Supply Chain Logistics for Methane Pyrolysis Facilities.

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Methane Pyrolysis Technology Background and Objectives

Methane pyrolysis represents a transformative approach to hydrogen production that has gained significant attention over the past decade. This process involves the thermal decomposition of methane (CH4) into hydrogen (H2) and solid carbon, offering a potentially low-carbon alternative to traditional hydrogen production methods such as steam methane reforming (SMR). The evolution of methane pyrolysis technology can be traced back to the early 20th century, but recent advancements in catalysts, reactor designs, and process intensification have dramatically improved its commercial viability.

The technology has progressed through several developmental phases, beginning with basic thermal decomposition approaches that required extremely high temperatures (>1000°C), to more recent innovations utilizing molten metal catalysts, plasma-assisted decomposition, and microwave-induced pyrolysis that operate at significantly lower temperatures and with greater efficiency. These advancements have positioned methane pyrolysis as a promising pathway for "turquoise hydrogen" production—a middle ground between "grey" (fossil-based) and "green" (renewable-based) hydrogen.

Current technological trends in methane pyrolysis focus on improving energy efficiency, increasing hydrogen yield, developing more durable catalysts, and finding valuable applications for the carbon byproduct. The carbon produced through methane pyrolysis can potentially be used in various industries including construction materials, battery production, and carbon fiber manufacturing, creating additional value streams beyond hydrogen production.

The primary technical objectives for methane pyrolysis facilities include achieving continuous operation at industrial scale, reducing energy inputs, optimizing reactor designs for improved heat transfer, developing robust supply chain logistics, and minimizing operational costs to compete with established hydrogen production methods. Particular emphasis is placed on developing systems that can operate reliably with minimal maintenance requirements and that can be integrated into existing natural gas infrastructure.

From a sustainability perspective, methane pyrolysis aims to provide a pathway for hydrogen production with significantly lower greenhouse gas emissions compared to conventional methods. When powered by renewable energy sources, the process can approach carbon-neutrality, with the added benefit of sequestering carbon in solid form rather than releasing it as CO2. This aligns with global decarbonization goals and hydrogen economy initiatives being pursued by numerous countries and industrial sectors.

The ultimate goal for methane pyrolysis technology development is to establish economically viable, large-scale production facilities that can contribute significantly to the growing hydrogen market while offering environmental advantages over traditional production methods. This requires addressing not only the core technology challenges but also the associated supply chain logistics to ensure efficient operation and market competitiveness.

The technology has progressed through several developmental phases, beginning with basic thermal decomposition approaches that required extremely high temperatures (>1000°C), to more recent innovations utilizing molten metal catalysts, plasma-assisted decomposition, and microwave-induced pyrolysis that operate at significantly lower temperatures and with greater efficiency. These advancements have positioned methane pyrolysis as a promising pathway for "turquoise hydrogen" production—a middle ground between "grey" (fossil-based) and "green" (renewable-based) hydrogen.

Current technological trends in methane pyrolysis focus on improving energy efficiency, increasing hydrogen yield, developing more durable catalysts, and finding valuable applications for the carbon byproduct. The carbon produced through methane pyrolysis can potentially be used in various industries including construction materials, battery production, and carbon fiber manufacturing, creating additional value streams beyond hydrogen production.

The primary technical objectives for methane pyrolysis facilities include achieving continuous operation at industrial scale, reducing energy inputs, optimizing reactor designs for improved heat transfer, developing robust supply chain logistics, and minimizing operational costs to compete with established hydrogen production methods. Particular emphasis is placed on developing systems that can operate reliably with minimal maintenance requirements and that can be integrated into existing natural gas infrastructure.

From a sustainability perspective, methane pyrolysis aims to provide a pathway for hydrogen production with significantly lower greenhouse gas emissions compared to conventional methods. When powered by renewable energy sources, the process can approach carbon-neutrality, with the added benefit of sequestering carbon in solid form rather than releasing it as CO2. This aligns with global decarbonization goals and hydrogen economy initiatives being pursued by numerous countries and industrial sectors.

The ultimate goal for methane pyrolysis technology development is to establish economically viable, large-scale production facilities that can contribute significantly to the growing hydrogen market while offering environmental advantages over traditional production methods. This requires addressing not only the core technology challenges but also the associated supply chain logistics to ensure efficient operation and market competitiveness.

