Methane Pyrolysis: Role in Heavy Industry Emission Control.

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Methane Pyrolysis Background and Decarbonization Goals

Methane pyrolysis represents a transformative approach to hydrogen production that has gained significant attention in recent years as industries seek viable decarbonization pathways. This process involves the thermal decomposition of methane (CH₄) into hydrogen (H₂) and solid carbon in the absence of oxygen, offering a stark contrast to conventional hydrogen production methods such as steam methane reforming (SMR) which generates substantial CO₂ emissions.

The historical development of methane pyrolysis dates back to the early 20th century, but recent technological advancements have revitalized interest in this process as a potential cornerstone of industrial decarbonization strategies. The evolution of high-temperature reactors, catalytic systems, and carbon handling technologies has significantly improved the economic and technical feasibility of methane pyrolysis at industrial scales.

Current global heavy industry sectors, including steel, cement, chemicals, and refining, collectively account for approximately 22% of global CO₂ emissions. These hard-to-abate sectors face unique challenges in their decarbonization journey due to high-temperature process requirements and feedstock-related emissions that cannot be eliminated through electrification alone.

Methane pyrolysis aligns with several critical decarbonization goals established under international frameworks such as the Paris Agreement and various national net-zero commitments. The technology offers a pathway to produce "turquoise hydrogen" – positioned between "gray hydrogen" (from SMR without carbon capture) and "green hydrogen" (from renewable-powered electrolysis) in terms of environmental impact and cost structure.

The primary technical goal for methane pyrolysis development centers on achieving high conversion efficiency while minimizing energy inputs. Current research aims to reduce reaction temperatures below 1000°C through advanced catalysts, improve reactor designs for continuous operation, and develop economically viable methods for solid carbon handling and valorization.

Market projections suggest that hydrogen demand could increase tenfold by 2050 in deep decarbonization scenarios, with industrial applications representing the largest growth segment. Methane pyrolysis is positioned to capture a significant portion of this market, particularly in regions with abundant natural gas resources but stringent carbon emission regulations.

The technology evolution trajectory indicates several promising developments, including molten metal reactors, plasma-assisted decomposition, and novel carbon nanomaterial production pathways that could transform waste carbon into valuable products, thereby improving the overall economics of the process.

As heavy industries face increasing regulatory pressure and carbon pricing mechanisms worldwide, methane pyrolysis represents a strategically important transitional technology that could enable significant emission reductions while leveraging existing natural gas infrastructure and expertise.

The historical development of methane pyrolysis dates back to the early 20th century, but recent technological advancements have revitalized interest in this process as a potential cornerstone of industrial decarbonization strategies. The evolution of high-temperature reactors, catalytic systems, and carbon handling technologies has significantly improved the economic and technical feasibility of methane pyrolysis at industrial scales.

Current global heavy industry sectors, including steel, cement, chemicals, and refining, collectively account for approximately 22% of global CO₂ emissions. These hard-to-abate sectors face unique challenges in their decarbonization journey due to high-temperature process requirements and feedstock-related emissions that cannot be eliminated through electrification alone.

Methane pyrolysis aligns with several critical decarbonization goals established under international frameworks such as the Paris Agreement and various national net-zero commitments. The technology offers a pathway to produce "turquoise hydrogen" – positioned between "gray hydrogen" (from SMR without carbon capture) and "green hydrogen" (from renewable-powered electrolysis) in terms of environmental impact and cost structure.

The primary technical goal for methane pyrolysis development centers on achieving high conversion efficiency while minimizing energy inputs. Current research aims to reduce reaction temperatures below 1000°C through advanced catalysts, improve reactor designs for continuous operation, and develop economically viable methods for solid carbon handling and valorization.

Market projections suggest that hydrogen demand could increase tenfold by 2050 in deep decarbonization scenarios, with industrial applications representing the largest growth segment. Methane pyrolysis is positioned to capture a significant portion of this market, particularly in regions with abundant natural gas resources but stringent carbon emission regulations.

The technology evolution trajectory indicates several promising developments, including molten metal reactors, plasma-assisted decomposition, and novel carbon nanomaterial production pathways that could transform waste carbon into valuable products, thereby improving the overall economics of the process.

As heavy industries face increasing regulatory pressure and carbon pricing mechanisms worldwide, methane pyrolysis represents a strategically important transitional technology that could enable significant emission reductions while leveraging existing natural gas infrastructure and expertise.

