery performance and longevity through precise polymer structure verification.

Medical device manufacturing constitutes a premium market segment for Cryo-EM polymer monitoring. Implantable devices, drug delivery systems, and diagnostic equipment require biocompatible polymers with precisely controlled crosslinking to ensure functionality and patient safety. The ability to visualize nanoscale crosslinking structures provides manufacturers with unprecedented quality assurance capabilities, addressing stringent regulatory requirements while improving product performance.

The electronics industry presents perhaps the most immediate growth opportunity. As device miniaturization continues, polymers used in semiconductor packaging, flexible electronics, and display technologies require increasingly precise crosslinking control. Cryo-EM monitoring enables manufacturers to optimize curing processes for enhanced electrical properties, thermal stability, and mechanical durability at nanoscale dimensions.

Emerging applications in sustainable materials represent a forward-looking market segment. Bio-based and recyclable polymers often present unique crosslinking challenges that can be addressed through advanced monitoring techniques. Cryo-EM analysis helps manufacturers optimize these environmentally friendly materials to match or exceed the performance of traditional polymers, accelerating market adoption.

The coatings industry also stands to benefit significantly from Cryo-EM monitoring capabilities. High-performance industrial coatings, particularly those used in corrosion protection and specialized functional applications, rely on precisely controlled crosslinking to achieve desired properties. Manufacturers can leverage Cryo-EM data to develop coatings with enhanced durability, chemical resistance, and application-specific performance characteristics.

In the aerospace industry, high-performance polymer composites require precise crosslinking control to ensure structural integrity under extreme conditions. Cryo-EM monitoring enables manufacturers to verify crosslinking uniformity in critical components, potentially reducing failure rates by enhancing quality control processes. This application segment is projected to grow substantially as aerospace manufacturers increasingly adopt advanced materials for fuel efficiency and performance improvements.

The automotive sector represents another significant market opportunity, particularly with the transition toward electric vehicles. Battery encapsulants and thermal management systems utilize specialized polymers whose performance depends on optimal crosslinking. Cryo-EM monitoring can help manufacturers achieve consistent battery performance and longevity through precise polymer structure verification.

Medical device manufacturing constitutes a premium market segment for Cryo-EM polymer monitoring. Implantable devices, drug delivery systems, and diagnostic equipment require biocompatible polymers with precisely controlled crosslinking to ensure functionality and patient safety. The ability to visualize nanoscale crosslinking structures provides manufacturers with unprecedented quality assurance capabilities, addressing stringent regulatory requirements while improving product performance.

The electronics industry presents perhaps the most immediate growth opportunity. As device miniaturization continues, polymers used in semiconductor packaging, flexible electronics, and display technologies require increasingly precise crosslinking control. Cryo-EM monitoring enables manufacturers to optimize curing processes for enhanced electrical properties, thermal stability, and mechanical durability at nanoscale dimensions.

Emerging applications in sustainable materials represent a forward-looking market segment. Bio-based and recyclable polymers often present unique crosslinking challenges that can be addressed through advanced monitoring techniques. Cryo-EM analysis helps manufacturers optimize these environmentally friendly materials to match or exceed the performance of traditional polymers, accelerating market adoption.

The coatings industry also stands to benefit significantly from Cryo-EM monitoring capabilities. High-performance industrial coatings, particularly those used in corrosion protection and specialized functional applications, rely on precisely controlled crosslinking to achieve desired properties. Manufacturers can leverage Cryo-EM data to develop coatings with enhanced durability, chemical resistance, and application-specific performance characteristics.

Current Challenges in Polymer Curing Visualization

Despite significant advancements in polymer science, visualizing and monitoring the crosslinking and curing processes in real-time remains a formidable challenge. Current visualization techniques struggle with several fundamental limitations that impede comprehensive understanding of these complex molecular transformations.

The primary challenge lies in achieving sufficient spatial resolution while maintaining temporal sensitivity. Traditional microscopy methods often fail to capture the nanoscale structural changes occurring during polymer curing, particularly in three-dimensional networks. Even advanced optical techniques encounter diffraction limits that prevent observation of molecular-level crosslinking events, which typically occur at scales below 10 nanometers.

Environmental constraints present another significant obstacle. Many polymers require specific curing conditions—elevated temperatures, pressure, or specialized atmospheres—that are incompatible with conventional imaging setups. This creates a fundamental disconnect between laboratory visualization capabilities and real-world manufacturing conditions, limiting the practical applicability of research findings.

