Business models for low-cost decentralized manufacturing hubs in low- and middle-income countries

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Decentralized Manufacturing Evolution and Objectives

Decentralized manufacturing represents a paradigm shift from traditional centralized production models, evolving significantly over the past two decades. Initially emerging as small-scale maker spaces and fab labs in developed economies, this concept has gradually transformed into a viable alternative production system with particular relevance for low- and middle-income countries (LMICs). The evolution has been accelerated by technological advancements in digital fabrication, additive manufacturing, and open-source hardware designs.

The trajectory began with rudimentary community workshops in the early 2000s, progressing through the democratization of production technologies around 2010-2015, and now entering a phase where networked manufacturing hubs can potentially address local production needs at competitive costs. This evolution has been particularly significant in regions with limited industrial infrastructure but growing technical capabilities and market demands.

Current decentralized manufacturing models in LMICs range from informal sector micro-enterprises to more structured community production centers and technology hubs. These models have demonstrated varying degrees of success in contexts such as rural India, urban Kenya, and peri-urban areas across Southeast Asia. The technological backbone has evolved from basic tools to increasingly sophisticated digital fabrication equipment that can be operated with minimal specialized training.

The primary objective of low-cost decentralized manufacturing hubs in LMICs is to create sustainable local production ecosystems that address specific community needs while generating economic opportunities. These hubs aim to leverage locally available resources, reduce dependency on imported goods, and create resilient supply chains that can withstand global disruptions. Additionally, they seek to democratize access to production technologies and foster indigenous innovation capabilities.

Secondary objectives include skills development for local populations, reduction of environmental impacts through localized production, and creation of inclusive economic models that can benefit marginalized communities. The technological goals focus on adapting advanced manufacturing techniques to operate reliably in challenging environments with limited infrastructure, while maintaining quality standards necessary for market acceptance.

The evolution trajectory suggests a future where these hubs may form interconnected networks, sharing designs, knowledge, and potentially creating distributed production systems that can compete with traditional manufacturing in specific product categories. The ultimate aim is to establish financially self-sustaining models that do not rely on continuous external funding but generate sufficient value to support ongoing operations and expansion.

The trajectory began with rudimentary community workshops in the early 2000s, progressing through the democratization of production technologies around 2010-2015, and now entering a phase where networked manufacturing hubs can potentially address local production needs at competitive costs. This evolution has been particularly significant in regions with limited industrial infrastructure but growing technical capabilities and market demands.

Current decentralized manufacturing models in LMICs range from informal sector micro-enterprises to more structured community production centers and technology hubs. These models have demonstrated varying degrees of success in contexts such as rural India, urban Kenya, and peri-urban areas across Southeast Asia. The technological backbone has evolved from basic tools to increasingly sophisticated digital fabrication equipment that can be operated with minimal specialized training.

The primary objective of low-cost decentralized manufacturing hubs in LMICs is to create sustainable local production ecosystems that address specific community needs while generating economic opportunities. These hubs aim to leverage locally available resources, reduce dependency on imported goods, and create resilient supply chains that can withstand global disruptions. Additionally, they seek to democratize access to production technologies and foster indigenous innovation capabilities.

Secondary objectives include skills development for local populations, reduction of environmental impacts through localized production, and creation of inclusive economic models that can benefit marginalized communities. The technological goals focus on adapting advanced manufacturing techniques to operate reliably in challenging environments with limited infrastructure, while maintaining quality standards necessary for market acceptance.

The evolution trajectory suggests a future where these hubs may form interconnected networks, sharing designs, knowledge, and potentially creating distributed production systems that can compete with traditional manufacturing in specific product categories. The ultimate aim is to establish financially self-sustaining models that do not rely on continuous external funding but generate sufficient value to support ongoing operations and expansion.

