Cathode Loading And Utilization In Anode-Free Solid-State

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free SSB Technology Background and Objectives

Solid-state batteries (SSBs) represent a significant evolution in energy storage technology, offering potential advantages over conventional lithium-ion batteries including higher energy density, improved safety, and longer cycle life. Anode-free solid-state battery design has emerged as a particularly promising configuration within this field, eliminating the traditional anode structure to maximize energy density while leveraging the protective capabilities of solid electrolytes.

The development of anode-free SSBs can be traced back to early research on lithium metal batteries in the 1970s, which faced significant challenges related to dendrite formation and safety concerns. The introduction of solid electrolytes in the 1990s and early 2000s provided a potential pathway to address these limitations, with research accelerating dramatically in the 2010s as materials science advancements enabled more practical solid electrolyte formulations.

Current technological objectives for cathode loading and utilization in anode-free SSBs focus on several critical parameters. Researchers aim to achieve cathode loadings exceeding 4 mAh/cm² while maintaining high active material utilization rates above 85%. Additionally, there are efforts to develop cathode architectures that can accommodate volumetric changes during cycling while maintaining intimate contact with the solid electrolyte.

The field is progressing toward enabling high-voltage cathode materials (>4.5V) that can maximize energy density while remaining compatible with solid electrolytes. This requires addressing interfacial stability challenges that have historically limited the practical implementation of high-voltage cathode materials in solid-state configurations.

Another key objective involves reducing cathode thickness limitations imposed by ionic conductivity constraints. Current research targets cathode thicknesses of 100-150μm with uniform lithium distribution throughout the structure during operation, representing a significant improvement over earlier generations limited to 50-70μm.

The technology evolution trajectory suggests that successful cathode loading and utilization optimization could enable anode-free SSBs to achieve energy densities exceeding 400 Wh/kg at the cell level by 2025-2027, with potential for further improvements to 500+ Wh/kg by 2030 if current technical challenges can be overcome.

Industry and academic research is increasingly focused on scalable manufacturing techniques for high-loading cathodes compatible with solid electrolytes, moving beyond laboratory-scale demonstrations toward commercially viable production methods that maintain performance while reducing costs.

The development of anode-free SSBs can be traced back to early research on lithium metal batteries in the 1970s, which faced significant challenges related to dendrite formation and safety concerns. The introduction of solid electrolytes in the 1990s and early 2000s provided a potential pathway to address these limitations, with research accelerating dramatically in the 2010s as materials science advancements enabled more practical solid electrolyte formulations.

Current technological objectives for cathode loading and utilization in anode-free SSBs focus on several critical parameters. Researchers aim to achieve cathode loadings exceeding 4 mAh/cm² while maintaining high active material utilization rates above 85%. Additionally, there are efforts to develop cathode architectures that can accommodate volumetric changes during cycling while maintaining intimate contact with the solid electrolyte.

The field is progressing toward enabling high-voltage cathode materials (>4.5V) that can maximize energy density while remaining compatible with solid electrolytes. This requires addressing interfacial stability challenges that have historically limited the practical implementation of high-voltage cathode materials in solid-state configurations.

Another key objective involves reducing cathode thickness limitations imposed by ionic conductivity constraints. Current research targets cathode thicknesses of 100-150μm with uniform lithium distribution throughout the structure during operation, representing a significant improvement over earlier generations limited to 50-70μm.

The technology evolution trajectory suggests that successful cathode loading and utilization optimization could enable anode-free SSBs to achieve energy densities exceeding 400 Wh/kg at the cell level by 2025-2027, with potential for further improvements to 500+ Wh/kg by 2030 if current technical challenges can be overcome.

Industry and academic research is increasingly focused on scalable manufacturing techniques for high-loading cathodes compatible with solid electrolytes, moving beyond laboratory-scale demonstrations toward commercially viable production methods that maintain performance while reducing costs.