The dynamic nature of crosslinking reactions poses additional complications. Curing processes often involve rapid chemical transformations occurring across multiple timescales, from milliseconds to hours. Current imaging technologies struggle to capture this full temporal spectrum without sacrificing spatial resolution or chemical specificity, creating blind spots in our understanding of reaction kinetics.

Sample preparation for high-resolution techniques introduces further complications. Methods like traditional electron microscopy typically require extensive sample modification—including dehydration, staining, or coating—that can fundamentally alter the polymer structure being studied, leading to artifacts and misinterpretation of results.

Chemical specificity represents another significant challenge. Many visualization techniques cannot differentiate between various chemical bonds forming during crosslinking, making it difficult to track specific reaction pathways or identify rate-limiting steps in the curing process. This limitation hampers the development of more efficient catalysts and curing agents.

Data interpretation complexities compound these technical challenges. The massive datasets generated by advanced imaging techniques require sophisticated computational approaches for meaningful analysis. Current algorithms often struggle to distinguish signal from noise when tracking subtle structural changes in heterogeneous polymer systems.

Finally, there exists a substantial gap between laboratory visualization capabilities and industrial monitoring needs. Manufacturing environments demand robust, real-time monitoring solutions that can operate reliably under production conditions, while providing actionable data for process control—a combination of requirements that current visualization technologies cannot fully satisfy.

The primary challenge lies in achieving sufficient spatial resolution while maintaining temporal sensitivity. Traditional microscopy methods often fail to capture the nanoscale structural changes occurring during polymer curing, particularly in three-dimensional networks. Even advanced optical techniques encounter diffraction limits that prevent observation of molecular-level crosslinking events, which typically occur at scales below 10 nanometers.

Environmental constraints present another significant obstacle. Many polymers require specific curing conditions—elevated temperatures, pressure, or specialized atmospheres—that are incompatible with conventional imaging setups. This creates a fundamental disconnect between laboratory visualization capabilities and real-world manufacturing conditions, limiting the practical applicability of research findings.

The dynamic nature of crosslinking reactions poses additional complications. Curing processes often involve rapid chemical transformations occurring across multiple timescales, from milliseconds to hours. Current imaging technologies struggle to capture this full temporal spectrum without sacrificing spatial resolution or chemical specificity, creating blind spots in our understanding of reaction kinetics.

Sample preparation for high-resolution techniques introduces further complications. Methods like traditional electron microscopy typically require extensive sample modification—including dehydration, staining, or coating—that can fundamentally alter the polymer structure being studied, leading to artifacts and misinterpretation of results.

Chemical specificity represents another significant challenge. Many visualization techniques cannot differentiate between various chemical bonds forming during crosslinking, making it difficult to track specific reaction pathways or identify rate-limiting steps in the curing process. This limitation hampers the development of more efficient catalysts and curing agents.

Data interpretation complexities compound these technical challenges. The massive datasets generated by advanced imaging techniques require sophisticated computational approaches for meaningful analysis. Current algorithms often struggle to distinguish signal from noise when tracking subtle structural changes in heterogeneous polymer systems.

Finally, there exists a substantial gap between laboratory visualization capabilities and industrial monitoring needs. Manufacturing environments demand robust, real-time monitoring solutions that can operate reliably under production conditions, while providing actionable data for process control—a combination of requirements that current visualization technologies cannot fully satisfy.

