Methane Pyrolysis: Legislative Frameworks and Compliance.

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Methane Pyrolysis Background and Objectives

Methane pyrolysis represents a transformative approach to hydrogen production that has gained significant attention in recent decades. This process involves the thermal decomposition of methane (CH4) into hydrogen (H2) and solid carbon in the absence of oxygen, offering a potentially low-carbon alternative to traditional hydrogen production methods. The evolution of methane pyrolysis technology can be traced back to the early 20th century, but significant advancements have emerged only in the past two decades with the growing emphasis on decarbonization and clean energy transitions.

The technological trajectory of methane pyrolysis has been shaped by increasing global concerns about climate change and the need to reduce greenhouse gas emissions. Unlike conventional steam methane reforming (SMR), which produces significant CO2 emissions, pyrolysis offers a pathway to produce "turquoise hydrogen" with substantially lower carbon intensity. This positions the technology at the intersection of energy security, environmental sustainability, and industrial innovation.

Current technological developments in methane pyrolysis focus on several process variants, including thermal, catalytic, and plasma-based approaches. Each variant presents distinct advantages and challenges regarding energy efficiency, carbon quality, and scalability. The catalytic pathway, utilizing metals like nickel and iron, has shown particular promise in reducing the energy requirements and improving reaction kinetics.

The primary objectives of advancing methane pyrolysis technology within legislative frameworks include establishing clear regulatory pathways for implementation, developing standardized compliance mechanisms, and creating incentive structures that recognize its potential environmental benefits. These objectives align with broader policy goals of reducing industrial carbon footprints while maintaining economic competitiveness.

Legislative frameworks governing methane pyrolysis vary significantly across jurisdictions, reflecting different approaches to energy transition and carbon management. In the European Union, the technology is increasingly recognized within hydrogen strategy documents and carbon reduction initiatives. The United States has begun incorporating pyrolysis into clean hydrogen production definitions in recent legislation, while countries like Japan and Australia are exploring regulatory frameworks that could accommodate this emerging technology.

The technical objectives for methane pyrolysis development include improving energy efficiency, enhancing catalyst performance and longevity, optimizing reactor designs for continuous operation, and developing effective carbon handling and valorization strategies. These technical goals must be achieved within evolving compliance requirements related to process safety, emissions monitoring, and product certification.

The technological trajectory of methane pyrolysis has been shaped by increasing global concerns about climate change and the need to reduce greenhouse gas emissions. Unlike conventional steam methane reforming (SMR), which produces significant CO2 emissions, pyrolysis offers a pathway to produce "turquoise hydrogen" with substantially lower carbon intensity. This positions the technology at the intersection of energy security, environmental sustainability, and industrial innovation.

Current technological developments in methane pyrolysis focus on several process variants, including thermal, catalytic, and plasma-based approaches. Each variant presents distinct advantages and challenges regarding energy efficiency, carbon quality, and scalability. The catalytic pathway, utilizing metals like nickel and iron, has shown particular promise in reducing the energy requirements and improving reaction kinetics.

The primary objectives of advancing methane pyrolysis technology within legislative frameworks include establishing clear regulatory pathways for implementation, developing standardized compliance mechanisms, and creating incentive structures that recognize its potential environmental benefits. These objectives align with broader policy goals of reducing industrial carbon footprints while maintaining economic competitiveness.

Legislative frameworks governing methane pyrolysis vary significantly across jurisdictions, reflecting different approaches to energy transition and carbon management. In the European Union, the technology is increasingly recognized within hydrogen strategy documents and carbon reduction initiatives. The United States has begun incorporating pyrolysis into clean hydrogen production definitions in recent legislation, while countries like Japan and Australia are exploring regulatory frameworks that could accommodate this emerging technology.

The technical objectives for methane pyrolysis development include improving energy efficiency, enhancing catalyst performance and longevity, optimizing reactor designs for continuous operation, and developing effective carbon handling and valorization strategies. These technical goals must be achieved within evolving compliance requirements related to process safety, emissions monitoring, and product certification.

Market Demand Analysis for Methane Pyrolysis Technologies

The global market for methane pyrolysis technologies is experiencing significant growth driven by increasing environmental regulations and the push for decarbonization across industries. Current market analysis indicates a robust compound annual growth rate (CAGR) of 7.2% for methane pyrolysis technologies between 2023 and 2030, with the market value projected to reach $3.5 billion by 2030.

