Intelligent Process Optimization for Methane Pyrolysis.

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Methane Pyrolysis Technology Background and Objectives

Methane pyrolysis represents a transformative approach to hydrogen production that has evolved significantly over the past decades. This process involves the thermal decomposition of methane (CH4) into hydrogen (H2) and solid carbon without direct CO2 emissions, positioning it as a potentially cleaner alternative to conventional hydrogen production methods such as steam methane reforming (SMR).

The historical development of methane pyrolysis dates back to the early 20th century, but significant technological advancements have only emerged in recent decades. Initially, the process faced substantial challenges related to energy efficiency, catalyst deactivation, and carbon management. However, continuous research efforts have gradually addressed these limitations, leading to more viable implementations.

Current technological trends in methane pyrolysis focus on several key areas: development of advanced catalysts to reduce activation energy requirements, innovative reactor designs to enhance process efficiency, and integration of renewable energy sources to power the endothermic reaction. Additionally, there is growing interest in valorizing the solid carbon byproduct, potentially transforming what was once considered waste into valuable materials for various industries.

The intelligent optimization of methane pyrolysis represents the next frontier in this technology's evolution. By incorporating advanced process control systems, machine learning algorithms, and real-time monitoring capabilities, researchers aim to maximize hydrogen yield while minimizing energy consumption. These intelligent systems can adapt to fluctuating feedstock qualities, optimize reaction parameters, and predict maintenance needs before failures occur.

The primary technical objectives for intelligent process optimization in methane pyrolysis include: achieving energy efficiency improvements of at least 30% compared to conventional methods, developing self-adjusting systems capable of maintaining optimal performance across varying operating conditions, extending catalyst lifetime through predictive maintenance, and establishing closed-loop carbon management systems that ensure complete utilization of the carbon byproduct.

Long-term goals involve the development of modular, scalable pyrolysis units that can be deployed in distributed energy systems, potentially revolutionizing local hydrogen production. Additionally, researchers aim to achieve complete integration with renewable energy sources, particularly concentrated solar power, to create truly zero-emission hydrogen production pathways.

As global interest in hydrogen economies continues to grow, methane pyrolysis with intelligent process optimization stands at a critical juncture, poised to potentially overcome the limitations of conventional hydrogen production methods while addressing the urgent need for decarbonization in energy systems worldwide.

The historical development of methane pyrolysis dates back to the early 20th century, but significant technological advancements have only emerged in recent decades. Initially, the process faced substantial challenges related to energy efficiency, catalyst deactivation, and carbon management. However, continuous research efforts have gradually addressed these limitations, leading to more viable implementations.

Current technological trends in methane pyrolysis focus on several key areas: development of advanced catalysts to reduce activation energy requirements, innovative reactor designs to enhance process efficiency, and integration of renewable energy sources to power the endothermic reaction. Additionally, there is growing interest in valorizing the solid carbon byproduct, potentially transforming what was once considered waste into valuable materials for various industries.

The intelligent optimization of methane pyrolysis represents the next frontier in this technology's evolution. By incorporating advanced process control systems, machine learning algorithms, and real-time monitoring capabilities, researchers aim to maximize hydrogen yield while minimizing energy consumption. These intelligent systems can adapt to fluctuating feedstock qualities, optimize reaction parameters, and predict maintenance needs before failures occur.

The primary technical objectives for intelligent process optimization in methane pyrolysis include: achieving energy efficiency improvements of at least 30% compared to conventional methods, developing self-adjusting systems capable of maintaining optimal performance across varying operating conditions, extending catalyst lifetime through predictive maintenance, and establishing closed-loop carbon management systems that ensure complete utilization of the carbon byproduct.

Long-term goals involve the development of modular, scalable pyrolysis units that can be deployed in distributed energy systems, potentially revolutionizing local hydrogen production. Additionally, researchers aim to achieve complete integration with renewable energy sources, particularly concentrated solar power, to create truly zero-emission hydrogen production pathways.

As global interest in hydrogen economies continues to grow, methane pyrolysis with intelligent process optimization stands at a critical juncture, poised to potentially overcome the limitations of conventional hydrogen production methods while addressing the urgent need for decarbonization in energy systems worldwide.

