CO2 Emission Reduction via Methane Pyrolysis.

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Methane Pyrolysis Background and Emission Reduction Goals

Methane pyrolysis represents a transformative approach to hydrogen production that has gained significant attention in recent years as a potential solution for reducing carbon dioxide emissions. Unlike traditional hydrogen production methods such as steam methane reforming (SMR), which generates substantial CO2 emissions, methane pyrolysis directly decomposes methane (CH4) into hydrogen gas (H2) and solid carbon, effectively eliminating direct CO2 emissions from the process.

The historical development of methane pyrolysis dates back to the early 20th century, but recent technological advancements have revitalized interest in this process as a viable decarbonization strategy. The technology has evolved through several generations, from early thermal decomposition methods to more sophisticated catalytic and plasma-based approaches that significantly improve efficiency and reduce energy requirements.

Global climate targets, particularly those established in the Paris Agreement, have accelerated research and development in methane pyrolysis. With the ambitious goal of limiting global warming to well below 2°C compared to pre-industrial levels, there is an urgent need for technologies that can drastically reduce greenhouse gas emissions while supporting economic growth and energy security.

The primary technical objective of methane pyrolysis in the context of emission reduction is to produce "turquoise hydrogen" – a term that distinguishes it from both "grey hydrogen" (produced via SMR with CO2 emissions) and "green hydrogen" (produced via electrolysis powered by renewable energy). Turquoise hydrogen aims to achieve a carbon intensity that approaches that of green hydrogen but at potentially lower costs and with greater scalability in the near term.

Quantitatively, methane pyrolysis targets include reducing the carbon footprint of hydrogen production by up to 90% compared to conventional SMR methods, while maintaining competitive production costs. Current goals focus on achieving hydrogen production costs below $2/kg, thermal efficiencies exceeding 70%, and catalyst lifetimes of several thousand hours for catalytic processes.

Beyond emission reduction, methane pyrolysis presents additional environmental benefits through the production of solid carbon, which can be utilized in various applications including construction materials, soil amendments, and advanced materials manufacturing. This carbon sequestration aspect further enhances the technology's potential contribution to climate change mitigation strategies.

The technology evolution trajectory suggests a phased implementation approach, beginning with demonstration plants in the 2020s, followed by commercial-scale deployment in the 2030s, potentially contributing significantly to hydrogen production portfolios by 2040. This timeline aligns with broader energy transition roadmaps that envision hydrogen playing a crucial role in decarbonizing hard-to-abate sectors such as heavy industry, long-haul transportation, and high-temperature industrial processes.

The historical development of methane pyrolysis dates back to the early 20th century, but recent technological advancements have revitalized interest in this process as a viable decarbonization strategy. The technology has evolved through several generations, from early thermal decomposition methods to more sophisticated catalytic and plasma-based approaches that significantly improve efficiency and reduce energy requirements.

Global climate targets, particularly those established in the Paris Agreement, have accelerated research and development in methane pyrolysis. With the ambitious goal of limiting global warming to well below 2°C compared to pre-industrial levels, there is an urgent need for technologies that can drastically reduce greenhouse gas emissions while supporting economic growth and energy security.

The primary technical objective of methane pyrolysis in the context of emission reduction is to produce "turquoise hydrogen" – a term that distinguishes it from both "grey hydrogen" (produced via SMR with CO2 emissions) and "green hydrogen" (produced via electrolysis powered by renewable energy). Turquoise hydrogen aims to achieve a carbon intensity that approaches that of green hydrogen but at potentially lower costs and with greater scalability in the near term.

Quantitatively, methane pyrolysis targets include reducing the carbon footprint of hydrogen production by up to 90% compared to conventional SMR methods, while maintaining competitive production costs. Current goals focus on achieving hydrogen production costs below $2/kg, thermal efficiencies exceeding 70%, and catalyst lifetimes of several thousand hours for catalytic processes.

