Case study analysis of unveiled V16 engine-driven conceptions

AUG 15, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine Evolution

The V16 engine has undergone a fascinating evolution since its inception in the early 20th century. Initially developed for high-performance applications, the V16 configuration emerged as a pinnacle of engineering prowess, offering unparalleled power and smoothness. The timeline of V16 engine development can be traced back to 1904 when the first V16 was conceptualized by Gobron-Brillié, although it never reached production.

The 1930s marked a significant era for V16 engines, with luxury automobile manufacturers like Cadillac and Marmon introducing V16-powered vehicles to the market. These engines were marvels of their time, boasting impressive power outputs and setting new standards for automotive excellence. Cadillac's 452 cubic inch (7.4-liter) V16, introduced in 1930, produced 165 horsepower and became an icon of American engineering.

During World War II, V16 engines found applications in military vehicles and aircraft, further advancing their development. The Chrysler IV-2220 aircraft engine, a liquid-cooled inverted V16, was a notable example that showcased the configuration's potential in aviation.

Post-war, the focus on V16 engines shifted primarily to specialized applications such as marine engines and motorsports. In the 1960s and 1970s, several racing teams experimented with V16 configurations in Formula One, including BRM's ambitious H16 engine, which was essentially two flat-8 engines stacked atop each other.

The late 20th and early 21st centuries saw a resurgence of interest in V16 engines for concept cars and ultra-luxury vehicles. BMW's Goldfish V16 prototype in the 1980s and Cadillac's Sixteen concept car in 2003 demonstrated the enduring appeal of this engine configuration. These modern interpretations often incorporated advanced technologies such as variable valve timing and cylinder deactivation to improve efficiency while maintaining the V16's characteristic power and smoothness.

Recent developments in V16 engine technology have focused on balancing performance with environmental considerations. Manufacturers have explored hybrid V16 powertrains and the use of alternative fuels to address emissions concerns while preserving the engine's prestigious status. The unveiling of V16-driven concepts in recent years highlights the ongoing fascination with this engine configuration, as designers and engineers continue to push the boundaries of what's possible in automotive propulsion.

The 1930s marked a significant era for V16 engines, with luxury automobile manufacturers like Cadillac and Marmon introducing V16-powered vehicles to the market. These engines were marvels of their time, boasting impressive power outputs and setting new standards for automotive excellence. Cadillac's 452 cubic inch (7.4-liter) V16, introduced in 1930, produced 165 horsepower and became an icon of American engineering.

During World War II, V16 engines found applications in military vehicles and aircraft, further advancing their development. The Chrysler IV-2220 aircraft engine, a liquid-cooled inverted V16, was a notable example that showcased the configuration's potential in aviation.

Post-war, the focus on V16 engines shifted primarily to specialized applications such as marine engines and motorsports. In the 1960s and 1970s, several racing teams experimented with V16 configurations in Formula One, including BRM's ambitious H16 engine, which was essentially two flat-8 engines stacked atop each other.

The late 20th and early 21st centuries saw a resurgence of interest in V16 engines for concept cars and ultra-luxury vehicles. BMW's Goldfish V16 prototype in the 1980s and Cadillac's Sixteen concept car in 2003 demonstrated the enduring appeal of this engine configuration. These modern interpretations often incorporated advanced technologies such as variable valve timing and cylinder deactivation to improve efficiency while maintaining the V16's characteristic power and smoothness.

Recent developments in V16 engine technology have focused on balancing performance with environmental considerations. Manufacturers have explored hybrid V16 powertrains and the use of alternative fuels to address emissions concerns while preserving the engine's prestigious status. The unveiling of V16-driven concepts in recent years highlights the ongoing fascination with this engine configuration, as designers and engineers continue to push the boundaries of what's possible in automotive propulsion.

Market for High-Power Engines

The market for high-power engines, particularly V16 configurations, represents a niche yet significant segment within the automotive and industrial sectors. These engines are primarily sought after for their exceptional power output, smooth operation, and prestige factor. The demand for V16 engines is driven by several key factors, including the luxury automotive market, marine applications, and specialized industrial uses.

In the automotive sector, V16 engines are predominantly associated with ultra-luxury and high-performance vehicles. Manufacturers such as Cadillac, BMW, and Bugatti have historically produced or conceptualized V16-powered cars, targeting affluent consumers who prioritize exclusivity and engineering excellence. The market for these vehicles, while limited in volume, commands premium prices and contributes significantly to brand prestige.