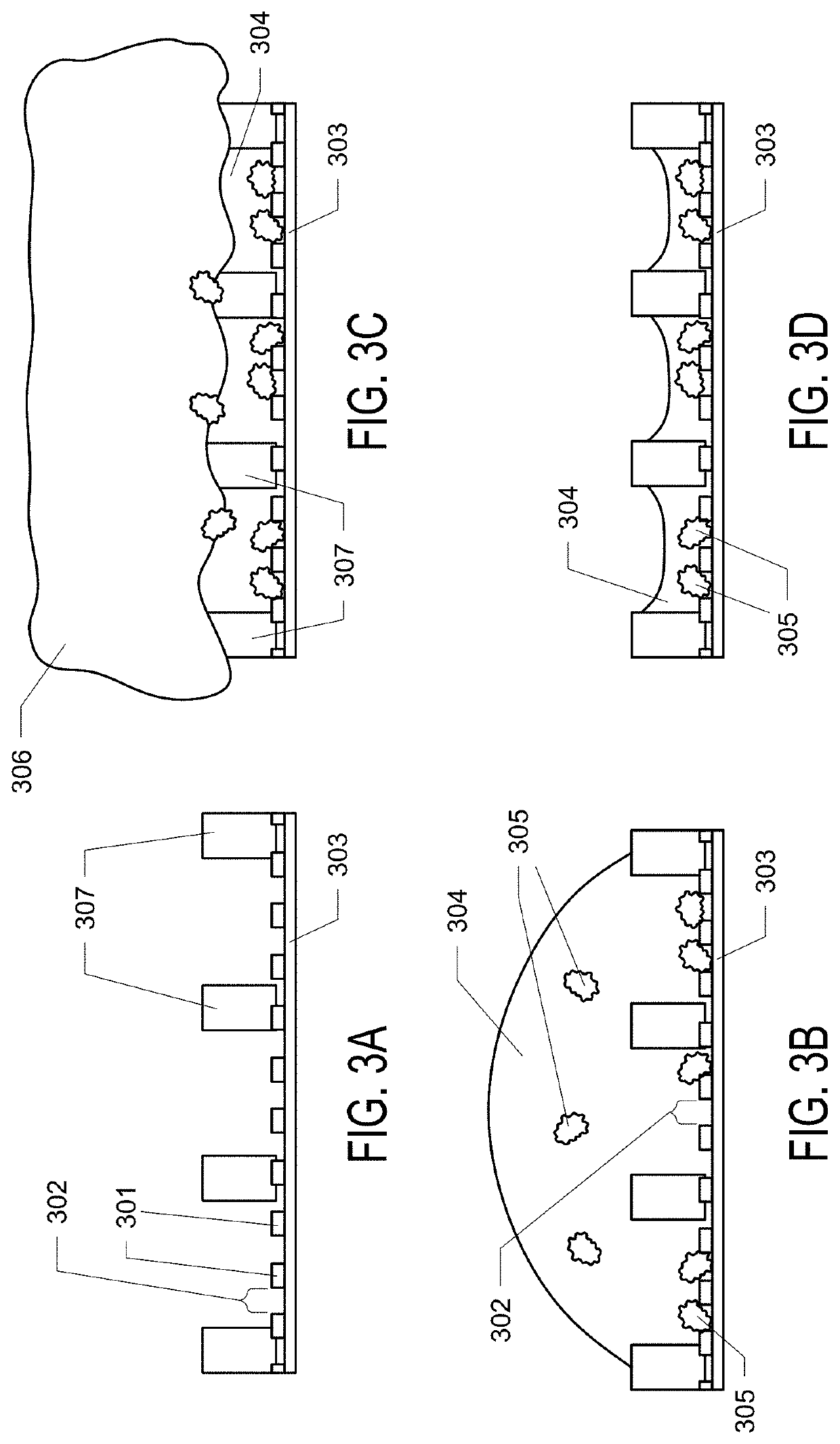

Existing Cryo-EM Methodologies for Polymer Science

01 Advanced sample preparation techniques for Cryo-EM

Various techniques have been developed to improve sample preparation for cryogenic electron microscopy. These include methods for vitrification, grid preparation, and specimen handling that minimize damage and preserve the native structure of biological samples. Advanced preparation techniques enable better resolution imaging and more accurate structural analysis, which is crucial for monitoring biological processes at the molecular level.- Automated monitoring systems for cryo-EM: Automated systems have been developed to monitor cryo-EM operations, including real-time data collection, sample quality assessment, and instrument performance. These systems utilize advanced algorithms to detect anomalies, optimize imaging parameters, and maintain optimal conditions during extended imaging sessions. Automation reduces human intervention, increases throughput, and ensures consistent data quality for structural biology research.

- Sample preparation and vitrification monitoring: Innovations in monitoring the critical sample preparation and vitrification processes for cryo-EM include technologies that assess ice thickness, sample distribution, and vitrification quality. These monitoring systems help researchers optimize freezing parameters, detect contamination, and ensure proper specimen embedding in vitreous ice. Real-time feedback during sample preparation significantly improves the success rate of high-resolution structural determinations.

- Environmental control and stability monitoring: Systems for monitoring and controlling the environmental conditions during cryo-EM operations focus on temperature stability, vacuum integrity, and electromagnetic interference. These technologies include sensors that continuously track microscope room conditions, vibration levels, and thermal fluctuations that could affect imaging quality. Advanced monitoring ensures stable cryogenic temperatures and prevents ice contamination or specimen degradation during data collection.