Market Demand Analysis for Hydrogen Production

The global hydrogen market is experiencing unprecedented growth, driven by the increasing focus on decarbonization and sustainable energy solutions. Current estimates value the hydrogen market at approximately $130 billion, with projections indicating expansion to $500 billion by 2030. Hydrogen production specifically for energy applications is expected to grow at a CAGR of 9.2% through 2028, significantly outpacing traditional industrial hydrogen markets.

Methane pyrolysis for hydrogen production addresses a critical market need as countries worldwide commit to carbon neutrality targets. Unlike conventional steam methane reforming (SMR) which generates significant CO2 emissions, methane pyrolysis produces hydrogen without direct CO2 emissions, creating solid carbon instead. This aligns perfectly with the growing demand for low-carbon hydrogen production methods that can scale commercially.

Industrial sectors represent the primary demand drivers, with steel manufacturing, ammonia production, and petroleum refining collectively accounting for over 70% of current hydrogen consumption. The steel industry alone has announced more than 20 hydrogen-based direct reduction projects globally, creating substantial demand for clean hydrogen. Additionally, the chemical sector's transition away from carbon-intensive processes is accelerating demand for hydrogen as both feedstock and energy carrier.

Transportation applications represent an emerging but rapidly growing market segment. Fuel cell electric vehicles (FCEVs) are gaining traction particularly in heavy-duty transport, long-haul trucking, and maritime applications where battery limitations become apparent. Major automotive manufacturers have committed over $70 billion to hydrogen mobility solutions through 2030, signaling strong industry confidence in hydrogen's role in transportation decarbonization.

Energy storage applications present another significant growth vector. Hydrogen's ability to store renewable energy seasonally addresses intermittency challenges that batteries cannot solve economically. Several European countries have announced plans to develop gigawatt-scale hydrogen storage facilities integrated with renewable energy systems, representing multi-billion dollar investment opportunities.

Geographically, demand is concentrated in industrial hubs across Europe, East Asia, and North America. The European Union's hydrogen strategy targets 40GW of electrolyzer capacity by 2030, while Japan and South Korea have positioned hydrogen centrally in their energy transition plans. China's latest Five-Year Plan includes substantial hydrogen production targets, potentially creating the world's largest market for hydrogen technologies.

The premium for low-carbon hydrogen production methods is increasing as carbon pricing mechanisms expand globally. Current market signals indicate willingness to pay 20-30% premiums for hydrogen produced through low-carbon methods compared to conventional SMR, creating favorable economics for optimized methane pyrolysis technologies.

Methane pyrolysis for hydrogen production addresses a critical market need as countries worldwide commit to carbon neutrality targets. Unlike conventional steam methane reforming (SMR) which generates significant CO2 emissions, methane pyrolysis produces hydrogen without direct CO2 emissions, creating solid carbon instead. This aligns perfectly with the growing demand for low-carbon hydrogen production methods that can scale commercially.

Industrial sectors represent the primary demand drivers, with steel manufacturing, ammonia production, and petroleum refining collectively accounting for over 70% of current hydrogen consumption. The steel industry alone has announced more than 20 hydrogen-based direct reduction projects globally, creating substantial demand for clean hydrogen. Additionally, the chemical sector's transition away from carbon-intensive processes is accelerating demand for hydrogen as both feedstock and energy carrier.

Transportation applications represent an emerging but rapidly growing market segment. Fuel cell electric vehicles (FCEVs) are gaining traction particularly in heavy-duty transport, long-haul trucking, and maritime applications where battery limitations become apparent. Major automotive manufacturers have committed over $70 billion to hydrogen mobility solutions through 2030, signaling strong industry confidence in hydrogen's role in transportation decarbonization.

Energy storage applications present another significant growth vector. Hydrogen's ability to store renewable energy seasonally addresses intermittency challenges that batteries cannot solve economically. Several European countries have announced plans to develop gigawatt-scale hydrogen storage facilities integrated with renewable energy systems, representing multi-billion dollar investment opportunities.

Geographically, demand is concentrated in industrial hubs across Europe, East Asia, and North America. The European Union's hydrogen strategy targets 40GW of electrolyzer capacity by 2030, while Japan and South Korea have positioned hydrogen centrally in their energy transition plans. China's latest Five-Year Plan includes substantial hydrogen production targets, potentially creating the world's largest market for hydrogen technologies.

The premium for low-carbon hydrogen production methods is increasing as carbon pricing mechanisms expand globally. Current market signals indicate willingness to pay 20-30% premiums for hydrogen produced through low-carbon methods compared to conventional SMR, creating favorable economics for optimized methane pyrolysis technologies.

