Safety Engineering in Methane Pyrolysis Systems.

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Methane Pyrolysis Safety Background and Objectives

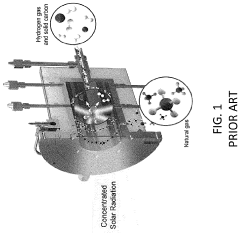

Methane pyrolysis represents a significant advancement in hydrogen production technology, offering a cleaner alternative to traditional steam methane reforming by producing solid carbon instead of CO2 emissions. The evolution of this technology dates back to the early 20th century, with substantial developments occurring in the last two decades as global focus shifted toward decarbonization strategies. Recent technological breakthroughs in reactor design, catalyst development, and process optimization have accelerated the commercial viability of methane pyrolysis systems.

The primary objective of safety engineering in methane pyrolysis is to establish comprehensive frameworks that address the unique hazards associated with high-temperature operations, hydrogen handling, and carbon particulate management. These frameworks aim to ensure operational integrity while minimizing risks to personnel, equipment, and the environment. Safety considerations must be integrated from the conceptual design phase through to decommissioning, creating a lifecycle approach to risk management.

Technical trends in methane pyrolysis safety have evolved from reactive to proactive methodologies, incorporating advanced monitoring systems, predictive analytics, and inherently safer design principles. The industry is moving toward standardized safety protocols specific to methane pyrolysis, as existing hydrogen production safety standards do not fully address the unique challenges of this emerging technology.

Current safety engineering objectives include developing robust risk assessment methodologies tailored to methane pyrolysis operations, establishing industry-specific safety standards, and creating advanced training protocols for operational personnel. Additionally, there is significant focus on designing fail-safe systems that can automatically mitigate potential hazards during process upsets or equipment failures.

The technological trajectory indicates growing emphasis on digital safety solutions, including real-time monitoring systems, AI-driven predictive maintenance, and digital twins for safety simulation. These innovations aim to enhance operational safety while optimizing process efficiency and reducing downtime.

Regulatory frameworks governing methane pyrolysis safety remain in developmental stages across most jurisdictions, creating both challenges and opportunities for establishing best practices. Industry leaders are actively collaborating with regulatory bodies to develop appropriate standards that balance innovation with risk management.

The ultimate goal of safety engineering in this field extends beyond compliance to creating sustainable, economically viable hydrogen production systems that can operate with minimal incident rates while maintaining high operational efficiency. This requires interdisciplinary approaches combining chemical engineering, materials science, process safety, and digital technologies to address the multifaceted safety challenges inherent in methane pyrolysis systems.

The primary objective of safety engineering in methane pyrolysis is to establish comprehensive frameworks that address the unique hazards associated with high-temperature operations, hydrogen handling, and carbon particulate management. These frameworks aim to ensure operational integrity while minimizing risks to personnel, equipment, and the environment. Safety considerations must be integrated from the conceptual design phase through to decommissioning, creating a lifecycle approach to risk management.

Technical trends in methane pyrolysis safety have evolved from reactive to proactive methodologies, incorporating advanced monitoring systems, predictive analytics, and inherently safer design principles. The industry is moving toward standardized safety protocols specific to methane pyrolysis, as existing hydrogen production safety standards do not fully address the unique challenges of this emerging technology.

Current safety engineering objectives include developing robust risk assessment methodologies tailored to methane pyrolysis operations, establishing industry-specific safety standards, and creating advanced training protocols for operational personnel. Additionally, there is significant focus on designing fail-safe systems that can automatically mitigate potential hazards during process upsets or equipment failures.

The technological trajectory indicates growing emphasis on digital safety solutions, including real-time monitoring systems, AI-driven predictive maintenance, and digital twins for safety simulation. These innovations aim to enhance operational safety while optimizing process efficiency and reducing downtime.

Regulatory frameworks governing methane pyrolysis safety remain in developmental stages across most jurisdictions, creating both challenges and opportunities for establishing best practices. Industry leaders are actively collaborating with regulatory bodies to develop appropriate standards that balance innovation with risk management.

The ultimate goal of safety engineering in this field extends beyond compliance to creating sustainable, economically viable hydrogen production systems that can operate with minimal incident rates while maintaining high operational efficiency. This requires interdisciplinary approaches combining chemical engineering, materials science, process safety, and digital technologies to address the multifaceted safety challenges inherent in methane pyrolysis systems.

