Methane Pyrolysis: Advances in Reactor Cooling Tech.

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Methane Pyrolysis Background and Objectives

Methane pyrolysis represents a transformative approach to hydrogen production that has gained significant attention in recent years as a potential pathway to decarbonize energy systems. This process involves the thermal decomposition of methane (CH4) into hydrogen (H2) and solid carbon, offering a cleaner alternative to traditional steam methane reforming which produces CO2 as a byproduct. The evolution of methane pyrolysis technology dates back to the early 20th century, but recent environmental imperatives have accelerated research and development efforts in this field.

The technological trajectory of methane pyrolysis has been marked by significant innovations in reactor design, catalysis, and process optimization. Early systems suffered from carbon deposition issues and inefficient heat transfer, limiting commercial viability. However, the past decade has witnessed remarkable advancements in reactor technologies, particularly in cooling systems that maintain optimal reaction conditions while managing the substantial heat requirements of the endothermic process.

Current research focuses on overcoming the thermal management challenges inherent in methane pyrolysis reactors. The process typically requires temperatures between 700-1200°C to achieve economically viable conversion rates, creating significant demands on cooling technology to maintain structural integrity and process efficiency. The development of advanced cooling systems has become a critical enabler for scaling this technology.

The primary objective of current methane pyrolysis research is to develop reactor cooling technologies that can efficiently manage heat distribution while maximizing hydrogen yield and minimizing energy consumption. This includes innovations in heat exchanger design, novel cooling media, and integrated thermal management systems that can operate reliably at industrial scales.

Secondary objectives include extending reactor lifespan by preventing thermal degradation, reducing capital and operational costs through more efficient cooling designs, and enabling modular, scalable systems that can be deployed across various industrial contexts. These advancements aim to position methane pyrolysis as a commercially viable pathway for clean hydrogen production.

The technology trend clearly points toward more sophisticated cooling solutions that integrate renewable energy sources, utilize waste heat recovery systems, and incorporate advanced materials capable of withstanding extreme thermal conditions. Computational fluid dynamics and digital twin technologies are increasingly employed to optimize cooling system designs before physical implementation.

As global hydrogen demand continues to grow, driven by decarbonization efforts across transportation, industry, and energy sectors, methane pyrolysis with advanced cooling technologies represents a promising bridge technology that could enable significant carbon emission reductions while leveraging existing natural gas infrastructure and expertise.

The technological trajectory of methane pyrolysis has been marked by significant innovations in reactor design, catalysis, and process optimization. Early systems suffered from carbon deposition issues and inefficient heat transfer, limiting commercial viability. However, the past decade has witnessed remarkable advancements in reactor technologies, particularly in cooling systems that maintain optimal reaction conditions while managing the substantial heat requirements of the endothermic process.

Current research focuses on overcoming the thermal management challenges inherent in methane pyrolysis reactors. The process typically requires temperatures between 700-1200°C to achieve economically viable conversion rates, creating significant demands on cooling technology to maintain structural integrity and process efficiency. The development of advanced cooling systems has become a critical enabler for scaling this technology.

The primary objective of current methane pyrolysis research is to develop reactor cooling technologies that can efficiently manage heat distribution while maximizing hydrogen yield and minimizing energy consumption. This includes innovations in heat exchanger design, novel cooling media, and integrated thermal management systems that can operate reliably at industrial scales.

Secondary objectives include extending reactor lifespan by preventing thermal degradation, reducing capital and operational costs through more efficient cooling designs, and enabling modular, scalable systems that can be deployed across various industrial contexts. These advancements aim to position methane pyrolysis as a commercially viable pathway for clean hydrogen production.

The technology trend clearly points toward more sophisticated cooling solutions that integrate renewable energy sources, utilize waste heat recovery systems, and incorporate advanced materials capable of withstanding extreme thermal conditions. Computational fluid dynamics and digital twin technologies are increasingly employed to optimize cooling system designs before physical implementation.