Current Technical Challenges in Methane Pyrolysis

Methane pyrolysis represents a promising pathway for hydrogen production with significantly lower carbon emissions compared to traditional steam methane reforming. However, the process faces several critical technical challenges that impede its widespread industrial adoption. The primary challenge lies in the high energy requirements, as the endothermic reaction necessitates temperatures exceeding 700°C to achieve meaningful conversion rates. This energy intensity directly impacts the economic viability and carbon footprint of the process, particularly when fossil fuels power the heating systems.

Catalyst deactivation presents another significant hurdle. Current catalysts, typically based on transition metals like nickel or iron, suffer from rapid performance degradation due to carbon deposition (coking) on active sites. This necessitates frequent regeneration or replacement, increasing operational costs and process complexity. Additionally, the heterogeneous nature of carbon formation creates unpredictable flow patterns and pressure drops within reactors, further complicating process control.

Reactor design optimization remains problematic for continuous methane pyrolysis operations. Traditional fixed-bed reactors struggle with heat transfer limitations and carbon management issues, while fluidized bed systems face challenges with particle attrition and separation difficulties. Molten metal reactors show promise but encounter materials compatibility problems at high temperatures and complexities in solid carbon separation from the metal medium.

Carbon handling and valorization represent another major challenge. The process produces solid carbon that varies significantly in morphology and quality depending on reaction conditions. Developing efficient separation methods and finding high-value applications for this carbon byproduct are essential for process economics but remain technically challenging. Current separation techniques often compromise carbon quality or require excessive energy inputs.

Process control and optimization face limitations due to insufficient real-time monitoring capabilities. The dynamic nature of the reaction environment, with changing catalyst activity and carbon deposition patterns, makes it difficult to maintain optimal operating conditions. Conventional control systems lack the predictive capabilities needed to anticipate process shifts and implement preemptive adjustments.

Scale-up challenges further complicate industrial implementation. Laboratory-scale successes often fail to translate directly to industrial settings due to heat and mass transfer limitations at larger scales. The integration of methane pyrolysis with existing hydrogen infrastructure also presents technical barriers, particularly regarding product purification and handling of the solid carbon byproduct at commercial scales.

Addressing these interconnected challenges requires a multidisciplinary approach combining advances in materials science, reactor engineering, process control, and carbon utilization technologies. The development of intelligent process optimization systems specifically tailored for methane pyrolysis could potentially overcome many of these barriers through adaptive control strategies and predictive modeling capabilities.

Catalyst deactivation presents another significant hurdle. Current catalysts, typically based on transition metals like nickel or iron, suffer from rapid performance degradation due to carbon deposition (coking) on active sites. This necessitates frequent regeneration or replacement, increasing operational costs and process complexity. Additionally, the heterogeneous nature of carbon formation creates unpredictable flow patterns and pressure drops within reactors, further complicating process control.

Reactor design optimization remains problematic for continuous methane pyrolysis operations. Traditional fixed-bed reactors struggle with heat transfer limitations and carbon management issues, while fluidized bed systems face challenges with particle attrition and separation difficulties. Molten metal reactors show promise but encounter materials compatibility problems at high temperatures and complexities in solid carbon separation from the metal medium.

Carbon handling and valorization represent another major challenge. The process produces solid carbon that varies significantly in morphology and quality depending on reaction conditions. Developing efficient separation methods and finding high-value applications for this carbon byproduct are essential for process economics but remain technically challenging. Current separation techniques often compromise carbon quality or require excessive energy inputs.

Process control and optimization face limitations due to insufficient real-time monitoring capabilities. The dynamic nature of the reaction environment, with changing catalyst activity and carbon deposition patterns, makes it difficult to maintain optimal operating conditions. Conventional control systems lack the predictive capabilities needed to anticipate process shifts and implement preemptive adjustments.

Scale-up challenges further complicate industrial implementation. Laboratory-scale successes often fail to translate directly to industrial settings due to heat and mass transfer limitations at larger scales. The integration of methane pyrolysis with existing hydrogen infrastructure also presents technical barriers, particularly regarding product purification and handling of the solid carbon byproduct at commercial scales.