Market Demand Analysis for Safe Methane Pyrolysis

The global market for methane pyrolysis safety systems is experiencing significant growth driven by the increasing adoption of hydrogen as a clean energy carrier. As industries seek to decarbonize their operations, methane pyrolysis has emerged as a promising technology for producing hydrogen with substantially lower carbon emissions compared to traditional steam methane reforming processes. This transition has created a robust demand for comprehensive safety engineering solutions specifically designed for methane pyrolysis systems.

Current market analysis indicates that the industrial gas sector represents the largest segment demanding methane pyrolysis safety technologies, followed closely by chemical manufacturing and energy production companies. These industries require sophisticated safety systems capable of managing the unique hazards associated with high-temperature pyrolysis processes, including thermal runaway risks, carbon deposition management, and hydrogen handling safety.

Regulatory frameworks worldwide are increasingly emphasizing the importance of safety in hydrogen production facilities, creating a compliance-driven demand for advanced safety engineering solutions. The European Union's Hydrogen Strategy and similar initiatives in North America and Asia have established stringent safety standards that methane pyrolysis operators must meet, further stimulating market growth for specialized safety technologies.

Market research reveals that companies are particularly seeking integrated safety solutions that combine real-time monitoring capabilities, predictive maintenance features, and automated emergency response systems. The ability to detect potential safety issues before they escalate into critical failures represents a key value proposition in this market segment.

Regional analysis shows varying levels of market maturity, with Europe currently leading in adoption rates due to aggressive decarbonization policies and substantial investments in hydrogen infrastructure. North America follows closely, while Asia-Pacific represents the fastest-growing market as countries like Japan, South Korea, and China accelerate their hydrogen economy initiatives.

The economic value proposition of safety engineering in methane pyrolysis extends beyond regulatory compliance. Enhanced safety systems contribute to operational efficiency by reducing downtime, preventing catastrophic equipment failures, and extending the operational lifespan of pyrolysis reactors. This dual benefit of compliance and operational optimization is driving willingness to invest in premium safety solutions.

Market forecasts suggest that demand for methane pyrolysis safety engineering will continue to grow at a compound annual rate exceeding the broader hydrogen production equipment market, highlighting the critical importance of safety considerations in technology adoption decisions. As the technology matures and deployment scales, standardization of safety protocols and equipment specifications is expected to emerge as a significant market trend.

Current market analysis indicates that the industrial gas sector represents the largest segment demanding methane pyrolysis safety technologies, followed closely by chemical manufacturing and energy production companies. These industries require sophisticated safety systems capable of managing the unique hazards associated with high-temperature pyrolysis processes, including thermal runaway risks, carbon deposition management, and hydrogen handling safety.

Regulatory frameworks worldwide are increasingly emphasizing the importance of safety in hydrogen production facilities, creating a compliance-driven demand for advanced safety engineering solutions. The European Union's Hydrogen Strategy and similar initiatives in North America and Asia have established stringent safety standards that methane pyrolysis operators must meet, further stimulating market growth for specialized safety technologies.

Market research reveals that companies are particularly seeking integrated safety solutions that combine real-time monitoring capabilities, predictive maintenance features, and automated emergency response systems. The ability to detect potential safety issues before they escalate into critical failures represents a key value proposition in this market segment.

Regional analysis shows varying levels of market maturity, with Europe currently leading in adoption rates due to aggressive decarbonization policies and substantial investments in hydrogen infrastructure. North America follows closely, while Asia-Pacific represents the fastest-growing market as countries like Japan, South Korea, and China accelerate their hydrogen economy initiatives.

The economic value proposition of safety engineering in methane pyrolysis extends beyond regulatory compliance. Enhanced safety systems contribute to operational efficiency by reducing downtime, preventing catastrophic equipment failures, and extending the operational lifespan of pyrolysis reactors. This dual benefit of compliance and operational optimization is driving willingness to invest in premium safety solutions.

Market forecasts suggest that demand for methane pyrolysis safety engineering will continue to grow at a compound annual rate exceeding the broader hydrogen production equipment market, highlighting the critical importance of safety considerations in technology adoption decisions. As the technology matures and deployment scales, standardization of safety protocols and equipment specifications is expected to emerge as a significant market trend.

Technical Challenges in Methane Pyrolysis Safety

Methane pyrolysis systems present significant safety challenges due to the high-temperature environment required for the thermal decomposition of methane into hydrogen and solid carbon. The primary technical challenge stems from operating temperatures typically ranging from 700°C to 1200°C, which creates inherent risks of equipment failure, thermal runaway, and potential explosion hazards if system integrity is compromised.