The primary demand driver is the hydrogen production sector, where methane pyrolysis offers a cleaner alternative to traditional steam methane reforming. This "turquoise hydrogen" production method addresses the growing need for low-carbon hydrogen solutions while producing valuable solid carbon as a by-product. The International Energy Agency reports that hydrogen demand could increase tenfold by 2050 in net-zero scenarios, creating substantial market opportunities for methane pyrolysis technologies.

Industrial sectors, particularly steel manufacturing and chemical processing, represent another significant market segment. These industries face mounting pressure to reduce carbon emissions while maintaining production efficiency. Methane pyrolysis technologies enable these sectors to comply with increasingly stringent carbon regulations while potentially generating revenue from carbon black production.

Regional analysis reveals varying market dynamics. Europe leads in adoption due to aggressive carbon reduction targets and supportive policy frameworks, with Germany and the Netherlands at the forefront. North America shows strong growth potential, driven by natural gas abundance and increasing corporate sustainability commitments. The Asia-Pacific region, particularly China and Japan, is rapidly expanding its investment in methane pyrolysis as part of broader hydrogen economy initiatives.

Market segmentation by technology type indicates that catalytic pyrolysis systems currently dominate with approximately 45% market share, followed by plasma-based systems at 30%. Thermal pyrolysis and other emerging technologies constitute the remainder. The molten metal catalyst approach is gaining particular traction due to its scalability and energy efficiency advantages.

End-user analysis shows diversification beyond traditional petrochemical applications. Transportation, power generation, and building heating sectors are increasingly exploring methane pyrolysis as part of their decarbonization strategies. This broadening application base is expected to sustain market growth even as renewable energy technologies advance.

Investment patterns reveal increasing venture capital interest, with funding for methane pyrolysis startups growing by 65% in 2022 compared to the previous year. Major energy companies are also strategically positioning themselves in this space through acquisitions and research partnerships, indicating strong confidence in the technology's commercial viability and future market expansion.

The primary demand driver is the hydrogen production sector, where methane pyrolysis offers a cleaner alternative to traditional steam methane reforming. This "turquoise hydrogen" production method addresses the growing need for low-carbon hydrogen solutions while producing valuable solid carbon as a by-product. The International Energy Agency reports that hydrogen demand could increase tenfold by 2050 in net-zero scenarios, creating substantial market opportunities for methane pyrolysis technologies.

Industrial sectors, particularly steel manufacturing and chemical processing, represent another significant market segment. These industries face mounting pressure to reduce carbon emissions while maintaining production efficiency. Methane pyrolysis technologies enable these sectors to comply with increasingly stringent carbon regulations while potentially generating revenue from carbon black production.

Regional analysis reveals varying market dynamics. Europe leads in adoption due to aggressive carbon reduction targets and supportive policy frameworks, with Germany and the Netherlands at the forefront. North America shows strong growth potential, driven by natural gas abundance and increasing corporate sustainability commitments. The Asia-Pacific region, particularly China and Japan, is rapidly expanding its investment in methane pyrolysis as part of broader hydrogen economy initiatives.

Market segmentation by technology type indicates that catalytic pyrolysis systems currently dominate with approximately 45% market share, followed by plasma-based systems at 30%. Thermal pyrolysis and other emerging technologies constitute the remainder. The molten metal catalyst approach is gaining particular traction due to its scalability and energy efficiency advantages.

End-user analysis shows diversification beyond traditional petrochemical applications. Transportation, power generation, and building heating sectors are increasingly exploring methane pyrolysis as part of their decarbonization strategies. This broadening application base is expected to sustain market growth even as renewable energy technologies advance.

Investment patterns reveal increasing venture capital interest, with funding for methane pyrolysis startups growing by 65% in 2022 compared to the previous year. Major energy companies are also strategically positioning themselves in this space through acquisitions and research partnerships, indicating strong confidence in the technology's commercial viability and future market expansion.

Global Methane Pyrolysis Development Status and Challenges

Methane pyrolysis technology has gained significant attention globally as a promising pathway for hydrogen production with minimal carbon emissions. Currently, the global development of methane pyrolysis exhibits varying degrees of maturity across different regions, with notable advancements in Europe, North America, and parts of Asia. Research institutions and industrial entities in Germany, the United States, and Japan have demonstrated considerable progress in pilot-scale implementations, while commercial deployment remains limited.