- Image quality and data processing monitoring: Real-time monitoring systems for cryo-EM image quality and data processing evaluate parameters such as contrast, resolution, drift, and beam-induced damage. These systems implement on-the-fly analysis of collected micrographs, enabling automatic adjustment of imaging conditions and early detection of data collection issues. Continuous quality assessment helps researchers make informed decisions about continuing or modifying experimental parameters during lengthy imaging sessions.

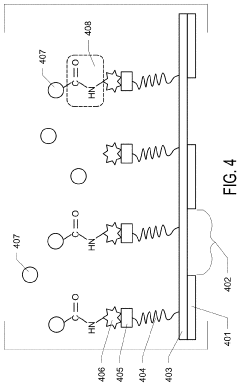

- Integration with AI and machine learning for cryo-EM: Advanced monitoring systems incorporate artificial intelligence and machine learning algorithms to enhance cryo-EM operations. These intelligent systems can predict instrument failures, automatically classify particles, optimize imaging parameters, and identify structural features in real-time. Machine learning approaches improve over time as they process more data, leading to increasingly accurate monitoring and control of cryo-EM experiments with reduced human intervention.

02 Real-time monitoring systems for Cryo-EM

Real-time monitoring systems have been developed to track and control critical parameters during cryo-EM experiments. These systems monitor temperature, pressure, electron dose, and other variables that affect sample integrity and image quality. By providing continuous feedback, these monitoring systems allow researchers to make adjustments during data collection, optimize imaging conditions, and ensure consistent results across experiments.Expand Specific Solutions03 Automated data processing and analysis for Cryo-EM

Automated systems have been developed to process and analyze the large volumes of data generated by cryo-EM experiments. These systems use advanced algorithms and machine learning techniques to identify particles, align images, and reconstruct three-dimensional structures. Automation reduces the time and expertise required for data analysis, enabling higher throughput and more consistent results in structural biology research.Expand Specific Solutions04 Environmental control systems for Cryo-EM facilities

Specialized environmental control systems have been designed for cryo-EM facilities to maintain optimal conditions for microscope operation and sample preservation. These systems regulate temperature, humidity, vibration, electromagnetic interference, and other environmental factors that can affect imaging quality. Precise environmental control is essential for achieving high-resolution structural data and ensuring reproducible results in cryo-EM experiments.Expand Specific Solutions05 Integration of Cryo-EM with other analytical techniques

Innovations in integrating cryo-EM with complementary analytical techniques have enhanced the monitoring capabilities of structural biology research. These integrated approaches combine cryo-EM with mass spectrometry, X-ray crystallography, nuclear magnetic resonance, or computational modeling to provide more comprehensive structural information. By correlating data from multiple techniques, researchers can monitor complex biological processes with greater accuracy and detail.Expand Specific Solutions

Leading Research Institutions and Industrial Players

The cryo-electron microscopy (cryo-EM) market for polymer crosslinking and curing monitoring is in its growth phase, with increasing adoption across materials science and polymer engineering. The global market is expanding as industries seek advanced characterization techniques for polymer development. Technologically, the field is maturing rapidly with key players demonstrating varying levels of expertise. DuPont de Nemours leads commercial applications, while academic institutions like National University of Singapore and University of Washington contribute significant research advancements. Specialized equipment providers such as Quantifoil Micro Tools supply critical infrastructure. The technology bridges fundamental research and industrial applications, with 3M Innovative Properties and ARKRAY developing proprietary implementations. Collaboration between academic centers and industry is accelerating technological maturity and expanding application scope.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced Cryo-EM techniques for polymer crosslinking and curing monitoring that enable real-time visualization of molecular structures during the curing process. Their approach combines time-resolved cryo-electron microscopy with specialized sample preparation methods to capture the dynamic changes in polymer networks at different stages of crosslinking. The technology employs rapid vitrification techniques to freeze samples at precise curing intervals, preserving the exact molecular configuration for high-resolution imaging. DuPont's system incorporates machine learning algorithms to analyze structural changes across multiple length scales, from nanometer to micrometer, providing comprehensive insights into crosslinking kinetics and network formation. This allows for precise correlation between processing conditions and final material properties, enabling optimization of curing parameters for enhanced performance characteristics.