Marine applications form another crucial market for high-power engines. Large yachts and commercial vessels often require the substantial power output that V16 engines can provide. The marine sector values these engines for their ability to deliver consistent high performance over extended periods, crucial for long-distance sea travel and heavy-duty operations.

In industrial applications, V16 engines find use in power generation, particularly in backup power systems for large facilities such as hospitals, data centers, and industrial complexes. The reliability and high power output of these engines make them suitable for critical applications where consistent, high-capacity power supply is essential.

The market size for high-power engines, including V16 configurations, is influenced by global economic trends, environmental regulations, and technological advancements. While precise market figures are challenging to determine due to the specialized nature of these engines, industry reports suggest a steady growth trajectory in the high-power engine segment.

Environmental concerns and stringent emissions regulations pose challenges to the V16 engine market. Manufacturers are increasingly focusing on developing more fuel-efficient and environmentally friendly high-power engines, incorporating technologies such as hybrid systems and alternative fuels to meet regulatory requirements while maintaining performance standards.

Looking ahead, the market for high-power engines is expected to evolve with technological advancements. Emerging trends include the integration of electric powertrains with traditional combustion engines, creating hybrid systems that offer both high power output and improved fuel efficiency. Additionally, research into sustainable fuels and advanced materials is likely to shape the future of high-power engine design and market demand.

In the automotive sector, V16 engines are predominantly associated with ultra-luxury and high-performance vehicles. Manufacturers such as Cadillac, BMW, and Bugatti have historically produced or conceptualized V16-powered cars, targeting affluent consumers who prioritize exclusivity and engineering excellence. The market for these vehicles, while limited in volume, commands premium prices and contributes significantly to brand prestige.

Marine applications form another crucial market for high-power engines. Large yachts and commercial vessels often require the substantial power output that V16 engines can provide. The marine sector values these engines for their ability to deliver consistent high performance over extended periods, crucial for long-distance sea travel and heavy-duty operations.

In industrial applications, V16 engines find use in power generation, particularly in backup power systems for large facilities such as hospitals, data centers, and industrial complexes. The reliability and high power output of these engines make them suitable for critical applications where consistent, high-capacity power supply is essential.

The market size for high-power engines, including V16 configurations, is influenced by global economic trends, environmental regulations, and technological advancements. While precise market figures are challenging to determine due to the specialized nature of these engines, industry reports suggest a steady growth trajectory in the high-power engine segment.

Environmental concerns and stringent emissions regulations pose challenges to the V16 engine market. Manufacturers are increasingly focusing on developing more fuel-efficient and environmentally friendly high-power engines, incorporating technologies such as hybrid systems and alternative fuels to meet regulatory requirements while maintaining performance standards.

Looking ahead, the market for high-power engines is expected to evolve with technological advancements. Emerging trends include the integration of electric powertrains with traditional combustion engines, creating hybrid systems that offer both high power output and improved fuel efficiency. Additionally, research into sustainable fuels and advanced materials is likely to shape the future of high-power engine design and market demand.

V16 Technical Challenges

The development of V16 engines presents a multitude of technical challenges that push the boundaries of automotive engineering. One of the primary hurdles is the sheer size and complexity of these powerplants. With 16 cylinders arranged in a V-configuration, these engines require intricate design solutions to manage the increased length and weight compared to more common V8 or V12 configurations.

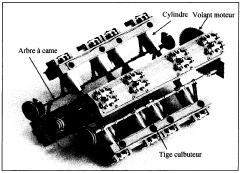

Balancing such a large number of cylinders poses significant difficulties. Engineers must meticulously design the crankshaft and implement advanced counterweighting techniques to minimize vibrations and ensure smooth operation across the entire RPM range. This challenge is further compounded by the need to maintain structural integrity under the immense forces generated by 16 firing cylinders.

Thermal management becomes a critical concern in V16 engines. The increased number of combustion chambers generates substantial heat, necessitating sophisticated cooling systems. Engineers must develop innovative solutions to efficiently dissipate heat from the engine's core while maintaining optimal operating temperatures throughout the powerplant.