Market Demand for Low-Carbon Heavy Industry Solutions

The heavy industry sector, encompassing steel, cement, chemicals, and other manufacturing processes, contributes significantly to global greenhouse gas emissions. Recent market analyses indicate that heavy industries account for approximately 22% of global CO2 emissions, with steel and cement production being the largest contributors. This substantial environmental footprint has created an urgent market demand for innovative low-carbon solutions, particularly as governments worldwide implement increasingly stringent emission regulations and carbon pricing mechanisms.

The market for low-carbon heavy industry solutions is experiencing rapid growth, driven by both regulatory pressures and corporate sustainability commitments. The global market for carbon reduction technologies in heavy industry was valued at $45 billion in 2022 and is projected to reach $120 billion by 2030, representing a compound annual growth rate of 13%. This growth trajectory reflects the increasing willingness of industrial players to invest in emission reduction technologies.

Methane pyrolysis has emerged as a particularly promising technology within this market landscape. Traditional heavy industry processes rely heavily on fossil fuels for both energy and as feedstock, resulting in substantial carbon emissions. Methane pyrolysis offers a pathway to produce hydrogen—a versatile clean energy carrier—while simultaneously capturing solid carbon instead of releasing CO2. This dual benefit addresses a critical market need for solutions that can be integrated into existing industrial infrastructure without requiring complete process redesigns.

Market research indicates that industrial stakeholders are increasingly prioritizing technologies that offer both environmental benefits and economic viability. A 2023 survey of heavy industry executives revealed that 78% consider emission reduction a strategic priority, but 65% cite cost concerns as the primary barrier to adoption. Methane pyrolysis addresses this market tension by potentially offering a more cost-effective pathway to decarbonization compared to alternatives like carbon capture and storage or complete electrification.

Regional market analysis shows varying levels of demand for low-carbon solutions. The European Union, with its ambitious European Green Deal and Emissions Trading System, represents the most mature market for industrial decarbonization technologies. North America follows with growing interest driven by both regulatory developments and corporate sustainability initiatives. The Asia-Pacific region, while currently lagging in adoption, represents the largest potential market due to its dominant position in global heavy manufacturing.

Industry-specific demand also varies significantly. The steel industry, facing particular challenges in decarbonization due to its reliance on coal for both energy and as a reducing agent, shows the highest interest in hydrogen-based solutions like those enabled by methane pyrolysis. The chemical industry similarly demonstrates strong demand, particularly for technologies that can produce low-carbon hydrogen as a feedstock for ammonia and other chemical processes.

The market for low-carbon heavy industry solutions is experiencing rapid growth, driven by both regulatory pressures and corporate sustainability commitments. The global market for carbon reduction technologies in heavy industry was valued at $45 billion in 2022 and is projected to reach $120 billion by 2030, representing a compound annual growth rate of 13%. This growth trajectory reflects the increasing willingness of industrial players to invest in emission reduction technologies.

Methane pyrolysis has emerged as a particularly promising technology within this market landscape. Traditional heavy industry processes rely heavily on fossil fuels for both energy and as feedstock, resulting in substantial carbon emissions. Methane pyrolysis offers a pathway to produce hydrogen—a versatile clean energy carrier—while simultaneously capturing solid carbon instead of releasing CO2. This dual benefit addresses a critical market need for solutions that can be integrated into existing industrial infrastructure without requiring complete process redesigns.

Market research indicates that industrial stakeholders are increasingly prioritizing technologies that offer both environmental benefits and economic viability. A 2023 survey of heavy industry executives revealed that 78% consider emission reduction a strategic priority, but 65% cite cost concerns as the primary barrier to adoption. Methane pyrolysis addresses this market tension by potentially offering a more cost-effective pathway to decarbonization compared to alternatives like carbon capture and storage or complete electrification.

Regional market analysis shows varying levels of demand for low-carbon solutions. The European Union, with its ambitious European Green Deal and Emissions Trading System, represents the most mature market for industrial decarbonization technologies. North America follows with growing interest driven by both regulatory developments and corporate sustainability initiatives. The Asia-Pacific region, while currently lagging in adoption, represents the largest potential market due to its dominant position in global heavy manufacturing.