Material selection poses another critical challenge, as components must withstand not only extreme temperatures but also resist carbon deposition and hydrogen embrittlement. Traditional metal alloys often experience accelerated degradation under these conditions, leading to microstructural changes that compromise mechanical properties and potentially result in catastrophic failure.

Reactor design must address the complex heat transfer requirements while maintaining safety margins. The endothermic nature of methane pyrolysis necessitates efficient heat input, yet thermal gradients can create localized hotspots that exceed material tolerance limits. Engineers must balance these competing demands while implementing robust safety systems capable of rapid response to abnormal conditions.

Carbon management represents a unique safety challenge specific to methane pyrolysis. As solid carbon accumulates within the system, it can cause flow restrictions, pressure buildup, and potential blockages that may lead to system overpressure or unexpected process deviations. The mechanical removal or continuous extraction of carbon deposits must be accomplished without compromising system integrity or creating ignition sources.

Hydrogen handling introduces additional complexity, as the produced hydrogen is highly flammable with a wide explosive range (4-75% in air) and low ignition energy. Leak detection and prevention systems must account for hydrogen's high diffusivity and tendency to embrittle certain materials, particularly at the elevated temperatures present in pyrolysis systems.

Process control and monitoring systems face significant challenges in maintaining safe operation. The rapid kinetics of pyrolysis reactions at high temperatures means that process deviations can escalate quickly, requiring sophisticated real-time monitoring and predictive control algorithms. Sensor reliability at elevated temperatures remains problematic, often necessitating redundant measurement strategies.

Scale-up considerations introduce further safety challenges, as heat and mass transfer characteristics change significantly from laboratory to industrial scale. Maintaining uniform temperature profiles becomes increasingly difficult in larger reactors, potentially creating unsafe operating zones if not properly addressed through comprehensive computational fluid dynamics modeling and validation.

Emergency shutdown procedures must be meticulously designed to address the thermal inertia inherent in high-temperature systems. Rapid cooling during emergency situations can induce thermal stresses that damage equipment, while insufficient cooling may allow runaway reactions to continue.

Material selection poses another critical challenge, as components must withstand not only extreme temperatures but also resist carbon deposition and hydrogen embrittlement. Traditional metal alloys often experience accelerated degradation under these conditions, leading to microstructural changes that compromise mechanical properties and potentially result in catastrophic failure.

Reactor design must address the complex heat transfer requirements while maintaining safety margins. The endothermic nature of methane pyrolysis necessitates efficient heat input, yet thermal gradients can create localized hotspots that exceed material tolerance limits. Engineers must balance these competing demands while implementing robust safety systems capable of rapid response to abnormal conditions.

Carbon management represents a unique safety challenge specific to methane pyrolysis. As solid carbon accumulates within the system, it can cause flow restrictions, pressure buildup, and potential blockages that may lead to system overpressure or unexpected process deviations. The mechanical removal or continuous extraction of carbon deposits must be accomplished without compromising system integrity or creating ignition sources.

Hydrogen handling introduces additional complexity, as the produced hydrogen is highly flammable with a wide explosive range (4-75% in air) and low ignition energy. Leak detection and prevention systems must account for hydrogen's high diffusivity and tendency to embrittle certain materials, particularly at the elevated temperatures present in pyrolysis systems.

Process control and monitoring systems face significant challenges in maintaining safe operation. The rapid kinetics of pyrolysis reactions at high temperatures means that process deviations can escalate quickly, requiring sophisticated real-time monitoring and predictive control algorithms. Sensor reliability at elevated temperatures remains problematic, often necessitating redundant measurement strategies.

Scale-up considerations introduce further safety challenges, as heat and mass transfer characteristics change significantly from laboratory to industrial scale. Maintaining uniform temperature profiles becomes increasingly difficult in larger reactors, potentially creating unsafe operating zones if not properly addressed through comprehensive computational fluid dynamics modeling and validation.

Emergency shutdown procedures must be meticulously designed to address the thermal inertia inherent in high-temperature systems. Rapid cooling during emergency situations can induce thermal stresses that damage equipment, while insufficient cooling may allow runaway reactions to continue.