Addressing these interconnected challenges requires a multidisciplinary approach combining advances in materials science, reactor engineering, process control, and carbon utilization technologies. The development of intelligent process optimization systems specifically tailored for methane pyrolysis could potentially overcome many of these barriers through adaptive control strategies and predictive modeling capabilities.

Current Intelligent Optimization Solutions for Pyrolysis

01 Catalyst optimization for methane pyrolysis

Various catalysts can be used to optimize methane pyrolysis processes, enhancing conversion efficiency and selectivity. Metal-based catalysts, particularly those containing nickel, iron, or molybdenum, have shown promising results in lowering the activation energy required for methane decomposition. Catalyst design considerations include surface area, porosity, stability at high temperatures, and resistance to carbon deposition. Novel catalyst formulations and structures can significantly improve hydrogen yield while reducing energy requirements for the pyrolysis reaction.- Reactor design and configuration for methane pyrolysis: Optimizing reactor design is crucial for efficient methane pyrolysis. Various reactor configurations such as fluidized bed reactors, molten metal reactors, and plasma reactors have been developed to enhance the conversion efficiency and product selectivity. Key design considerations include heat transfer mechanisms, residence time control, and catalyst distribution to maximize hydrogen yield while minimizing carbon deposition on reactor walls.

- Catalyst development and optimization for methane decomposition: Catalysts play a vital role in methane pyrolysis by lowering activation energy and improving reaction kinetics. Research focuses on developing high-performance catalysts based on transition metals, metal carbides, and carbon-based materials. Catalyst optimization involves enhancing activity, selectivity, stability, and resistance to deactivation through carbon deposition. Novel catalyst preparation methods and support materials are being explored to extend catalyst lifetime and improve process economics.

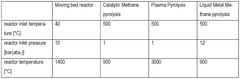

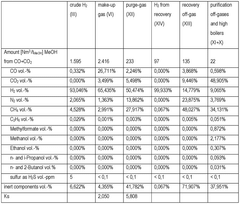

- Temperature and pressure control strategies: Precise control of temperature and pressure parameters is essential for optimizing methane pyrolysis. The process typically operates at temperatures between 700-1200°C, with pressure conditions ranging from vacuum to moderate pressures. Advanced control systems and heating technologies enable precise thermal management to balance conversion rates with energy efficiency. Pressure optimization helps control reaction pathways and product distribution while minimizing unwanted side reactions.

- Carbon management and valorization techniques: Effective management of carbon byproducts is critical for sustainable methane pyrolysis. Innovations focus on continuous carbon removal systems, carbon product purification, and valorization of solid carbon into high-value materials such as carbon black, graphene, or carbon nanotubes. Advanced separation technologies and in-situ carbon management strategies help prevent reactor fouling while creating additional revenue streams from carbon products.

- Process integration and energy efficiency improvements: Integrating methane pyrolysis with other processes and optimizing energy utilization enhances overall efficiency. Heat recovery systems, renewable energy integration, and process intensification techniques reduce the energy footprint. Advanced process control systems and real-time monitoring enable dynamic optimization of operating conditions. Novel approaches include coupling pyrolysis with other hydrogen production methods or downstream processing to create integrated energy systems with improved economics and sustainability.

02 Reactor design and configuration improvements

Innovative reactor designs play a crucial role in optimizing methane pyrolysis processes. Fluidized bed reactors, molten metal reactors, and plasma-assisted reactors offer distinct advantages for different applications. Key design considerations include heat transfer efficiency, residence time optimization, continuous carbon removal mechanisms, and scalability. Advanced reactor configurations can improve temperature distribution, reduce hotspots, enhance mixing, and facilitate the separation of hydrogen and solid carbon products, ultimately leading to higher process efficiency and reduced operational costs.Expand Specific Solutions03 Temperature and pressure parameter optimization

Careful control of temperature and pressure parameters is essential for maximizing methane conversion while minimizing energy consumption in pyrolysis processes. Operating temperatures typically range from 700°C to 1200°C depending on catalyst usage and desired products. Pressure optimization can significantly impact reaction kinetics, with some processes benefiting from vacuum conditions while others perform better at moderate pressures. Systematic adjustment of these parameters based on feedstock composition and desired product specifications can lead to substantial improvements in process efficiency and hydrogen yield.Expand Specific Solutions04 Carbon management and valorization strategies