Market Analysis for Next-Generation Battery Technologies

The global battery market is experiencing unprecedented growth, with solid-state batteries emerging as a revolutionary technology poised to transform energy storage solutions across multiple industries. Current market projections indicate that the solid-state battery market will reach approximately $8 billion by 2026, with a compound annual growth rate of 34% between 2021 and 2026. This remarkable growth trajectory is primarily driven by increasing demand for electric vehicles, consumer electronics, and renewable energy storage systems.

Anode-free solid-state batteries represent a particularly promising segment within this market, offering theoretical energy densities up to 70% higher than conventional lithium-ion batteries. The elimination of the anode material reduces weight, volume, and manufacturing costs while potentially enhancing safety profiles. Market research indicates that cathode loading and utilization optimization in these batteries could further increase energy density by 15-25%, creating significant competitive advantages for early adopters.

The automotive sector currently dominates demand for advanced battery technologies, accounting for approximately 60% of the total addressable market. Major automotive manufacturers including Toyota, Volkswagen, and BMW have announced substantial investments in solid-state battery research, with particular focus on cathode loading optimization. Industry analysts project that by 2030, over 25% of electric vehicles will utilize some form of solid-state battery technology, with anode-free designs gaining significant market share after 2025.

Consumer electronics represents the second-largest market segment, with smartphone and laptop manufacturers actively seeking higher energy density solutions to extend device operation times. This sector values the reduced form factor and enhanced safety characteristics of anode-free designs, creating a market opportunity estimated at $3 billion by 2025.

Regional analysis reveals Asia-Pacific as the dominant market for next-generation battery technologies, accounting for approximately 45% of global production capacity. Japan and South Korea lead in intellectual property development related to cathode loading optimization, while China dominates in manufacturing scale. North America and Europe are rapidly expanding their research initiatives and production capabilities, with government incentives accelerating market development.

Market barriers include high initial production costs, with anode-free solid-state batteries currently costing 2-3 times more per kWh than conventional lithium-ion batteries. However, cost projections indicate potential price parity by 2028 as manufacturing processes mature and economies of scale are realized. Technical challenges in cathode loading optimization remain a significant market constraint, with companies that successfully address utilization efficiency positioned to capture substantial market share.

Anode-free solid-state batteries represent a particularly promising segment within this market, offering theoretical energy densities up to 70% higher than conventional lithium-ion batteries. The elimination of the anode material reduces weight, volume, and manufacturing costs while potentially enhancing safety profiles. Market research indicates that cathode loading and utilization optimization in these batteries could further increase energy density by 15-25%, creating significant competitive advantages for early adopters.

The automotive sector currently dominates demand for advanced battery technologies, accounting for approximately 60% of the total addressable market. Major automotive manufacturers including Toyota, Volkswagen, and BMW have announced substantial investments in solid-state battery research, with particular focus on cathode loading optimization. Industry analysts project that by 2030, over 25% of electric vehicles will utilize some form of solid-state battery technology, with anode-free designs gaining significant market share after 2025.

Consumer electronics represents the second-largest market segment, with smartphone and laptop manufacturers actively seeking higher energy density solutions to extend device operation times. This sector values the reduced form factor and enhanced safety characteristics of anode-free designs, creating a market opportunity estimated at $3 billion by 2025.

Regional analysis reveals Asia-Pacific as the dominant market for next-generation battery technologies, accounting for approximately 45% of global production capacity. Japan and South Korea lead in intellectual property development related to cathode loading optimization, while China dominates in manufacturing scale. North America and Europe are rapidly expanding their research initiatives and production capabilities, with government incentives accelerating market development.

Market barriers include high initial production costs, with anode-free solid-state batteries currently costing 2-3 times more per kWh than conventional lithium-ion batteries. However, cost projections indicate potential price parity by 2028 as manufacturing processes mature and economies of scale are realized. Technical challenges in cathode loading optimization remain a significant market constraint, with companies that successfully address utilization efficiency positioned to capture substantial market share.