Industry-specific demand also varies significantly. The steel industry, facing particular challenges in decarbonization due to its reliance on coal for both energy and as a reducing agent, shows the highest interest in hydrogen-based solutions like those enabled by methane pyrolysis. The chemical industry similarly demonstrates strong demand, particularly for technologies that can produce low-carbon hydrogen as a feedstock for ammonia and other chemical processes.

Global Methane Pyrolysis Technology Status and Barriers

Methane pyrolysis technology has emerged as a promising solution for emission control in heavy industries, yet its global implementation faces significant challenges. Currently, the technology exists primarily at laboratory and pilot scales, with limited commercial deployment. Leading research institutions in Germany, the United States, and Australia have demonstrated successful methane decomposition into hydrogen and solid carbon, achieving conversion rates of 70-85% under optimal conditions. However, scaling these processes to industrial levels remains problematic due to reactor design limitations and catalyst deactivation issues.

The primary technical barrier involves maintaining stable high-temperature operations (700-1200°C) required for efficient pyrolysis while managing carbon deposition that gradually reduces catalytic activity. Most existing reactors experience significant performance degradation after 100-200 hours of operation, necessitating frequent maintenance cycles that impact economic viability. Molten metal catalysts, particularly those using nickel or iron-based systems, show promise but face challenges in metal loss and contamination over extended operation periods.

Energy efficiency represents another significant hurdle, as current systems require substantial thermal input, with energy conversion efficiencies typically ranging from 45-65%. This limitation reduces the net carbon benefit when considering the full lifecycle emissions, particularly if the energy source is not renewable. Advanced reactor designs utilizing concentrated solar thermal energy or renewable electricity for heating show potential but remain in early development stages.

Carbon handling and valorization constitute a critical barrier to widespread adoption. The solid carbon byproduct, while theoretically valuable, lacks established large-scale markets and standardized quality specifications. Current pyrolysis systems produce carbon with varying properties, making consistent commercialization difficult. Without reliable carbon offtake pathways, the economic model for methane pyrolysis becomes significantly less attractive.

Regulatory frameworks globally remain inconsistent regarding hydrogen production classification and carbon accounting methodologies. While the European Union has begun developing standards for "turquoise hydrogen" (produced via pyrolysis), many regions lack clear policies that would incentivize investment in this technology pathway. This regulatory uncertainty compounds the technical challenges, creating hesitation among potential industrial adopters.

Capital costs for methane pyrolysis systems currently exceed those of conventional steam methane reforming by approximately 30-50%, though this gap is expected to narrow as the technology matures and carbon pricing mechanisms become more widespread. Material science innovations, particularly in high-temperature resistant alloys and novel catalyst formulations, represent promising pathways to overcome several of these barriers simultaneously.

The primary technical barrier involves maintaining stable high-temperature operations (700-1200°C) required for efficient pyrolysis while managing carbon deposition that gradually reduces catalytic activity. Most existing reactors experience significant performance degradation after 100-200 hours of operation, necessitating frequent maintenance cycles that impact economic viability. Molten metal catalysts, particularly those using nickel or iron-based systems, show promise but face challenges in metal loss and contamination over extended operation periods.

Energy efficiency represents another significant hurdle, as current systems require substantial thermal input, with energy conversion efficiencies typically ranging from 45-65%. This limitation reduces the net carbon benefit when considering the full lifecycle emissions, particularly if the energy source is not renewable. Advanced reactor designs utilizing concentrated solar thermal energy or renewable electricity for heating show potential but remain in early development stages.

Carbon handling and valorization constitute a critical barrier to widespread adoption. The solid carbon byproduct, while theoretically valuable, lacks established large-scale markets and standardized quality specifications. Current pyrolysis systems produce carbon with varying properties, making consistent commercialization difficult. Without reliable carbon offtake pathways, the economic model for methane pyrolysis becomes significantly less attractive.

Regulatory frameworks globally remain inconsistent regarding hydrogen production classification and carbon accounting methodologies. While the European Union has begun developing standards for "turquoise hydrogen" (produced via pyrolysis), many regions lack clear policies that would incentivize investment in this technology pathway. This regulatory uncertainty compounds the technical challenges, creating hesitation among potential industrial adopters.

Capital costs for methane pyrolysis systems currently exceed those of conventional steam methane reforming by approximately 30-50%, though this gap is expected to narrow as the technology matures and carbon pricing mechanisms become more widespread. Material science innovations, particularly in high-temperature resistant alloys and novel catalyst formulations, represent promising pathways to overcome several of these barriers simultaneously.