As global hydrogen demand continues to grow, driven by decarbonization efforts across transportation, industry, and energy sectors, methane pyrolysis with advanced cooling technologies represents a promising bridge technology that could enable significant carbon emission reductions while leveraging existing natural gas infrastructure and expertise.

Market Demand for Clean Hydrogen Production

The global hydrogen market is experiencing a significant shift towards cleaner production methods, with methane pyrolysis emerging as a promising technology for producing low-carbon hydrogen. Current market analysis indicates that hydrogen demand is projected to grow substantially over the next decade, driven by decarbonization efforts across multiple industries. The International Energy Agency estimates that hydrogen use could expand from the current 70 million tonnes annually to over 200 million tonnes by 2030, with clean hydrogen comprising an increasingly significant portion.

Traditional hydrogen production methods, particularly steam methane reforming (SMR), account for approximately 95% of current hydrogen production but generate substantial CO2 emissions—approximately 9-10 kg CO2 per kg of hydrogen produced. This creates a substantial market opportunity for cleaner alternatives like methane pyrolysis, which produces solid carbon instead of CO2 as a byproduct.

The industrial sector represents the largest current market for hydrogen, with petroleum refining and ammonia production as primary consumers. However, emerging applications in steel manufacturing, transportation, and energy storage are expected to drive significant new demand. The steel industry alone could potentially consume 12-20 million tonnes of hydrogen annually by 2050 if widespread adoption of hydrogen-based direct reduction processes occurs.

Transportation applications present another substantial growth market, with fuel cell vehicles gaining traction in heavy-duty transport, maritime shipping, and potentially aviation. Major automotive manufacturers have increased investments in hydrogen fuel cell technology, particularly for long-haul trucking where battery electric solutions face range and refueling time limitations.

Energy system applications represent perhaps the largest potential market, with hydrogen increasingly viewed as a critical component for grid-scale energy storage and seasonal balancing of renewable energy. Several European countries have announced plans to develop gigawatt-scale hydrogen storage facilities integrated with renewable energy systems.

The economic drivers for clean hydrogen production are strengthening, with carbon pricing mechanisms, renewable energy cost reductions, and government incentives improving the competitiveness of low-carbon hydrogen. The EU Hydrogen Strategy targets 40 GW of renewable hydrogen electrolyzers by 2030, while the US Inflation Reduction Act provides production tax credits of up to $3 per kilogram for clean hydrogen.

For methane pyrolysis specifically, the market opportunity is enhanced by the potential value of solid carbon byproducts, which can be sold into existing markets for carbon black, graphite, and advanced carbon materials, potentially offsetting production costs by 15-30% depending on carbon quality and market conditions.

Traditional hydrogen production methods, particularly steam methane reforming (SMR), account for approximately 95% of current hydrogen production but generate substantial CO2 emissions—approximately 9-10 kg CO2 per kg of hydrogen produced. This creates a substantial market opportunity for cleaner alternatives like methane pyrolysis, which produces solid carbon instead of CO2 as a byproduct.

The industrial sector represents the largest current market for hydrogen, with petroleum refining and ammonia production as primary consumers. However, emerging applications in steel manufacturing, transportation, and energy storage are expected to drive significant new demand. The steel industry alone could potentially consume 12-20 million tonnes of hydrogen annually by 2050 if widespread adoption of hydrogen-based direct reduction processes occurs.

Transportation applications present another substantial growth market, with fuel cell vehicles gaining traction in heavy-duty transport, maritime shipping, and potentially aviation. Major automotive manufacturers have increased investments in hydrogen fuel cell technology, particularly for long-haul trucking where battery electric solutions face range and refueling time limitations.

Energy system applications represent perhaps the largest potential market, with hydrogen increasingly viewed as a critical component for grid-scale energy storage and seasonal balancing of renewable energy. Several European countries have announced plans to develop gigawatt-scale hydrogen storage facilities integrated with renewable energy systems.