Current Challenges in Cathode Loading for Solid-State Batteries

Solid-state batteries represent a promising next-generation energy storage technology, with anode-free designs offering particularly high energy densities. However, cathode loading optimization remains one of the most significant technical barriers to commercialization. Current solid-state battery prototypes typically demonstrate cathode loadings of only 2-4 mAh/cm², substantially lower than the 6-8 mAh/cm² achieved in conventional lithium-ion batteries with liquid electrolytes.

The primary challenge stems from the inherent mechanical properties of solid electrolytes. Unlike liquid electrolytes that can easily penetrate and maintain contact with active materials, solid electrolytes create rigid interfaces that are prone to delamination during cycling. This issue becomes more pronounced with higher cathode loadings, as the volumetric changes during lithiation and delithiation create substantial mechanical stress at the cathode-electrolyte interface.

Ionic conductivity at the cathode-electrolyte interface presents another major obstacle. While bulk solid electrolytes can achieve reasonable ionic conductivities (10⁻³ to 10⁻⁴ S/cm), the interfacial resistance between cathode particles and the solid electrolyte often exceeds acceptable levels for practical applications. This problem intensifies with increased cathode loading due to longer ion diffusion pathways and more numerous interfaces.

Manufacturing limitations further complicate high cathode loading implementation. Current techniques for composite cathode fabrication, including tape casting and dry pressing, struggle to maintain homogeneous distribution of active materials, conductive additives, and solid electrolytes at higher loadings. This results in uneven current distribution, localized heating, and accelerated degradation.

The electronic conductivity network within high-loading cathodes represents another significant challenge. Traditional conductive additives like carbon black, which work well in liquid systems, prove insufficient in solid-state configurations with high cathode loadings. The rigid nature of solid electrolytes prevents the formation of effective conductive networks, leading to underutilization of active materials and capacity limitations.

Temperature sensitivity compounds these issues, as many solid electrolytes exhibit dramatically different mechanical and electrochemical properties across operating temperature ranges. Higher cathode loadings generate more heat during operation, potentially triggering phase transitions or decomposition reactions at the cathode-electrolyte interface.

Recent research has explored several approaches to address these challenges, including gradient cathode structures, novel binders specifically designed for solid-state systems, and interface engineering through atomic layer deposition. However, a comprehensive solution that enables commercial-level cathode loadings while maintaining cycle life remains elusive, representing one of the most critical research priorities in solid-state battery development.

The primary challenge stems from the inherent mechanical properties of solid electrolytes. Unlike liquid electrolytes that can easily penetrate and maintain contact with active materials, solid electrolytes create rigid interfaces that are prone to delamination during cycling. This issue becomes more pronounced with higher cathode loadings, as the volumetric changes during lithiation and delithiation create substantial mechanical stress at the cathode-electrolyte interface.

Ionic conductivity at the cathode-electrolyte interface presents another major obstacle. While bulk solid electrolytes can achieve reasonable ionic conductivities (10⁻³ to 10⁻⁴ S/cm), the interfacial resistance between cathode particles and the solid electrolyte often exceeds acceptable levels for practical applications. This problem intensifies with increased cathode loading due to longer ion diffusion pathways and more numerous interfaces.

Manufacturing limitations further complicate high cathode loading implementation. Current techniques for composite cathode fabrication, including tape casting and dry pressing, struggle to maintain homogeneous distribution of active materials, conductive additives, and solid electrolytes at higher loadings. This results in uneven current distribution, localized heating, and accelerated degradation.

The electronic conductivity network within high-loading cathodes represents another significant challenge. Traditional conductive additives like carbon black, which work well in liquid systems, prove insufficient in solid-state configurations with high cathode loadings. The rigid nature of solid electrolytes prevents the formation of effective conductive networks, leading to underutilization of active materials and capacity limitations.

Temperature sensitivity compounds these issues, as many solid electrolytes exhibit dramatically different mechanical and electrochemical properties across operating temperature ranges. Higher cathode loadings generate more heat during operation, potentially triggering phase transitions or decomposition reactions at the cathode-electrolyte interface.