Current Methane Pyrolysis Implementation Methods

01 Catalytic systems for methane pyrolysis emission control

Various catalytic systems can be employed to control emissions during methane pyrolysis. These catalysts facilitate the decomposition of methane into hydrogen and solid carbon while minimizing unwanted byproducts and emissions. Advanced catalytic materials can operate at lower temperatures, reducing energy consumption and associated emissions. The catalysts can be designed to selectively promote desired reaction pathways while suppressing the formation of pollutants such as CO2 and other greenhouse gases.- Catalytic systems for methane pyrolysis emission control: Various catalytic systems can be employed to control emissions during methane pyrolysis. These catalysts facilitate the decomposition of methane into hydrogen and solid carbon while minimizing the formation of harmful byproducts. Advanced catalytic materials such as metal-based catalysts and novel support structures enhance conversion efficiency and reduce unwanted emissions. These systems often operate at optimized temperatures and pressures to maximize methane conversion while minimizing the release of greenhouse gases and other pollutants.

- Carbon capture and utilization in methane pyrolysis: Carbon capture technologies are integrated into methane pyrolysis processes to manage carbon emissions. The solid carbon produced during pyrolysis can be captured and utilized in various applications, including as a raw material for manufacturing carbon-based products. This approach not only controls emissions but also creates valuable byproducts. Advanced separation techniques ensure efficient carbon capture while maintaining the purity of hydrogen production. These systems contribute to reducing the overall carbon footprint of methane pyrolysis operations.

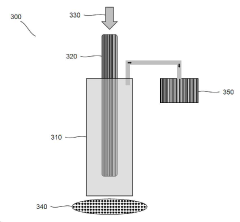

- Reactor design innovations for emission reduction: Innovative reactor designs play a crucial role in controlling emissions during methane pyrolysis. These designs include specialized chambers, improved heat management systems, and enhanced gas flow patterns that optimize the pyrolysis process while minimizing unwanted emissions. Some reactors incorporate integrated filtration systems to capture particulate matter and other pollutants. Advanced materials used in reactor construction can withstand high temperatures while preventing leakage of gases. These design innovations significantly reduce the environmental impact of methane pyrolysis operations.

- Process monitoring and control systems: Sophisticated monitoring and control systems are implemented to manage emissions during methane pyrolysis. These systems utilize sensors, analyzers, and automated control mechanisms to continuously monitor process parameters and emission levels. Real-time data analysis allows for immediate adjustments to operating conditions when emission thresholds are approached. Advanced algorithms optimize process efficiency while maintaining emission compliance. These monitoring systems can detect leaks, equipment malfunctions, or process deviations that might lead to increased emissions, enabling prompt corrective actions.

- Integration with renewable energy for cleaner pyrolysis: Methane pyrolysis processes can be integrated with renewable energy sources to reduce overall emissions. By using solar, wind, or other renewable energy to power the pyrolysis process, the carbon footprint associated with the energy requirements is significantly reduced. This approach creates a more environmentally friendly hydrogen production pathway. Some systems utilize excess renewable energy during off-peak periods, contributing to grid stability while producing clean hydrogen. The integration of thermal energy storage systems further enhances the efficiency of renewable-powered pyrolysis operations.

02 Reactor design optimization for emission reduction

Specialized reactor designs can significantly reduce emissions in methane pyrolysis processes. These designs include fluidized bed reactors, molten metal reactors, and plasma-assisted reactors that enhance reaction efficiency while minimizing unwanted byproducts. Improved heat transfer mechanisms and residence time control help optimize the pyrolysis conditions. Advanced reactor configurations also incorporate features for continuous carbon removal, preventing catalyst deactivation and ensuring stable operation with minimal emissions.Expand Specific Solutions03 Carbon capture and utilization systems

Integrated carbon capture systems can be implemented to manage the solid carbon produced during methane pyrolysis. These systems collect and process the carbon for various applications, including advanced materials production, soil amendment, or long-term sequestration. By effectively capturing and utilizing the carbon byproduct, these technologies prevent its release as CO2 or other emissions. The captured carbon can be transformed into value-added products, creating a circular economy approach to emission control.Expand Specific Solutions04 Process monitoring and control technologies