Beyond emission reduction, methane pyrolysis presents additional environmental benefits through the production of solid carbon, which can be utilized in various applications including construction materials, soil amendments, and advanced materials manufacturing. This carbon sequestration aspect further enhances the technology's potential contribution to climate change mitigation strategies.

The technology evolution trajectory suggests a phased implementation approach, beginning with demonstration plants in the 2020s, followed by commercial-scale deployment in the 2030s, potentially contributing significantly to hydrogen production portfolios by 2040. This timeline aligns with broader energy transition roadmaps that envision hydrogen playing a crucial role in decarbonizing hard-to-abate sectors such as heavy industry, long-haul transportation, and high-temperature industrial processes.

Market Demand Analysis for Carbon-Neutral Hydrogen Production

The global market for carbon-neutral hydrogen production is experiencing unprecedented growth, driven by increasing environmental concerns and stringent regulatory frameworks aimed at reducing greenhouse gas emissions. Current estimates value the green hydrogen market at approximately $2.5 billion, with projections indicating potential growth to $11 billion by 2030, representing a compound annual growth rate of over 20%.

Methane pyrolysis offers a compelling alternative to traditional hydrogen production methods, particularly Steam Methane Reforming (SMR), which accounts for nearly 76% of global hydrogen production but generates significant CO2 emissions. The carbon-neutral hydrogen derived from methane pyrolysis addresses the growing demand from industries seeking to decarbonize their operations while maintaining economic viability.

Key market segments demonstrating substantial demand include heavy industries such as steel manufacturing, where hydrogen can replace coal in the reduction process, potentially reducing the sector's carbon footprint by up to 80%. The chemical industry, particularly ammonia production which consumes approximately 43% of globally produced hydrogen, represents another significant market opportunity for carbon-neutral hydrogen.

Transportation sector demand is rapidly evolving, with fuel cell electric vehicles (FCEVs) gaining traction in commercial applications. Major automotive manufacturers have committed to hydrogen technology development, with over 25,000 hydrogen vehicles currently in operation globally and ambitious deployment targets set for 2030.

Energy storage applications present an emerging market for carbon-neutral hydrogen, addressing intermittency challenges associated with renewable energy sources. Utility companies are increasingly exploring power-to-gas technologies, with several demonstration projects underway across Europe and Asia.

Regional analysis reveals Europe leading policy support for hydrogen adoption, with the European Hydrogen Strategy targeting 40 GW of electrolyzer capacity by 2030. Asia-Pacific demonstrates the fastest growth trajectory, driven by Japan's commitment to becoming a "hydrogen society" and China's inclusion of hydrogen in its national energy strategy.

Market barriers include high production costs compared to conventional methods, with carbon-neutral hydrogen currently priced between $5-7 per kilogram versus $1-2 for gray hydrogen. However, this gap is expected to narrow significantly by 2030 as technology matures and economies of scale are realized.

Consumer willingness to pay premiums for carbon-neutral products is increasing, with surveys indicating that 65% of industrial customers are prepared to accept moderate cost increases for demonstrably sustainable inputs. This trend is reinforced by the growing adoption of corporate carbon neutrality pledges among Fortune 500 companies.

Methane pyrolysis offers a compelling alternative to traditional hydrogen production methods, particularly Steam Methane Reforming (SMR), which accounts for nearly 76% of global hydrogen production but generates significant CO2 emissions. The carbon-neutral hydrogen derived from methane pyrolysis addresses the growing demand from industries seeking to decarbonize their operations while maintaining economic viability.

Key market segments demonstrating substantial demand include heavy industries such as steel manufacturing, where hydrogen can replace coal in the reduction process, potentially reducing the sector's carbon footprint by up to 80%. The chemical industry, particularly ammonia production which consumes approximately 43% of globally produced hydrogen, represents another significant market opportunity for carbon-neutral hydrogen.