The economic drivers for clean hydrogen production are strengthening, with carbon pricing mechanisms, renewable energy cost reductions, and government incentives improving the competitiveness of low-carbon hydrogen. The EU Hydrogen Strategy targets 40 GW of renewable hydrogen electrolyzers by 2030, while the US Inflation Reduction Act provides production tax credits of up to $3 per kilogram for clean hydrogen.

For methane pyrolysis specifically, the market opportunity is enhanced by the potential value of solid carbon byproducts, which can be sold into existing markets for carbon black, graphite, and advanced carbon materials, potentially offsetting production costs by 15-30% depending on carbon quality and market conditions.

Reactor Cooling Challenges in Methane Pyrolysis

Methane pyrolysis represents a promising pathway for hydrogen production with significantly reduced carbon emissions compared to traditional steam methane reforming. However, the process faces substantial thermal management challenges that must be addressed to achieve commercial viability. The primary cooling challenge stems from the high operating temperatures (800-1200°C) required to crack methane molecules into hydrogen and solid carbon, creating extreme thermal stress on reactor materials.

The endothermic nature of methane pyrolysis reactions necessitates continuous heat input, while simultaneously requiring effective heat removal systems to prevent localized hotspots and material degradation. This thermal balancing act presents a fundamental engineering challenge that has limited industrial-scale implementation despite the process's theoretical advantages.

Current reactor designs struggle with carbon deposition on heat transfer surfaces, which progressively reduces thermal efficiency and increases pressure drop across the system. This carbon fouling accelerates material degradation through carburization and metal dusting, particularly in metal-based reactor systems, leading to premature component failure and increased maintenance requirements.

Cooling system design is further complicated by the need to maintain precise temperature gradients within the reactor. Too rapid cooling can quench the pyrolysis reaction prematurely, while insufficient cooling risks structural damage to reactor components. This delicate balance must be maintained while handling hydrogen at high temperatures, introducing additional safety considerations related to hydrogen embrittlement of containment materials.

The selection of appropriate cooling media presents another significant challenge. Traditional cooling approaches using water or steam risk introducing oxygen into the system, potentially contaminating the hydrogen product or creating hazardous conditions. Alternative cooling media such as molten salts offer improved thermal properties but introduce corrosion concerns and operational complexities.

Heat recovery from the pyrolysis process represents both a challenge and opportunity. Effective heat integration could significantly improve overall process efficiency, but requires sophisticated heat exchanger designs capable of operating reliably under extreme conditions while maintaining separation between process streams.

Scale-up of laboratory cooling solutions to industrial-scale reactors introduces additional complexities related to thermal expansion, mechanical stress, and flow distribution. Many cooling approaches that function effectively in small-scale demonstrations fail to perform adequately when scaled to commercially relevant dimensions, creating a significant barrier to technology commercialization.

The endothermic nature of methane pyrolysis reactions necessitates continuous heat input, while simultaneously requiring effective heat removal systems to prevent localized hotspots and material degradation. This thermal balancing act presents a fundamental engineering challenge that has limited industrial-scale implementation despite the process's theoretical advantages.

Current reactor designs struggle with carbon deposition on heat transfer surfaces, which progressively reduces thermal efficiency and increases pressure drop across the system. This carbon fouling accelerates material degradation through carburization and metal dusting, particularly in metal-based reactor systems, leading to premature component failure and increased maintenance requirements.

Cooling system design is further complicated by the need to maintain precise temperature gradients within the reactor. Too rapid cooling can quench the pyrolysis reaction prematurely, while insufficient cooling risks structural damage to reactor components. This delicate balance must be maintained while handling hydrogen at high temperatures, introducing additional safety considerations related to hydrogen embrittlement of containment materials.

The selection of appropriate cooling media presents another significant challenge. Traditional cooling approaches using water or steam risk introducing oxygen into the system, potentially contaminating the hydrogen product or creating hazardous conditions. Alternative cooling media such as molten salts offer improved thermal properties but introduce corrosion concerns and operational complexities.