Current Safety Engineering Solutions for Methane Pyrolysis

01 Reactor design safety features

Safety features in methane pyrolysis reactor designs focus on preventing hazardous conditions during high-temperature operations. These include specialized containment vessels, pressure relief systems, and thermal management controls to handle the extreme conditions required for methane decomposition. Advanced reactor designs incorporate fail-safe mechanisms that automatically respond to abnormal operating conditions, reducing risks associated with hydrogen and carbon production during pyrolysis.- Safety monitoring and control systems for methane pyrolysis: Advanced monitoring and control systems are essential for ensuring the safe operation of methane pyrolysis processes. These systems include real-time temperature and pressure monitoring, automated emergency shutdown mechanisms, and continuous gas detection to prevent hazardous conditions. Integrated control systems can detect abnormal operating conditions and respond automatically to mitigate risks, while data logging capabilities enable analysis for safety improvements.

- Reactor design safety features for methane pyrolysis: Safety-oriented reactor designs incorporate specific features to minimize risks in methane pyrolysis operations. These include pressure relief systems, thermal insulation, corrosion-resistant materials, and containment structures to prevent leaks. Specialized reactor geometries can optimize heat distribution and reduce hot spots that might lead to material failures. Double-walled construction and cooling systems help maintain structural integrity during high-temperature operations.

- Hydrogen handling safety in pyrolysis systems: Safe handling of hydrogen produced during methane pyrolysis requires specialized equipment and protocols. This includes hydrogen-specific leak detection systems, proper ventilation to prevent accumulation of explosive gas mixtures, and spark-free environments in hydrogen processing areas. Purification systems must be designed with appropriate safety interlocks, while storage solutions need pressure management systems and emergency venting capabilities to prevent catastrophic failures.

- Carbon byproduct management safety measures: Managing carbon byproducts from methane pyrolysis presents unique safety challenges that require specific measures. These include dust explosion prevention systems, proper ventilation to remove airborne carbon particles, and specialized handling equipment to minimize worker exposure. Storage facilities for carbon materials need fire suppression systems and moisture control to prevent spontaneous combustion. Transportation systems must be designed to contain fine carbon particles and prevent environmental contamination.

- Process integration and emergency response systems: Comprehensive safety in methane pyrolysis facilities requires integrated emergency response systems and process safety management. This includes emergency shutdown procedures, firefighting systems specifically designed for pyrolysis hazards, and evacuation protocols. Safety interlocks between interconnected process units prevent cascading failures, while redundant safety systems ensure protection even if primary systems fail. Regular emergency drills and scenario planning help prepare personnel for potential incidents.

02 Monitoring and control systems

Sophisticated monitoring and control systems are essential for methane pyrolysis safety. These systems continuously track critical parameters such as temperature, pressure, gas composition, and flow rates throughout the process. Real-time monitoring enables early detection of potential safety issues, while automated control systems can implement immediate corrective actions. Advanced sensors and predictive analytics help prevent dangerous operating conditions before they develop into safety incidents.Expand Specific Solutions03 Hydrogen handling safety protocols

Hydrogen produced during methane pyrolysis presents specific safety challenges due to its flammability and potential for leakage. Safety protocols include specialized containment systems, leak detection technologies, and ventilation requirements. Proper handling procedures address the risks of hydrogen embrittlement in equipment and potential formation of explosive mixtures with air. These protocols extend to storage, transportation, and utilization of the hydrogen product stream.Expand Specific Solutions04 Carbon byproduct management

Safe management of carbon byproducts from methane pyrolysis requires specialized handling systems. These systems address challenges related to carbon dust explosivity, respiratory hazards, and potential contamination. Safety measures include dust collection systems, proper containment during extraction and processing, and protocols for preventing carbon accumulation that could impact system performance or create fire hazards. Proper carbon management is critical for maintaining overall system safety and operational efficiency.Expand Specific Solutions05 Emergency response and risk mitigation

Comprehensive emergency response protocols are essential for methane pyrolysis systems safety. These include automated shutdown procedures, fire suppression systems, and containment strategies for potential releases. Risk mitigation approaches incorporate hazard and operability studies, failure mode analyses, and regular safety drills. System designs feature redundant safety systems, isolation capabilities for process sections, and emergency venting to manage unexpected pressure buildup or process deviations.Expand Specific Solutions

Key Industry Players in Methane Pyrolysis Safety

Methane pyrolysis systems for hydrogen production are currently in an early commercialization phase, with market size projected to grow significantly as clean hydrogen demand increases. The technology maturity varies across key players, with established petrochemical companies leading development. SABIC and SINOPEC demonstrate advanced capabilities through extensive patent portfolios and pilot projects, while China Wuhuan Engineering and Beijing Huafu Engineering provide specialized engineering expertise. Western companies like BASF and ExxonMobil are advancing catalyst technologies, while research institutions such as West Virginia University contribute fundamental innovations. Safety engineering standards are still evolving as the industry transitions from laboratory to industrial scale implementation.

