How Methane Pyrolysis Contributes to Industry Decarbonization.

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Methane Pyrolysis Background and Decarbonization Goals

Methane pyrolysis represents a significant technological advancement in the field of hydrogen production, offering a pathway to produce hydrogen without direct carbon dioxide emissions. This process involves the thermal decomposition of methane (CH4) into hydrogen (H2) and solid carbon at high temperatures, typically between 700-1200°C. Unlike traditional hydrogen production methods such as steam methane reforming (SMR), which generates CO2 as a byproduct, methane pyrolysis captures carbon in solid form, effectively preventing its release into the atmosphere.

The evolution of methane pyrolysis technology dates back to the early 20th century, but recent advancements have significantly improved its efficiency and commercial viability. Over the past decade, innovations in catalyst development, reactor design, and process integration have positioned methane pyrolysis as a promising solution for decarbonization efforts across various industries.

Industry decarbonization has become an urgent global priority as countries and corporations commit to ambitious climate targets. The Paris Agreement's goal of limiting global warming to well below 2°C above pre-industrial levels has accelerated the search for technologies that can enable deep emissions reductions in hard-to-abate sectors. Methane pyrolysis aligns with these objectives by offering a pathway to produce hydrogen—a versatile clean energy carrier—while avoiding the carbon emissions associated with conventional production methods.

The technical goals for methane pyrolysis in the context of industry decarbonization are multifaceted. Primary objectives include increasing energy efficiency, reducing production costs to achieve price parity with conventional hydrogen, scaling up reactor designs for industrial implementation, and developing valuable applications for the solid carbon byproduct. Additionally, researchers aim to optimize catalyst performance, enhance process stability, and integrate methane pyrolysis systems with renewable energy sources to further reduce the carbon footprint.

Current technological trajectories suggest that methane pyrolysis will continue to evolve along several paths, including molten metal reactors, plasma-assisted decomposition, and advanced catalytic systems. Each approach offers distinct advantages and challenges, with ongoing research focused on overcoming technical barriers related to carbon handling, heat management, and continuous operation.

The potential impact of methane pyrolysis extends beyond hydrogen production. As industries seek to decarbonize their operations, this technology could serve as a transitional solution that leverages existing natural gas infrastructure while significantly reducing carbon emissions. Furthermore, the solid carbon byproduct presents opportunities for carbon sequestration or utilization in various applications, from construction materials to advanced carbon products, potentially creating additional value streams that enhance the economic viability of the process.

The evolution of methane pyrolysis technology dates back to the early 20th century, but recent advancements have significantly improved its efficiency and commercial viability. Over the past decade, innovations in catalyst development, reactor design, and process integration have positioned methane pyrolysis as a promising solution for decarbonization efforts across various industries.

Industry decarbonization has become an urgent global priority as countries and corporations commit to ambitious climate targets. The Paris Agreement's goal of limiting global warming to well below 2°C above pre-industrial levels has accelerated the search for technologies that can enable deep emissions reductions in hard-to-abate sectors. Methane pyrolysis aligns with these objectives by offering a pathway to produce hydrogen—a versatile clean energy carrier—while avoiding the carbon emissions associated with conventional production methods.

The technical goals for methane pyrolysis in the context of industry decarbonization are multifaceted. Primary objectives include increasing energy efficiency, reducing production costs to achieve price parity with conventional hydrogen, scaling up reactor designs for industrial implementation, and developing valuable applications for the solid carbon byproduct. Additionally, researchers aim to optimize catalyst performance, enhance process stability, and integrate methane pyrolysis systems with renewable energy sources to further reduce the carbon footprint.

Current technological trajectories suggest that methane pyrolysis will continue to evolve along several paths, including molten metal reactors, plasma-assisted decomposition, and advanced catalytic systems. Each approach offers distinct advantages and challenges, with ongoing research focused on overcoming technical barriers related to carbon handling, heat management, and continuous operation.

The potential impact of methane pyrolysis extends beyond hydrogen production. As industries seek to decarbonize their operations, this technology could serve as a transitional solution that leverages existing natural gas infrastructure while significantly reducing carbon emissions. Furthermore, the solid carbon byproduct presents opportunities for carbon sequestration or utilization in various applications, from construction materials to advanced carbon products, potentially creating additional value streams that enhance the economic viability of the process.