Heat recovery from the pyrolysis process represents both a challenge and opportunity. Effective heat integration could significantly improve overall process efficiency, but requires sophisticated heat exchanger designs capable of operating reliably under extreme conditions while maintaining separation between process streams.

Scale-up of laboratory cooling solutions to industrial-scale reactors introduces additional complexities related to thermal expansion, mechanical stress, and flow distribution. Many cooling approaches that function effectively in small-scale demonstrations fail to perform adequately when scaled to commercially relevant dimensions, creating a significant barrier to technology commercialization.

Current Reactor Cooling Solutions and Approaches

01 External cooling systems for methane pyrolysis reactors

External cooling systems are employed to manage the high temperatures generated during methane pyrolysis. These systems typically include cooling jackets, heat exchangers, or cooling coils that surround the reactor vessel. The cooling medium, often water or specialized coolants, circulates through these external components to absorb and remove excess heat from the reactor walls, maintaining optimal operating temperatures and preventing structural damage to the reactor materials.- External cooling systems for methane pyrolysis reactors: External cooling systems are employed to manage the high temperatures generated during methane pyrolysis. These systems typically include cooling jackets, heat exchangers, or cooling coils that surround the reactor vessel. The cooling medium, often water or specialized coolants, circulates through these external components to absorb and remove excess heat from the reactor walls, maintaining optimal operating temperatures and preventing structural damage to the reactor materials.

- Internal cooling mechanisms for temperature control: Internal cooling mechanisms are integrated directly within methane pyrolysis reactors to provide precise temperature control at specific zones. These may include internal cooling tubes, baffles with cooling channels, or direct injection of cooling agents into the reaction chamber. Such systems allow for targeted cooling of catalyst beds, reaction zones, or hot spots, enabling better control of the pyrolysis process and preventing unwanted side reactions or catalyst deactivation.

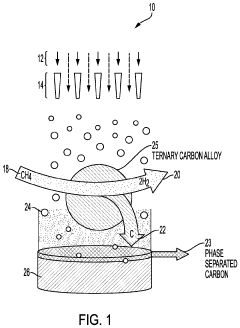

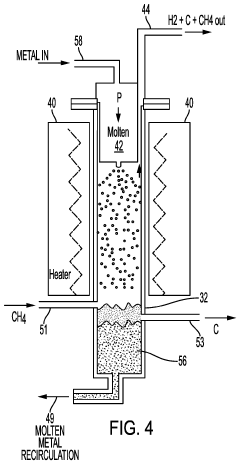

- Molten metal cooling techniques for pyrolysis reactors: Molten metal cooling techniques utilize liquid metals as both reaction media and heat transfer agents in methane pyrolysis reactors. Metals such as tin, lead, bismuth, or their alloys serve as excellent heat conductors, enabling efficient temperature management throughout the reactor. The molten metal can absorb heat from the pyrolysis reaction and transfer it to cooling systems, while simultaneously providing a medium for carbon separation and collection.

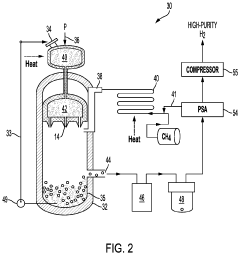

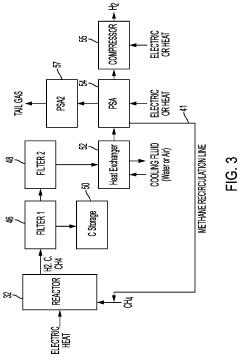

- Advanced heat recovery and energy efficiency systems: Advanced heat recovery systems capture and utilize the thermal energy generated during methane pyrolysis to improve overall process efficiency. These systems incorporate heat exchangers, thermal storage units, or waste heat recovery boilers to transfer excess heat to other process streams or convert it to useful energy forms. By recovering and repurposing thermal energy, these systems reduce cooling requirements, minimize energy consumption, and improve the economic viability of methane pyrolysis operations.