Strengths: Industry-leading expertise in polymer chemistry combined with advanced imaging capabilities allows for unprecedented insights into structure-property relationships. The technology enables optimization of curing processes for improved product performance and manufacturing efficiency. Weaknesses: Requires significant capital investment in specialized equipment and highly trained personnel. Sample preparation challenges may limit applicability to certain polymer systems.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered a multi-modal Cryo-EM approach for monitoring polymer crosslinking that integrates direct electron detection with spectroscopic analysis. Their technology utilizes specialized environmental chambers that maintain precise temperature and humidity control during the curing process, allowing for in-situ observation of crosslinking reactions. The system employs beam-sensitive imaging protocols that minimize radiation damage while maximizing structural information, crucial for accurate analysis of polymer networks. 3M's approach incorporates tomographic reconstruction techniques to generate 3D models of the evolving network architecture, providing spatial distribution data of crosslinks and revealing heterogeneities in the curing process. This comprehensive visualization enables correlation between molecular-level changes and macroscopic material properties, facilitating the development of predictive models for curing behavior across different polymer systems.

Strengths: Comprehensive 3D visualization capabilities provide deeper insights into spatial distribution of crosslinks than traditional 2D imaging. Integration with spectroscopic techniques allows for chemical characterization alongside structural analysis. Weaknesses: Complex data processing requirements may limit throughput. The technology may struggle with highly dynamic, fast-curing systems where temporal resolution becomes critical.

Key Technical Innovations in Cryo-EM Resolution

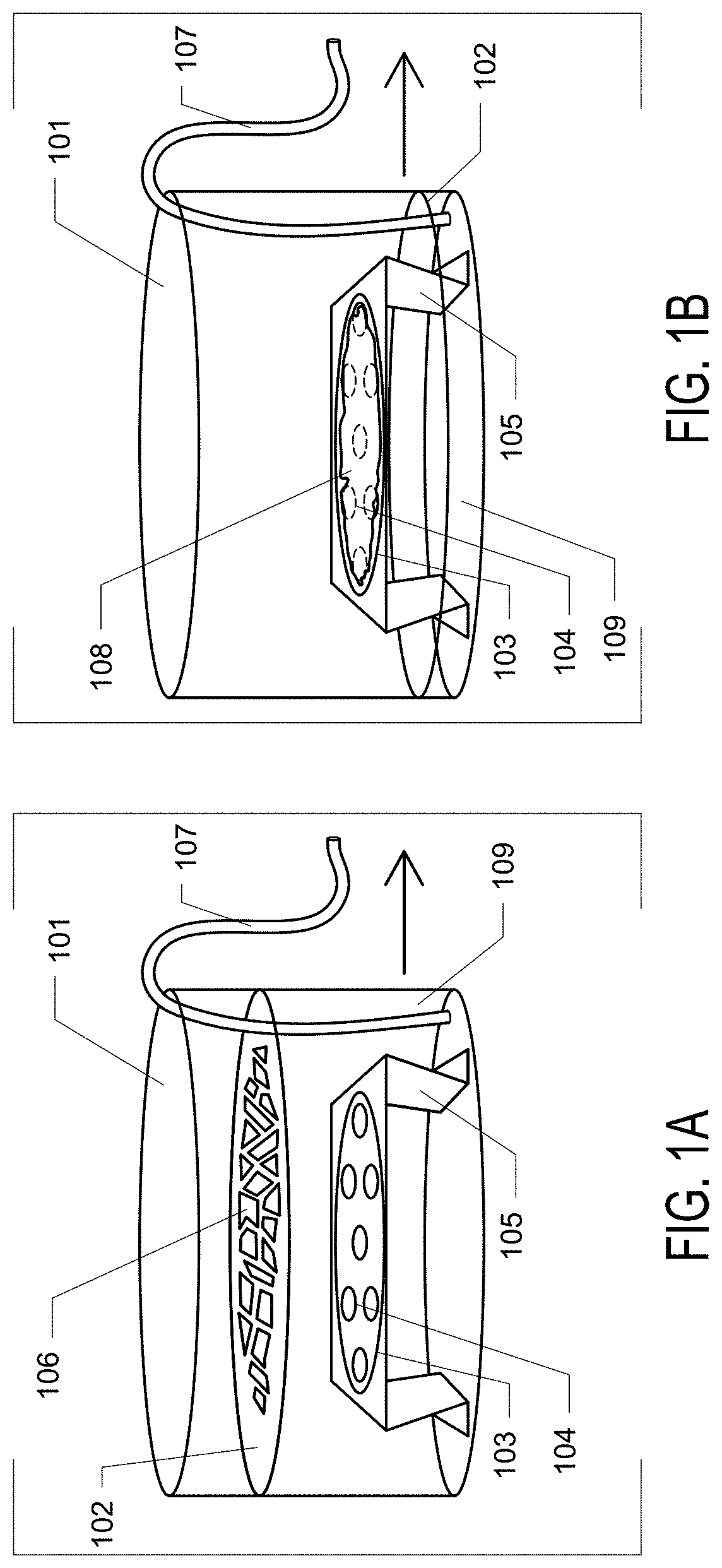

Method for preparing a cross-linked hydrogel nanomembrane, the cross-linked hydrogel nanomembrane, TEM grid comprising the same and use thereof