Market Analysis for Low-Cost Manufacturing in LMICs

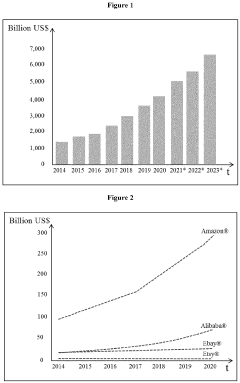

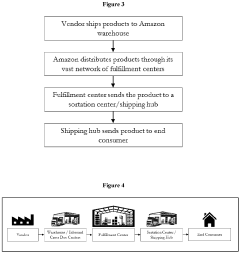

The market for low-cost decentralized manufacturing in Low and Middle-Income Countries (LMICs) demonstrates significant growth potential, driven by increasing urbanization, rising consumer demand, and the need for localized production solutions. Current market size estimates indicate that small-scale manufacturing enterprises in LMICs contribute between 15-20% of GDP in many developing economies, with annual growth rates exceeding 5% in regions like Sub-Saharan Africa and Southeast Asia.

Demand analysis reveals three primary market segments: consumer goods production (household items, textiles, food processing), light industrial manufacturing (construction materials, agricultural tools), and technology-enabled production (mobile accessories, simple electronics). The consumer goods segment currently dominates with approximately 60% market share, though technology-enabled production shows the fastest growth trajectory at 12-15% annually.

Geographic distribution of market demand is concentrated in rapidly urbanizing regions, with particularly strong growth in secondary cities where formal manufacturing infrastructure remains underdeveloped. Countries like Nigeria, Kenya, Bangladesh, and Vietnam demonstrate especially favorable market conditions due to their combination of growing middle classes, entrepreneurial ecosystems, and improving digital connectivity.

Key market drivers include rising disposable incomes, increasing internet penetration enabling e-commerce distribution channels, and growing consumer preference for locally-manufactured products. The COVID-19 pandemic has accelerated these trends by disrupting global supply chains and highlighting the importance of local manufacturing resilience.

Market barriers remain significant, including limited access to financing for small manufacturers, inconsistent electricity supply, logistical challenges in distribution networks, and regulatory complexity. However, these barriers also create opportunities for innovative business models that can address these constraints through shared facilities, renewable energy solutions, and digital platforms.

Customer segmentation reveals diverse buyer profiles, from individual entrepreneurs seeking manufacturing capabilities to small businesses looking to expand production capacity, and larger companies interested in distributed manufacturing networks to reach underserved markets. Each segment demonstrates different price sensitivity, quality requirements, and service expectations.

Pricing analysis indicates that successful decentralized manufacturing hubs must balance affordability with quality assurance. Current market data suggests optimal pricing structures involve tiered membership models, pay-per-use arrangements, or output-based revenue sharing, with typical manufacturing cost reductions of 30-40% compared to traditional centralized facilities.

Future market projections suggest compound annual growth rates of 8-10% over the next five years, with particularly strong expansion in technology-enabled manufacturing segments as digital fabrication technologies become more accessible and affordable in LMIC contexts.

Demand analysis reveals three primary market segments: consumer goods production (household items, textiles, food processing), light industrial manufacturing (construction materials, agricultural tools), and technology-enabled production (mobile accessories, simple electronics). The consumer goods segment currently dominates with approximately 60% market share, though technology-enabled production shows the fastest growth trajectory at 12-15% annually.

Geographic distribution of market demand is concentrated in rapidly urbanizing regions, with particularly strong growth in secondary cities where formal manufacturing infrastructure remains underdeveloped. Countries like Nigeria, Kenya, Bangladesh, and Vietnam demonstrate especially favorable market conditions due to their combination of growing middle classes, entrepreneurial ecosystems, and improving digital connectivity.

Key market drivers include rising disposable incomes, increasing internet penetration enabling e-commerce distribution channels, and growing consumer preference for locally-manufactured products. The COVID-19 pandemic has accelerated these trends by disrupting global supply chains and highlighting the importance of local manufacturing resilience.

Market barriers remain significant, including limited access to financing for small manufacturers, inconsistent electricity supply, logistical challenges in distribution networks, and regulatory complexity. However, these barriers also create opportunities for innovative business models that can address these constraints through shared facilities, renewable energy solutions, and digital platforms.

Customer segmentation reveals diverse buyer profiles, from individual entrepreneurs seeking manufacturing capabilities to small businesses looking to expand production capacity, and larger companies interested in distributed manufacturing networks to reach underserved markets. Each segment demonstrates different price sensitivity, quality requirements, and service expectations.