- Innovative reactor designs for enhanced thermal management: Innovative reactor designs incorporate structural and material features specifically engineered for superior thermal management during methane pyrolysis. These designs may include fluidized bed configurations, moving bed reactors, or microreactor arrays that facilitate better heat distribution and removal. Advanced materials with high thermal conductivity or specialized coatings that enhance heat transfer are also employed to improve cooling efficiency and reactor durability under the extreme conditions of methane pyrolysis.

02 Internal cooling mechanisms for temperature control

Internal cooling mechanisms are integrated directly within methane pyrolysis reactors to provide precise temperature control at critical reaction zones. These systems may include internal cooling tubes, baffles with cooling channels, or direct injection of cooling agents into the reaction chamber. Such mechanisms allow for targeted cooling of specific reactor sections where exothermic reactions occur, helping to maintain reaction efficiency while preventing overheating and carbon deposition on catalyst surfaces.Expand Specific Solutions03 Molten metal cooling techniques for pyrolysis reactors

Molten metal cooling techniques utilize liquid metals as both reaction media and heat transfer agents in methane pyrolysis reactors. Metals such as tin, lead, or gallium alloys with high thermal conductivity absorb heat from the pyrolysis reaction and can be circulated through external heat exchangers for cooling. This approach offers advantages including efficient heat removal, prevention of carbon fouling, and potential for continuous carbon separation from the reaction environment.Expand Specific Solutions04 Regenerative and recuperative cooling systems

Regenerative and recuperative cooling systems recover thermal energy from methane pyrolysis processes for improved energy efficiency. These systems capture waste heat from hot reaction products or exhaust gases and use it to preheat incoming reactants or generate steam for other processes. Heat exchange occurs through specialized heat exchangers, thermal storage media, or cyclic flow arrangements, reducing overall energy consumption while simultaneously providing necessary reactor cooling.Expand Specific Solutions05 Advanced materials and coatings for thermal management

Advanced materials and specialized coatings are employed in methane pyrolysis reactors to enhance thermal management capabilities. These include ceramic linings, refractory materials, and thermal barrier coatings that can withstand extreme temperatures while providing insulation properties. Some designs incorporate composite materials with tailored thermal conductivity or phase-change materials that absorb heat during temperature spikes. These material solutions help extend reactor lifespan by reducing thermal stress and preventing structural degradation.Expand Specific Solutions

Leading Companies and Research Institutions in Pyrolysis

Methane pyrolysis for hydrogen production is currently in an early commercialization phase, with the global market expected to grow significantly as clean hydrogen demand increases. The technology demonstrates moderate maturity, with cooling systems being a critical focus area for efficiency improvements. Key players like SINOPEC Engineering, ExxonMobil Chemical Patents, and TotalEnergies OneTech are leading development efforts, while specialized companies such as Coolbrook Oy are introducing innovative reactor designs. Chinese entities, including China Petroleum & Chemical Corp., are making substantial investments in scaling the technology. Academic-industry partnerships involving institutions like China Petroleum University Beijing and École Polytechnique Fédérale de Lausanne are accelerating technological breakthroughs in reactor cooling systems, which remain essential for commercial viability.

ExxonMobil Chemical Patents, Inc.