Recent research has explored several approaches to address these challenges, including gradient cathode structures, novel binders specifically designed for solid-state systems, and interface engineering through atomic layer deposition. However, a comprehensive solution that enables commercial-level cathode loadings while maintaining cycle life remains elusive, representing one of the most critical research priorities in solid-state battery development.

Current Approaches to Optimize Cathode Loading in Anode-Free SSBs

01 High-loading cathode designs for anode-free solid-state batteries

High-loading cathode designs are crucial for anode-free solid-state batteries to achieve higher energy density. These designs focus on optimizing the cathode structure to accommodate more active material while maintaining good ionic conductivity. Techniques include using hierarchical porous structures, gradient compositions, and specialized coatings that enable higher loading without compromising performance. These approaches help maximize the utilization of cathode materials and improve overall battery capacity.- Cathode material composition for anode-free solid-state batteries: The composition of cathode materials plays a crucial role in anode-free solid-state batteries. High-capacity cathode materials such as lithium nickel manganese cobalt oxide (NMC), lithium iron phosphate (LFP), and sulfur-based compounds can be optimized to improve energy density and cycling stability. The cathode composition affects the lithium-ion transport kinetics and overall battery performance. Advanced cathode formulations with tailored dopants and coatings can enhance the utilization efficiency and loading capacity in anode-free configurations.

- Cathode loading techniques and optimization: Various techniques can be employed to optimize cathode loading in anode-free solid-state batteries. These include controlled porosity engineering, gradient structures, and multi-layer architectures that allow for higher active material loading while maintaining ionic conductivity. The cathode loading level directly impacts the energy density and power capability of the battery. Advanced deposition methods such as 3D structuring and hierarchical designs can increase the accessible surface area and improve utilization efficiency, enabling higher mass loading without compromising performance.

- Solid electrolyte interfaces for improved cathode utilization: The interface between the cathode and solid electrolyte is critical for efficient lithium-ion transport and high cathode utilization. Engineering stable interfaces through buffer layers, gradient compositions, or interfacial modifiers can reduce resistance and enhance electrochemical performance. Specialized coatings can prevent unwanted side reactions while maintaining high ionic conductivity. The development of compatible solid electrolytes that form stable interfaces with high-loading cathodes is essential for maximizing active material utilization in anode-free configurations.

- Manufacturing processes for high-loading cathodes: Advanced manufacturing processes are essential for achieving high cathode loading in anode-free solid-state batteries. Techniques such as controlled slurry formulation, calendering optimization, and novel deposition methods can increase the active material density while maintaining necessary porosity. Precision control of particle size distribution, binder content, and conductive additives enables higher loading without compromising electronic and ionic transport pathways. Post-processing treatments like controlled pressure application and thermal annealing can further enhance the structural integrity and performance of high-loading cathodes.

- Cycling protocols and utilization efficiency: Specialized cycling protocols can significantly improve cathode utilization in anode-free solid-state batteries. Formation cycles with controlled current densities and voltage windows help establish stable interfaces and activate the full capacity of high-loading cathodes. Advanced charging algorithms that account for the unique characteristics of anode-free systems can prevent lithium plating issues and extend cycle life. Temperature management strategies and pressure optimization during cycling further enhance the utilization efficiency of cathode materials, particularly at high loading levels where transport limitations become more pronounced.