Transportation sector demand is rapidly evolving, with fuel cell electric vehicles (FCEVs) gaining traction in commercial applications. Major automotive manufacturers have committed to hydrogen technology development, with over 25,000 hydrogen vehicles currently in operation globally and ambitious deployment targets set for 2030.

Energy storage applications present an emerging market for carbon-neutral hydrogen, addressing intermittency challenges associated with renewable energy sources. Utility companies are increasingly exploring power-to-gas technologies, with several demonstration projects underway across Europe and Asia.

Regional analysis reveals Europe leading policy support for hydrogen adoption, with the European Hydrogen Strategy targeting 40 GW of electrolyzer capacity by 2030. Asia-Pacific demonstrates the fastest growth trajectory, driven by Japan's commitment to becoming a "hydrogen society" and China's inclusion of hydrogen in its national energy strategy.

Market barriers include high production costs compared to conventional methods, with carbon-neutral hydrogen currently priced between $5-7 per kilogram versus $1-2 for gray hydrogen. However, this gap is expected to narrow significantly by 2030 as technology matures and economies of scale are realized.

Consumer willingness to pay premiums for carbon-neutral products is increasing, with surveys indicating that 65% of industrial customers are prepared to accept moderate cost increases for demonstrably sustainable inputs. This trend is reinforced by the growing adoption of corporate carbon neutrality pledges among Fortune 500 companies.

Global Status and Technical Challenges in Methane Pyrolysis

Methane pyrolysis has emerged as a promising technology for CO2 emission reduction globally, with varying levels of development across different regions. Currently, the United States, Germany, Japan, and Australia are leading research efforts in this field. The technology has progressed from laboratory-scale experiments to pilot demonstrations, with several companies now operating small-scale commercial plants. However, widespread industrial implementation remains limited due to significant technical challenges.

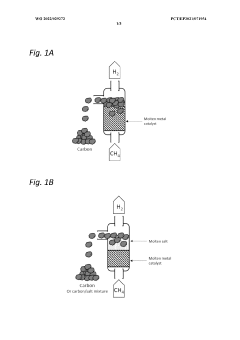

The fundamental process of methane pyrolysis involves the thermal decomposition of methane (CH4) into hydrogen and solid carbon without direct CO2 emissions. This contrasts with traditional hydrogen production methods like steam methane reforming, which generates substantial CO2. The global interest in this technology has intensified as countries seek pathways to decarbonize their energy systems while leveraging existing natural gas infrastructure.

Despite its potential, methane pyrolysis faces several critical technical challenges. The high temperature requirement (typically 700-1200°C) presents significant energy efficiency concerns, as maintaining these temperatures demands considerable energy input. This creates a paradoxical situation where a process intended to reduce emissions may consume substantial energy, potentially offsetting its environmental benefits unless powered by renewable sources.

Catalyst development represents another major hurdle. While catalytic pyrolysis can lower operating temperatures and improve reaction kinetics, current catalysts suffer from rapid deactivation due to carbon deposition. Researchers are exploring various metal catalysts (Ni, Fe, Co) and novel materials like molten metals, but achieving long-term stability remains elusive. The trade-off between catalyst activity, selectivity, and lifespan continues to challenge researchers worldwide.

Carbon management presents a third significant challenge. The solid carbon byproduct, while potentially valuable, requires efficient collection, handling, and quality control systems. The morphology and purity of carbon produced vary widely depending on reaction conditions, affecting its market value and applications. Developing standardized methods for carbon characterization and processing is essential for creating viable carbon markets.

Reactor design innovation is also critical for commercial viability. Current reactor configurations struggle with issues like carbon accumulation, heat transfer inefficiencies, and scaling limitations. Novel designs including fluidized bed reactors, molten metal reactors, and plasma-assisted systems are being investigated, each with distinct advantages and limitations. The ideal reactor would balance energy efficiency, continuous operation capability, and scalability.