Advanced monitoring and control systems play a crucial role in minimizing emissions during methane pyrolysis. These technologies include real-time sensors, predictive analytics, and automated control systems that optimize process parameters. By continuously monitoring reaction conditions and adjusting variables such as temperature, pressure, and feed rate, these systems can prevent the formation of unwanted byproducts. Machine learning algorithms can further enhance process efficiency by identifying optimal operating conditions that minimize emissions while maximizing hydrogen yield.Expand Specific Solutions05 Heat recovery and energy integration methods

Heat recovery and energy integration techniques can significantly reduce the overall environmental impact of methane pyrolysis processes. These methods capture and reuse thermal energy from the pyrolysis reaction, reducing the need for external heating and associated emissions. Waste heat can be utilized for preheating feed streams, generating steam, or producing electricity. Advanced heat exchanger designs and thermal management systems ensure efficient energy utilization throughout the process, minimizing the carbon footprint of hydrogen production via methane pyrolysis.Expand Specific Solutions

Key Industrial Players and Research Institutions

Methane pyrolysis is emerging as a critical technology for emission control in heavy industry, currently in the early commercialization phase with a growing market projected to reach significant scale as decarbonization efforts intensify. The competitive landscape features established energy companies like Shell, BASF, and ExxonMobil leveraging their industrial infrastructure, alongside innovative startups such as Molten Industries and Hazer Group developing novel catalytic approaches. Research institutions including Taiyuan University of Technology and Dalian University of Technology are advancing fundamental science, while engineering firms like SINOPEC and GTI Energy focus on scalable implementation solutions. The technology's maturity varies across applications, with thermal decomposition methods more developed than newer catalytic processes that promise greater efficiency and lower energy requirements.

Molten Industries Inc.

Technical Solution: Molten Industries has pioneered a methane pyrolysis technology specifically designed for heavy industry emission control called "MeltH2". Their approach utilizes a proprietary molten metal bath reactor system that employs a eutectic mixture of nickel, bismuth, and tin alloys as both heat transfer medium and catalyst. Operating at temperatures between 850-950°C, the system achieves methane conversion rates of up to 90% with hydrogen purity exceeding 99.5% after minimal post-processing[5]. The MeltH2 technology features a continuous carbon extraction mechanism that removes solid carbon from the molten metal bath using mechanical skimming combined with electromagnetic separation, preventing catalyst poisoning and reactor fouling. Molten Industries has developed a unique heat management system that utilizes the exothermic nature of certain stages of the reaction to partially self-sustain the process temperature, reducing external energy requirements by approximately 35% compared to conventional methane pyrolysis approaches. The system is designed with a modular architecture that can be scaled from pilot plants producing 50 kg/day to full industrial installations capable of generating up to 50 tons of hydrogen daily, making it adaptable to various industrial settings including steel mills, cement plants, and chemical manufacturing facilities[6].

Strengths: Molten Industries' technology produces zero-emission hydrogen without CO2 generation, creates high-value carbon nanomaterials as byproducts that can offset operational costs, and offers flexible scaling options for different industrial applications. Weaknesses: The system requires sophisticated materials to withstand the corrosive nature of molten metals at high temperatures, faces challenges in maintaining consistent carbon extraction efficiency at scale, and demands specialized expertise for operation and maintenance.

BASF Corp.

Technical Solution: BASF has developed a comprehensive methane pyrolysis technology platform called "CarbonH" specifically designed for integration into heavy industrial processes. Their approach utilizes a moving bed reactor system with proprietary metal alloy catalysts that operate at temperatures between 800-950°C. The process achieves methane conversion rates exceeding 85% with hydrogen purity of over 98% prior to final purification steps[9]. BASF's technology incorporates a continuous catalyst regeneration system that addresses carbon deposition challenges, maintaining catalyst activity for extended operational periods of up to 8,000 hours before major maintenance is required. The CarbonH platform features advanced heat integration that recovers thermal energy from multiple process streams, reducing overall energy consumption by approximately 40% compared to conventional steam methane reforming. A distinguishing aspect of BASF's approach is their carbon handling system, which processes the solid carbon byproduct into various forms tailored for specific applications, including carbon black for rubber manufacturing, graphitic carbon for battery materials, and activated carbon for filtration applications. The technology has been designed with modular scalability, allowing deployment across various industrial settings from chemical plants to steel mills, with hydrogen production capacities ranging from 5 to 100 tons per day[10].