PatentWO2018202837A1

Innovation

- A method for preparing cross-linked hydrogel nanomembranes, specifically self-perforating hydrogel nanomembranes (SPHyNs), which stabilize the thin water film, minimize protein adsorption, and facilitate uniform distribution by transferring the nanomembranes to a TEM grid, allowing for improved specimen preparation and high-resolution data collection.

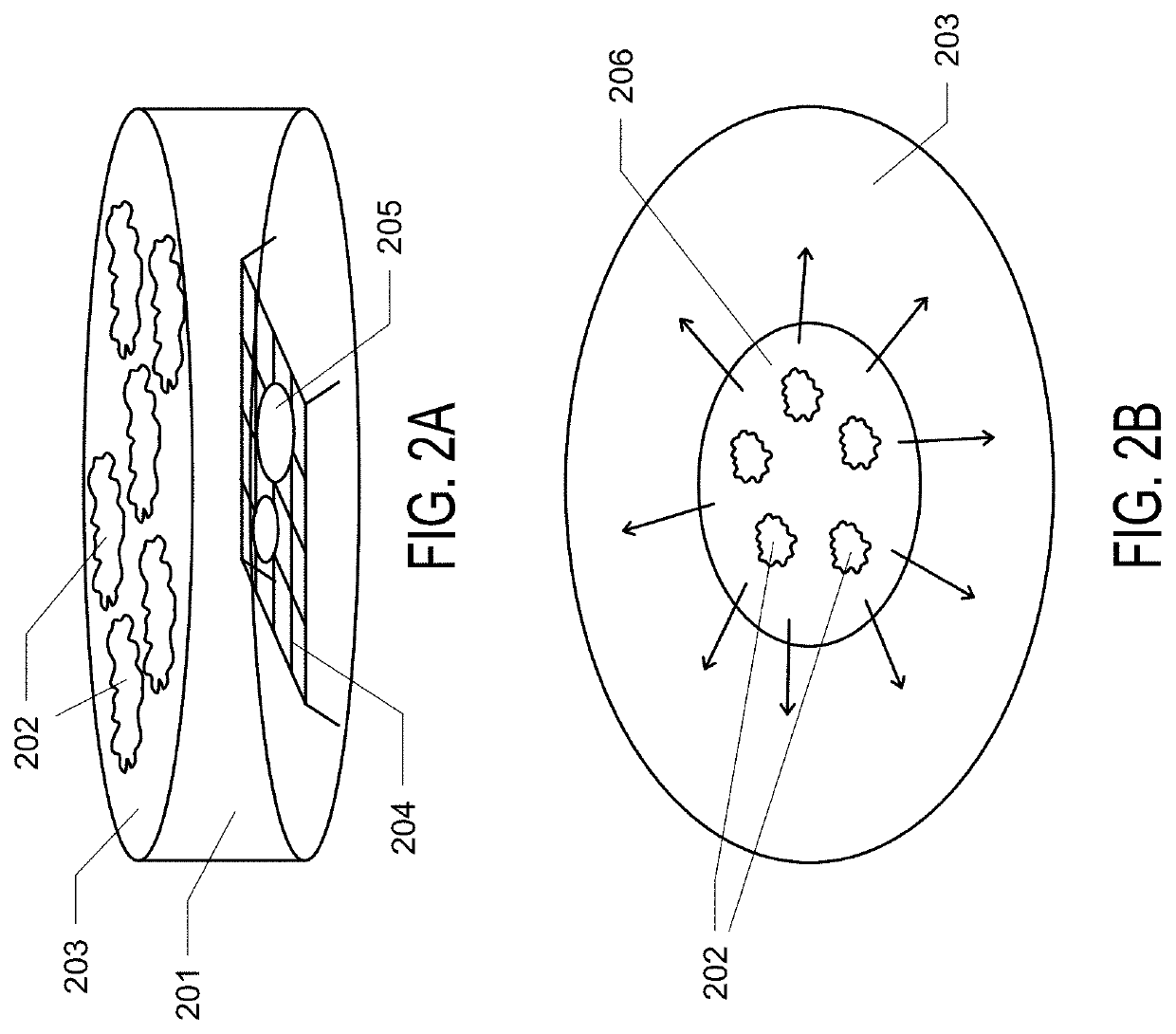

Graphene Oxide Affinity Sample Grids for Cyro-EM

PatentActiveUS20210310910A1

Innovation

- The use of graphene oxide films functionalized with various chemistries for immobilizing diverse target species on cryo-EM grids, combined with polyethylene glycol linkers to position samples optimally away from the air-water interface and substrate, enabling efficient and versatile sample preparation for high-quality cryo-EM imaging.

Material Science Integration Opportunities

The integration of cryo-electron microscopy (cryo-EM) with materials science opens unprecedented opportunities for advancing polymer science and engineering. This powerful imaging technique can be strategically incorporated into existing materials characterization workflows to provide unique insights into crosslinking and curing processes at the molecular level.

Materials science laboratories can implement cryo-EM as a complementary technique to conventional analytical methods such as differential scanning calorimetry (DSC), rheology, and spectroscopy. By capturing the structural evolution during polymer curing at different time points, researchers can correlate macroscopic property changes with nanoscale structural transformations, creating a multi-scale understanding of material behavior.

Interdisciplinary collaboration between cryo-EM specialists and polymer scientists presents a particularly promising integration pathway. Shared facilities and joint research initiatives between biological imaging centers and materials departments can maximize resource utilization while fostering knowledge exchange across traditionally separate domains. This collaborative model has already proven successful in several academic institutions where biological imaging expertise has been leveraged for materials characterization.

Industrial R&D departments in sectors such as adhesives, composites, and coatings can benefit from integrating cryo-EM into their product development cycles. By establishing dedicated cryo-EM capabilities or partnering with specialized service providers, manufacturers can accelerate formulation optimization and quality control processes. The high-resolution structural information obtained can inform computational modeling efforts, creating a feedback loop between experimental observations and predictive design.

Educational integration represents another valuable opportunity, with materials science curricula incorporating cryo-EM techniques into advanced characterization courses. This approach prepares the next generation of materials scientists with cross-disciplinary skills spanning both traditional polymer characterization and advanced microscopy methods.