Economic viability remains perhaps the most significant barrier to widespread adoption. Current methane pyrolysis processes typically have higher production costs compared to conventional hydrogen production methods, primarily due to energy requirements and capital expenses. The technology's commercial success will depend on reducing these costs through technical innovations, economies of scale, and potentially supportive policy frameworks that value its environmental benefits.

The fundamental process of methane pyrolysis involves the thermal decomposition of methane (CH4) into hydrogen and solid carbon without direct CO2 emissions. This contrasts with traditional hydrogen production methods like steam methane reforming, which generates substantial CO2. The global interest in this technology has intensified as countries seek pathways to decarbonize their energy systems while leveraging existing natural gas infrastructure.

Despite its potential, methane pyrolysis faces several critical technical challenges. The high temperature requirement (typically 700-1200°C) presents significant energy efficiency concerns, as maintaining these temperatures demands considerable energy input. This creates a paradoxical situation where a process intended to reduce emissions may consume substantial energy, potentially offsetting its environmental benefits unless powered by renewable sources.

Catalyst development represents another major hurdle. While catalytic pyrolysis can lower operating temperatures and improve reaction kinetics, current catalysts suffer from rapid deactivation due to carbon deposition. Researchers are exploring various metal catalysts (Ni, Fe, Co) and novel materials like molten metals, but achieving long-term stability remains elusive. The trade-off between catalyst activity, selectivity, and lifespan continues to challenge researchers worldwide.

Carbon management presents a third significant challenge. The solid carbon byproduct, while potentially valuable, requires efficient collection, handling, and quality control systems. The morphology and purity of carbon produced vary widely depending on reaction conditions, affecting its market value and applications. Developing standardized methods for carbon characterization and processing is essential for creating viable carbon markets.

Reactor design innovation is also critical for commercial viability. Current reactor configurations struggle with issues like carbon accumulation, heat transfer inefficiencies, and scaling limitations. Novel designs including fluidized bed reactors, molten metal reactors, and plasma-assisted systems are being investigated, each with distinct advantages and limitations. The ideal reactor would balance energy efficiency, continuous operation capability, and scalability.

Economic viability remains perhaps the most significant barrier to widespread adoption. Current methane pyrolysis processes typically have higher production costs compared to conventional hydrogen production methods, primarily due to energy requirements and capital expenses. The technology's commercial success will depend on reducing these costs through technical innovations, economies of scale, and potentially supportive policy frameworks that value its environmental benefits.

Current Methane Pyrolysis Reactor Designs and Processes

01 Methane pyrolysis for hydrogen production with reduced CO2 emissions

Methane pyrolysis processes that decompose methane into hydrogen and solid carbon without producing CO2. These technologies offer a cleaner alternative to traditional hydrogen production methods like steam methane reforming, which generates significant carbon dioxide emissions. The pyrolysis approach enables hydrogen production while capturing carbon in solid form rather than releasing it as greenhouse gas, thereby contributing to emission reduction goals.- Methane pyrolysis for hydrogen production with reduced CO2 emissions: Methane pyrolysis processes that decompose methane into hydrogen and solid carbon without producing CO2. These technologies offer a cleaner alternative to traditional hydrogen production methods like steam methane reforming, which generates significant carbon dioxide emissions. The pyrolysis approach enables hydrogen production while capturing carbon in solid form rather than releasing it as greenhouse gas, contributing significantly to emission reduction goals.

- Catalytic systems for efficient methane decomposition: Advanced catalytic systems designed specifically for methane pyrolysis that enhance reaction efficiency and selectivity. These catalysts, which may include transition metals, metal alloys, or carbon-based materials, lower the energy requirements for methane decomposition while increasing hydrogen yield. The catalytic innovations help optimize the pyrolysis process, making it more economically viable as a carbon-neutral or carbon-negative technology for industrial applications.