Strengths: BASF's technology produces hydrogen with over 90% lower CO2 emissions than conventional methods, creates multiple value streams through tailored carbon byproducts, and integrates seamlessly with existing industrial infrastructure. Weaknesses: The process requires sophisticated materials to withstand high-temperature operation, faces challenges in maintaining consistent carbon quality across different operating conditions, and demands significant initial capital investment for implementation.

Critical Patents and Innovations in Methane Decomposition

Methane pyrolysis process, fabrication method for alloy powder catalysts for methane pyrolysis and device for methane pyrolysis

PatentActiveKR1020240053230A

Innovation

- A methane pyrolysis process utilizing a molten alloy catalyst formed by mixing metals like nickel, copper, tin, and bismuth, produced through ball-milling or cryomilling, to facilitate thermal decomposition of methane into carbon and hydrogen, with a methane pyrolysis device incorporating a reaction vessel and heating unit.

Pyrolysis of methane with a molten salt based catalyst system

PatentWO2019197256A1

Innovation

- A molten salt-based catalyst system is developed, comprising halides of specific metals and dispersed catalytically active metals like iron, molybdenum, and copper, which promotes high-temperature methane pyrolysis and controls carbon morphology, preventing solid carbon deposition on reactor walls.

Economic Viability and Cost Analysis

The economic viability of methane pyrolysis as an emission control strategy in heavy industries hinges on several interconnected factors. Current cost analyses indicate that methane pyrolysis requires an initial capital investment ranging from $500-1,200 per ton of hydrogen production capacity, significantly higher than conventional steam methane reforming methods. However, this comparison fails to account for the avoided carbon tax costs and potential revenue streams from solid carbon byproducts.

When factoring in carbon pricing mechanisms, methane pyrolysis becomes increasingly competitive. In regions with carbon prices exceeding $50-60 per ton of CO2, the technology approaches cost parity with traditional methods. The production of solid carbon as a byproduct represents a potential revenue stream valued at $1,000-2,500 per ton depending on carbon quality and market applications, which can substantially improve the economic equation.

Operational costs present both challenges and opportunities. Energy consumption remains a significant expense, with methane pyrolysis requiring 37-45 kWh per kg of hydrogen produced. However, integration with renewable energy sources can mitigate these costs while further enhancing environmental benefits. Maintenance costs for high-temperature reactors and specialized catalysts add approximately 15-20% to annual operational expenses.

Scale economies play a crucial role in cost reduction pathways. Current pilot installations demonstrate that scaling from laboratory to industrial implementation can reduce unit costs by 30-40%. Industry projections suggest that with technological maturation and wider adoption, costs could decrease by an additional 25-35% over the next decade.

Financing mechanisms and policy incentives significantly impact economic feasibility. Green bonds, sustainability-linked loans, and climate tech venture capital have emerged as key funding sources for methane pyrolysis projects. Government subsidies, tax incentives, and preferential financing terms in various jurisdictions can reduce effective costs by 15-30%, dramatically improving return on investment calculations.

Comparative lifecycle cost analyses reveal that methane pyrolysis becomes economically advantageous over a 10-15 year horizon when accounting for increasingly stringent emission regulations and rising carbon prices. The technology offers a particularly compelling value proposition for industries facing limited decarbonization alternatives, such as steel manufacturing, cement production, and chemical processing.

When factoring in carbon pricing mechanisms, methane pyrolysis becomes increasingly competitive. In regions with carbon prices exceeding $50-60 per ton of CO2, the technology approaches cost parity with traditional methods. The production of solid carbon as a byproduct represents a potential revenue stream valued at $1,000-2,500 per ton depending on carbon quality and market applications, which can substantially improve the economic equation.

Operational costs present both challenges and opportunities. Energy consumption remains a significant expense, with methane pyrolysis requiring 37-45 kWh per kg of hydrogen produced. However, integration with renewable energy sources can mitigate these costs while further enhancing environmental benefits. Maintenance costs for high-temperature reactors and specialized catalysts add approximately 15-20% to annual operational expenses.

Scale economies play a crucial role in cost reduction pathways. Current pilot installations demonstrate that scaling from laboratory to industrial implementation can reduce unit costs by 30-40%. Industry projections suggest that with technological maturation and wider adoption, costs could decrease by an additional 25-35% over the next decade.

Financing mechanisms and policy incentives significantly impact economic feasibility. Green bonds, sustainability-linked loans, and climate tech venture capital have emerged as key funding sources for methane pyrolysis projects. Government subsidies, tax incentives, and preferential financing terms in various jurisdictions can reduce effective costs by 15-30%, dramatically improving return on investment calculations.