Pricing analysis indicates that successful decentralized manufacturing hubs must balance affordability with quality assurance. Current market data suggests optimal pricing structures involve tiered membership models, pay-per-use arrangements, or output-based revenue sharing, with typical manufacturing cost reductions of 30-40% compared to traditional centralized facilities.

Future market projections suggest compound annual growth rates of 8-10% over the next five years, with particularly strong expansion in technology-enabled manufacturing segments as digital fabrication technologies become more accessible and affordable in LMIC contexts.

Current Challenges and Technological Barriers

Despite the promising potential of decentralized manufacturing hubs in low- and middle-income countries (LMICs), several significant technological and operational barriers impede their widespread implementation. Infrastructure limitations represent a primary challenge, with unreliable electricity supply, inadequate internet connectivity, and poor transportation networks hampering operational efficiency. Many regions experience frequent power outages lasting several hours daily, forcing manufacturing hubs to rely on expensive backup generators that increase operational costs by 20-30%.

Technical knowledge gaps present another substantial barrier. The local workforce often lacks specialized training in advanced manufacturing technologies, digital fabrication processes, and equipment maintenance. This necessitates either costly international expertise or extensive training programs, both of which strain limited financial resources. Studies indicate that technical training costs can consume up to 15-25% of initial setup budgets for these manufacturing hubs.

Equipment acquisition and maintenance pose significant challenges in resource-constrained environments. The high import duties (ranging from 25-60% in many LMICs), complex customs procedures, and limited access to spare parts create substantial barriers to entry and operational continuity. When equipment malfunctions, repair times can extend to weeks or months due to parts availability issues, resulting in production downtime and revenue loss.

Quality control and standardization remain problematic in decentralized manufacturing contexts. Without sophisticated testing equipment and standardized procedures, ensuring consistent product quality becomes difficult. This challenge is particularly acute for products requiring regulatory compliance or precision manufacturing, limiting the range of viable products these hubs can produce.

Supply chain vulnerabilities further complicate operations. Raw material sourcing often depends on imports subject to currency fluctuations, trade restrictions, and logistical delays. Local sourcing alternatives may be limited or inconsistent in quality and availability, creating production bottlenecks and increasing inventory costs to mitigate supply uncertainties.

Financial sustainability represents perhaps the most persistent challenge. Current business models struggle to balance affordability for local markets with operational viability. Many hubs operate at thin margins (3-7%) that provide little buffer against unexpected costs or market fluctuations. Traditional financing mechanisms remain largely inaccessible, with interest rates in many LMICs exceeding 15-20% for small manufacturing enterprises.

Regulatory environments in many LMICs present additional complications through complex business registration processes, unclear intellectual property frameworks, and frequently changing compliance requirements. These factors increase operational uncertainty and administrative burdens for decentralized manufacturing initiatives.

Technical knowledge gaps present another substantial barrier. The local workforce often lacks specialized training in advanced manufacturing technologies, digital fabrication processes, and equipment maintenance. This necessitates either costly international expertise or extensive training programs, both of which strain limited financial resources. Studies indicate that technical training costs can consume up to 15-25% of initial setup budgets for these manufacturing hubs.

Equipment acquisition and maintenance pose significant challenges in resource-constrained environments. The high import duties (ranging from 25-60% in many LMICs), complex customs procedures, and limited access to spare parts create substantial barriers to entry and operational continuity. When equipment malfunctions, repair times can extend to weeks or months due to parts availability issues, resulting in production downtime and revenue loss.

Quality control and standardization remain problematic in decentralized manufacturing contexts. Without sophisticated testing equipment and standardized procedures, ensuring consistent product quality becomes difficult. This challenge is particularly acute for products requiring regulatory compliance or precision manufacturing, limiting the range of viable products these hubs can produce.

Supply chain vulnerabilities further complicate operations. Raw material sourcing often depends on imports subject to currency fluctuations, trade restrictions, and logistical delays. Local sourcing alternatives may be limited or inconsistent in quality and availability, creating production bottlenecks and increasing inventory costs to mitigate supply uncertainties.