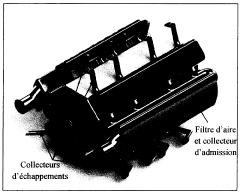

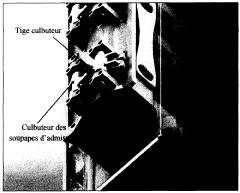

Fuel delivery and air management systems face unique challenges in V16 configurations. Designing intake and exhaust manifolds that provide equal flow to all cylinders requires careful computational fluid dynamics analysis and extensive testing. Additionally, fuel injection systems must be precisely calibrated to ensure uniform fuel distribution across all 16 cylinders, a task that grows exponentially more complex with the increased cylinder count.

Emissions control presents another significant hurdle for V16 engines. Meeting increasingly stringent environmental regulations while maintaining high performance is a delicate balancing act. Engineers must implement advanced catalytic converter systems and precise engine management software to minimize pollutants without sacrificing the power output that is expected from such a large displacement engine.

The mechanical complexity of V16 engines also impacts manufacturability and maintenance. Precision machining of components, assembly processes, and quality control measures must be exceptionally rigorous to ensure reliability and longevity. Furthermore, servicing such engines requires specialized tools and expertise, presenting challenges for both manufacturers and end-users.

Packaging a V16 engine within a vehicle chassis presents its own set of challenges. The increased length and weight of these powerplants necessitate careful consideration of weight distribution, center of gravity, and overall vehicle dynamics. Engineers must often employ creative solutions in chassis design and component placement to accommodate these massive engines while maintaining desirable handling characteristics.

Balancing such a large number of cylinders poses significant difficulties. Engineers must meticulously design the crankshaft and implement advanced counterweighting techniques to minimize vibrations and ensure smooth operation across the entire RPM range. This challenge is further compounded by the need to maintain structural integrity under the immense forces generated by 16 firing cylinders.

Thermal management becomes a critical concern in V16 engines. The increased number of combustion chambers generates substantial heat, necessitating sophisticated cooling systems. Engineers must develop innovative solutions to efficiently dissipate heat from the engine's core while maintaining optimal operating temperatures throughout the powerplant.

Fuel delivery and air management systems face unique challenges in V16 configurations. Designing intake and exhaust manifolds that provide equal flow to all cylinders requires careful computational fluid dynamics analysis and extensive testing. Additionally, fuel injection systems must be precisely calibrated to ensure uniform fuel distribution across all 16 cylinders, a task that grows exponentially more complex with the increased cylinder count.

Emissions control presents another significant hurdle for V16 engines. Meeting increasingly stringent environmental regulations while maintaining high performance is a delicate balancing act. Engineers must implement advanced catalytic converter systems and precise engine management software to minimize pollutants without sacrificing the power output that is expected from such a large displacement engine.

The mechanical complexity of V16 engines also impacts manufacturability and maintenance. Precision machining of components, assembly processes, and quality control measures must be exceptionally rigorous to ensure reliability and longevity. Furthermore, servicing such engines requires specialized tools and expertise, presenting challenges for both manufacturers and end-users.

Packaging a V16 engine within a vehicle chassis presents its own set of challenges. The increased length and weight of these powerplants necessitate careful consideration of weight distribution, center of gravity, and overall vehicle dynamics. Engineers must often employ creative solutions in chassis design and component placement to accommodate these massive engines while maintaining desirable handling characteristics.

Current V16 Engine Designs

01 Design and appearance of V16 engines

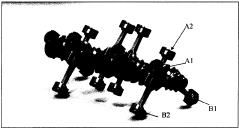

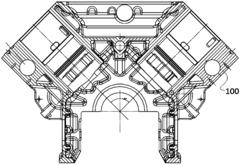

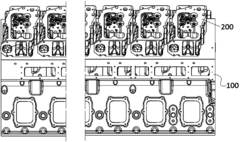

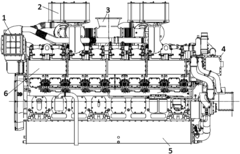

V16 engines have a distinctive design and appearance, characterized by their large size and unique configuration. These engines are often used in high-performance vehicles and industrial applications, requiring specialized design considerations for optimal performance and efficiency.- V16 engine design and configuration: V16 engines are characterized by their unique configuration of 16 cylinders arranged in a V-shape. This design allows for high power output while maintaining a relatively compact size. The V-configuration helps in balancing the engine and reducing vibrations, making it suitable for high-performance applications.