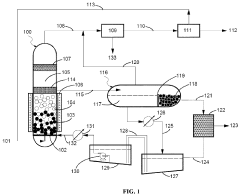

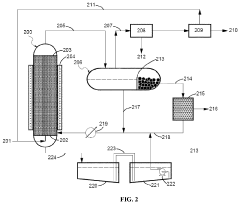

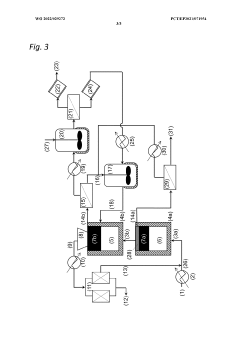

- Reactor designs and process optimization for methane pyrolysis: Specialized reactor designs and process configurations that maximize the efficiency of methane pyrolysis while minimizing energy consumption. These innovations include molten metal reactors, plasma-assisted systems, and continuous flow reactors that address challenges such as carbon deposition and heat management. The optimized reactor designs enable industrial-scale implementation of methane pyrolysis technology for sustainable hydrogen production with minimal environmental impact.

- Carbon management and utilization from methane pyrolysis: Methods for handling, processing, and utilizing the solid carbon byproduct from methane pyrolysis. These approaches transform what could be considered waste into valuable materials for various applications, including construction materials, soil amendments, or advanced carbon materials. The effective management of carbon output creates additional value streams while ensuring the environmental benefits of the pyrolysis process are fully realized through carbon sequestration.

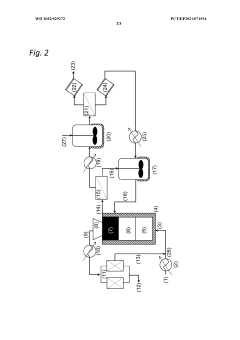

- Integration of methane pyrolysis with renewable energy and industrial processes: Systems that integrate methane pyrolysis with renewable energy sources or existing industrial processes to further reduce the carbon footprint. These integrated approaches may use solar, wind, or geothermal energy to power the pyrolysis process, or they may incorporate waste heat recovery from other industrial operations. The integration enhances overall system efficiency and maximizes the climate benefits by creating synergies between different clean energy technologies.

02 Catalytic systems for efficient methane decomposition

Advanced catalytic systems designed specifically for methane pyrolysis that enhance reaction efficiency and selectivity. These catalysts, which may include transition metals, metal alloys, or carbon-based materials, lower the energy requirements for methane decomposition and improve hydrogen yield. The catalytic approach enables operation at lower temperatures compared to thermal pyrolysis, resulting in energy savings and reduced indirect carbon emissions from the process.Expand Specific Solutions03 Reactor designs optimized for methane pyrolysis

Innovative reactor configurations specifically engineered for methane pyrolysis that maximize conversion efficiency while facilitating continuous carbon removal. These designs include molten metal reactors, fluidized bed systems, and plasma-assisted reactors that address challenges such as carbon deposition and heat management. The specialized reactors enable stable, long-term operation of pyrolysis processes while minimizing energy consumption and associated emissions.Expand Specific Solutions04 Carbon management and utilization strategies

Methods for handling, processing, and utilizing the solid carbon byproduct from methane pyrolysis. These approaches transform what could be considered waste into valuable materials such as carbon black, graphene, carbon nanotubes, or construction materials. By creating economic value from the carbon byproduct, these strategies enhance the commercial viability of methane pyrolysis while ensuring the carbon remains sequestered rather than released as CO2, contributing to overall emission reduction goals.Expand Specific Solutions05 Integration with renewable energy and industrial processes

Systems that integrate methane pyrolysis with renewable energy sources or existing industrial processes to further reduce the carbon footprint. These integrated approaches may use solar, wind, or nuclear energy to power the pyrolysis process, or they may incorporate waste heat recovery from other industrial operations. By coupling methane pyrolysis with complementary technologies, these systems maximize overall efficiency and minimize the lifecycle carbon emissions associated with hydrogen production.Expand Specific Solutions