Financial sustainability represents perhaps the most persistent challenge. Current business models struggle to balance affordability for local markets with operational viability. Many hubs operate at thin margins (3-7%) that provide little buffer against unexpected costs or market fluctuations. Traditional financing mechanisms remain largely inaccessible, with interest rates in many LMICs exceeding 15-20% for small manufacturing enterprises.

Regulatory environments in many LMICs present additional complications through complex business registration processes, unclear intellectual property frameworks, and frequently changing compliance requirements. These factors increase operational uncertainty and administrative burdens for decentralized manufacturing initiatives.

Existing Business Models and Implementation Strategies

01 Cost optimization through distributed manufacturing networks

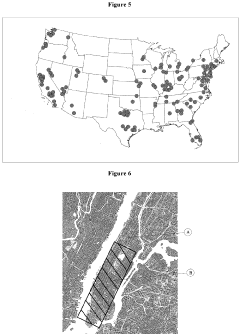

Decentralized manufacturing hubs can optimize costs by distributing production closer to end markets, reducing transportation expenses and inventory holding costs. These networks enable more efficient resource allocation, allowing companies to scale production up or down based on local demand. The distributed approach also minimizes risks associated with centralized manufacturing disruptions and provides flexibility in responding to market changes.- Cost optimization in decentralized manufacturing networks: Decentralized manufacturing hubs can optimize costs through strategic placement of production facilities closer to end markets, reducing transportation and logistics expenses. These networks enable more efficient resource allocation, inventory management, and just-in-time production capabilities. By distributing manufacturing operations across multiple locations, companies can minimize overhead costs while maintaining production flexibility and responsiveness to local market demands.

- Blockchain-based cost management for decentralized manufacturing: Blockchain technology provides secure, transparent cost tracking and management systems for decentralized manufacturing operations. This approach enables real-time monitoring of production costs across distributed facilities, automated smart contracts for supplier payments, and immutable record-keeping for financial transactions. The technology helps reduce administrative overhead, minimize disputes, and create trust among various stakeholders in the decentralized manufacturing ecosystem.

- Energy efficiency and sustainability cost benefits: Decentralized manufacturing hubs can achieve significant cost savings through improved energy efficiency and sustainability practices. Smaller, distributed facilities can implement localized renewable energy solutions, reduce carbon footprints, and minimize waste through optimized production runs. These sustainability initiatives not only reduce direct operational costs but also help companies avoid potential carbon taxes and comply with environmental regulations while improving brand reputation.

- Labor and automation cost considerations: Decentralized manufacturing models present unique labor cost dynamics, including access to varied labor markets with different wage structures. These hubs can strategically balance human workforce with automation technologies based on local conditions and production requirements. While initial setup costs for multiple facilities may be higher, the distributed approach allows for targeted automation investments where most beneficial, potentially reducing overall labor costs while maintaining production quality and flexibility.

- Supply chain resilience and risk mitigation costs: Decentralized manufacturing networks provide enhanced supply chain resilience that can justify their implementation costs through risk mitigation. By distributing production across multiple locations, companies reduce vulnerability to localized disruptions such as natural disasters, political instability, or transportation bottlenecks. While maintaining multiple facilities increases some operational costs, the ability to quickly shift production between sites during disruptions can prevent costly production stoppages and maintain customer service levels.

02 Blockchain-based cost management for decentralized manufacturing

Blockchain technology enables secure, transparent cost tracking across decentralized manufacturing networks. Smart contracts automate payments, royalties, and resource allocation between distributed hubs, reducing administrative overhead. This technology creates immutable records of transactions, ensuring fair compensation for all participants in the manufacturing ecosystem while optimizing operational costs through improved supply chain visibility.Expand Specific Solutions03 Infrastructure and equipment sharing models

Decentralized manufacturing can leverage shared infrastructure and equipment models to reduce capital expenditure. By implementing collaborative ownership structures or pay-per-use systems, multiple businesses can access manufacturing capabilities without bearing the full cost burden individually. These models enable smaller enterprises to utilize advanced manufacturing technologies that would otherwise be prohibitively expensive, while maximizing equipment utilization rates.Expand Specific Solutions04 AI-driven cost optimization for hub operations