Comparative lifecycle cost analyses reveal that methane pyrolysis becomes economically advantageous over a 10-15 year horizon when accounting for increasingly stringent emission regulations and rising carbon prices. The technology offers a particularly compelling value proposition for industries facing limited decarbonization alternatives, such as steel manufacturing, cement production, and chemical processing.

Regulatory Framework and Carbon Credit Implications

The regulatory landscape surrounding methane emissions is rapidly evolving, creating both challenges and opportunities for heavy industry adopting methane pyrolysis technologies. The Paris Agreement has established a framework requiring signatory nations to implement progressively stringent emission reduction targets, with methane specifically identified as a critical greenhouse gas requiring immediate attention. In the European Union, the European Green Deal and subsequent Carbon Border Adjustment Mechanism (CBAM) have created direct financial incentives for industries to adopt low-carbon technologies like methane pyrolysis.

In the United States, the EPA's Methane Emissions Reduction Action Plan targets a 30% reduction in methane emissions by 2030, with heavy industry facing increasingly stringent compliance requirements. The Inflation Reduction Act of 2022 has allocated substantial funding for clean hydrogen production, including methane pyrolysis pathways, offering tax credits of up to $3 per kilogram for zero-emission hydrogen production.

Carbon pricing mechanisms worldwide have created a financial framework that increasingly favors methane pyrolysis adoption. The average carbon price across regulated markets has risen from approximately $15/tCO2e in 2018 to over $50/tCO2e in several major economies by 2023, making emission-reduction technologies economically competitive with traditional processes. Industries implementing methane pyrolysis can potentially generate carbon credits through verified emission reduction protocols.

The voluntary carbon market presents additional opportunities, with methane abatement credits commanding premium prices of $25-75/tCO2e compared to standard carbon offsets. Companies like ArcelorMittal and BASF have already incorporated carbon credit generation into their methane pyrolysis implementation strategies, creating secondary revenue streams that improve project economics.

Regulatory frameworks are increasingly recognizing the dual benefits of methane pyrolysis: emissions reduction and valuable solid carbon production. Several jurisdictions have implemented regulatory classifications that recognize solid carbon as a product rather than a waste stream, simplifying permitting processes and creating additional economic incentives through circular economy frameworks.

Looking forward, the regulatory trajectory suggests increasing financial penalties for methane emissions alongside growing incentives for innovative abatement technologies. Industry leaders implementing methane pyrolysis today are positioning themselves advantageously for future regulatory requirements, while simultaneously developing expertise in carbon credit generation that may represent significant value as carbon markets mature and prices continue to rise.

In the United States, the EPA's Methane Emissions Reduction Action Plan targets a 30% reduction in methane emissions by 2030, with heavy industry facing increasingly stringent compliance requirements. The Inflation Reduction Act of 2022 has allocated substantial funding for clean hydrogen production, including methane pyrolysis pathways, offering tax credits of up to $3 per kilogram for zero-emission hydrogen production.

Carbon pricing mechanisms worldwide have created a financial framework that increasingly favors methane pyrolysis adoption. The average carbon price across regulated markets has risen from approximately $15/tCO2e in 2018 to over $50/tCO2e in several major economies by 2023, making emission-reduction technologies economically competitive with traditional processes. Industries implementing methane pyrolysis can potentially generate carbon credits through verified emission reduction protocols.

The voluntary carbon market presents additional opportunities, with methane abatement credits commanding premium prices of $25-75/tCO2e compared to standard carbon offsets. Companies like ArcelorMittal and BASF have already incorporated carbon credit generation into their methane pyrolysis implementation strategies, creating secondary revenue streams that improve project economics.

Regulatory frameworks are increasingly recognizing the dual benefits of methane pyrolysis: emissions reduction and valuable solid carbon production. Several jurisdictions have implemented regulatory classifications that recognize solid carbon as a product rather than a waste stream, simplifying permitting processes and creating additional economic incentives through circular economy frameworks.

Looking forward, the regulatory trajectory suggests increasing financial penalties for methane emissions alongside growing incentives for innovative abatement technologies. Industry leaders implementing methane pyrolysis today are positioning themselves advantageously for future regulatory requirements, while simultaneously developing expertise in carbon credit generation that may represent significant value as carbon markets mature and prices continue to rise.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!