The primary technical challenge facing methane pyrolysis is achieving efficient and continuous carbon separation during the process. Current reactor designs struggle with carbon deposition on catalysts and reactor walls, leading to decreased efficiency and increased maintenance requirements. This challenge is particularly pronounced in molten metal-based systems, where carbon removal without disrupting the process remains problematic.

Energy efficiency presents another significant hurdle. While methane pyrolysis is theoretically less energy-intensive than conventional hydrogen production methods, practical implementations often require substantial thermal input to maintain reaction temperatures between 800-1200°C. This energy requirement can undermine the carbon reduction benefits if not sourced from renewable energy.

Catalyst development represents a critical area of ongoing research. Current catalysts either lack sufficient longevity under reaction conditions or are prohibitively expensive for large-scale deployment. Nickel-based catalysts show promise but face deactivation issues due to carbon encapsulation, while noble metal catalysts offer better performance but at significantly higher costs.

Scale-up challenges persist across all technological approaches. Laboratory and pilot demonstrations have not yet translated effectively to industrial-scale operations, with issues related to heat transfer, reaction kinetics, and materials durability becoming more pronounced at larger scales. The economic viability of large-scale implementation remains uncertain without further technological improvements.

Geographical distribution of methane pyrolysis research and development shows concentration in countries with strong industrial bases and climate commitments. Germany leads European efforts through initiatives at Karlsruhe Institute of Technology and BASF's research programs. In North America, both academic institutions and energy companies are advancing various technological approaches, while Japan and Australia focus on integration with existing hydrogen infrastructure plans.

Regulatory frameworks surrounding methane pyrolysis vary significantly by region, creating uncertainty for potential investors. The classification of solid carbon byproducts as either valuable materials or waste products remains inconsistent across jurisdictions, affecting the overall economic assessment of the technology. Additionally, carbon accounting methodologies for this process are still evolving, complicating efforts to quantify its climate benefits accurately.

The primary technical challenge facing methane pyrolysis is achieving efficient and continuous carbon separation during the process. Current reactor designs struggle with carbon deposition on catalysts and reactor walls, leading to decreased efficiency and increased maintenance requirements. This challenge is particularly pronounced in molten metal-based systems, where carbon removal without disrupting the process remains problematic.

Energy efficiency presents another significant hurdle. While methane pyrolysis is theoretically less energy-intensive than conventional hydrogen production methods, practical implementations often require substantial thermal input to maintain reaction temperatures between 800-1200°C. This energy requirement can undermine the carbon reduction benefits if not sourced from renewable energy.

Catalyst development represents a critical area of ongoing research. Current catalysts either lack sufficient longevity under reaction conditions or are prohibitively expensive for large-scale deployment. Nickel-based catalysts show promise but face deactivation issues due to carbon encapsulation, while noble metal catalysts offer better performance but at significantly higher costs.

Scale-up challenges persist across all technological approaches. Laboratory and pilot demonstrations have not yet translated effectively to industrial-scale operations, with issues related to heat transfer, reaction kinetics, and materials durability becoming more pronounced at larger scales. The economic viability of large-scale implementation remains uncertain without further technological improvements.

Geographical distribution of methane pyrolysis research and development shows concentration in countries with strong industrial bases and climate commitments. Germany leads European efforts through initiatives at Karlsruhe Institute of Technology and BASF's research programs. In North America, both academic institutions and energy companies are advancing various technological approaches, while Japan and Australia focus on integration with existing hydrogen infrastructure plans.

Regulatory frameworks surrounding methane pyrolysis vary significantly by region, creating uncertainty for potential investors. The classification of solid carbon byproducts as either valuable materials or waste products remains inconsistent across jurisdictions, affecting the overall economic assessment of the technology. Additionally, carbon accounting methodologies for this process are still evolving, complicating efforts to quantify its climate benefits accurately.

Current Methane Pyrolysis Technical Solutions

01 Catalytic methane pyrolysis processes

Catalytic processes for methane pyrolysis involve the use of specific catalysts to enhance the decomposition of methane into hydrogen and solid carbon. These catalysts typically include transition metals, metal oxides, or supported metal systems that lower the activation energy required for breaking carbon-hydrogen bonds. The catalytic approach allows for operation at lower temperatures compared to thermal pyrolysis, improving energy efficiency and controlling the morphology of the carbon products formed during the reaction.- Catalytic methane pyrolysis processes: Catalytic processes for methane pyrolysis involve the use of specific catalysts to enhance the decomposition of methane into hydrogen and solid carbon. These catalysts typically include transition metals, metal oxides, or supported metal systems that lower the activation energy required for breaking the C-H bonds in methane. The catalytic approach allows for operation at lower temperatures compared to thermal pyrolysis, improving energy efficiency and reducing operational costs. Various reactor designs have been developed to optimize catalyst contact time and prevent catalyst deactivation due to carbon deposition.