Artificial intelligence systems can optimize operational costs in decentralized manufacturing hubs by predicting maintenance needs, automating quality control, and dynamically adjusting production schedules. These systems analyze real-time data from manufacturing processes to identify inefficiencies and recommend cost-saving measures. AI-driven predictive analytics help prevent costly downtime and optimize resource allocation across the manufacturing network.Expand Specific Solutions05 Local supply chain integration for cost reduction

Integrating decentralized manufacturing hubs with local supply chains can significantly reduce costs through decreased logistics expenses and improved material sourcing. This approach minimizes cross-border shipping, customs delays, and associated fees while enabling just-in-time inventory practices. Local integration also provides resilience against global supply chain disruptions and currency fluctuations, while potentially qualifying for regional economic incentives or tax benefits.Expand Specific Solutions

Key Stakeholders and Industry Leaders

The decentralized manufacturing landscape in low- and middle-income countries is in its early growth stage, with an estimated market potential of $15-20 billion by 2030. The technology maturity varies significantly across regions, with established players like IBM, Robert Bosch, and BASF leading industrial solutions, while academic institutions such as University of Michigan, Nanjing University, and Harbin Institute of Technology contribute research innovations. Emerging companies like Omega Grid and Xuelang Shuzhi are developing specialized platforms for local manufacturing contexts. The competitive landscape is characterized by a mix of multinational corporations providing technology infrastructure and regional players adapting solutions to local economic constraints, with increasing focus on sustainable business models that leverage digital platforms to reduce capital requirements.

International Business Machines Corp.

Technical Solution: IBM has developed a comprehensive approach to low-cost decentralized manufacturing in developing regions through their "Microenterprise Mesh Network" platform. This system connects small-scale manufacturers with digital design resources, market access, and supply chain integration. IBM's solution leverages blockchain technology to create transparent supply chains and smart contracts that enable fair compensation and quality control across distributed manufacturing nodes. Their platform includes AI-powered demand forecasting that helps local manufacturing hubs optimize production schedules and resource allocation based on regional needs. IBM has implemented this model in several African and South Asian countries, creating manufacturing networks that produce everything from medical supplies to agricultural equipment. The system incorporates digital twin technology to enable remote technical support and quality assurance, allowing experts from anywhere to guide local production processes without physical presence. IBM's approach emphasizes skills development through integrated training modules and knowledge transfer protocols that build local capacity over time.

Strengths: IBM's solution leverages their extensive global technology infrastructure and AI capabilities to create sophisticated coordination systems. Their blockchain implementation provides transparency and trust in complex supply networks. Weaknesses: The technology-heavy approach may create dependencies on IBM's proprietary systems and require significant initial investment in digital infrastructure that may be challenging in low-resource settings.

Robert Bosch GmbH

Technical Solution: Bosch has pioneered the "Micro-Factory Network" model specifically designed for low and middle-income countries. This approach centers on standardized, modular manufacturing units that can be rapidly deployed in various locations with minimal infrastructure requirements. Each micro-factory operates as a semi-autonomous production node capable of manufacturing components or finished products based on digital designs shared across the network. Bosch's system incorporates energy-efficient manufacturing equipment designed to operate reliably in unstable power environments, including integrated renewable energy solutions. Their model emphasizes appropriate technology transfer, using simplified versions of advanced manufacturing techniques that can be maintained locally. The micro-factories are connected through a digital platform that coordinates production, manages quality control, and facilitates knowledge sharing between hubs. Bosch has implemented this model in Southeast Asia and parts of Africa, creating manufacturing networks that produce both Bosch-designed products and locally developed innovations. The business model includes tiered ownership structures where local entrepreneurs can gradually increase their stake in the micro-factories as they develop capacity and demonstrate success.

Strengths: Bosch's approach balances technological sophistication with practical implementation in challenging environments. Their modular design allows for gradual scaling and adaptation to local conditions. Weaknesses: The system may still require significant initial capital investment and ongoing technical support from Bosch, potentially creating dependencies that limit true local ownership and autonomy.