Market Demand for Low-Carbon Hydrogen Solutions

The global hydrogen market is experiencing a significant shift towards low-carbon solutions, driven primarily by intensifying climate change concerns and increasingly stringent emissions regulations across major economies. Current estimates place the global hydrogen market at approximately $130 billion, with projections indicating growth to $500 billion by 2030 if decarbonization efforts accelerate as anticipated. Traditional hydrogen production methods, particularly steam methane reforming (SMR), account for over 95% of current hydrogen production but generate substantial CO2 emissions—approximately 9-12 kg CO2 per kg of hydrogen produced.

Industrial sectors represent the primary demand centers for low-carbon hydrogen solutions. The chemical industry, particularly ammonia and methanol production, constitutes roughly 60% of current hydrogen consumption. Refineries account for another 25%, while emerging applications in steel manufacturing, transportation, and energy storage are rapidly expanding market segments. These sectors face mounting pressure to reduce their carbon footprints while maintaining operational efficiency and economic viability.

Regional policy frameworks are significantly influencing market development. The European Union's Hydrogen Strategy targets 40 GW of renewable hydrogen electrolyzers by 2030, while Japan's Basic Hydrogen Strategy aims to reduce hydrogen costs to $3/kg by 2030. China's 14th Five-Year Plan emphasizes hydrogen as a frontier area for achieving carbon neutrality goals, and the United States has allocated substantial funding through the Infrastructure Investment and Jobs Act specifically for hydrogen hubs development.

Cost considerations remain paramount in market adoption dynamics. Currently, conventional gray hydrogen costs between $1-2/kg, while blue hydrogen (with carbon capture) ranges from $2-3/kg, and green hydrogen (from renewable electrolysis) costs $3-6/kg. Methane pyrolysis-derived hydrogen, often termed "turquoise hydrogen," occupies a promising middle ground at approximately $1.5-3/kg, with the additional benefit of producing solid carbon rather than CO2.

Market research indicates that industrial customers prioritize three key factors when evaluating hydrogen solutions: cost competitiveness with existing processes, reliability of supply, and compatibility with existing infrastructure. Methane pyrolysis addresses these concerns by offering a production method that can utilize existing natural gas infrastructure while eliminating direct CO2 emissions.

The investment landscape reflects growing confidence in low-carbon hydrogen technologies. Venture capital funding in hydrogen technologies has increased by over 500% since 2015, with particular interest in scalable production methods that offer near-term commercial viability. Major industrial gas companies and energy corporations are strategically positioning themselves through partnerships and acquisitions to capture market share in this rapidly evolving sector.

Industrial sectors represent the primary demand centers for low-carbon hydrogen solutions. The chemical industry, particularly ammonia and methanol production, constitutes roughly 60% of current hydrogen consumption. Refineries account for another 25%, while emerging applications in steel manufacturing, transportation, and energy storage are rapidly expanding market segments. These sectors face mounting pressure to reduce their carbon footprints while maintaining operational efficiency and economic viability.

Regional policy frameworks are significantly influencing market development. The European Union's Hydrogen Strategy targets 40 GW of renewable hydrogen electrolyzers by 2030, while Japan's Basic Hydrogen Strategy aims to reduce hydrogen costs to $3/kg by 2030. China's 14th Five-Year Plan emphasizes hydrogen as a frontier area for achieving carbon neutrality goals, and the United States has allocated substantial funding through the Infrastructure Investment and Jobs Act specifically for hydrogen hubs development.

Cost considerations remain paramount in market adoption dynamics. Currently, conventional gray hydrogen costs between $1-2/kg, while blue hydrogen (with carbon capture) ranges from $2-3/kg, and green hydrogen (from renewable electrolysis) costs $3-6/kg. Methane pyrolysis-derived hydrogen, often termed "turquoise hydrogen," occupies a promising middle ground at approximately $1.5-3/kg, with the additional benefit of producing solid carbon rather than CO2.

Market research indicates that industrial customers prioritize three key factors when evaluating hydrogen solutions: cost competitiveness with existing processes, reliability of supply, and compatibility with existing infrastructure. Methane pyrolysis addresses these concerns by offering a production method that can utilize existing natural gas infrastructure while eliminating direct CO2 emissions.

The investment landscape reflects growing confidence in low-carbon hydrogen technologies. Venture capital funding in hydrogen technologies has increased by over 500% since 2015, with particular interest in scalable production methods that offer near-term commercial viability. Major industrial gas companies and energy corporations are strategically positioning themselves through partnerships and acquisitions to capture market share in this rapidly evolving sector.