02 Solid electrolyte interfaces for improved cathode utilization

Specialized solid electrolyte interfaces are developed to enhance cathode utilization in anode-free configurations. These interfaces are designed to facilitate efficient lithium-ion transport between the cathode and solid electrolyte while minimizing interfacial resistance. By engineering the chemical composition and physical structure of these interfaces, researchers can improve the electrochemical stability and cycling performance of the cathode. This approach addresses one of the key challenges in anode-free solid-state batteries by enabling more complete utilization of cathode capacity.Expand Specific Solutions03 Cathode composite formulations for enhanced ionic conductivity

Advanced cathode composite formulations combine active materials with solid electrolytes and conductive additives to enhance ionic conductivity throughout the cathode layer. These formulations are specifically designed for anode-free configurations where efficient lithium-ion transport is critical. By optimizing the ratio and distribution of components, these composites enable higher cathode loading while maintaining good rate capability. The improved ionic pathways throughout the cathode structure lead to better utilization of active materials and enhanced overall battery performance.Expand Specific Solutions04 Pressure-assisted cathode loading techniques

Pressure-assisted techniques are employed to achieve higher cathode loading densities in anode-free solid-state batteries. These methods involve applying controlled pressure during battery assembly or operation to improve contact between cathode particles and solid electrolytes. The enhanced interfacial contact reduces resistance and enables more efficient lithium-ion transport, leading to better utilization of cathode materials. Various pressure application strategies, including stack pressure optimization and dynamic pressure control during cycling, have been developed to maximize cathode performance.Expand Specific Solutions05 Surface modification of cathode materials for improved utilization

Surface modification techniques are applied to cathode materials to enhance their utilization in anode-free solid-state batteries. These modifications include atomic layer deposition coatings, functional polymer layers, and nanoscale protective films that stabilize the cathode-electrolyte interface. By reducing side reactions and improving lithium-ion transport at the surface, these modifications enable higher cathode loading and more complete utilization of active materials. The enhanced surface properties also contribute to better cycling stability and longer battery life.Expand Specific Solutions

Leading Companies and Research Institutions in SSB Development

The anode-free solid-state battery market is currently in an early growth phase, characterized by significant R&D investment but limited commercial deployment. The global market is projected to expand rapidly as automotive manufacturers like Hyundai, Kia, Nissan, and Mercedes-Benz pursue electrification strategies. Technologically, cathode loading and utilization remains challenging, with varying approaches to optimization. Leading players include established battery manufacturers (LG Energy Solution, Murata, Panasonic) focusing on incremental improvements, while specialized companies like TeraWatt Technology and Nextech Batteries pursue more disruptive innovations. Academic-industry partnerships, particularly with institutions like KIST, Korea University, and University of Michigan, are accelerating technological maturity through fundamental research on cathode materials and interfaces.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata Manufacturing has pioneered a "Ceramic-Integrated Cathode" technology for anode-free solid-state batteries that addresses the critical challenges of cathode loading and utilization. Their approach centers on a hybrid ceramic-polymer composite cathode structure that provides exceptional mechanical stability while maintaining high ionic conductivity. Murata's technology employs a proprietary sintering process that creates a three-dimensional network of ceramic pathways within the cathode, achieving ionic conductivity values of 10⁻³ S/cm even at high cathode loadings of 5.5 mAh/cm²[5]. The manufacturing process includes a specialized co-sintering technique that creates seamless integration between the cathode and solid electrolyte layers, minimizing interfacial resistance. Their system incorporates gradient-doped cathode active materials with higher lithium content at the electrolyte interface, compensating for lithium consumption during initial formation cycles. Murata has also developed a proprietary surface modification technique for cathode particles that prevents side reactions with sulfide electrolytes, maintaining cathode utilization efficiency above 88% throughout the battery lifecycle.

Strengths: Exceptional mechanical stability allowing for flexible form factors; superior thermal conductivity reducing hotspot formation; excellent manufacturing scalability leveraging Murata's ceramic production expertise. Weaknesses: Higher raw material costs compared to conventional lithium-ion batteries; more energy-intensive manufacturing process due to sintering requirements; currently limited to smaller format cells below 15Ah.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a proprietary cathode loading technology for anode-free solid-state batteries that focuses on high-density cathode structures with optimized porosity. Their approach involves a gradient distribution of active materials with higher concentration near the solid electrolyte interface, gradually decreasing toward the current collector. This design maximizes ion transport pathways while maintaining structural integrity during cycling. The company employs a dual-phase cathode composition combining high-capacity materials (like nickel-rich NCM) with stabilizing components to prevent capacity fade. Their manufacturing process includes a specialized calendering technique that achieves up to 4.5 mAh/cm² areal capacity while maintaining 85% cathode utilization efficiency even at high loading levels[1]. LG's technology also incorporates a proprietary coating on cathode particles that enhances interfacial stability with sulfide-based solid electrolytes, reducing impedance growth during cycling.