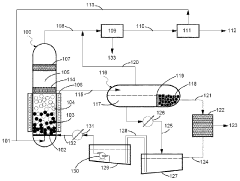

Technical Solution: ExxonMobil has developed a sophisticated methane pyrolysis system featuring advanced multi-phase cooling technology. Their approach utilizes a fluidized bed reactor design with integrated cooling systems that maintain precise temperature control while maximizing hydrogen yield. The cooling technology incorporates a primary internal cooling circuit with specialized heat transfer tubes distributed throughout the catalyst bed, allowing for uniform temperature distribution and preventing hotspots. These cooling elements are constructed from advanced alloys that resist carbon deposition and maintain structural integrity at temperatures exceeding 1000°C. ExxonMobil's system features a secondary external cooling loop that removes heat from the primary circuit and either dissipates it or recovers it for other processes. The company has implemented proprietary heat exchanger designs that maximize heat transfer efficiency while minimizing pressure drop. Their cooling system includes advanced flow distribution technology that ensures uniform coolant distribution throughout the reactor, preventing localized overheating. ExxonMobil has also developed specialized catalyst formulations that work synergistically with their cooling system, allowing operation at lower temperatures while maintaining high conversion rates, thus reducing overall cooling requirements[7][8].

Strengths: Excellent temperature uniformity through distributed cooling elements; reduced energy consumption through catalyst-cooling system integration; modular design allows for scaling; potential for heat integration with other processes. Weaknesses: Complex internal cooling elements may be susceptible to fouling over time; higher capital costs due to specialized materials requirements; potential for thermal stress in cooling elements during startup/shutdown cycles.

UOP LLC

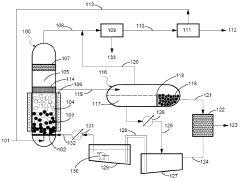

Technical Solution: UOP (a Honeywell company) has developed an advanced methane pyrolysis technology featuring innovative reactor cooling systems. Their approach utilizes a moving bed reactor design with integrated heat management technology that precisely controls temperature profiles throughout the reaction zone. The cooling system incorporates a series of concentric cooling jackets surrounding the reactor vessel, each operating at different temperatures to create an optimized temperature gradient. These cooling zones utilize specialized heat transfer fluids capable of operating efficiently at temperatures ranging from 700-1200°C. UOP's technology features proprietary heat exchanger designs that maximize surface area while minimizing pressure drop, allowing for efficient heat removal without compromising process flow. The company has implemented advanced ceramic materials as thermal barriers between reaction zones and cooling systems, providing both insulation and protection against carbon deposition. Their cooling technology includes a sophisticated control system that continuously monitors temperature at multiple points throughout the reactor and adjusts coolant flow rates accordingly. UOP has also developed heat recovery systems that capture thermal energy from the process gas stream and utilize it for preheating feed gas or generating steam, significantly improving overall energy efficiency[9][10].

Strengths: Precise temperature gradient control through multiple cooling zones; excellent energy recovery capabilities; reduced carbon deposition through optimized temperature profiles; advanced process control systems. Weaknesses: Complex cooling jacket design increases manufacturing complexity and cost; specialized heat transfer fluids may require frequent replacement; potential for thermal stress at interfaces between different temperature zones.

Key Innovations in Thermal Management for Pyrolysis

High throughput methane pyrolysis reactor for low-cost hydrogen production

PatentActiveUS11981563B2

Innovation

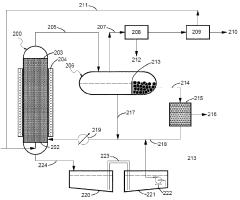

- A liquid mist reactor system using catalytically active molten alloys to decompose hydrocarbons into hydrogen and solid carbon, with a reactor design that enhances catalyst surface area and gas hourly space velocity, allowing for high reactor utilization and efficient carbon separation.

Molten salts reactor systems for methane pyrolysis

PatentActiveAU2021343870B2

Innovation

- A molten salt reactor system with halide salts and a solid catalyst, where the catalyst is placed as suspended particles or in a structured packed form, allowing for effective methane conversion to hydrogen and solid carbon with continuous removal of carbon products, optimizing catalyst size and density to prevent plugging and agglomeration.

Carbon Management and Utilization Strategies

Carbon management and utilization strategies represent a critical component in the advancement of methane pyrolysis technology, particularly in relation to reactor cooling innovations. The primary carbon output from methane pyrolysis is solid carbon, which offers significant advantages over CO2 emissions from traditional hydrogen production methods. This solid carbon byproduct can be effectively managed through various pathways that transform it from a waste product into a valuable resource.