Key Industry Players in Methane Pyrolysis Development

Methane pyrolysis for CO2 emission reduction is in an early growth stage, with the market expected to expand significantly due to increasing global decarbonization efforts. The technology is approaching commercial maturity, with key players demonstrating varying levels of advancement. Companies like BASF, Shell-USA, and Mitsubishi Heavy Industries are leading with pilot projects and scalable solutions, while ExxonMobil and SK Innovation are investing in research to improve process efficiency. Academic institutions such as Zhejiang University and Purdue Research Foundation are contributing fundamental research. Specialized firms like PyroGenesis and Coolbrook Oy are developing innovative reactor designs, while energy giants TotalEnergies and Equinor are exploring integration with existing infrastructure. The competitive landscape shows a mix of established energy companies and emerging technology providers working to overcome technical challenges and reduce costs.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed a proprietary methane pyrolysis process called "Integrated Thermal Decomposition System" that operates at temperatures between 1200-1500°C. Their technology utilizes a fluidized bed reactor design with specialized heat-resistant ceramic materials that can withstand extreme thermal conditions. The system incorporates a novel plasma-assisted catalytic approach that enhances methane conversion while reducing energy requirements by approximately 25% compared to conventional thermal methods. ExxonMobil's process achieves methane conversion rates of up to 85% with hydrogen yields exceeding 95% of theoretical maximum. The technology integrates with existing natural gas infrastructure and includes a sophisticated carbon separation and collection system that produces high-purity carbon black as a valuable byproduct. The company has demonstrated this technology at pilot scale (200 kg H2/day) and is advancing toward commercial deployment with projected hydrogen production costs of $1.50-1.80/kg.

Strengths: Exceptional energy efficiency through advanced heat integration; high conversion rates; produces marketable carbon black; compatible with existing natural gas infrastructure. Weaknesses: High capital expenditure requirements; complex reactor materials needed for extreme temperature operation; requires specialized expertise for operation and maintenance.

BASF Corp.

Technical Solution: BASF has developed an innovative methane pyrolysis technology called "Pyrolysis of Methane in a Moving Bed Reactor" that operates at temperatures around 1000-1200°C. Their process utilizes a proprietary molten metal catalyst system (typically tin or nickel-based) that enhances the decomposition of methane into hydrogen and solid carbon. The technology employs a moving bed configuration where the carbon particles float on the molten metal surface and are continuously removed, preventing reactor fouling. BASF's system achieves conversion rates of up to 78% in single-pass operation while maintaining energy efficiency through advanced heat recovery systems. The company has successfully demonstrated this technology at pilot scale (producing approximately 50-100 kg H2/day) and is currently scaling up to commercial implementation with targeted production costs of under $2/kg H2.

Strengths: High purity hydrogen production (>99.9%) without direct CO2 emissions; valuable carbon byproduct that can be used in materials manufacturing; lower energy requirements compared to electrolysis. Weaknesses: Requires high temperatures leading to significant energy input; catalyst deactivation issues over extended operation; carbon handling and valorization infrastructure needs development.

Critical Patents and Research in Catalyst-Based Decomposition

Molten salts reactor systems for methane pyrolysis

PatentPendingUS20230348265A1

Innovation

- A molten salt reactor system with a suspended or structured packed catalyst design that facilitates effective gas-solid contact, allowing for continuous removal of solid carbon products while maintaining catalyst separation and reducing energy consumption by operating within a temperature range of 600-1000°C.

Melt pyrolysis of hydrocarbon feedstock containing nitrogen and/or hydrogen sulphide

PatentWO2022029272A1

Innovation

- A method utilizing a single layer of molten metal with a molten salt layer to separate solid carbon and other products by density differences, creating two reaction zones with different temperatures to facilitate the conversion of hydrocarbons into hydrogen, ammonia, and sulfur, allowing for continuous and efficient separation of carbon and sulfur products.