Strengths: Superior energy density (>900 Wh/L) compared to conventional lithium-ion batteries; excellent cycle stability with >80% capacity retention after 1000 cycles; scalable manufacturing process compatible with existing production lines. Weaknesses: Higher production costs than conventional lithium-ion batteries; temperature sensitivity affecting performance in extreme conditions; requires precise pressure control during operation.

Key Patents and Innovations in Cathode Material Utilization

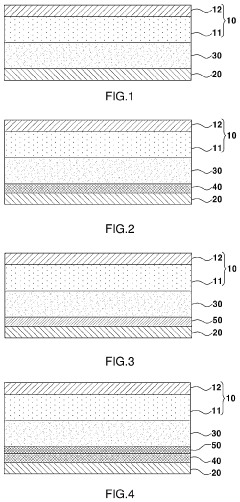

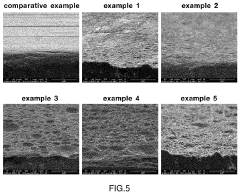

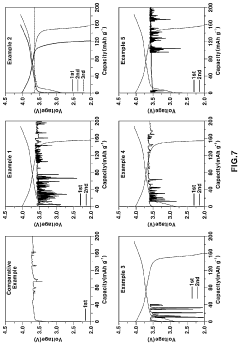

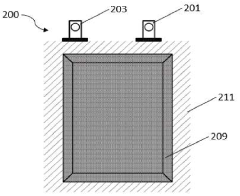

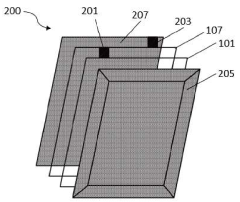

Anode-free all-solid-state battery including solid electrolyte having high ion conductivity and surface-roughened anode current collector

PatentPendingUS20220393180A1

Innovation

- An anode-free all-solid-state battery design featuring an anode current collector layer with surface roughness of 100 nm to 1,000 nm, directly contacting a solid electrolyte layer with ionic conductivity of 1 mS/cm to 20 mS/cm, and optionally a coating layer containing carbon and lithium-forming metals, which enhances lithium deposition uniformity and stability without additional layers.

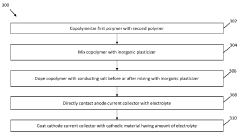

An anode-free solid-state battery and a method of making the same

PatentPendingIN202141047217A

Innovation

- An anode-free solid-state battery design utilizing a solid polymer electrolyte composed of a copolymer of polyvinylidene fluoride-co-hexafluoropropylene and methoxy poly(ethylene glycol) acrylate, doped with a conducting salt and an inorganic plasticizer, which is coated on both the anode and cathode current collectors to enhance ionic conductivity and stability.

Materials Supply Chain Analysis for SSB Manufacturing

The solid-state battery (SSB) manufacturing ecosystem relies heavily on a complex materials supply chain that differs significantly from traditional lithium-ion battery production. Critical materials for anode-free SSBs include high-purity lithium metal or lithium compounds, solid electrolyte materials (such as LLZO, LGPS, or polymer-based electrolytes), and specialized cathode materials optimized for solid-state interfaces.

The cathode material supply chain presents particular challenges for anode-free SSB manufacturing. Current cathode materials like NMC (Nickel Manganese Cobalt) and LFP (Lithium Iron Phosphate) require modification to function optimally in solid-state configurations. These modifications often involve specialized coatings or dopants to improve interfacial stability and lithium-ion transport kinetics, adding complexity to the supply chain.