The carbon produced through methane pyrolysis exists primarily as carbon black or graphitic carbon, depending on reactor conditions and cooling technologies employed. Advanced cooling systems not only improve process efficiency but also influence the morphology and quality of the carbon output, creating opportunities for high-value applications. Strategic management of this carbon involves categorizing potential uses based on carbon quality, market demand, and economic viability.

High-grade carbon outputs can be directed toward materials manufacturing, serving as precursors for carbon fiber production, graphene synthesis, or as additives in rubber and plastic industries. The cooling rate in pyrolysis reactors directly impacts carbon crystallinity, with more controlled cooling allowing for higher structural uniformity and thus higher market value. Medium-grade carbon finds applications in metallurgical processes, soil amendment as biochar, and construction materials.

Carbon utilization strategies must be integrated with reactor design and cooling technology selection. For instance, molten metal reactors with optimized cooling systems produce carbon with distinct characteristics from those generated in plasma-based systems. This relationship between cooling technology and carbon quality necessitates a holistic approach to reactor design that considers the end-use of carbon byproducts.

Economic analyses indicate that carbon utilization can significantly improve the overall economics of methane pyrolysis hydrogen production. By converting carbon from a waste management challenge into a marketable product, the technology becomes more commercially viable. Current market assessments suggest potential revenue streams from carbon sales could offset 15-30% of production costs, depending on carbon quality and market conditions.

Regulatory frameworks increasingly recognize the value of carbon sequestration and utilization pathways. Carbon credits and incentives for carbon-negative technologies are evolving to include solid carbon sequestration, potentially enhancing the economic proposition of methane pyrolysis with advanced cooling systems. Future policy developments may further strengthen these incentives, making carbon management strategies an even more integral component of technology deployment.

The carbon produced through methane pyrolysis exists primarily as carbon black or graphitic carbon, depending on reactor conditions and cooling technologies employed. Advanced cooling systems not only improve process efficiency but also influence the morphology and quality of the carbon output, creating opportunities for high-value applications. Strategic management of this carbon involves categorizing potential uses based on carbon quality, market demand, and economic viability.

High-grade carbon outputs can be directed toward materials manufacturing, serving as precursors for carbon fiber production, graphene synthesis, or as additives in rubber and plastic industries. The cooling rate in pyrolysis reactors directly impacts carbon crystallinity, with more controlled cooling allowing for higher structural uniformity and thus higher market value. Medium-grade carbon finds applications in metallurgical processes, soil amendment as biochar, and construction materials.

Carbon utilization strategies must be integrated with reactor design and cooling technology selection. For instance, molten metal reactors with optimized cooling systems produce carbon with distinct characteristics from those generated in plasma-based systems. This relationship between cooling technology and carbon quality necessitates a holistic approach to reactor design that considers the end-use of carbon byproducts.

Economic analyses indicate that carbon utilization can significantly improve the overall economics of methane pyrolysis hydrogen production. By converting carbon from a waste management challenge into a marketable product, the technology becomes more commercially viable. Current market assessments suggest potential revenue streams from carbon sales could offset 15-30% of production costs, depending on carbon quality and market conditions.

Regulatory frameworks increasingly recognize the value of carbon sequestration and utilization pathways. Carbon credits and incentives for carbon-negative technologies are evolving to include solid carbon sequestration, potentially enhancing the economic proposition of methane pyrolysis with advanced cooling systems. Future policy developments may further strengthen these incentives, making carbon management strategies an even more integral component of technology deployment.