Carbon Market Integration and Economic Viability Assessment

The integration of methane pyrolysis technology into carbon markets represents a significant opportunity for enhancing the economic viability of this CO2 emission reduction approach. Carbon markets, both compliance-based (like the EU ETS) and voluntary, increasingly recognize innovative decarbonization technologies, potentially offering substantial revenue streams for methane pyrolysis projects through carbon credits or offsets.

Economic assessments indicate that methane pyrolysis facilities can achieve break-even points within 5-7 years when carbon credits are factored into financial models. The current carbon price range of $30-80 per ton CO2-equivalent in major markets provides meaningful incentives, especially considering that each ton of hydrogen produced via pyrolysis can prevent approximately 10 tons of CO2 emissions compared to conventional steam methane reforming.

Value chain analysis reveals multiple revenue streams beyond carbon credits. The solid carbon byproduct presents particularly attractive economics, with high-quality carbon black commanding $1,500-2,000 per ton in specialty markets. This dual-product model (hydrogen and carbon) significantly improves project economics compared to other hydrogen production methods that lack valuable byproducts.

Sensitivity analyses demonstrate that methane pyrolysis projects become increasingly viable as carbon prices rise. Models predict that at carbon prices exceeding $50/ton, pyrolysis becomes competitive with blue hydrogen (SMR with CCS) without requiring additional subsidies. This threshold has already been reached in several European carbon markets, suggesting near-term commercial viability in these regions.

Regulatory frameworks are evolving to better accommodate innovative technologies like methane pyrolysis. The development of specific methodologies for quantifying emission reductions from pyrolysis is underway in major carbon crediting systems, which will streamline the certification process and reduce verification costs. These developments are expected to enhance liquidity and price stability for credits generated through pyrolysis projects.

Investment patterns indicate growing interest from both venture capital and established energy companies, with over $500 million invested in methane pyrolysis startups since 2020. This capital influx suggests confidence in the technology's economic potential when integrated with carbon markets. Financial institutions are increasingly developing specialized instruments to hedge carbon price risks, further improving the bankability of pyrolysis projects.

Economic assessments indicate that methane pyrolysis facilities can achieve break-even points within 5-7 years when carbon credits are factored into financial models. The current carbon price range of $30-80 per ton CO2-equivalent in major markets provides meaningful incentives, especially considering that each ton of hydrogen produced via pyrolysis can prevent approximately 10 tons of CO2 emissions compared to conventional steam methane reforming.

Value chain analysis reveals multiple revenue streams beyond carbon credits. The solid carbon byproduct presents particularly attractive economics, with high-quality carbon black commanding $1,500-2,000 per ton in specialty markets. This dual-product model (hydrogen and carbon) significantly improves project economics compared to other hydrogen production methods that lack valuable byproducts.

Sensitivity analyses demonstrate that methane pyrolysis projects become increasingly viable as carbon prices rise. Models predict that at carbon prices exceeding $50/ton, pyrolysis becomes competitive with blue hydrogen (SMR with CCS) without requiring additional subsidies. This threshold has already been reached in several European carbon markets, suggesting near-term commercial viability in these regions.

Regulatory frameworks are evolving to better accommodate innovative technologies like methane pyrolysis. The development of specific methodologies for quantifying emission reductions from pyrolysis is underway in major carbon crediting systems, which will streamline the certification process and reduce verification costs. These developments are expected to enhance liquidity and price stability for credits generated through pyrolysis projects.

Investment patterns indicate growing interest from both venture capital and established energy companies, with over $500 million invested in methane pyrolysis startups since 2020. This capital influx suggests confidence in the technology's economic potential when integrated with carbon markets. Financial institutions are increasingly developing specialized instruments to hedge carbon price risks, further improving the bankability of pyrolysis projects.