- V16 engine applications in vehicles: V16 engines are often used in luxury and high-performance vehicles, including cars, boats, and aircraft. Their powerful output makes them suitable for large vehicles that require significant torque and horsepower. These engines are also found in some industrial and marine applications where high power is necessary.

- V16 engine control systems: Advanced control systems are crucial for managing the complex operations of V16 engines. These systems may include electronic fuel injection, variable valve timing, and sophisticated engine management computers. Such controls help optimize performance, fuel efficiency, and emissions across various operating conditions.

- V16 engine cooling and lubrication: Effective cooling and lubrication systems are essential for V16 engines due to their high power output and heat generation. These may include advanced oil circulation systems, multiple radiators, and precision-engineered cooling channels to maintain optimal operating temperatures and ensure longevity of engine components.

- V16 engine sound and vibration management: Managing sound and vibration is crucial in V16 engines to enhance performance and user experience. This may involve the use of specialized mufflers, sound-dampening materials, and advanced balancing techniques. Some designs may also incorporate active noise cancellation systems to reduce unwanted engine noise while preserving the characteristic V16 sound.

02 Historical development of V16 engines

V16 engines have a rich history in automotive and industrial applications. Their development has spanned several decades, with various improvements and innovations introduced over time to enhance power output, efficiency, and reliability.Expand Specific Solutions03 Applications of V16 engines

V16 engines find applications in various fields, including high-performance automobiles, marine vessels, and industrial machinery. Their high power output and torque make them suitable for demanding applications that require significant mechanical power.Expand Specific Solutions04 Technical improvements in V16 engine design

Ongoing research and development efforts focus on improving V16 engine performance, efficiency, and environmental impact. These improvements may include advanced fuel injection systems, turbocharging technologies, and materials science applications to reduce weight and increase durability.Expand Specific Solutions05 Control systems for V16 engines

Modern V16 engines incorporate sophisticated control systems to optimize performance, fuel efficiency, and emissions. These systems may include electronic engine management, variable valve timing, and advanced diagnostics to ensure optimal operation under various conditions.Expand Specific Solutions

Key V16 Engine Manufacturers

The case study analysis of unveiled V16 engine-driven conceptions reveals a competitive landscape in a niche, high-performance segment of the automotive industry. This technology is in a relatively early stage of development, with limited market size due to its specialized nature. The technical maturity varies among key players, with established automotive giants like Honda, Toyota, Ford, and GM likely having more advanced capabilities. Emerging companies such as Everllence and Power Solutions International are also making strides in this field. The competition is intensifying as manufacturers seek to push the boundaries of engine performance and efficiency, potentially leading to breakthrough innovations in the coming years.

Ford Global Technologies LLC

Technical Solution: Ford has been exploring V16 engine concepts, particularly for high-performance applications. Their approach involves a modular design that allows for scalability and adaptability across different vehicle platforms. The V16 configuration is achieved by essentially combining two V8 engines, resulting in a 6.8-liter displacement [1]. Ford's design incorporates advanced fuel injection systems and variable valve timing to optimize performance and efficiency. The engine is rumored to produce over 800 horsepower and 1,000 lb-ft of torque, making it suitable for luxury and performance vehicles [2]. Ford has also integrated cylinder deactivation technology to improve fuel economy during low-load conditions [3].

Strengths: Massive power output, scalable design, potential for luxury and performance applications. Weaknesses: High fuel consumption, complex manufacturing process, limited practical applications in mass-market vehicles.

Toyota Motor Corp.

Technical Solution: Toyota's approach to V16 engine development focuses on a balance between performance and efficiency. Their concept utilizes a hybrid powertrain system, combining a naturally aspirated V16 engine with electric motors. The V16 engine features Toyota's D-4S dual injection system, which combines direct and port fuel injection for optimal fuel delivery across all operating conditions [11]. The engine incorporates variable valve timing on both intake and exhaust camshafts, as well as a variable-length intake manifold to enhance torque across the rev range. Toyota's hybrid integration allows for electric-only operation at low speeds and provides additional power boost when needed. The company has also explored the use of lightweight materials such as carbon fiber reinforced plastics for certain engine components to reduce overall weight [12].

Strengths: Hybrid technology integration, potential for improved fuel efficiency, Toyota's reputation for reliability. Weaknesses: Complex powertrain system, high development costs, limited market for V16 hybrid powertrains.