Economic Viability and Scaling Considerations

The economic viability of methane pyrolysis technology is heavily influenced by the efficiency and cost-effectiveness of reactor cooling systems. Current economic analyses indicate that methane pyrolysis with advanced cooling technologies can achieve hydrogen production costs between $1.50-2.50/kg, positioning it competitively against conventional steam methane reforming with carbon capture ($1.70-2.40/kg) when carbon pricing is considered. The capital expenditure for cooling systems typically represents 15-25% of total plant costs, making optimization critical for commercial deployment.

Energy efficiency improvements through advanced cooling technologies directly impact operational economics. Regenerative cooling systems that recover thermal energy can reduce overall energy consumption by 20-30%, significantly lowering operational expenses. Additionally, the solid carbon byproduct, when effectively separated through temperature-controlled processes, can be marketed as a valuable commodity, potentially offsetting 30-40% of production costs depending on carbon quality and market conditions.

Scaling considerations present both challenges and opportunities for methane pyrolysis cooling technologies. Laboratory-scale reactors (1-10 kg H₂/day) have demonstrated effective cooling management, but industrial-scale systems (1-10 tons H₂/day) face significant heat transfer challenges. The non-linear scaling of surface-to-volume ratios necessitates fundamentally different cooling approaches at commercial scales, with modular designs emerging as a promising solution to balance efficiency and capital costs.

Material selection for cooling systems significantly impacts both initial investment and long-term operational costs. While high-performance alloys and ceramics offer superior thermal management and longevity, their higher initial costs must be balanced against lifecycle considerations. Economic modeling suggests that premium materials can reduce maintenance frequency by 60-70%, justifying their 2-3x higher initial investment through extended operational lifespans and reduced downtime.

Integration with existing infrastructure represents another critical economic consideration. Facilities with access to industrial cooling water systems can reduce cooling infrastructure costs by 30-40%, while those requiring standalone systems face higher capital requirements. Similarly, grid connection costs for electrically-driven cooling systems vary significantly by location, affecting overall project economics.

The economic threshold for widespread adoption appears to be approaching, with several demonstration plants showing positive return-on-investment projections when carbon credits are included in financial models. Industry analysts project that with continued cooling technology improvements and economies of scale, methane pyrolysis could achieve cost parity with conventional hydrogen production methods by 2025-2027, even without carbon pricing mechanisms.

Energy efficiency improvements through advanced cooling technologies directly impact operational economics. Regenerative cooling systems that recover thermal energy can reduce overall energy consumption by 20-30%, significantly lowering operational expenses. Additionally, the solid carbon byproduct, when effectively separated through temperature-controlled processes, can be marketed as a valuable commodity, potentially offsetting 30-40% of production costs depending on carbon quality and market conditions.

Scaling considerations present both challenges and opportunities for methane pyrolysis cooling technologies. Laboratory-scale reactors (1-10 kg H₂/day) have demonstrated effective cooling management, but industrial-scale systems (1-10 tons H₂/day) face significant heat transfer challenges. The non-linear scaling of surface-to-volume ratios necessitates fundamentally different cooling approaches at commercial scales, with modular designs emerging as a promising solution to balance efficiency and capital costs.

Material selection for cooling systems significantly impacts both initial investment and long-term operational costs. While high-performance alloys and ceramics offer superior thermal management and longevity, their higher initial costs must be balanced against lifecycle considerations. Economic modeling suggests that premium materials can reduce maintenance frequency by 60-70%, justifying their 2-3x higher initial investment through extended operational lifespans and reduced downtime.

Integration with existing infrastructure represents another critical economic consideration. Facilities with access to industrial cooling water systems can reduce cooling infrastructure costs by 30-40%, while those requiring standalone systems face higher capital requirements. Similarly, grid connection costs for electrically-driven cooling systems vary significantly by location, affecting overall project economics.

The economic threshold for widespread adoption appears to be approaching, with several demonstration plants showing positive return-on-investment projections when carbon credits are included in financial models. Industry analysts project that with continued cooling technology improvements and economies of scale, methane pyrolysis could achieve cost parity with conventional hydrogen production methods by 2025-2027, even without carbon pricing mechanisms.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!