Market Demand Analysis for Hydrogen Production via Pyrolysis

The global hydrogen market is experiencing significant growth, with demand projected to reach 94 million tons by 2030, representing a compound annual growth rate (CAGR) of approximately 5.6% from 2023. Traditional hydrogen production methods, primarily steam methane reforming (SMR), account for over 76% of current production but generate substantial CO2 emissions—approximately 9-12 kg CO2 per kg H2 produced. This environmental impact has created a strong market pull for cleaner alternatives like methane pyrolysis.

Methane pyrolysis offers a compelling value proposition by producing hydrogen without direct CO2 emissions, yielding solid carbon as a byproduct instead. This "turquoise hydrogen" occupies a strategic middle ground between gray hydrogen (from SMR) and green hydrogen (from electrolysis), combining relatively low production costs with significantly reduced environmental impact.

Market analysis indicates that industrial sectors represent the primary demand drivers for hydrogen produced via pyrolysis. The chemical industry, which consumes approximately 45% of global hydrogen production, seeks carbon-neutral feedstock for ammonia and methanol production. Refineries, accounting for roughly 33% of hydrogen consumption, face increasing regulatory pressure to reduce the carbon intensity of their operations, making pyrolysis-derived hydrogen an attractive alternative.

The transportation sector presents a rapidly expanding market opportunity, with hydrogen fuel cell vehicles gaining traction particularly in heavy-duty applications. Market forecasts suggest that hydrogen demand for mobility could grow tenfold by 2050, with clean hydrogen production methods like pyrolysis well-positioned to capture significant market share.

Geographically, regions with abundant natural gas resources coupled with stringent carbon regulations present the most favorable markets for methane pyrolysis technology. The European Union, with its ambitious hydrogen strategy targeting 40 GW of electrolyzer capacity by 2030, has created a supportive policy environment for all low-carbon hydrogen production methods, including pyrolysis.

The economic viability of methane pyrolysis is further enhanced by the potential revenue streams from carbon byproducts. High-quality carbon black, graphite, and carbon nanotubes produced during pyrolysis can serve markets ranging from tire manufacturing to advanced materials, potentially offsetting production costs by 15-30% depending on carbon quality and market conditions.

Investor interest in pyrolysis technologies has grown substantially, with venture capital funding in this sector increasing by over 200% between 2020 and 2023. This reflects market confidence in the technology's potential to deliver cost-competitive clean hydrogen at scale, particularly as carbon pricing mechanisms become more widespread globally.

Methane pyrolysis offers a compelling value proposition by producing hydrogen without direct CO2 emissions, yielding solid carbon as a byproduct instead. This "turquoise hydrogen" occupies a strategic middle ground between gray hydrogen (from SMR) and green hydrogen (from electrolysis), combining relatively low production costs with significantly reduced environmental impact.

Market analysis indicates that industrial sectors represent the primary demand drivers for hydrogen produced via pyrolysis. The chemical industry, which consumes approximately 45% of global hydrogen production, seeks carbon-neutral feedstock for ammonia and methanol production. Refineries, accounting for roughly 33% of hydrogen consumption, face increasing regulatory pressure to reduce the carbon intensity of their operations, making pyrolysis-derived hydrogen an attractive alternative.

The transportation sector presents a rapidly expanding market opportunity, with hydrogen fuel cell vehicles gaining traction particularly in heavy-duty applications. Market forecasts suggest that hydrogen demand for mobility could grow tenfold by 2050, with clean hydrogen production methods like pyrolysis well-positioned to capture significant market share.

Geographically, regions with abundant natural gas resources coupled with stringent carbon regulations present the most favorable markets for methane pyrolysis technology. The European Union, with its ambitious hydrogen strategy targeting 40 GW of electrolyzer capacity by 2030, has created a supportive policy environment for all low-carbon hydrogen production methods, including pyrolysis.

The economic viability of methane pyrolysis is further enhanced by the potential revenue streams from carbon byproducts. High-quality carbon black, graphite, and carbon nanotubes produced during pyrolysis can serve markets ranging from tire manufacturing to advanced materials, potentially offsetting production costs by 15-30% depending on carbon quality and market conditions.

Investor interest in pyrolysis technologies has grown substantially, with venture capital funding in this sector increasing by over 200% between 2020 and 2023. This reflects market confidence in the technology's potential to deliver cost-competitive clean hydrogen at scale, particularly as carbon pricing mechanisms become more widespread globally.