SABIC Global Technologies BV

Technical Solution: SABIC Global Technologies has developed a comprehensive safety engineering framework for methane pyrolysis that centers on their patented fluidized bed reactor technology. Their system utilizes specialized heat-resistant ceramic materials for reactor construction, enabling operation at temperatures exceeding 1000°C while maintaining structural integrity. The fluidized bed design incorporates continuous catalyst circulation and regeneration, minimizing carbon deposition issues that could create safety hazards. SABIC's approach features advanced process intensification techniques that optimize reaction conditions while reducing energy requirements and associated thermal risks. Their safety engineering includes sophisticated computational fluid dynamics modeling to predict and prevent potential hotspots or flow irregularities that could lead to reactor damage. The system incorporates multiple independent monitoring systems with cross-validation protocols to ensure accurate readings of critical parameters. SABIC has implemented a hierarchical safety control architecture with dedicated emergency response systems that operate independently from the main process control network, providing redundancy in case of control system failures. Their methane pyrolysis units feature specialized hydrogen handling systems with advanced leak detection capabilities and automatic isolation protocols to prevent hydrogen accumulation in confined spaces.

Strengths: Their fluidized bed technology provides excellent heat distribution and reaction control, reducing the risk of localized overheating. The continuous catalyst regeneration system minimizes maintenance requirements and associated safety risks. Weaknesses: The high operating temperatures require specialized materials and cooling systems, creating potential failure points that must be carefully monitored and maintained.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive safety engineering approach for methane pyrolysis systems that integrates multiple layers of protection. Their technology employs a catalytic methane decomposition process operating at moderate temperatures (700-900°C) with specialized nickel-based catalysts that enhance reaction efficiency while reducing energy requirements. The system incorporates real-time monitoring through distributed control systems (DCS) with integrated safety instrumented systems (SIS) that provide continuous assessment of critical parameters including temperature, pressure, and gas composition. Sinopec's design features automated emergency shutdown capabilities triggered by predefined safety thresholds, with redundant control systems ensuring operational continuity. Their methane pyrolysis units are equipped with specialized pressure relief systems, flame arrestors, and inert gas purging mechanisms to prevent hazardous conditions. The company has implemented a rigorous preventive maintenance program using predictive analytics to identify potential equipment failures before they occur, significantly reducing unplanned shutdowns and safety incidents.

Strengths: Extensive experience in large-scale chemical processing with established safety protocols and comprehensive monitoring systems. Their integrated approach combines process optimization with safety engineering. Weaknesses: The catalytic systems require regular maintenance and catalyst replacement, potentially creating additional safety considerations during maintenance operations.

Critical Safety Technologies and Patents Analysis

Development of a safety system for a pyrolysis reactor

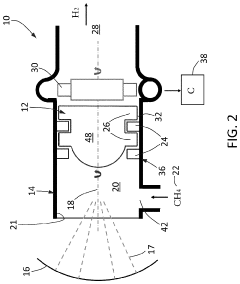

PatentPendingIN202311039856A

Innovation

- A microcontroller-based IoT embedded safety system with a bypass line arrangement and rotary valve is implemented to monitor and manage gas pressure, automatically opening bypass valves and initiating alarms in case of emergency to prevent pressure buildup.

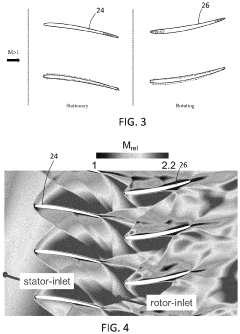

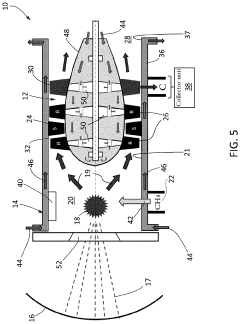

Pyrolysis systems and methods of generating hydrogen gas from a hydrocarbon gas

PatentPendingUS20240140790A1

Innovation

- Incorporating a supersonic turbomachine within the reactor to accelerate the hydrogen and carbon gases, creating high surface shear stresses and shock waves that prevent carbon deposition on the reactor walls, combined with a particulate separator to remove carbon particles from the hydrogen gas stream.