- Thermal methane pyrolysis technologies: Thermal methane pyrolysis involves the direct decomposition of methane into hydrogen and carbon at high temperatures (typically 800-1200°C) without catalysts. This approach relies on thermal energy to break the strong C-H bonds in methane molecules. Various reactor designs have been developed for thermal pyrolysis, including plasma reactors, molten metal reactors, and fluidized bed systems. These technologies focus on optimizing heat transfer, residence time, and energy efficiency to maximize methane conversion while producing high-purity hydrogen and valuable carbon materials.

- Carbon material recovery and utilization: Methods for recovering and utilizing the solid carbon byproduct from methane pyrolysis processes. The carbon produced can take various forms including carbon black, graphite, carbon nanotubes, or amorphous carbon depending on the process conditions. Technologies have been developed for efficient separation of carbon from reaction systems, post-processing treatments to enhance carbon properties, and applications of the recovered carbon in various industries such as rubber manufacturing, construction materials, electronics, and advanced materials. These approaches transform what could be a waste product into a valuable resource, improving the economic viability of methane pyrolysis.

- Reactor designs for methane pyrolysis: Innovative reactor designs specifically engineered for methane pyrolysis processes. These include molten metal reactors that use liquid metals as heat transfer media, fluidized bed reactors that enhance gas-solid contact, plasma reactors that generate extremely high temperatures, and membrane reactors that allow for continuous hydrogen separation. The reactor designs address challenges such as carbon management, heat transfer efficiency, continuous operation, and scaling capabilities. Advanced materials and construction techniques are employed to withstand the harsh operating conditions of high temperatures and potential carbon deposition.

- Integration with hydrogen production systems: Technologies for integrating methane pyrolysis with broader hydrogen production and utilization systems. These approaches include purification methods for the hydrogen product, compression and storage solutions, and integration with downstream hydrogen applications such as fuel cells or chemical synthesis. Some systems combine methane pyrolysis with other hydrogen production methods like steam methane reforming or electrolysis to create hybrid systems with enhanced efficiency or flexibility. Process integration techniques optimize energy use through heat recovery systems and minimize environmental impact by creating closed-loop operations where byproducts are utilized effectively.

02 Reactor designs for methane pyrolysis

Various reactor designs have been developed for methane pyrolysis, including fluidized bed reactors, molten metal reactors, and plasma reactors. These designs address challenges such as carbon separation, heat transfer efficiency, and continuous operation. Advanced reactor configurations incorporate features for improved residence time distribution, enhanced mixing, and effective carbon product recovery, while maintaining stable operation conditions for optimal hydrogen production and carbon yield.Expand Specific Solutions03 Carbon product valorization from methane pyrolysis

Methane pyrolysis produces solid carbon as a co-product, which can be valorized in various applications. The carbon materials obtained can range from amorphous carbon to structured forms like carbon nanotubes or graphene, depending on process conditions. These carbon products can be utilized in applications such as construction materials, soil amendments, battery electrodes, or as precursors for advanced carbon materials. The ability to produce valuable carbon products enhances the economic viability of methane pyrolysis as a hydrogen production method.Expand Specific Solutions04 Integration of methane pyrolysis with renewable energy systems

Methane pyrolysis processes can be integrated with renewable energy systems to create more sustainable hydrogen production pathways. By utilizing renewable electricity or concentrated solar thermal energy to provide the heat required for the endothermic pyrolysis reaction, the overall carbon footprint of hydrogen production can be significantly reduced. These integrated systems may incorporate thermal energy storage, heat recovery mechanisms, and smart control systems to optimize energy utilization and process efficiency.Expand Specific Solutions05 Process intensification and scale-up strategies

Process intensification and scale-up strategies for methane pyrolysis focus on improving reaction kinetics, heat transfer, and overall system efficiency. Approaches include the development of structured catalysts, microreactor technology, and advanced heating methods such as induction or microwave heating. Scale-up considerations address challenges related to carbon handling, catalyst deactivation, and process control to maintain performance at industrial scales. These innovations aim to reduce capital and operating costs while increasing hydrogen production capacity.Expand Specific Solutions