Data integration frameworks that combine cryo-EM observations with other analytical techniques will be essential for extracting maximum value from these complementary approaches. Machine learning algorithms can help identify patterns across multiple characterization methods, potentially revealing correlations between processing conditions, nanostructure development, and final material properties that would otherwise remain hidden in isolated datasets.

The integration of cryo-EM into materials science also creates opportunities for standardization bodies to develop new protocols specifically designed for polymer materials, ensuring reproducibility and facilitating data sharing across the research community.

Materials science laboratories can implement cryo-EM as a complementary technique to conventional analytical methods such as differential scanning calorimetry (DSC), rheology, and spectroscopy. By capturing the structural evolution during polymer curing at different time points, researchers can correlate macroscopic property changes with nanoscale structural transformations, creating a multi-scale understanding of material behavior.

Interdisciplinary collaboration between cryo-EM specialists and polymer scientists presents a particularly promising integration pathway. Shared facilities and joint research initiatives between biological imaging centers and materials departments can maximize resource utilization while fostering knowledge exchange across traditionally separate domains. This collaborative model has already proven successful in several academic institutions where biological imaging expertise has been leveraged for materials characterization.

Industrial R&D departments in sectors such as adhesives, composites, and coatings can benefit from integrating cryo-EM into their product development cycles. By establishing dedicated cryo-EM capabilities or partnering with specialized service providers, manufacturers can accelerate formulation optimization and quality control processes. The high-resolution structural information obtained can inform computational modeling efforts, creating a feedback loop between experimental observations and predictive design.

Educational integration represents another valuable opportunity, with materials science curricula incorporating cryo-EM techniques into advanced characterization courses. This approach prepares the next generation of materials scientists with cross-disciplinary skills spanning both traditional polymer characterization and advanced microscopy methods.

Data integration frameworks that combine cryo-EM observations with other analytical techniques will be essential for extracting maximum value from these complementary approaches. Machine learning algorithms can help identify patterns across multiple characterization methods, potentially revealing correlations between processing conditions, nanostructure development, and final material properties that would otherwise remain hidden in isolated datasets.