Current State and Challenges of Methane Pyrolysis Technology

Methane pyrolysis technology has emerged as a promising pathway for hydrogen production with significantly reduced carbon emissions compared to conventional methods. Currently, the technology exists at various stages of development globally, with several pilot plants and demonstration facilities operating in Europe, North America, and Asia. Laboratory-scale research has demonstrated the technical feasibility of methane decomposition into hydrogen and solid carbon, achieving conversion rates of 70-90% under optimal conditions.

The primary technological approaches include thermal pyrolysis (utilizing temperatures of 900-1200°C), catalytic pyrolysis (employing metal catalysts like nickel or iron at lower temperatures of 500-900°C), and plasma-assisted pyrolysis. Each method presents distinct advantages and limitations in terms of energy efficiency, carbon quality, and scalability. Thermal methods offer simplicity but require substantial energy input, while catalytic approaches reduce energy requirements but face catalyst deactivation challenges.

Despite promising developments, methane pyrolysis faces significant technical hurdles that impede widespread industrial adoption. The most pressing challenge is the energy intensity of the process, which requires substantial heat input to break carbon-hydrogen bonds. Current systems struggle to achieve energy efficiency levels necessary for economic viability at industrial scale, with energy consumption typically ranging from 37-65 kWh per kg of hydrogen produced.

Catalyst deactivation represents another major obstacle, particularly for catalytic pyrolysis systems. Carbon deposition on catalyst surfaces progressively reduces catalytic activity, necessitating frequent regeneration or replacement cycles that impact operational continuity and economic feasibility. Most catalytic systems currently demonstrate stable operation for only 100-200 hours before requiring intervention.

Reactor design presents complex engineering challenges, particularly regarding continuous carbon removal without process interruption. The accumulation of solid carbon can lead to reactor clogging, pressure drops, and reduced heat transfer efficiency. Current reactor configurations, including fluidized bed, moving bed, and molten metal reactors, each present trade-offs between conversion efficiency, carbon handling, and operational complexity.

Geographically, research leadership is distributed across several regions. Germany leads in molten metal reactor technology through companies like BASF and research institutions like Karlsruhe Institute of Technology. The United States demonstrates strength in plasma-assisted pyrolysis through startups like C-Zero and Monolith Materials. Japan and South Korea focus on catalytic approaches, while Australia has emerging initiatives in solar-thermal pyrolysis methods.

Scale-up challenges remain significant, with most current installations operating at production capacities of 100-500 kg hydrogen per day, far below the multi-ton daily production needed for industrial applications. The technology readiness level (TRL) of methane pyrolysis varies between 5-7 depending on the specific approach, indicating the need for further development before full commercial deployment.

The primary technological approaches include thermal pyrolysis (utilizing temperatures of 900-1200°C), catalytic pyrolysis (employing metal catalysts like nickel or iron at lower temperatures of 500-900°C), and plasma-assisted pyrolysis. Each method presents distinct advantages and limitations in terms of energy efficiency, carbon quality, and scalability. Thermal methods offer simplicity but require substantial energy input, while catalytic approaches reduce energy requirements but face catalyst deactivation challenges.

Despite promising developments, methane pyrolysis faces significant technical hurdles that impede widespread industrial adoption. The most pressing challenge is the energy intensity of the process, which requires substantial heat input to break carbon-hydrogen bonds. Current systems struggle to achieve energy efficiency levels necessary for economic viability at industrial scale, with energy consumption typically ranging from 37-65 kWh per kg of hydrogen produced.

Catalyst deactivation represents another major obstacle, particularly for catalytic pyrolysis systems. Carbon deposition on catalyst surfaces progressively reduces catalytic activity, necessitating frequent regeneration or replacement cycles that impact operational continuity and economic feasibility. Most catalytic systems currently demonstrate stable operation for only 100-200 hours before requiring intervention.

Reactor design presents complex engineering challenges, particularly regarding continuous carbon removal without process interruption. The accumulation of solid carbon can lead to reactor clogging, pressure drops, and reduced heat transfer efficiency. Current reactor configurations, including fluidized bed, moving bed, and molten metal reactors, each present trade-offs between conversion efficiency, carbon handling, and operational complexity.