Current Logistics Challenges in Methane Pyrolysis Supply Chain

Methane pyrolysis facilities face significant logistical challenges across their supply chain networks. The process of converting methane into hydrogen and solid carbon requires specialized infrastructure and creates unique material handling requirements that conventional logistics systems are not optimized to address. These facilities must manage the inbound flow of methane feedstock, which often requires specialized transportation methods including high-pressure pipelines or cryogenic tankers for liquefied natural gas.

The transportation of solid carbon byproducts presents a particularly complex challenge. Unlike traditional petrochemical processes that produce liquid or gaseous byproducts, methane pyrolysis generates substantial volumes of solid carbon that must be collected, stored, and transported. Current logistics systems lack standardized handling protocols for this material, resulting in inefficient operations and increased costs. The carbon's physical properties—including particle size, density, and potential for dust generation—create handling difficulties throughout the supply chain.

Equipment compatibility issues further complicate logistics operations. The specialized nature of methane pyrolysis technology means that standard material handling equipment often requires significant modification or complete replacement. This incompatibility extends to storage facilities, transportation containers, and loading/unloading systems, creating bottlenecks in the supply chain and increasing capital requirements.

Geographical constraints add another layer of complexity. Methane pyrolysis facilities ideally should be located near both natural gas sources and hydrogen consumers to minimize transportation costs. However, this optimal positioning is rarely achievable, necessitating complex multi-modal transportation networks that must balance efficiency with practicality. The resulting extended supply chains increase vulnerability to disruptions and complicate inventory management.

Regulatory compliance presents evolving challenges, particularly regarding the transportation of hydrogen. Current regulations for hydrogen transport were largely developed for industrial applications rather than energy distribution, creating uncertainty and potential barriers to efficient logistics operations. Similarly, the classification and transportation requirements for solid carbon byproducts remain inconsistently defined across different jurisdictions.

Digital integration limitations hinder supply chain visibility and optimization. Many methane pyrolysis operations lack end-to-end digital tracking systems that can monitor material flows, predict maintenance needs, and optimize logistics scheduling. This technological gap prevents the implementation of advanced supply chain management techniques such as predictive analytics and real-time optimization that could significantly improve operational efficiency.

The nascent state of the industry means there is limited standardization across equipment, processes, and materials handling protocols. This lack of standardization complicates efforts to develop shared logistics infrastructure or industry-wide best practices, forcing each facility to develop customized solutions at significant cost.

The transportation of solid carbon byproducts presents a particularly complex challenge. Unlike traditional petrochemical processes that produce liquid or gaseous byproducts, methane pyrolysis generates substantial volumes of solid carbon that must be collected, stored, and transported. Current logistics systems lack standardized handling protocols for this material, resulting in inefficient operations and increased costs. The carbon's physical properties—including particle size, density, and potential for dust generation—create handling difficulties throughout the supply chain.

Equipment compatibility issues further complicate logistics operations. The specialized nature of methane pyrolysis technology means that standard material handling equipment often requires significant modification or complete replacement. This incompatibility extends to storage facilities, transportation containers, and loading/unloading systems, creating bottlenecks in the supply chain and increasing capital requirements.

Geographical constraints add another layer of complexity. Methane pyrolysis facilities ideally should be located near both natural gas sources and hydrogen consumers to minimize transportation costs. However, this optimal positioning is rarely achievable, necessitating complex multi-modal transportation networks that must balance efficiency with practicality. The resulting extended supply chains increase vulnerability to disruptions and complicate inventory management.

Regulatory compliance presents evolving challenges, particularly regarding the transportation of hydrogen. Current regulations for hydrogen transport were largely developed for industrial applications rather than energy distribution, creating uncertainty and potential barriers to efficient logistics operations. Similarly, the classification and transportation requirements for solid carbon byproducts remain inconsistently defined across different jurisdictions.

Digital integration limitations hinder supply chain visibility and optimization. Many methane pyrolysis operations lack end-to-end digital tracking systems that can monitor material flows, predict maintenance needs, and optimize logistics scheduling. This technological gap prevents the implementation of advanced supply chain management techniques such as predictive analytics and real-time optimization that could significantly improve operational efficiency.

The nascent state of the industry means there is limited standardization across equipment, processes, and materials handling protocols. This lack of standardization complicates efforts to develop shared logistics infrastructure or industry-wide best practices, forcing each facility to develop customized solutions at significant cost.