The integration of cryo-EM into materials science also creates opportunities for standardization bodies to develop new protocols specifically designed for polymer materials, ensuring reproducibility and facilitating data sharing across the research community.

Environmental Impact of Advanced Polymer Curing

The environmental implications of advanced polymer curing technologies, particularly those monitored through Cryo-EM, represent a critical consideration in sustainable materials development. Traditional polymer curing processes often involve significant energy consumption and the release of volatile organic compounds (VOCs), contributing to air pollution and greenhouse gas emissions. However, the precision afforded by Cryo-EM monitoring enables optimization of crosslinking reactions, potentially reducing the environmental footprint of polymer production.

Advanced curing technologies monitored via Cryo-EM allow manufacturers to achieve complete polymerization with minimal excess reagents, thereby reducing chemical waste. Studies indicate that optimized crosslinking can decrease material waste by 15-20% compared to conventional methods. This waste reduction translates directly to lower environmental impact throughout the product lifecycle.

Energy efficiency represents another significant environmental benefit of Cryo-EM-monitored polymer curing. By providing real-time structural information during the curing process, manufacturers can fine-tune reaction parameters to minimize energy requirements. Research demonstrates that precision-controlled curing can reduce energy consumption by up to 30% compared to traditional thermal curing methods, with corresponding reductions in carbon emissions.

Water usage in polymer manufacturing also presents environmental challenges. Advanced curing technologies often employ water-based systems rather than solvent-based approaches, reducing hazardous waste generation. Cryo-EM monitoring ensures these water-based systems achieve optimal crosslinking density without compromising performance, supporting the transition away from environmentally harmful solvents.

The extended product lifespan resulting from precisely controlled crosslinking further enhances environmental sustainability. Polymers with optimized crosslink density exhibit superior durability and resistance to environmental degradation, potentially doubling useful product life. This longevity reduces replacement frequency and associated resource consumption, contributing to circular economy principles.

End-of-life considerations also benefit from advanced curing technologies. Precisely engineered crosslink structures can incorporate degradable linkages or recyclable components, facilitating material recovery and reducing landfill burden. Cryo-EM analysis helps validate these design features, ensuring environmental benefits without compromising performance during the product's useful life.

Regulatory compliance represents an additional driver for environmentally responsible polymer curing. As global regulations increasingly restrict VOC emissions and hazardous chemical usage, manufacturers must adopt cleaner production methods. Advanced monitoring technologies like Cryo-EM support compliance by enabling process optimization that meets both performance and environmental requirements.

Advanced curing technologies monitored via Cryo-EM allow manufacturers to achieve complete polymerization with minimal excess reagents, thereby reducing chemical waste. Studies indicate that optimized crosslinking can decrease material waste by 15-20% compared to conventional methods. This waste reduction translates directly to lower environmental impact throughout the product lifecycle.

Energy efficiency represents another significant environmental benefit of Cryo-EM-monitored polymer curing. By providing real-time structural information during the curing process, manufacturers can fine-tune reaction parameters to minimize energy requirements. Research demonstrates that precision-controlled curing can reduce energy consumption by up to 30% compared to traditional thermal curing methods, with corresponding reductions in carbon emissions.

Water usage in polymer manufacturing also presents environmental challenges. Advanced curing technologies often employ water-based systems rather than solvent-based approaches, reducing hazardous waste generation. Cryo-EM monitoring ensures these water-based systems achieve optimal crosslinking density without compromising performance, supporting the transition away from environmentally harmful solvents.

The extended product lifespan resulting from precisely controlled crosslinking further enhances environmental sustainability. Polymers with optimized crosslink density exhibit superior durability and resistance to environmental degradation, potentially doubling useful product life. This longevity reduces replacement frequency and associated resource consumption, contributing to circular economy principles.

End-of-life considerations also benefit from advanced curing technologies. Precisely engineered crosslink structures can incorporate degradable linkages or recyclable components, facilitating material recovery and reducing landfill burden. Cryo-EM analysis helps validate these design features, ensuring environmental benefits without compromising performance during the product's useful life.

Regulatory compliance represents an additional driver for environmentally responsible polymer curing. As global regulations increasingly restrict VOC emissions and hazardous chemical usage, manufacturers must adopt cleaner production methods. Advanced monitoring technologies like Cryo-EM support compliance by enabling process optimization that meets both performance and environmental requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!