Key Industry Players in Methane Pyrolysis Field

Methane pyrolysis is currently in an early growth phase within the clean hydrogen production sector, with market size expanding due to increasing focus on decarbonization. The technology demonstrates moderate maturity, with significant R&D investments from major players across energy and chemical sectors. Companies like Shell, ExxonMobil, BASF, and SABIC are leading commercial development, while innovative startups such as Molten Industries, Ekona Power, and Hazer Group are advancing novel approaches. Academic-industrial partnerships involving institutions like King Abdullah University and China University of Petroleum are accelerating technological progress. The regulatory landscape is evolving, with compliance frameworks developing as governments worldwide establish standards for low-carbon hydrogen production methods.

BASF Corp.

Technical Solution: BASF has pioneered a methane pyrolysis technology called "BASF Carbon Management Program" that utilizes a specialized fixed-bed reactor system with proprietary carbon-based catalysts. Their process operates at temperatures between 800-1000°C and employs a moving bed reactor design that allows for continuous carbon removal while maintaining catalyst activity. BASF's approach focuses on maximizing hydrogen yield while minimizing energy consumption through innovative heat recovery systems. The company has developed comprehensive compliance protocols aligned with the European Union's Hydrogen Strategy and various national hydrogen roadmaps. Their technology incorporates advanced monitoring systems that track emissions and process efficiency to ensure adherence to evolving regulatory standards. BASF has also established partnerships with regulatory bodies to help shape future legislative frameworks for methane pyrolysis technologies, particularly focusing on carbon accounting methodologies and certification standards for low-carbon hydrogen[2][5].

Strengths: BASF's technology achieves high conversion efficiency (>90%), produces high-purity hydrogen suitable for fuel cell applications, and features an innovative continuous carbon removal system that enhances operational stability. Weaknesses: The process requires specialized catalysts that may degrade over time, has relatively high capital costs compared to conventional hydrogen production methods, and faces regulatory uncertainty regarding carbon credit mechanisms in different jurisdictions.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed an advanced methane pyrolysis technology called the Shell Blue Hydrogen Process, which uses a proprietary molten metal catalyst system to decompose methane into hydrogen and solid carbon. The process operates at temperatures around 1000-1200°C in a bubble column reactor where natural gas is injected into a molten metal bath (typically tin or nickel-bismuth alloys). This approach enables efficient heat transfer and catalyst contact while producing hydrogen with significantly lower CO2 emissions compared to conventional steam methane reforming. Shell has integrated comprehensive compliance systems that address various regulatory frameworks, including the EU Hydrogen Strategy and the European Green Deal. Their technology is designed to meet stringent emissions standards while providing a scalable solution for clean hydrogen production that aligns with carbon border adjustment mechanisms and international climate agreements[1][3].

Strengths: Shell's technology produces hydrogen with up to 80% lower carbon emissions than conventional methods, generates easily sequesterable solid carbon instead of CO2, and integrates well with existing natural gas infrastructure. Weaknesses: The process still requires significant energy input for heating, faces challenges with continuous carbon removal from the molten metal bath, and depends on regional regulatory frameworks that are still evolving.

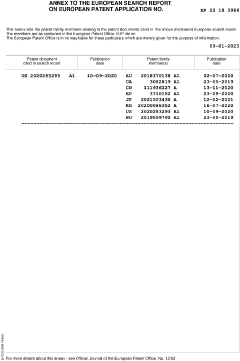

Core Patents and Innovations in Methane Pyrolysis

Handling Carbon Nanoparticles Produced From Methane Pyrolysis

PatentPendingUS20250263300A1

Innovation

- A method and system for producing hydrogen through methane pyrolysis, capturing carbon nanoparticles in a separator, and forming a slurry or paste with a liquid to mitigate handling risks, enabling safe and efficient power distribution using hydrogen fuel cells or engines.

Molten metal catalysed pyrolysis

PatentPendingEP4303177A1

Innovation

- A method using molten metal pyrolysis with molten salt to reform methane and carbon dioxide into hydrogen gas and carbon monoxide, where a feedstock comprising hydrocarbons and CO2 is fed into a pyrolysis reactor containing molten metal and molten salt, allowing for direct production of syngas while managing contaminants effectively.