Current Supply Chain Management Solutions for Pyrolysis Operations

01 Reactor designs for methane pyrolysis

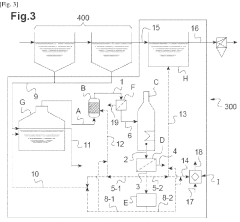

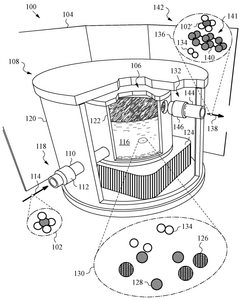

Various reactor designs have been developed for methane pyrolysis facilities to efficiently convert methane into hydrogen and solid carbon. These designs include fluidized bed reactors, molten metal reactors, and plasma-based systems. Each design offers specific advantages in terms of conversion efficiency, energy consumption, and carbon handling. The reactor configuration plays a crucial role in determining the overall performance and economic viability of methane pyrolysis facilities.- Reactor designs for methane pyrolysis: Various reactor designs are employed for methane pyrolysis facilities, including fluidized bed reactors, molten metal reactors, and plasma reactors. These designs aim to optimize the thermal decomposition of methane into hydrogen and solid carbon. The reactor configuration affects factors such as conversion efficiency, energy consumption, and carbon product quality. Advanced designs incorporate features for continuous operation, improved heat transfer, and catalyst integration.

- Catalytic systems for methane decomposition: Catalytic systems play a crucial role in methane pyrolysis facilities by lowering the activation energy required for decomposition and improving process efficiency. Various catalysts including transition metals (Ni, Fe, Co), metal alloys, and carbon-based materials are utilized. These catalysts can be supported on different substrates to enhance their stability and activity. Catalyst design focuses on maximizing hydrogen yield while minimizing deactivation caused by carbon deposition.

- Carbon capture and utilization systems: Methane pyrolysis facilities incorporate specialized systems for capturing, processing, and utilizing the solid carbon byproduct. These systems include separation units, carbon handling equipment, and post-processing technologies to convert raw carbon into valuable products such as carbon black, graphite, or carbon nanotubes. Advanced facilities integrate continuous carbon removal to prevent reactor fouling while maintaining process efficiency and enabling the production of high-purity carbon materials with tailored properties.

- Heat management and energy efficiency: Effective heat management is critical in methane pyrolysis facilities to maintain optimal reaction temperatures (typically 700-1200°C) while minimizing energy consumption. Systems employ various heating methods including electrical resistance, induction heating, concentrated solar, and partial oxidation. Heat recovery systems capture and recycle thermal energy from process streams. Advanced facilities integrate renewable energy sources and utilize innovative heat transfer media such as molten metals or salts to improve overall energy efficiency and reduce operational costs.

- Process control and automation systems: Modern methane pyrolysis facilities utilize sophisticated process control and automation systems to optimize operation, ensure safety, and maintain product quality. These systems monitor and regulate critical parameters such as temperature, pressure, flow rates, and gas composition in real-time. Advanced control strategies incorporate predictive modeling, machine learning algorithms, and digital twins to anticipate process deviations and implement corrective actions. Automation extends to catalyst regeneration cycles, carbon removal operations, and maintenance scheduling to maximize facility uptime and operational efficiency.

02 Catalytic systems for methane decomposition

Catalytic systems are employed in methane pyrolysis facilities to lower the activation energy required for methane decomposition. Various catalysts including transition metals, metal alloys, and carbon-based materials can significantly enhance the reaction kinetics and selectivity. The choice of catalyst affects the purity of hydrogen produced, the morphology of carbon deposits, and the overall energy efficiency of the process. Catalyst development focuses on improving stability, activity, and resistance to deactivation under pyrolysis conditions.Expand Specific Solutions03 Carbon management and utilization systems

Methane pyrolysis facilities incorporate specialized systems for managing and utilizing the solid carbon byproduct. These systems include carbon separation units, handling equipment, and storage facilities. The carbon produced can be processed into various forms such as carbon black, graphite, or carbon nanotubes, depending on the process conditions. Advanced facilities integrate carbon valorization pathways to transform this byproduct into valuable materials for applications in construction, electronics, and advanced materials manufacturing.Expand Specific Solutions04 Heat management and energy integration