V16 Innovations Analysis

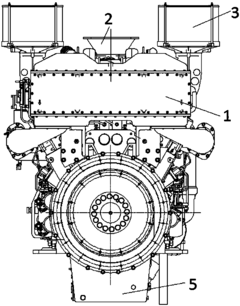

16-cylinder X-engine.

PatentActiveTN2017000127A1

Innovation

- X-shaped configuration of 16 cylinders minimizes crankshaft vibrations and improves engine stability.

- Elimination of balance shafts due to the self-cancelling combustion forces in the X-configuration.

- Compact design relative to cylinder count, allowing for high power output in a smaller package.

High-power V16 diesel engine

PatentActiveCN108194198A

Innovation

- A high-power V-shaped 16-cylinder diesel engine is designed, which uses a V-shaped cylinder block, 16 single cylinder heads, four turbochargers and an intercooler, combined with a cooling system of high and low temperature water circulation loops, to achieve turbocharging through Technology and classified cooling systems increase air density and lower temperatures to meet the needs of high power and torque.

Emissions Regulations Impact

The impact of emissions regulations on V16 engine-driven conceptions has been significant and far-reaching. As environmental concerns have grown, governments worldwide have implemented increasingly stringent emissions standards, forcing manufacturers to adapt their engine designs or face obsolescence.

In the European Union, the introduction of Euro 6 standards in 2014 marked a turning point for large displacement engines. These regulations set strict limits on nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter emissions. For V16 engines, meeting these standards while maintaining performance became a formidable challenge, often requiring extensive redesigns and the integration of advanced aftertreatment systems.

Similarly, in the United States, the Environmental Protection Agency (EPA) has progressively tightened emissions standards for both on-road and off-road engines. The Tier 4 Final standards for off-road engines, phased in between 2008 and 2015, posed particular challenges for high-power applications where V16 engines are often employed, such as in marine and industrial sectors.

These regulatory pressures have led to significant technological advancements in V16 engine design. Manufacturers have invested heavily in developing cleaner combustion processes, improved fuel injection systems, and more efficient turbocharging technologies. Additionally, the integration of selective catalytic reduction (SCR) systems and diesel particulate filters (DPF) has become commonplace to meet emissions targets.

However, the cost of compliance has been substantial. The complexity of modern V16 engines has increased dramatically, leading to higher production costs and potentially reduced reliability. This has, in some cases, pushed manufacturers to explore alternative powertrain solutions, including downsized engines with forced induction or hybrid systems.

The marine sector, a traditional stronghold for V16 engines, has seen a shift towards more efficient and cleaner alternatives. The International Maritime Organization (IMO) has implemented global sulfur caps and NOx emission control areas, prompting a reevaluation of large displacement engines in favor of more environmentally friendly options.

Looking forward, the trend towards electrification and zero-emission vehicles poses an existential threat to V16 engine concepts. As countries announce plans to phase out internal combustion engines, the long-term viability of V16 engines in many applications is increasingly uncertain. This has led some manufacturers to explore hybrid V16 concepts as a transitional technology, combining the power density of the V16 configuration with electric propulsion to meet both performance and emissions requirements.

In the European Union, the introduction of Euro 6 standards in 2014 marked a turning point for large displacement engines. These regulations set strict limits on nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter emissions. For V16 engines, meeting these standards while maintaining performance became a formidable challenge, often requiring extensive redesigns and the integration of advanced aftertreatment systems.

Similarly, in the United States, the Environmental Protection Agency (EPA) has progressively tightened emissions standards for both on-road and off-road engines. The Tier 4 Final standards for off-road engines, phased in between 2008 and 2015, posed particular challenges for high-power applications where V16 engines are often employed, such as in marine and industrial sectors.

These regulatory pressures have led to significant technological advancements in V16 engine design. Manufacturers have invested heavily in developing cleaner combustion processes, improved fuel injection systems, and more efficient turbocharging technologies. Additionally, the integration of selective catalytic reduction (SCR) systems and diesel particulate filters (DPF) has become commonplace to meet emissions targets.

However, the cost of compliance has been substantial. The complexity of modern V16 engines has increased dramatically, leading to higher production costs and potentially reduced reliability. This has, in some cases, pushed manufacturers to explore alternative powertrain solutions, including downsized engines with forced induction or hybrid systems.