Critical Technologies and Operational Frameworks

Low capital and operational cost e-commerce logistics system

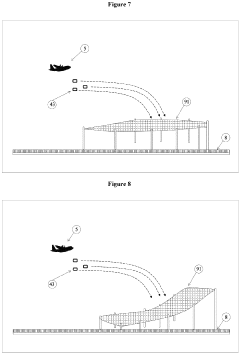

PatentInactiveEP4361912A2

Innovation

- A low capital and operational cost logistics system that uses Central Fulfillment Centers to store merchandise, which are then air-dropped in multibox packages to strategically located drop zones, eliminating the need for multiple warehouses and reducing cardboard usage through efficient packaging and delivery via manned aircraft and last-mile delivery systems.

Sustainability and Resource Optimization Approaches

Sustainability in decentralized manufacturing hubs represents a critical dimension for long-term viability in low- and middle-income countries. These hubs must balance economic objectives with environmental responsibility and resource efficiency to create truly sustainable operations. The implementation of circular economy principles offers significant potential, where manufacturing waste becomes input for other processes, creating closed-loop systems that minimize environmental impact while maximizing resource utilization.

Energy optimization stands as a fundamental consideration, particularly in regions with unreliable grid infrastructure. Successful hubs increasingly incorporate renewable energy solutions such as solar panels and biomass generators, reducing operational costs while enhancing sustainability credentials. These systems often include energy storage components to ensure continuous operations during outages, a common challenge in developing regions.

Water conservation technologies represent another crucial optimization approach. Manufacturing processes typically require substantial water resources, creating potential strain in water-scarce regions. Advanced water recycling systems, rainwater harvesting infrastructure, and process modifications that reduce water consumption are becoming standard features in forward-thinking manufacturing hubs.

Material efficiency strategies further enhance sustainability profiles. This includes implementing lean manufacturing principles to reduce waste, utilizing locally sourced materials to minimize transportation emissions, and exploring alternative materials with lower environmental footprints. Some innovative hubs have successfully integrated agricultural by-products and other locally abundant materials into their manufacturing processes.

Digital technologies play an increasingly important role in resource optimization. IoT sensors monitoring resource consumption in real-time, AI systems optimizing production schedules to minimize waste, and blockchain solutions ensuring supply chain transparency all contribute to more efficient operations. These technologies enable precise resource management previously impossible with manual systems.

Community-based approaches to sustainability deserve special attention. Successful hubs often implement training programs focused on sustainable practices, creating local expertise in resource management. Some establish community recycling initiatives that simultaneously address waste management challenges while providing manufacturing inputs, creating virtuous cycles of resource utilization.

The financial sustainability of these optimization approaches requires careful consideration. While many resource-efficient technologies require upfront investment, they typically deliver substantial long-term savings. Innovative financing mechanisms, including green bonds, impact investment, and sustainability-linked loans, are emerging to support these initiatives, making implementation more feasible for resource-constrained operations.

Energy optimization stands as a fundamental consideration, particularly in regions with unreliable grid infrastructure. Successful hubs increasingly incorporate renewable energy solutions such as solar panels and biomass generators, reducing operational costs while enhancing sustainability credentials. These systems often include energy storage components to ensure continuous operations during outages, a common challenge in developing regions.

Water conservation technologies represent another crucial optimization approach. Manufacturing processes typically require substantial water resources, creating potential strain in water-scarce regions. Advanced water recycling systems, rainwater harvesting infrastructure, and process modifications that reduce water consumption are becoming standard features in forward-thinking manufacturing hubs.

Material efficiency strategies further enhance sustainability profiles. This includes implementing lean manufacturing principles to reduce waste, utilizing locally sourced materials to minimize transportation emissions, and exploring alternative materials with lower environmental footprints. Some innovative hubs have successfully integrated agricultural by-products and other locally abundant materials into their manufacturing processes.

Digital technologies play an increasingly important role in resource optimization. IoT sensors monitoring resource consumption in real-time, AI systems optimizing production schedules to minimize waste, and blockchain solutions ensuring supply chain transparency all contribute to more efficient operations. These technologies enable precise resource management previously impossible with manual systems.

Community-based approaches to sustainability deserve special attention. Successful hubs often implement training programs focused on sustainable practices, creating local expertise in resource management. Some establish community recycling initiatives that simultaneously address waste management challenges while providing manufacturing inputs, creating virtuous cycles of resource utilization.