Effective heat management and energy integration are critical aspects of methane pyrolysis facilities. These facilities employ various heating methods including electrical heating, microwave heating, or indirect heating through heat exchangers. Energy recovery systems capture and reuse thermal energy from the high-temperature pyrolysis process. Advanced facilities incorporate heat integration strategies to minimize external energy inputs and improve overall energy efficiency, making the hydrogen production process more economically viable and environmentally sustainable.Expand Specific Solutions05 Process control and monitoring systems

Sophisticated process control and monitoring systems are essential components of modern methane pyrolysis facilities. These systems include temperature controllers, pressure regulators, flow meters, and gas analyzers that ensure optimal operating conditions. Real-time monitoring enables precise control of reaction parameters to maximize hydrogen yield while maintaining product quality. Advanced facilities incorporate automation and digital technologies for process optimization, predictive maintenance, and safety management, enhancing operational reliability and reducing downtime.Expand Specific Solutions

Key Industry Players in Methane Pyrolysis Logistics

The methane pyrolysis supply chain logistics market is in an early growth phase, characterized by increasing investments but limited commercial-scale facilities. The market is projected to expand significantly as hydrogen demand grows, with current estimates suggesting a multi-billion dollar opportunity by 2030. Technologically, the field shows varying maturity levels across different players. Industry leaders like Air Liquide, ExxonMobil, and Shell are advancing proprietary technologies, while specialized firms such as Molten Industries and BASF are developing innovative catalytic processes. Research institutions including South China University of Technology and Korea Institute of Energy Research are contributing fundamental breakthroughs. The competitive landscape features both established energy corporations (SABIC, Air Products) and emerging technology providers, with increasing collaboration between sectors to overcome logistics challenges.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has pioneered an integrated supply chain management system for methane pyrolysis facilities focused on maximizing operational efficiency and minimizing carbon footprint. Their approach incorporates advanced digital twin technology to simulate and optimize the entire supply chain from natural gas sourcing to hydrogen and carbon black distribution. Shell's system features adaptive scheduling algorithms that respond to fluctuations in feedstock availability, energy prices, and market demand. The company has developed specialized logistics protocols for handling the solid carbon byproduct, including modular packaging systems and dedicated transport solutions that prevent contamination. Their platform also includes comprehensive carbon accounting tools that track emissions throughout the supply chain, supporting regulatory compliance and carbon credit generation.

Strengths: Global presence with extensive natural gas supply networks; Advanced digital capabilities for supply chain optimization; Strong integration with existing energy infrastructure. Weaknesses: Complex implementation requiring significant coordination across multiple business units; Higher initial capital requirements compared to conventional hydrogen production logistics.

Air Products & Chemicals, Inc.

Technical Solution: Air Products has developed an advanced supply chain logistics system for methane pyrolysis facilities that integrates real-time monitoring and predictive analytics. Their solution employs IoT sensors throughout the supply chain to track critical parameters such as temperature, pressure, and flow rates. The company utilizes a hub-and-spoke distribution model specifically designed for hydrogen and carbon black products resulting from methane pyrolysis. Their logistics platform incorporates blockchain technology for transparent tracking of carbon credits associated with the low-carbon hydrogen production. Air Products has also implemented specialized transportation solutions for handling high-purity hydrogen, including dedicated pipeline networks and cryogenic transport vessels that maintain product integrity throughout the distribution process.

Strengths: Extensive existing hydrogen infrastructure network; Decades of experience in industrial gas logistics; Comprehensive end-to-end supply chain visibility. Weaknesses: Higher implementation costs compared to conventional logistics systems; Requires significant capital investment in specialized transport equipment.

Critical Technologies in Methane Pyrolysis Logistics

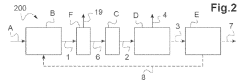

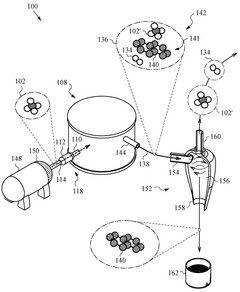

Methane pyrolysis process with recirculation of the solid carbon produced

PatentPendingFR3138136A1

Innovation

- Recirculating solid carbon produced during methane pyrolysis as an adsorbent media for pollutant removal, eliminating the need for expensive adsorbents by using it in fixed bed reactors and cyclonic or filtration separation methods, and optionally shaping it for enhanced use.