Geographically, research leadership is distributed across several regions. Germany leads in molten metal reactor technology through companies like BASF and research institutions like Karlsruhe Institute of Technology. The United States demonstrates strength in plasma-assisted pyrolysis through startups like C-Zero and Monolith Materials. Japan and South Korea focus on catalytic approaches, while Australia has emerging initiatives in solar-thermal pyrolysis methods.

Scale-up challenges remain significant, with most current installations operating at production capacities of 100-500 kg hydrogen per day, far below the multi-ton daily production needed for industrial applications. The technology readiness level (TRL) of methane pyrolysis varies between 5-7 depending on the specific approach, indicating the need for further development before full commercial deployment.

Current Methane Pyrolysis Implementation Approaches

01 Catalytic methane pyrolysis for hydrogen production

Catalytic processes can be employed to enhance methane pyrolysis for hydrogen production while capturing solid carbon. These processes typically use metal catalysts such as nickel, iron, or molybdenum to lower the activation energy required for breaking carbon-hydrogen bonds. The catalytic approach allows for operation at lower temperatures compared to thermal pyrolysis, making the process more energy-efficient and economically viable for decarbonization applications.- Methane pyrolysis reactor designs for hydrogen production: Various reactor designs have been developed for methane pyrolysis to produce hydrogen without CO2 emissions. These include molten metal reactors, fluidized bed reactors, and plasma-based systems that enable the thermal decomposition of methane into hydrogen and solid carbon. The reactor designs focus on optimizing heat transfer, residence time, and catalyst interaction to achieve efficient conversion rates while minimizing energy consumption.

- Catalytic systems for methane decomposition: Catalytic materials play a crucial role in methane pyrolysis by lowering the activation energy required for decomposition. Various catalysts including transition metals, metal carbides, and carbon-based materials have been developed to enhance reaction kinetics and selectivity. These catalytic systems improve conversion efficiency at lower temperatures, resulting in reduced energy requirements and increased hydrogen yield while producing valuable carbon co-products.

- Carbon management and utilization strategies: Effective management of the solid carbon byproduct is essential for sustainable methane pyrolysis. Technologies have been developed for carbon separation, collection, and processing into valuable products such as carbon black, graphene, or construction materials. These approaches transform what could be a waste product into marketable materials, enhancing the economic viability of methane pyrolysis while ensuring permanent carbon sequestration.

- Process integration and system optimization: Integrated systems have been designed to optimize the overall methane pyrolysis process by recovering waste heat, improving gas separation, and enhancing operational efficiency. These systems incorporate advanced control mechanisms, heat exchangers, and separation technologies to maximize hydrogen yield while minimizing energy consumption. Process integration approaches also focus on coupling methane pyrolysis with existing industrial processes to utilize waste heat and improve overall system economics.

- Renewable energy integration for zero-emission hydrogen: Combining methane pyrolysis with renewable energy sources creates pathways for truly zero-emission hydrogen production. Systems have been developed that utilize solar, wind, or geothermal energy to provide the heat required for pyrolysis, eliminating the need for fossil fuel combustion. These integrated approaches enable carbon-negative hydrogen production when coupled with sustainable methane sources such as biogas, further enhancing the decarbonization potential of the technology.

02 Molten metal reactors for methane decomposition

Molten metal reactors provide an innovative approach to methane pyrolysis by using liquid metals such as tin, bismuth, or gallium as both heat transfer medium and catalyst. The methane bubbles through the molten metal bath where it decomposes into hydrogen gas and solid carbon. This technology offers advantages including continuous carbon removal, excellent heat transfer properties, and prevention of carbon deposition on reactor walls, making it particularly effective for decarbonization applications.Expand Specific Solutions03 Plasma-assisted methane pyrolysis systems

Plasma technology can be utilized to achieve methane pyrolysis at lower bulk temperatures by creating localized high-energy environments. These systems use electrical discharges to generate plasma that breaks down methane molecules into hydrogen and solid carbon. The plasma approach offers rapid reaction rates, reduced energy consumption compared to purely thermal methods, and can be powered by renewable electricity, making it a promising carbon-neutral pathway for hydrogen production.Expand Specific Solutions04 Carbon capture and utilization from pyrolysis

Methods for capturing, processing, and utilizing the solid carbon byproduct from methane pyrolysis contribute significantly to the decarbonization value of the process. These approaches include techniques for carbon separation, purification, and conversion into valuable products such as carbon fibers, graphene, or carbon black. By creating marketable carbon products, these methods improve the economic viability of methane pyrolysis while preventing carbon dioxide emissions associated with conventional hydrogen production.Expand Specific Solutions05 Integrated systems for methane pyrolysis decarbonization