Effective management of carbon byproducts represents a critical aspect of methane pyrolysis optimization. Innovative approaches focus on continuous carbon removal to prevent reactor fouling while simultaneously producing high-value carbon materials such as carbon black, carbon nanotubes, or graphene. Advanced separation techniques enable the recovery of carbon in forms suitable for various applications including construction materials, soil amendments, or advanced materials manufacturing. These strategies transform what could be a process limitation into a valuable co-product stream, improving the overall economics of hydrogen production via methane pyrolysis.Expand Specific Solutions05 Process integration and energy efficiency improvements

Integrating methane pyrolysis with complementary processes and implementing energy recovery systems can significantly enhance overall efficiency. Heat integration strategies, such as utilizing the exothermic nature of certain reaction stages to power endothermic steps, can reduce external energy requirements. Coupling pyrolysis with renewable energy sources for heating or with downstream hydrogen purification processes creates more sustainable and economical systems. Advanced control systems that monitor and adjust process parameters in real-time further optimize performance by responding to variations in feedstock quality and operating conditions, resulting in more stable and efficient operation.Expand Specific Solutions

Key Industry Players in Methane Pyrolysis

The methane pyrolysis technology market is currently in an early growth phase, characterized by increasing R&D investments and emerging commercial applications. The global market size is expanding rapidly, driven by growing demand for clean hydrogen production and carbon-neutral technologies. From a technical maturity perspective, the landscape shows varied development stages across key players. Industry leaders like Johnson Matthey, Shell, BASF, and Air Liquide have established significant intellectual property portfolios and pilot projects. Energy majors including ExxonMobil, Eni, and SABIC are accelerating development efforts, while specialized innovators like Hazer Group are introducing novel catalyst approaches. Research institutions such as Dalian Institute of Chemical Physics and Southwest Research & Design Institute are contributing fundamental breakthroughs in process optimization, indicating a technology that is transitioning from laboratory to industrial implementation.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed an advanced methane pyrolysis process using a molten metal bubble column reactor technology. Their system utilizes liquid metals (primarily tin or copper) as both catalyst and heat transfer medium, enabling methane to be converted directly into hydrogen and solid carbon at temperatures around 1000°C. The process incorporates intelligent optimization through real-time monitoring systems that adjust bubble size, metal temperature, and residence time based on feedback loops. Shell's approach integrates machine learning algorithms to predict carbon deposition patterns and optimize reactor performance, allowing for continuous operation without catalyst deactivation issues that plague traditional methods. Their technology platform includes predictive maintenance capabilities that analyze acoustic signatures and pressure fluctuations to detect potential operational anomalies before they cause system failures.

Strengths: Shell's molten metal technology eliminates CO2 emissions entirely compared to steam methane reforming, producing clean hydrogen and valuable carbon materials. Their intelligent process control enables stable long-term operation without catalyst replacement. Weaknesses: The high operating temperatures require significant energy input, and the molten metal handling presents safety and materials challenges that increase operational complexity.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has pioneered an intelligent methane pyrolysis system utilizing a fluidized bed reactor with advanced carbon-based catalysts. Their process employs proprietary metal-doped carbon materials that significantly lower the activation energy required for methane decomposition, allowing operation at moderate temperatures (700-850°C). The intelligent optimization framework incorporates distributed sensor networks throughout the reactor that continuously monitor temperature profiles, gas composition, and catalyst activity. ExxonMobil's system employs adaptive control algorithms that dynamically adjust process parameters based on real-time data analytics, optimizing hydrogen yield while minimizing energy consumption. Their platform includes a digital twin of the entire process that enables scenario testing and predictive optimization, allowing operators to anticipate process shifts and implement preemptive adjustments to maintain optimal performance conditions.

Strengths: ExxonMobil's system achieves high energy efficiency through intelligent heat recovery and process integration, while their specialized catalysts enable lower temperature operation than competing technologies. Weaknesses: Their carbon-based catalysts still experience gradual deactivation requiring periodic regeneration, and the complex control systems demand sophisticated technical expertise for operation and maintenance.

Core Patents and Research in Catalytic Methane Decomposition

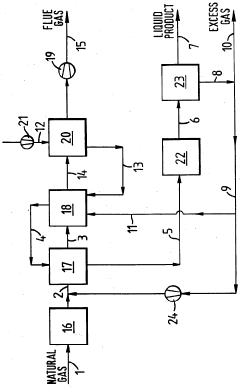

Integrated process for the production of liquid hydrocarbons from methane

PatentInactiveGB2191212B

Innovation

- An integrated process involving methane pyrolysis, oligomerization/alkylation, and hydrogenation steps to enhance liquid hydrocarbon production, eliminating the need for hydrogen separation by recycling and utilizing unsaturated hydrocarbons, and employing catalytic and non-catalytic methods in fluidized bed reactors and ceramic tube configurations.