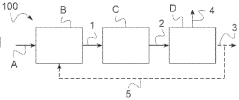

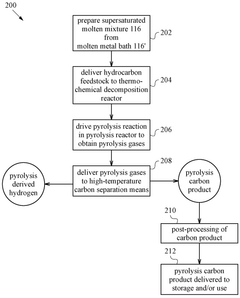

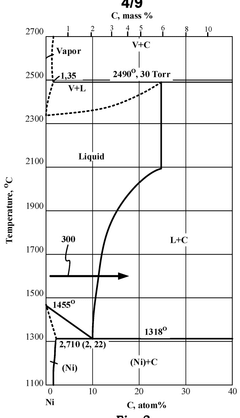

Methane pyrolysis in a supersaturated molten mixture of metal and carbon

PatentWO2025085450A1

Innovation

- The process involves performing methane pyrolysis in a supersaturated molten mixture of metal and carbon, where the metal is selected from among Mn, Fe, Co, and Ni or their alloys, and the mixture is heated to maintain supersaturation with carbon, allowing for the formation of highly graphitic carbon and hydrogen.

Carbon Management Strategies in Pyrolysis Supply Networks

Carbon management represents a critical dimension in methane pyrolysis supply networks, particularly as this technology gains prominence as a low-carbon hydrogen production method. The pyrolysis process generates solid carbon as a byproduct, creating both challenges and opportunities within the supply chain ecosystem. Effective carbon management strategies must address collection, transportation, quality control, and market development for these carbon materials.

The carbon produced through methane pyrolysis varies significantly in quality and characteristics depending on process conditions. High-quality carbon black or graphite commands premium prices in specialized markets, while lower-grade carbon requires different handling and application pathways. This quality spectrum necessitates sophisticated sorting, grading, and processing systems integrated directly into pyrolysis facility logistics.

Transportation infrastructure for solid carbon presents unique challenges compared to gaseous or liquid byproducts. Carbon dust management, moisture control, and contamination prevention require specialized containment systems during transport. The physical properties of different carbon forms (powders, granules, or structured carbon) dictate distinct handling protocols and equipment requirements throughout the supply network.

Market development for pyrolysis-derived carbon represents a strategic opportunity to enhance overall process economics. Current applications span diverse industries including rubber manufacturing, metallurgy, construction materials, and emerging fields like advanced battery technologies. Supply chain design must accommodate multiple potential offtake pathways, allowing flexibility as carbon markets evolve and mature.

Circular economy principles increasingly influence carbon management strategies, with emphasis on designing supply networks that facilitate carbon product reuse and recycling. This approach requires traceability systems tracking carbon quality parameters throughout the value chain, enabling appropriate matching between carbon characteristics and end-use applications.

Regulatory frameworks governing carbon handling vary significantly across regions, impacting logistics planning and compliance requirements. Carbon storage protocols, transportation permits, and quality certification standards must be integrated into supply chain design. Forward-looking logistics systems anticipate regulatory evolution, particularly regarding carbon accounting and potential carbon credit mechanisms applicable to permanently sequestered carbon products.

Digital technologies enable optimization of carbon management through real-time tracking, predictive quality assessment, and market matching algorithms. These systems can significantly reduce logistics costs while maximizing carbon value recovery, creating competitive advantages for pyrolysis operators with sophisticated carbon management capabilities.

The carbon produced through methane pyrolysis varies significantly in quality and characteristics depending on process conditions. High-quality carbon black or graphite commands premium prices in specialized markets, while lower-grade carbon requires different handling and application pathways. This quality spectrum necessitates sophisticated sorting, grading, and processing systems integrated directly into pyrolysis facility logistics.

Transportation infrastructure for solid carbon presents unique challenges compared to gaseous or liquid byproducts. Carbon dust management, moisture control, and contamination prevention require specialized containment systems during transport. The physical properties of different carbon forms (powders, granules, or structured carbon) dictate distinct handling protocols and equipment requirements throughout the supply network.

Market development for pyrolysis-derived carbon represents a strategic opportunity to enhance overall process economics. Current applications span diverse industries including rubber manufacturing, metallurgy, construction materials, and emerging fields like advanced battery technologies. Supply chain design must accommodate multiple potential offtake pathways, allowing flexibility as carbon markets evolve and mature.