Integrated systems combine methane pyrolysis with complementary processes to enhance overall efficiency and decarbonization potential. These systems may incorporate heat recovery, renewable energy inputs, or integration with existing industrial processes. Some designs feature continuous operation capabilities with automated carbon removal and hydrogen purification. The integration approach maximizes energy efficiency, improves hydrogen yield, and optimizes the economic and environmental benefits of methane pyrolysis for decarbonization applications.Expand Specific Solutions

Key Industry Players in Methane Pyrolysis Development

Methane pyrolysis is emerging as a promising technology for industry decarbonization, currently in the early growth phase with increasing market adoption. The global market is expanding rapidly, projected to reach significant scale as industries seek carbon-neutral hydrogen production methods. Technologically, the field shows varying maturity levels across different approaches, with companies like BASF, Shell, and ExxonMobil leading commercial development through advanced catalyst systems and reactor designs. Academic institutions including Karlsruhe Institute of Technology and Universidad Politécnica de Madrid are advancing fundamental research, while specialized firms like Coolbrook Oy and New Wave Hydrogen are developing innovative process technologies. The competitive landscape features both established energy corporations and agile startups, with collaborative partnerships between industry and research institutions accelerating technology commercialization and industrial-scale implementation.

BASF Corp.

Technical Solution: BASF has developed an innovative methane pyrolysis process that uses a liquid metal technology to split methane into hydrogen and solid carbon. Their process operates in a bubble column reactor where methane is fed through molten tin at temperatures around 1000°C. The reaction produces hydrogen with significantly lower CO2 emissions compared to conventional steam methane reforming. BASF's approach enables the capture of carbon in solid form rather than as CO2, making it easier to handle and potentially marketable as a byproduct. The company has been operating a test facility in Ludwigshafen, Germany since 2020, demonstrating the scalability of this technology. BASF's methane pyrolysis process requires approximately 80% less energy than conventional hydrogen production methods and produces no direct CO2 emissions.

Strengths: Produces hydrogen with minimal CO2 emissions; carbon is captured in solid form; energy requirement is significantly lower than conventional methods. Weaknesses: Still requires high temperatures; technology is not yet fully commercialized at industrial scale; depends on natural gas as feedstock which is still a fossil fuel.

Karlsruher Institut für Technologie

Technical Solution: Karlsruhe Institute of Technology (KIT) has pioneered a methane pyrolysis process using a liquid metal bubble column reactor. Their technology employs molten tin as a heat transfer medium and catalyst, operating at temperatures between 900-1200°C. Methane bubbles through the liquid metal, thermally decomposing into hydrogen and solid carbon without direct CO2 emissions. KIT's innovation includes a continuous carbon separation system that prevents reactor clogging, a critical challenge in methane pyrolysis. Their process achieves hydrogen production with an energy efficiency of approximately 50-60%, significantly higher than many competing technologies. KIT has demonstrated this technology at laboratory scale and is working on scaling up to industrial applications. The process is particularly notable for its ability to operate continuously for extended periods without performance degradation due to carbon accumulation.

Strengths: Zero direct CO2 emissions; continuous carbon removal system prevents reactor fouling; high energy efficiency compared to other pyrolysis methods. Weaknesses: High temperature requirements increase operational costs; scaling challenges remain for industrial implementation; requires high-purity methane input to prevent catalyst poisoning.

Core Patents and Innovations in Methane Cracking

Pyrolysis of methane with a molten salt based catalyst system

PatentInactiveUS20210363013A1

Innovation

- A catalyst system utilizing a molten salt with dispersed catalytically active metals like iron, molybdenum, and copper, which promotes high temperature methane pyrolysis and controls carbon morphology by maintaining thermal stability and preventing carbon deposition on reactor walls, allowing for efficient production of hydrogen and solid carbon with desired structures.