Regulatory Frameworks and Compliance Requirements

Methane pyrolysis operates within a complex regulatory landscape that varies significantly across regions and jurisdictions. In the United States, the Environmental Protection Agency (EPA) regulates methane emissions under the Clean Air Act, with specific provisions addressing hydrogen production technologies. The Department of Energy (DOE) has established guidelines for carbon-neutral hydrogen production methods, including methane pyrolysis, under the Hydrogen Program Plan. These frameworks set emission standards, safety protocols, and reporting requirements that directly impact implementation feasibility.

The European Union has developed more stringent regulatory frameworks through its Hydrogen Strategy and European Green Deal. The EU Taxonomy for Sustainable Activities specifically recognizes methane pyrolysis as a transitional technology for hydrogen production with significantly lower carbon footprint compared to conventional methods. Compliance requirements include life-cycle carbon accounting, process verification protocols, and regular emissions monitoring.

In Asia-Pacific regions, regulatory approaches vary considerably. Japan's Green Growth Strategy includes specific provisions for methane pyrolysis within its hydrogen roadmap, while China has incorporated methane pyrolysis technologies into its latest Five-Year Plan with emphasis on industrial decarbonization pathways. These frameworks typically mandate technology certification, safety standards compliance, and emissions verification.

International standards organizations have developed specific compliance protocols for methane pyrolysis technologies. The International Organization for Standardization (ISO) has published standards addressing hydrogen production methods (ISO 14687), while the International Electrotechnical Commission (IEC) provides standards for associated electrical systems. Adherence to these standards is increasingly becoming a prerequisite for market access and regulatory approval.

Carbon accounting methodologies represent a critical compliance challenge for methane pyrolysis implementations. Current frameworks require detailed life-cycle assessments that document carbon intensity across the entire value chain. The Greenhouse Gas Protocol provides standardized accounting methods, while industry-specific protocols are emerging to address the unique characteristics of pyrolysis processes and solid carbon byproducts.

Permitting requirements present significant compliance hurdles, particularly for commercial-scale facilities. Environmental impact assessments, safety management systems, and community engagement processes are typically mandated. The regulatory timeline for approval can range from 12-36 months depending on jurisdiction, creating substantial planning challenges for technology deployment.

Emerging regulatory trends indicate movement toward performance-based standards rather than prescriptive requirements. This shift potentially benefits methane pyrolysis technologies by allowing flexibility in implementation while maintaining focus on emissions outcomes. Several jurisdictions are developing regulatory sandboxes specifically designed to accelerate approval processes for promising decarbonization technologies while maintaining appropriate oversight.

The European Union has developed more stringent regulatory frameworks through its Hydrogen Strategy and European Green Deal. The EU Taxonomy for Sustainable Activities specifically recognizes methane pyrolysis as a transitional technology for hydrogen production with significantly lower carbon footprint compared to conventional methods. Compliance requirements include life-cycle carbon accounting, process verification protocols, and regular emissions monitoring.

In Asia-Pacific regions, regulatory approaches vary considerably. Japan's Green Growth Strategy includes specific provisions for methane pyrolysis within its hydrogen roadmap, while China has incorporated methane pyrolysis technologies into its latest Five-Year Plan with emphasis on industrial decarbonization pathways. These frameworks typically mandate technology certification, safety standards compliance, and emissions verification.

International standards organizations have developed specific compliance protocols for methane pyrolysis technologies. The International Organization for Standardization (ISO) has published standards addressing hydrogen production methods (ISO 14687), while the International Electrotechnical Commission (IEC) provides standards for associated electrical systems. Adherence to these standards is increasingly becoming a prerequisite for market access and regulatory approval.

Carbon accounting methodologies represent a critical compliance challenge for methane pyrolysis implementations. Current frameworks require detailed life-cycle assessments that document carbon intensity across the entire value chain. The Greenhouse Gas Protocol provides standardized accounting methods, while industry-specific protocols are emerging to address the unique characteristics of pyrolysis processes and solid carbon byproducts.

Permitting requirements present significant compliance hurdles, particularly for commercial-scale facilities. Environmental impact assessments, safety management systems, and community engagement processes are typically mandated. The regulatory timeline for approval can range from 12-36 months depending on jurisdiction, creating substantial planning challenges for technology deployment.

Emerging regulatory trends indicate movement toward performance-based standards rather than prescriptive requirements. This shift potentially benefits methane pyrolysis technologies by allowing flexibility in implementation while maintaining focus on emissions outcomes. Several jurisdictions are developing regulatory sandboxes specifically designed to accelerate approval processes for promising decarbonization technologies while maintaining appropriate oversight.