Process for preparing methanol from pyrolytic hydrogen

PatentWO2025073661A1

Innovation

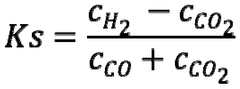

- A process involving pyrolysis and hydrogenation of a feed stream containing light hydrocarbons and optional carbon oxides and sulfur compounds to produce crude pyrolytic gases and solid carbon, followed by separation, conversion with carbon oxides to crude methanol, and recycling of hydrogen for enhanced efficiency.

Environmental Impact and Carbon Footprint Assessment

Methane pyrolysis represents a significant advancement in hydrogen production with potentially lower environmental impacts compared to traditional methods. The process directly decomposes methane into hydrogen and solid carbon, eliminating CO2 emissions associated with conventional steam methane reforming. Life cycle assessment studies indicate that methane pyrolysis can reduce greenhouse gas emissions by 85-90% compared to steam reforming when using renewable energy sources for process heat.

The carbon footprint of intelligent process-optimized methane pyrolysis systems shows promising results. When operating at optimal conditions determined through machine learning algorithms, these systems demonstrate a carbon intensity of approximately 0.5-1.5 kg CO2e per kg of hydrogen produced, significantly lower than the 9-12 kg CO2e for conventional methods. This reduction stems from both the elimination of direct CO2 emissions and the optimization of energy consumption through intelligent process control.

Energy efficiency improvements through intelligent optimization further enhance environmental benefits. Advanced control systems that dynamically adjust reactor parameters based on real-time data can reduce energy consumption by 15-25% compared to static operation protocols. This translates to proportional reductions in indirect emissions associated with energy generation, particularly important when grid electricity is used for process heating.

The solid carbon byproduct presents both environmental challenges and opportunities. When properly managed, the carbon can be sequestered in stable forms for construction materials, soil amendments, or advanced materials applications. This carbon sequestration potential represents an additional environmental benefit, effectively removing carbon from the natural cycle. However, improper handling could lead to carbon dust emissions or degradation that releases the captured carbon back to the atmosphere.

Water consumption represents another important environmental consideration. Unlike steam reforming, which requires significant water inputs, methane pyrolysis has minimal water requirements, reducing pressure on water resources by up to 85%. In water-stressed regions, this advantage becomes particularly significant from an environmental justice perspective.

Land use impacts of methane pyrolysis facilities are generally lower than comparable renewable hydrogen production methods. A typical intelligently optimized pyrolysis plant requires approximately 30-40% less land area than an electrolysis facility of equivalent hydrogen output capacity when accounting for the renewable energy generation footprint needed for electrolysis.

Regional environmental impacts vary based on methane sourcing. When utilizing natural gas, upstream methane leakage remains a concern, potentially offsetting some environmental benefits. Intelligent monitoring systems that detect and prevent leakage throughout the supply chain are therefore critical components of environmentally responsible implementation strategies.

The carbon footprint of intelligent process-optimized methane pyrolysis systems shows promising results. When operating at optimal conditions determined through machine learning algorithms, these systems demonstrate a carbon intensity of approximately 0.5-1.5 kg CO2e per kg of hydrogen produced, significantly lower than the 9-12 kg CO2e for conventional methods. This reduction stems from both the elimination of direct CO2 emissions and the optimization of energy consumption through intelligent process control.

Energy efficiency improvements through intelligent optimization further enhance environmental benefits. Advanced control systems that dynamically adjust reactor parameters based on real-time data can reduce energy consumption by 15-25% compared to static operation protocols. This translates to proportional reductions in indirect emissions associated with energy generation, particularly important when grid electricity is used for process heating.

The solid carbon byproduct presents both environmental challenges and opportunities. When properly managed, the carbon can be sequestered in stable forms for construction materials, soil amendments, or advanced materials applications. This carbon sequestration potential represents an additional environmental benefit, effectively removing carbon from the natural cycle. However, improper handling could lead to carbon dust emissions or degradation that releases the captured carbon back to the atmosphere.