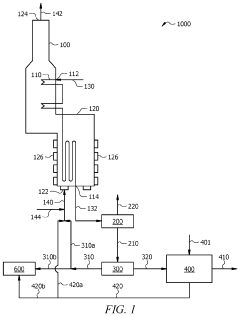

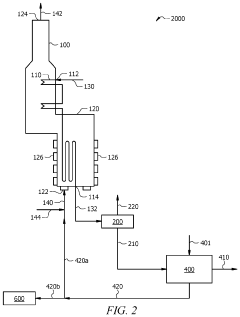

Use of methane pyrolysis to decarbonize a hydrocarbon cracking system

PatentActiveUS11958745B1

Innovation

- Implementing a methane pyrolysis unit to convert methane from tail gases into hydrogen and solid carbon, shifting the carbon capture focus from flue gases to tail gases, and utilizing the hydrogen as a fuel in hydrocarbon cracking systems, thereby reducing carbon dioxide emissions.

Carbon Policy Frameworks Impacting Pyrolysis Adoption

Carbon policy frameworks worldwide are increasingly shaping the adoption trajectory of methane pyrolysis as a decarbonization technology. The European Union's Emissions Trading System (EU ETS) has established a robust carbon pricing mechanism that incentivizes low-carbon hydrogen production methods, including pyrolysis. With carbon prices exceeding €80 per tonne in recent periods, the economic case for methane pyrolysis has strengthened considerably against conventional steam methane reforming without carbon capture.

In North America, the U.S. Inflation Reduction Act of 2022 provides significant production tax credits for clean hydrogen, with tiered incentives based on lifecycle carbon intensity. Methane pyrolysis can potentially qualify for the highest tier of credits ($3/kg H₂) if powered by renewable electricity and demonstrating minimal methane leakage, dramatically improving its economic competitiveness.

The Carbon Border Adjustment Mechanism (CBAM) being implemented by the EU represents another policy driver, as it will impose carbon-equivalent tariffs on imported goods from regions with less stringent climate policies. This creates strong incentives for global industries to adopt low-carbon production methods like methane pyrolysis to maintain market access.

National hydrogen strategies across major economies including Germany, Japan, South Korea, and Australia have explicitly recognized pyrolysis as a strategic technology for decarbonization. Germany's National Hydrogen Strategy specifically allocates funding for pyrolysis demonstration projects, while Japan's Green Growth Strategy positions turquoise hydrogen as a transitional solution toward their carbon neutrality goals.

Voluntary carbon markets are also evolving to potentially recognize and monetize the carbon benefits of methane pyrolysis. The development of methodologies to quantify emissions reductions from pyrolysis compared to conventional hydrogen production could create additional revenue streams through carbon credits.

Regulatory frameworks for solid carbon utilization and storage are emerging as complementary policies. The classification of pyrolytic carbon as a valuable material rather than a waste product in certain jurisdictions enhances the overall economics of the pyrolysis process. Countries like Canada have begun developing regulatory frameworks specifically addressing carbon materials from pyrolysis.

Industry-specific decarbonization roadmaps in steel, chemicals, and heavy transport sectors increasingly reference methane pyrolysis as a compliance pathway for meeting mandated emissions reduction targets, further driving technology adoption through regulatory pressure.

In North America, the U.S. Inflation Reduction Act of 2022 provides significant production tax credits for clean hydrogen, with tiered incentives based on lifecycle carbon intensity. Methane pyrolysis can potentially qualify for the highest tier of credits ($3/kg H₂) if powered by renewable electricity and demonstrating minimal methane leakage, dramatically improving its economic competitiveness.

The Carbon Border Adjustment Mechanism (CBAM) being implemented by the EU represents another policy driver, as it will impose carbon-equivalent tariffs on imported goods from regions with less stringent climate policies. This creates strong incentives for global industries to adopt low-carbon production methods like methane pyrolysis to maintain market access.

National hydrogen strategies across major economies including Germany, Japan, South Korea, and Australia have explicitly recognized pyrolysis as a strategic technology for decarbonization. Germany's National Hydrogen Strategy specifically allocates funding for pyrolysis demonstration projects, while Japan's Green Growth Strategy positions turquoise hydrogen as a transitional solution toward their carbon neutrality goals.

Voluntary carbon markets are also evolving to potentially recognize and monetize the carbon benefits of methane pyrolysis. The development of methodologies to quantify emissions reductions from pyrolysis compared to conventional hydrogen production could create additional revenue streams through carbon credits.

Regulatory frameworks for solid carbon utilization and storage are emerging as complementary policies. The classification of pyrolytic carbon as a valuable material rather than a waste product in certain jurisdictions enhances the overall economics of the pyrolysis process. Countries like Canada have begun developing regulatory frameworks specifically addressing carbon materials from pyrolysis.