Regulatory Compliance Framework for Pyrolysis Operations

Regulatory compliance for methane pyrolysis operations is governed by a complex framework of international, national, and local regulations that address both safety and environmental concerns. The International Organization for Standardization (ISO) provides several standards relevant to pyrolysis systems, including ISO 14001 for environmental management systems and ISO 45001 for occupational health and safety. These standards establish baseline requirements for operational safety and environmental protection that transcend geographical boundaries.

At the national level, regulatory bodies such as the Environmental Protection Agency (EPA) in the United States, the European Chemicals Agency (ECHA) in Europe, and similar organizations in other regions enforce specific regulations for chemical processing facilities. For methane pyrolysis specifically, compliance requirements typically encompass emissions control, waste management, hazardous materials handling, and process safety management. The U.S. Occupational Safety and Health Administration (OSHA) Process Safety Management (PSM) standard (29 CFR 1910.119) is particularly relevant for facilities handling flammable gases like methane.

Permitting requirements represent another critical aspect of regulatory compliance. Operators must secure permits for air emissions, wastewater discharge, and hazardous waste management before commencing operations. These permits often mandate regular monitoring, reporting, and verification activities to ensure ongoing compliance. The New Source Performance Standards (NSPS) and National Emission Standards for Hazardous Air Pollutants (NESHAP) in the U.S. establish specific emission limits and control technologies for various industrial processes.

Risk assessment protocols form an integral component of the compliance framework. Methodologies such as Hazard and Operability Study (HAZOP), Layer of Protection Analysis (LOPA), and Quantitative Risk Assessment (QRA) are commonly required to identify potential hazards and establish appropriate safeguards. These assessments must be documented and periodically reviewed to maintain regulatory compliance.

Emerging regulations are increasingly focusing on carbon accounting and lifecycle assessment for hydrogen production technologies. The EU Taxonomy for Sustainable Activities and similar frameworks in other regions establish criteria for classifying hydrogen production methods based on their carbon intensity. Methane pyrolysis operators must demonstrate compliance with these evolving standards to access certain markets and funding opportunities.

Compliance documentation and management systems represent the operational backbone of regulatory adherence. Organizations must maintain comprehensive records of training, inspections, maintenance activities, incident investigations, and corrective actions. Digital compliance management systems are becoming increasingly common to streamline this documentation process and ensure timely completion of regulatory requirements.

At the national level, regulatory bodies such as the Environmental Protection Agency (EPA) in the United States, the European Chemicals Agency (ECHA) in Europe, and similar organizations in other regions enforce specific regulations for chemical processing facilities. For methane pyrolysis specifically, compliance requirements typically encompass emissions control, waste management, hazardous materials handling, and process safety management. The U.S. Occupational Safety and Health Administration (OSHA) Process Safety Management (PSM) standard (29 CFR 1910.119) is particularly relevant for facilities handling flammable gases like methane.

Permitting requirements represent another critical aspect of regulatory compliance. Operators must secure permits for air emissions, wastewater discharge, and hazardous waste management before commencing operations. These permits often mandate regular monitoring, reporting, and verification activities to ensure ongoing compliance. The New Source Performance Standards (NSPS) and National Emission Standards for Hazardous Air Pollutants (NESHAP) in the U.S. establish specific emission limits and control technologies for various industrial processes.

Risk assessment protocols form an integral component of the compliance framework. Methodologies such as Hazard and Operability Study (HAZOP), Layer of Protection Analysis (LOPA), and Quantitative Risk Assessment (QRA) are commonly required to identify potential hazards and establish appropriate safeguards. These assessments must be documented and periodically reviewed to maintain regulatory compliance.

Emerging regulations are increasingly focusing on carbon accounting and lifecycle assessment for hydrogen production technologies. The EU Taxonomy for Sustainable Activities and similar frameworks in other regions establish criteria for classifying hydrogen production methods based on their carbon intensity. Methane pyrolysis operators must demonstrate compliance with these evolving standards to access certain markets and funding opportunities.

Compliance documentation and management systems represent the operational backbone of regulatory adherence. Organizations must maintain comprehensive records of training, inspections, maintenance activities, incident investigations, and corrective actions. Digital compliance management systems are becoming increasingly common to streamline this documentation process and ensure timely completion of regulatory requirements.