The financial sustainability of these optimization approaches requires careful consideration. While many resource-efficient technologies require upfront investment, they typically deliver substantial long-term savings. Innovative financing mechanisms, including green bonds, impact investment, and sustainability-linked loans, are emerging to support these initiatives, making implementation more feasible for resource-constrained operations.

Local Economic Impact and Community Integration

Decentralized manufacturing hubs in low- and middle-income countries create significant ripple effects throughout local economies, extending far beyond direct employment opportunities. These hubs stimulate economic growth by creating new value chains that connect local suppliers, manufacturers, and distributors, thereby increasing the circulation of capital within communities rather than allowing it to flow outward to distant manufacturing centers.

The establishment of manufacturing hubs typically generates three tiers of economic impact: primary employment within the hub itself, secondary employment through supply chain relationships, and tertiary employment in service sectors that support the increased economic activity. Research indicates that each manufacturing job can create between 2.5-4 additional jobs in the surrounding economy, making these hubs powerful catalysts for broad-based economic development.

Community integration represents a critical success factor for these decentralized manufacturing models. Hubs that actively engage with local stakeholders through participatory planning processes demonstrate significantly higher sustainability rates than those imposed without community consultation. Successful integration strategies include establishing local governance committees, implementing transparent profit-sharing mechanisms, and creating pathways for community members to transition from consumers to producers within the manufacturing ecosystem.

Educational partnerships with local institutions serve dual purposes of workforce development and community integration. By offering apprenticeship programs, technical training, and knowledge transfer initiatives, manufacturing hubs can address skill gaps while simultaneously building community goodwill and stakeholder buy-in. These educational components help transform manufacturing hubs from isolated economic entities into integrated community assets.

Cultural sensitivity in operational practices significantly impacts community acceptance and long-term viability. Manufacturing hubs that adapt their business models to accommodate local cultural norms, traditional knowledge systems, and indigenous practices demonstrate stronger community relationships and reduced operational friction. This includes respecting local decision-making structures, incorporating traditional craftsmanship into production processes, and aligning business calendars with important cultural events.

Environmental stewardship represents another dimension of community integration, particularly in regions where livelihoods depend directly on natural resources. Manufacturing hubs that implement sustainable production practices, waste management systems, and resource conservation measures not only reduce their ecological footprint but also strengthen their social license to operate within environmentally conscious communities.

The establishment of manufacturing hubs typically generates three tiers of economic impact: primary employment within the hub itself, secondary employment through supply chain relationships, and tertiary employment in service sectors that support the increased economic activity. Research indicates that each manufacturing job can create between 2.5-4 additional jobs in the surrounding economy, making these hubs powerful catalysts for broad-based economic development.

Community integration represents a critical success factor for these decentralized manufacturing models. Hubs that actively engage with local stakeholders through participatory planning processes demonstrate significantly higher sustainability rates than those imposed without community consultation. Successful integration strategies include establishing local governance committees, implementing transparent profit-sharing mechanisms, and creating pathways for community members to transition from consumers to producers within the manufacturing ecosystem.

Educational partnerships with local institutions serve dual purposes of workforce development and community integration. By offering apprenticeship programs, technical training, and knowledge transfer initiatives, manufacturing hubs can address skill gaps while simultaneously building community goodwill and stakeholder buy-in. These educational components help transform manufacturing hubs from isolated economic entities into integrated community assets.

Cultural sensitivity in operational practices significantly impacts community acceptance and long-term viability. Manufacturing hubs that adapt their business models to accommodate local cultural norms, traditional knowledge systems, and indigenous practices demonstrate stronger community relationships and reduced operational friction. This includes respecting local decision-making structures, incorporating traditional craftsmanship into production processes, and aligning business calendars with important cultural events.

Environmental stewardship represents another dimension of community integration, particularly in regions where livelihoods depend directly on natural resources. Manufacturing hubs that implement sustainable production practices, waste management systems, and resource conservation measures not only reduce their ecological footprint but also strengthen their social license to operate within environmentally conscious communities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!