Environmental Impact Assessment and Carbon Credits

Methane pyrolysis operations require comprehensive environmental impact assessments (EIAs) to quantify their ecological footprint and potential for carbon credit generation. These assessments typically evaluate greenhouse gas emissions reductions compared to traditional natural gas processing methods, with methane pyrolysis offering significant advantages through its near-zero CO2 emissions profile when powered by renewable energy sources.

The carbon credit potential for methane pyrolysis projects is substantial, with preliminary market analyses suggesting values of $50-150 per ton of CO2 equivalent avoided. This creates a compelling secondary revenue stream for operators beyond the sale of hydrogen and solid carbon products. Several carbon credit methodologies are being developed specifically for methane pyrolysis under major carbon registries including Verra, Gold Standard, and the American Carbon Registry.

Regulatory frameworks increasingly recognize methane pyrolysis as an eligible activity for carbon offset generation, particularly in jurisdictions with established carbon markets such as the EU, California, and emerging national schemes in Canada and Australia. The Clean Development Mechanism under the Paris Agreement is also developing methodologies applicable to methane pyrolysis technologies deployed in developing nations.

Life cycle assessment (LCA) methodologies play a crucial role in validating environmental claims and carbon credit applications. ISO 14040/14044-compliant LCAs are becoming standard requirements for project developers seeking to monetize emissions reductions. These assessments must account for upstream methane leakage, energy inputs, and downstream utilization of carbon products to establish accurate carbon intensity values.

Monitoring, reporting, and verification (MRV) protocols specific to methane pyrolysis are being standardized across jurisdictions to ensure transparency and credibility in carbon accounting. These typically require continuous emissions monitoring systems, mass balance calculations, and third-party verification of carbon reduction claims.

The solid carbon byproduct presents unique opportunities for permanent carbon sequestration when utilized in construction materials, soil amendments, or other long-term applications. Emerging methodologies are beginning to recognize and quantify this additional carbon removal benefit, potentially increasing the carbon credit value of methane pyrolysis operations by 20-30% compared to hydrogen production methods that do not sequester carbon.

Regional variations in environmental assessment requirements and carbon credit valuation create strategic opportunities for project developers to maximize financial returns through careful site selection and regulatory engagement. Jurisdictions with both stringent methane regulations and robust carbon markets currently offer the most favorable economics for methane pyrolysis deployment.

The carbon credit potential for methane pyrolysis projects is substantial, with preliminary market analyses suggesting values of $50-150 per ton of CO2 equivalent avoided. This creates a compelling secondary revenue stream for operators beyond the sale of hydrogen and solid carbon products. Several carbon credit methodologies are being developed specifically for methane pyrolysis under major carbon registries including Verra, Gold Standard, and the American Carbon Registry.

Regulatory frameworks increasingly recognize methane pyrolysis as an eligible activity for carbon offset generation, particularly in jurisdictions with established carbon markets such as the EU, California, and emerging national schemes in Canada and Australia. The Clean Development Mechanism under the Paris Agreement is also developing methodologies applicable to methane pyrolysis technologies deployed in developing nations.

Life cycle assessment (LCA) methodologies play a crucial role in validating environmental claims and carbon credit applications. ISO 14040/14044-compliant LCAs are becoming standard requirements for project developers seeking to monetize emissions reductions. These assessments must account for upstream methane leakage, energy inputs, and downstream utilization of carbon products to establish accurate carbon intensity values.

Monitoring, reporting, and verification (MRV) protocols specific to methane pyrolysis are being standardized across jurisdictions to ensure transparency and credibility in carbon accounting. These typically require continuous emissions monitoring systems, mass balance calculations, and third-party verification of carbon reduction claims.

The solid carbon byproduct presents unique opportunities for permanent carbon sequestration when utilized in construction materials, soil amendments, or other long-term applications. Emerging methodologies are beginning to recognize and quantify this additional carbon removal benefit, potentially increasing the carbon credit value of methane pyrolysis operations by 20-30% compared to hydrogen production methods that do not sequester carbon.

Regional variations in environmental assessment requirements and carbon credit valuation create strategic opportunities for project developers to maximize financial returns through careful site selection and regulatory engagement. Jurisdictions with both stringent methane regulations and robust carbon markets currently offer the most favorable economics for methane pyrolysis deployment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!