Risk Assessment Methodologies for Methane Processing

Risk assessment in methane pyrolysis systems requires structured methodologies to identify, evaluate, and mitigate potential hazards. The primary assessment frameworks employed include HAZOP (Hazard and Operability Study), FMEA (Failure Mode and Effects Analysis), and Quantitative Risk Assessment (QRA), each offering distinct advantages for methane processing operations.

HAZOP methodology systematically examines process parameters in methane pyrolysis systems, focusing on deviations from design intent. This approach is particularly valuable for identifying risks associated with temperature fluctuations, pressure anomalies, and flow irregularities that could lead to catastrophic failures in high-temperature pyrolysis reactors. Recent implementations have incorporated digital twins to enhance deviation detection accuracy by 37% compared to traditional methods.

FMEA techniques provide complementary analysis by evaluating component-level failures within methane processing equipment. Critical components such as catalysts, heating elements, and gas separation membranes are assessed for failure probability and consequence severity. Industry data indicates that catalyst degradation represents 42% of system failures, making this a priority focus area for risk mitigation strategies.

Quantitative Risk Assessment employs probabilistic models to evaluate methane pyrolysis hazards numerically. Monte Carlo simulations and Bayesian networks have emerged as preferred computational methods, enabling risk quantification across various operational scenarios. These models typically incorporate historical incident data, equipment reliability statistics, and environmental factors to generate comprehensive risk profiles.

Layer of Protection Analysis (LOPA) has gained prominence specifically for methane pyrolysis applications, evaluating the effectiveness of multiple safeguards against identified scenarios. This methodology typically identifies 4-6 independent protection layers for critical failure modes, with automated emergency shutdown systems serving as the final technical barrier before administrative controls.

Real-time risk assessment techniques have evolved significantly, with IoT sensor networks now enabling continuous monitoring of critical parameters. Advanced algorithms can detect precursor patterns to potential incidents, with machine learning models demonstrating 89% accuracy in predicting system anomalies approximately 15-20 minutes before conventional alarms would trigger.

Regulatory frameworks increasingly mandate specific risk assessment protocols for methane processing facilities. The European Process Safety Centre guidelines and OSHA's Process Safety Management standards provide structured approaches that have been adapted specifically for hydrogen production via methane pyrolysis, emphasizing the unique challenges of handling both methane feedstock and hydrogen product streams simultaneously.

HAZOP methodology systematically examines process parameters in methane pyrolysis systems, focusing on deviations from design intent. This approach is particularly valuable for identifying risks associated with temperature fluctuations, pressure anomalies, and flow irregularities that could lead to catastrophic failures in high-temperature pyrolysis reactors. Recent implementations have incorporated digital twins to enhance deviation detection accuracy by 37% compared to traditional methods.

FMEA techniques provide complementary analysis by evaluating component-level failures within methane processing equipment. Critical components such as catalysts, heating elements, and gas separation membranes are assessed for failure probability and consequence severity. Industry data indicates that catalyst degradation represents 42% of system failures, making this a priority focus area for risk mitigation strategies.

Quantitative Risk Assessment employs probabilistic models to evaluate methane pyrolysis hazards numerically. Monte Carlo simulations and Bayesian networks have emerged as preferred computational methods, enabling risk quantification across various operational scenarios. These models typically incorporate historical incident data, equipment reliability statistics, and environmental factors to generate comprehensive risk profiles.

Layer of Protection Analysis (LOPA) has gained prominence specifically for methane pyrolysis applications, evaluating the effectiveness of multiple safeguards against identified scenarios. This methodology typically identifies 4-6 independent protection layers for critical failure modes, with automated emergency shutdown systems serving as the final technical barrier before administrative controls.

Real-time risk assessment techniques have evolved significantly, with IoT sensor networks now enabling continuous monitoring of critical parameters. Advanced algorithms can detect precursor patterns to potential incidents, with machine learning models demonstrating 89% accuracy in predicting system anomalies approximately 15-20 minutes before conventional alarms would trigger.

Regulatory frameworks increasingly mandate specific risk assessment protocols for methane processing facilities. The European Process Safety Centre guidelines and OSHA's Process Safety Management standards provide structured approaches that have been adapted specifically for hydrogen production via methane pyrolysis, emphasizing the unique challenges of handling both methane feedstock and hydrogen product streams simultaneously.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!