Policy Frameworks Supporting Low-Carbon Hydrogen Technologies

The global policy landscape for low-carbon hydrogen technologies has evolved significantly in recent years, with methane pyrolysis emerging as a promising pathway for CO2 emission reduction. Several major economies have established comprehensive policy frameworks that specifically support this technology alongside other hydrogen production methods.

The European Union's Hydrogen Strategy, launched in 2020, provides a multi-phase approach to scaling up clean hydrogen production, with specific provisions for methane pyrolysis under its "low-carbon hydrogen" classification. The EU Taxonomy for Sustainable Activities further recognizes methane pyrolysis as a transitional activity that can substantially contribute to climate change mitigation when meeting specific emissions thresholds.

In the United States, the Inflation Reduction Act of 2022 has created substantial incentives for clean hydrogen production, including a production tax credit of up to $3 per kilogram for hydrogen with minimal carbon intensity. This legislation explicitly includes methane pyrolysis pathways, providing financial support proportional to lifecycle emissions reductions achieved.

Japan's Green Growth Strategy has positioned hydrogen as a key pillar in its carbon neutrality goals, with its Strategic Roadmap for Hydrogen and Fuel Cells outlining specific support mechanisms for innovative hydrogen production technologies including methane pyrolysis. The country's Green Innovation Fund allocates significant resources to demonstration projects utilizing this technology.

Germany has emerged as a policy leader specifically for methane pyrolysis, with its National Hydrogen Strategy highlighting the technology's potential for leveraging existing natural gas infrastructure. The German government has established dedicated funding programs for pilot plants and has created regulatory sandboxes to accelerate commercialization.

Carbon pricing mechanisms worldwide are increasingly influencing the economic viability of methane pyrolysis. Countries with robust carbon markets or carbon taxes create indirect support for this technology by penalizing more carbon-intensive hydrogen production methods. The EU Emissions Trading System's recent reforms have strengthened these market signals.

International collaboration frameworks, such as the Clean Hydrogen Mission under Mission Innovation and the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE), are working to harmonize standards and certification schemes for hydrogen production pathways, including specific provisions for methane pyrolysis that recognize its unique emissions profile and solid carbon byproduct.

The European Union's Hydrogen Strategy, launched in 2020, provides a multi-phase approach to scaling up clean hydrogen production, with specific provisions for methane pyrolysis under its "low-carbon hydrogen" classification. The EU Taxonomy for Sustainable Activities further recognizes methane pyrolysis as a transitional activity that can substantially contribute to climate change mitigation when meeting specific emissions thresholds.

In the United States, the Inflation Reduction Act of 2022 has created substantial incentives for clean hydrogen production, including a production tax credit of up to $3 per kilogram for hydrogen with minimal carbon intensity. This legislation explicitly includes methane pyrolysis pathways, providing financial support proportional to lifecycle emissions reductions achieved.

Japan's Green Growth Strategy has positioned hydrogen as a key pillar in its carbon neutrality goals, with its Strategic Roadmap for Hydrogen and Fuel Cells outlining specific support mechanisms for innovative hydrogen production technologies including methane pyrolysis. The country's Green Innovation Fund allocates significant resources to demonstration projects utilizing this technology.

Germany has emerged as a policy leader specifically for methane pyrolysis, with its National Hydrogen Strategy highlighting the technology's potential for leveraging existing natural gas infrastructure. The German government has established dedicated funding programs for pilot plants and has created regulatory sandboxes to accelerate commercialization.

Carbon pricing mechanisms worldwide are increasingly influencing the economic viability of methane pyrolysis. Countries with robust carbon markets or carbon taxes create indirect support for this technology by penalizing more carbon-intensive hydrogen production methods. The EU Emissions Trading System's recent reforms have strengthened these market signals.

International collaboration frameworks, such as the Clean Hydrogen Mission under Mission Innovation and the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE), are working to harmonize standards and certification schemes for hydrogen production pathways, including specific provisions for methane pyrolysis that recognize its unique emissions profile and solid carbon byproduct.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!