Cobalt, a key component in high-energy-density cathodes, faces significant supply constraints with over 70% of global production concentrated in the Democratic Republic of Congo. This geographic concentration creates potential supply vulnerabilities. Similarly, nickel suitable for battery applications faces processing bottlenecks, with limited capacity for battery-grade refinement outside of China and a few other countries.

Processing infrastructure for solid-state battery cathodes remains underdeveloped compared to liquid electrolyte systems. The equipment and processes for achieving higher cathode loadings in anode-free configurations require specialized manufacturing capabilities that are currently limited to a few technology leaders and research institutions.

Scaling challenges are particularly acute for solid electrolyte materials production. Current manufacturing capacity for materials like LLZO ceramic electrolytes or sulfide-based solid electrolytes remains at pilot scale, with few suppliers capable of meeting automotive-grade quality requirements at commercial volumes. This creates a significant bottleneck in the overall SSB supply chain.

Regional dependencies are evident in the SSB materials ecosystem. Japan leads in sulfide electrolyte development, South Korea in polymer electrolytes, while China dominates in cathode material production and processing. The United States and Europe have invested heavily in research but lag in manufacturing scale for most SSB components.

Future supply chain resilience will depend on developing alternative material sources and processing routes. Efforts to reduce cathode loading requirements through more efficient utilization in anode-free designs could potentially alleviate some supply constraints, particularly for critical materials like cobalt and nickel. However, these approaches require further development to reach commercial viability.

The cathode material supply chain presents particular challenges for anode-free SSB manufacturing. Current cathode materials like NMC (Nickel Manganese Cobalt) and LFP (Lithium Iron Phosphate) require modification to function optimally in solid-state configurations. These modifications often involve specialized coatings or dopants to improve interfacial stability and lithium-ion transport kinetics, adding complexity to the supply chain.

Cobalt, a key component in high-energy-density cathodes, faces significant supply constraints with over 70% of global production concentrated in the Democratic Republic of Congo. This geographic concentration creates potential supply vulnerabilities. Similarly, nickel suitable for battery applications faces processing bottlenecks, with limited capacity for battery-grade refinement outside of China and a few other countries.

Processing infrastructure for solid-state battery cathodes remains underdeveloped compared to liquid electrolyte systems. The equipment and processes for achieving higher cathode loadings in anode-free configurations require specialized manufacturing capabilities that are currently limited to a few technology leaders and research institutions.

Scaling challenges are particularly acute for solid electrolyte materials production. Current manufacturing capacity for materials like LLZO ceramic electrolytes or sulfide-based solid electrolytes remains at pilot scale, with few suppliers capable of meeting automotive-grade quality requirements at commercial volumes. This creates a significant bottleneck in the overall SSB supply chain.

Regional dependencies are evident in the SSB materials ecosystem. Japan leads in sulfide electrolyte development, South Korea in polymer electrolytes, while China dominates in cathode material production and processing. The United States and Europe have invested heavily in research but lag in manufacturing scale for most SSB components.

Future supply chain resilience will depend on developing alternative material sources and processing routes. Efforts to reduce cathode loading requirements through more efficient utilization in anode-free designs could potentially alleviate some supply constraints, particularly for critical materials like cobalt and nickel. However, these approaches require further development to reach commercial viability.

Safety and Reliability Assessment of Anode-Free SSB Designs

Safety assessment of anode-free solid-state battery (SSB) designs reveals several critical reliability challenges that must be addressed before widespread commercial adoption. The absence of a pre-deposited anode creates unique safety considerations compared to conventional lithium-ion or even traditional solid-state batteries with pre-formed anodes.

The primary safety concern in anode-free SSBs relates to lithium plating behavior during charging cycles. Without a dedicated anode structure, lithium ions from the cathode must plate directly onto the current collector, creating potential for dendritic growth that can penetrate the solid electrolyte. Recent studies by Albertus et al. (2021) demonstrate that even solid electrolytes with high mechanical strength remain vulnerable to lithium penetration under certain operating conditions.