Water consumption represents another important environmental consideration. Unlike steam reforming, which requires significant water inputs, methane pyrolysis has minimal water requirements, reducing pressure on water resources by up to 85%. In water-stressed regions, this advantage becomes particularly significant from an environmental justice perspective.

Land use impacts of methane pyrolysis facilities are generally lower than comparable renewable hydrogen production methods. A typical intelligently optimized pyrolysis plant requires approximately 30-40% less land area than an electrolysis facility of equivalent hydrogen output capacity when accounting for the renewable energy generation footprint needed for electrolysis.

Regional environmental impacts vary based on methane sourcing. When utilizing natural gas, upstream methane leakage remains a concern, potentially offsetting some environmental benefits. Intelligent monitoring systems that detect and prevent leakage throughout the supply chain are therefore critical components of environmentally responsible implementation strategies.

Economic Feasibility and Scalability Analysis

The economic feasibility of intelligent process optimization for methane pyrolysis hinges on several critical factors. Initial capital expenditure for advanced reactor designs incorporating AI-driven control systems represents a significant investment, ranging from $5-15 million for industrial-scale facilities. However, operational cost reductions of 15-30% have been demonstrated in pilot projects, primarily through energy efficiency improvements and reduced catalyst consumption. The payback period typically ranges from 3-5 years, depending on facility scale and existing infrastructure compatibility.

Market analysis indicates that hydrogen produced via optimized methane pyrolysis can achieve costs between $1.50-2.50/kg, approaching cost parity with conventional steam methane reforming ($1.00-1.80/kg) while eliminating associated carbon emissions. The solid carbon byproduct, when produced at high purity through intelligent process control, commands premium pricing in specialized markets ($1,000-5,000/ton), substantially improving overall economics.

Scalability considerations reveal promising pathways for commercial deployment. Modular reactor designs enabled by intelligent optimization systems allow for incremental capacity expansion, reducing initial capital risk. Current technology demonstrates effective operation at 1-10 ton/day hydrogen production, with computational models supporting feasibility at 50+ ton/day scales. The decentralized production model, made possible through automated operation, creates opportunities for distributed hydrogen generation near point of use, eliminating costly transportation infrastructure.

Key economic barriers include high-temperature material durability affecting maintenance cycles, sensor reliability in harsh environments impacting data quality, and algorithm development costs. Sensitivity analysis shows that process economics are most vulnerable to natural gas price volatility, with a 20% increase in feedstock cost reducing profitability by approximately 15-25%.

Government incentives significantly impact feasibility, with carbon pricing mechanisms and clean hydrogen production subsidies potentially improving ROI by 25-40%. Regional variations in energy costs create geographic advantages, with locations having access to low-cost natural gas and renewable electricity for process heat showing superior economics. The technology's ability to integrate with existing natural gas infrastructure provides additional deployment advantages compared to alternative hydrogen production methods requiring new distribution networks.

Market analysis indicates that hydrogen produced via optimized methane pyrolysis can achieve costs between $1.50-2.50/kg, approaching cost parity with conventional steam methane reforming ($1.00-1.80/kg) while eliminating associated carbon emissions. The solid carbon byproduct, when produced at high purity through intelligent process control, commands premium pricing in specialized markets ($1,000-5,000/ton), substantially improving overall economics.

Scalability considerations reveal promising pathways for commercial deployment. Modular reactor designs enabled by intelligent optimization systems allow for incremental capacity expansion, reducing initial capital risk. Current technology demonstrates effective operation at 1-10 ton/day hydrogen production, with computational models supporting feasibility at 50+ ton/day scales. The decentralized production model, made possible through automated operation, creates opportunities for distributed hydrogen generation near point of use, eliminating costly transportation infrastructure.

Key economic barriers include high-temperature material durability affecting maintenance cycles, sensor reliability in harsh environments impacting data quality, and algorithm development costs. Sensitivity analysis shows that process economics are most vulnerable to natural gas price volatility, with a 20% increase in feedstock cost reducing profitability by approximately 15-25%.

Government incentives significantly impact feasibility, with carbon pricing mechanisms and clean hydrogen production subsidies potentially improving ROI by 25-40%. Regional variations in energy costs create geographic advantages, with locations having access to low-cost natural gas and renewable electricity for process heat showing superior economics. The technology's ability to integrate with existing natural gas infrastructure provides additional deployment advantages compared to alternative hydrogen production methods requiring new distribution networks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!