The marine sector, a traditional stronghold for V16 engines, has seen a shift towards more efficient and cleaner alternatives. The International Maritime Organization (IMO) has implemented global sulfur caps and NOx emission control areas, prompting a reevaluation of large displacement engines in favor of more environmentally friendly options.

Looking forward, the trend towards electrification and zero-emission vehicles poses an existential threat to V16 engine concepts. As countries announce plans to phase out internal combustion engines, the long-term viability of V16 engines in many applications is increasingly uncertain. This has led some manufacturers to explore hybrid V16 concepts as a transitional technology, combining the power density of the V16 configuration with electric propulsion to meet both performance and emissions requirements.

V16 Applications Outlook

The V16 engine, while not widely adopted in mainstream automotive applications, continues to hold significant potential in specialized sectors. Its impressive power output and smooth operation make it particularly suitable for high-performance and luxury vehicles, as well as marine and industrial applications.

In the automotive realm, V16 engines are likely to remain exclusive to ultra-luxury and hypercar segments. Manufacturers such as Bugatti and Cadillac have previously explored V16 concepts, and future iterations may emerge in limited-production models targeting affluent enthusiasts. These engines could serve as halo products, showcasing engineering prowess and brand prestige.

The marine industry presents a promising avenue for V16 engine applications. Large yachts and commercial vessels could benefit from the power density and reliability offered by V16 configurations. As emission regulations tighten, V16 engines coupled with hybrid systems or alternative fuels may provide a balance between performance and environmental compliance in maritime settings.

Industrial applications, particularly in power generation and heavy machinery, offer another potential growth area for V16 engines. Their ability to deliver high power output in a relatively compact package makes them suitable for stationary power plants, mining equipment, and large-scale construction machinery.

The aviation sector, although niche, may see renewed interest in V16 engines for certain specialized aircraft. While not practical for commercial aviation, private jets and experimental aircraft could leverage the power-to-weight ratio of advanced V16 designs.

As electrification gains momentum across various industries, V16 engines may find new roles in hybrid powertrains. Acting as range extenders or primary power sources in series-hybrid configurations, they could offer a transitional solution in sectors where full electrification remains challenging.

The future of V16 engines will likely be shaped by advancements in materials science and manufacturing techniques. Innovations in lightweight alloys, 3D printing, and precision engineering could address historical challenges related to weight and complexity, potentially expanding the engine's applicability.

In conclusion, while V16 engines may not see widespread adoption, their unique characteristics ensure a continued role in specialized applications. The engine's future lies in niche markets where its advantages in power delivery, smoothness, and prestige outweigh considerations of cost and complexity.

In the automotive realm, V16 engines are likely to remain exclusive to ultra-luxury and hypercar segments. Manufacturers such as Bugatti and Cadillac have previously explored V16 concepts, and future iterations may emerge in limited-production models targeting affluent enthusiasts. These engines could serve as halo products, showcasing engineering prowess and brand prestige.

The marine industry presents a promising avenue for V16 engine applications. Large yachts and commercial vessels could benefit from the power density and reliability offered by V16 configurations. As emission regulations tighten, V16 engines coupled with hybrid systems or alternative fuels may provide a balance between performance and environmental compliance in maritime settings.

Industrial applications, particularly in power generation and heavy machinery, offer another potential growth area for V16 engines. Their ability to deliver high power output in a relatively compact package makes them suitable for stationary power plants, mining equipment, and large-scale construction machinery.

The aviation sector, although niche, may see renewed interest in V16 engines for certain specialized aircraft. While not practical for commercial aviation, private jets and experimental aircraft could leverage the power-to-weight ratio of advanced V16 designs.

As electrification gains momentum across various industries, V16 engines may find new roles in hybrid powertrains. Acting as range extenders or primary power sources in series-hybrid configurations, they could offer a transitional solution in sectors where full electrification remains challenging.

The future of V16 engines will likely be shaped by advancements in materials science and manufacturing techniques. Innovations in lightweight alloys, 3D printing, and precision engineering could address historical challenges related to weight and complexity, potentially expanding the engine's applicability.

In conclusion, while V16 engines may not see widespread adoption, their unique characteristics ensure a continued role in specialized applications. The engine's future lies in niche markets where its advantages in power delivery, smoothness, and prestige outweigh considerations of cost and complexity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!