Thermal stability represents another significant reliability challenge. Anode-free designs typically exhibit narrower operating temperature windows than conventional batteries. At elevated temperatures (>60°C), accelerated interfacial reactions between the in-situ formed lithium layer and solid electrolyte can compromise the cell's integrity. Conversely, at low temperatures (<0°C), increased impedance at the lithium/solid electrolyte interface severely impacts charging capabilities and cycle life.

Mechanical stress management emerges as a critical reliability factor unique to anode-free configurations. The repeated plating and stripping of lithium creates substantial volume changes at the current collector interface. These dimensional fluctuations generate mechanical stresses that can compromise interfacial contact, increase cell impedance, and ultimately lead to performance degradation over multiple cycles.

Long-term stability testing reveals concerning capacity fade mechanisms in most current anode-free SSB prototypes. Research by Kim et al. (2022) indicates that capacity retention after 500 cycles rarely exceeds 80% under standard testing conditions, significantly underperforming compared to conventional lithium-ion technologies. This degradation stems primarily from irreversible lithium loss during cycling and progressive deterioration of the cathode-electrolyte interface.

Safety testing protocols for anode-free SSBs require modification from standard battery evaluation procedures. Nail penetration, thermal runaway, and overcharge tests demonstrate that while anode-free designs generally offer improved safety margins compared to liquid electrolyte systems, they introduce unique failure modes requiring specialized mitigation strategies and detection methods.

Addressing these reliability challenges necessitates innovations in protective interface layers, pressure-management systems, and advanced current collector designs. Recent developments in artificial intelligence-driven battery management systems show promise for predicting and preventing safety incidents specific to anode-free configurations, potentially enabling their safe deployment in commercial applications.

The primary safety concern in anode-free SSBs relates to lithium plating behavior during charging cycles. Without a dedicated anode structure, lithium ions from the cathode must plate directly onto the current collector, creating potential for dendritic growth that can penetrate the solid electrolyte. Recent studies by Albertus et al. (2021) demonstrate that even solid electrolytes with high mechanical strength remain vulnerable to lithium penetration under certain operating conditions.

Thermal stability represents another significant reliability challenge. Anode-free designs typically exhibit narrower operating temperature windows than conventional batteries. At elevated temperatures (>60°C), accelerated interfacial reactions between the in-situ formed lithium layer and solid electrolyte can compromise the cell's integrity. Conversely, at low temperatures (<0°C), increased impedance at the lithium/solid electrolyte interface severely impacts charging capabilities and cycle life.

Mechanical stress management emerges as a critical reliability factor unique to anode-free configurations. The repeated plating and stripping of lithium creates substantial volume changes at the current collector interface. These dimensional fluctuations generate mechanical stresses that can compromise interfacial contact, increase cell impedance, and ultimately lead to performance degradation over multiple cycles.

Long-term stability testing reveals concerning capacity fade mechanisms in most current anode-free SSB prototypes. Research by Kim et al. (2022) indicates that capacity retention after 500 cycles rarely exceeds 80% under standard testing conditions, significantly underperforming compared to conventional lithium-ion technologies. This degradation stems primarily from irreversible lithium loss during cycling and progressive deterioration of the cathode-electrolyte interface.

Safety testing protocols for anode-free SSBs require modification from standard battery evaluation procedures. Nail penetration, thermal runaway, and overcharge tests demonstrate that while anode-free designs generally offer improved safety margins compared to liquid electrolyte systems, they introduce unique failure modes requiring specialized mitigation strategies and detection methods.

Addressing these reliability challenges necessitates innovations in protective interface layers, pressure-management systems, and advanced current collector designs. Recent developments in artificial intelligence-driven battery management systems show promise for predicting and preventing safety incidents specific to anode-free configurations, potentially enabling their safe deployment in commercial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!