Industry-specific decarbonization roadmaps in steel, chemicals, and heavy transport sectors increasingly reference methane pyrolysis as a compliance pathway for meeting mandated emissions reduction targets, further driving technology adoption through regulatory pressure.

Economic Viability and Scaling Challenges

The economic viability of methane pyrolysis as a decarbonization strategy faces significant challenges despite its promising technical attributes. Current cost analyses indicate that methane pyrolysis hydrogen production ranges between $1.50-3.00/kg, compared to conventional steam methane reforming at $1.00-1.50/kg. This cost differential primarily stems from high capital expenditure requirements for specialized reactors capable of withstanding extreme temperatures and managing carbon deposition.

Energy efficiency represents another critical economic factor. While methane pyrolysis eliminates CO2 emissions directly associated with hydrogen production, the process remains energy-intensive, requiring temperatures of 700-1200°C. The economic equation improves significantly when renewable energy sources power these operations, but this integration adds complexity and potentially higher initial investment costs.

Scaling challenges present formidable barriers to widespread adoption. Laboratory-scale demonstrations have proven the concept, but industrial-scale implementation faces several technical hurdles. Carbon management represents a primary concern - as reactors scale up, carbon deposition on catalysts and reactor walls increases proportionally, necessitating frequent maintenance cycles that impact operational efficiency and economics.

Market readiness constitutes another scaling challenge. The solid carbon byproduct, while theoretically valuable, lacks established large-scale markets. Current carbon black markets could become saturated if methane pyrolysis were deployed at industrial scale, potentially transforming a revenue stream into a waste management challenge. Developing new applications for pyrolytic carbon remains essential for improving the overall economics.

Infrastructure requirements present additional scaling obstacles. Unlike conventional hydrogen production facilities, methane pyrolysis plants require specialized equipment for solid carbon handling and processing. This necessitates significant modifications to existing industrial facilities or entirely new purpose-built installations, increasing capital costs and implementation timelines.

Regulatory frameworks also impact economic viability. While carbon pricing mechanisms could significantly improve methane pyrolysis economics relative to carbon-intensive alternatives, current carbon prices in most jurisdictions remain insufficient to bridge the cost gap. Policy uncertainty further complicates investment decisions for large-scale deployment.

The pathway to economic viability likely requires a multi-faceted approach: technological improvements to reduce energy requirements and capital costs, development of high-value markets for solid carbon byproducts, supportive policy frameworks including carbon pricing, and strategic deployment in industries where alternatives face even greater challenges.

Energy efficiency represents another critical economic factor. While methane pyrolysis eliminates CO2 emissions directly associated with hydrogen production, the process remains energy-intensive, requiring temperatures of 700-1200°C. The economic equation improves significantly when renewable energy sources power these operations, but this integration adds complexity and potentially higher initial investment costs.

Scaling challenges present formidable barriers to widespread adoption. Laboratory-scale demonstrations have proven the concept, but industrial-scale implementation faces several technical hurdles. Carbon management represents a primary concern - as reactors scale up, carbon deposition on catalysts and reactor walls increases proportionally, necessitating frequent maintenance cycles that impact operational efficiency and economics.

Market readiness constitutes another scaling challenge. The solid carbon byproduct, while theoretically valuable, lacks established large-scale markets. Current carbon black markets could become saturated if methane pyrolysis were deployed at industrial scale, potentially transforming a revenue stream into a waste management challenge. Developing new applications for pyrolytic carbon remains essential for improving the overall economics.

Infrastructure requirements present additional scaling obstacles. Unlike conventional hydrogen production facilities, methane pyrolysis plants require specialized equipment for solid carbon handling and processing. This necessitates significant modifications to existing industrial facilities or entirely new purpose-built installations, increasing capital costs and implementation timelines.

Regulatory frameworks also impact economic viability. While carbon pricing mechanisms could significantly improve methane pyrolysis economics relative to carbon-intensive alternatives, current carbon prices in most jurisdictions remain insufficient to bridge the cost gap. Policy uncertainty further complicates investment decisions for large-scale deployment.

The pathway to economic viability likely requires a multi-faceted approach: technological improvements to reduce energy requirements and capital costs, development of high-value markets for solid carbon byproducts, supportive policy frameworks including carbon pricing, and strategic deployment in industries where alternatives face even greater challenges.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!