Circular economy principles increasingly influence carbon management strategies, with emphasis on designing supply networks that facilitate carbon product reuse and recycling. This approach requires traceability systems tracking carbon quality parameters throughout the value chain, enabling appropriate matching between carbon characteristics and end-use applications.

Regulatory frameworks governing carbon handling vary significantly across regions, impacting logistics planning and compliance requirements. Carbon storage protocols, transportation permits, and quality certification standards must be integrated into supply chain design. Forward-looking logistics systems anticipate regulatory evolution, particularly regarding carbon accounting and potential carbon credit mechanisms applicable to permanently sequestered carbon products.

Digital technologies enable optimization of carbon management through real-time tracking, predictive quality assessment, and market matching algorithms. These systems can significantly reduce logistics costs while maximizing carbon value recovery, creating competitive advantages for pyrolysis operators with sophisticated carbon management capabilities.

Regulatory Framework for Methane Pyrolysis Material Transport

The regulatory landscape governing methane pyrolysis material transport is complex and multifaceted, spanning international, national, and local jurisdictions. At the international level, the transport of hydrogen—a primary product of methane pyrolysis—falls under dangerous goods regulations such as the UN Recommendations on the Transport of Dangerous Goods, which classifies hydrogen as a Class 2.1 flammable gas. These recommendations form the basis for modal regulations including the International Maritime Dangerous Goods (IMDG) Code and the International Civil Aviation Organization (ICAO) Technical Instructions.

In the United States, the Department of Transportation's Pipeline and Hazardous Materials Safety Administration (PHMSA) regulates hydrogen transport through 49 CFR Parts 171-180, with specific provisions for compressed gases in cylinders, tube trailers, and pipelines. The Occupational Safety and Health Administration (OSHA) further imposes workplace safety requirements through 29 CFR 1910.103, specifically addressing hydrogen handling.

For carbon black—another valuable byproduct of methane pyrolysis—transport regulations are less stringent as it is generally not classified as hazardous. However, as a fine particulate, it falls under dust control regulations during handling and transport, with requirements varying by jurisdiction.

The European Union's regulatory framework includes the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) and the Regulations concerning the International Carriage of Dangerous Goods by Rail (RID), both of which contain specific provisions for hydrogen transport. Additionally, the EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation may apply to carbon black depending on production volume and intended use.

Emerging regulatory trends include increasing focus on lifecycle carbon accounting, with several jurisdictions developing frameworks to certify and track the carbon intensity of hydrogen production methods. This is particularly relevant for methane pyrolysis, which produces "turquoise hydrogen" with potentially lower carbon footprint than traditional methods.

Compliance challenges for methane pyrolysis facilities include navigating inconsistent regulations across jurisdictions, particularly for cross-border transport. The novelty of large-scale methane pyrolysis also means that regulatory frameworks may be evolving, requiring operators to maintain vigilance regarding changing requirements and potentially participate in the development of new standards specific to turquoise hydrogen and its byproducts.

In the United States, the Department of Transportation's Pipeline and Hazardous Materials Safety Administration (PHMSA) regulates hydrogen transport through 49 CFR Parts 171-180, with specific provisions for compressed gases in cylinders, tube trailers, and pipelines. The Occupational Safety and Health Administration (OSHA) further imposes workplace safety requirements through 29 CFR 1910.103, specifically addressing hydrogen handling.

For carbon black—another valuable byproduct of methane pyrolysis—transport regulations are less stringent as it is generally not classified as hazardous. However, as a fine particulate, it falls under dust control regulations during handling and transport, with requirements varying by jurisdiction.

The European Union's regulatory framework includes the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) and the Regulations concerning the International Carriage of Dangerous Goods by Rail (RID), both of which contain specific provisions for hydrogen transport. Additionally, the EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation may apply to carbon black depending on production volume and intended use.

Emerging regulatory trends include increasing focus on lifecycle carbon accounting, with several jurisdictions developing frameworks to certify and track the carbon intensity of hydrogen production methods. This is particularly relevant for methane pyrolysis, which produces "turquoise hydrogen" with potentially lower carbon footprint than traditional methods.

Compliance challenges for methane pyrolysis facilities include navigating inconsistent regulations across jurisdictions, particularly for cross-border transport. The novelty of large-scale methane pyrolysis also means that regulatory frameworks may be evolving, requiring operators to maintain vigilance regarding changing requirements and potentially participate in the development of new standards specific to turquoise hydrogen and its byproducts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!