Gate Valve Maintenance in Methane Pyrolysis Facilities.

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Methane Pyrolysis Gate Valve Technology Background

Methane pyrolysis represents a significant advancement in hydrogen production technology, offering a cleaner alternative to traditional steam methane reforming processes. The evolution of this technology dates back to the early 2000s when researchers began exploring methods to produce hydrogen without CO2 emissions. Over the past two decades, methane pyrolysis has progressed from laboratory-scale experiments to pilot plants and now approaches commercial viability in several regions globally.

The technical trajectory has been marked by innovations in reactor design, catalyst development, and carbon handling systems. Early methane pyrolysis systems suffered from carbon deposition issues that significantly reduced operational efficiency and increased maintenance requirements. Gate valves, critical components in these systems, have undergone parallel evolution to withstand the harsh operating conditions characteristic of pyrolysis processes.

Gate valves in methane pyrolysis facilities operate under extreme conditions, including temperatures ranging from 800°C to 1200°C and exposure to carbon particulates, hydrogen gas, and occasionally methane. These conditions create unique challenges for valve integrity and functionality that conventional valve technologies were not designed to address.

The technological advancement of gate valves for methane pyrolysis has focused on materials science innovations, with progression from standard stainless steel components to advanced ceramic-metal composites and specialized coatings. These developments aim to extend valve service life and reduce maintenance frequency in high-temperature carbon-rich environments.

Current technology trends point toward intelligent valve systems with integrated sensors for real-time monitoring of valve condition, predictive maintenance capabilities, and remote operation features. These smart valve technologies align with broader Industry 4.0 principles being adopted across the hydrogen production sector.

The expected technical objectives for next-generation gate valves include extending operational lifespans to match facility turnaround schedules (typically 2-3 years), reducing maintenance costs by at least 30%, and improving safety through enhanced sealing technologies and failure prediction algorithms.

Research institutions and industrial partners are increasingly focusing on developing gate valve technologies specifically engineered for methane pyrolysis applications, recognizing that repurposed conventional valves fail to deliver optimal performance. This specialized development pathway represents a significant shift from earlier approaches that relied on adapting existing valve technologies from adjacent industries.

The convergence of materials science, digital technologies, and process engineering is expected to drive the next wave of innovations in this field, with particular emphasis on solving the persistent challenges of carbon fouling and high-temperature seal degradation that currently limit valve reliability in methane pyrolysis applications.

The technical trajectory has been marked by innovations in reactor design, catalyst development, and carbon handling systems. Early methane pyrolysis systems suffered from carbon deposition issues that significantly reduced operational efficiency and increased maintenance requirements. Gate valves, critical components in these systems, have undergone parallel evolution to withstand the harsh operating conditions characteristic of pyrolysis processes.

Gate valves in methane pyrolysis facilities operate under extreme conditions, including temperatures ranging from 800°C to 1200°C and exposure to carbon particulates, hydrogen gas, and occasionally methane. These conditions create unique challenges for valve integrity and functionality that conventional valve technologies were not designed to address.

The technological advancement of gate valves for methane pyrolysis has focused on materials science innovations, with progression from standard stainless steel components to advanced ceramic-metal composites and specialized coatings. These developments aim to extend valve service life and reduce maintenance frequency in high-temperature carbon-rich environments.

Current technology trends point toward intelligent valve systems with integrated sensors for real-time monitoring of valve condition, predictive maintenance capabilities, and remote operation features. These smart valve technologies align with broader Industry 4.0 principles being adopted across the hydrogen production sector.

The expected technical objectives for next-generation gate valves include extending operational lifespans to match facility turnaround schedules (typically 2-3 years), reducing maintenance costs by at least 30%, and improving safety through enhanced sealing technologies and failure prediction algorithms.

Research institutions and industrial partners are increasingly focusing on developing gate valve technologies specifically engineered for methane pyrolysis applications, recognizing that repurposed conventional valves fail to deliver optimal performance. This specialized development pathway represents a significant shift from earlier approaches that relied on adapting existing valve technologies from adjacent industries.

The convergence of materials science, digital technologies, and process engineering is expected to drive the next wave of innovations in this field, with particular emphasis on solving the persistent challenges of carbon fouling and high-temperature seal degradation that currently limit valve reliability in methane pyrolysis applications.

Market Demand Analysis for High-Performance Valves

The global market for high-performance valves in methane pyrolysis facilities has experienced significant growth over the past decade, driven by increasing adoption of methane pyrolysis as a cleaner alternative for hydrogen production. Current market estimates value the specialized valve segment at approximately $2.3 billion, with projections indicating a compound annual growth rate of 7.8% through 2030.

The demand for gate valves specifically designed for methane pyrolysis environments stems from the unique operational challenges these facilities face. With operating temperatures often exceeding 1000°C and carbon particulate formation being a constant concern, conventional valve solutions frequently experience premature failure, leading to costly downtime and maintenance cycles.

Industry surveys reveal that facility operators identify valve reliability as one of their top three operational concerns, with 68% of respondents reporting that valve-related issues account for at least 15% of their unplanned maintenance activities. This represents a significant pain point and market opportunity for improved solutions.

Regional analysis shows particularly strong demand growth in Asia-Pacific, where methane pyrolysis adoption is accelerating as countries seek to develop blue and turquoise hydrogen production capabilities. North America follows closely, driven by natural gas abundance and increasing investment in low-carbon hydrogen infrastructure.

The market segmentation reveals distinct customer profiles with varying needs. Large-scale industrial hydrogen producers prioritize longevity and minimal maintenance intervals, willing to invest in premium solutions that reduce total cost of ownership. Research facilities and smaller-scale operations tend to focus more on flexibility and adaptability to changing process conditions.

From a product perspective, the highest demand exists for gate valves capable of handling high-temperature carbon-rich environments while maintaining tight sealing properties. Valves incorporating advanced ceramic components, specialized coatings, or novel self-cleaning mechanisms command premium pricing, with customers demonstrating willingness to pay 30-40% above standard industrial valve costs for solutions that extend maintenance intervals.

Market feedback indicates growing interest in smart valve technologies that incorporate condition monitoring capabilities, allowing predictive maintenance approaches rather than scheduled interventions. This trend aligns with broader Industry 4.0 adoption across process industries and represents a potential value-added feature for next-generation valve designs.

The competitive landscape remains fragmented, with specialized valve manufacturers capturing market share from traditional industrial valve suppliers through purpose-built solutions for pyrolysis environments. This creates opportunities for innovation-focused companies to establish leadership positions in this growing niche.

The demand for gate valves specifically designed for methane pyrolysis environments stems from the unique operational challenges these facilities face. With operating temperatures often exceeding 1000°C and carbon particulate formation being a constant concern, conventional valve solutions frequently experience premature failure, leading to costly downtime and maintenance cycles.

Industry surveys reveal that facility operators identify valve reliability as one of their top three operational concerns, with 68% of respondents reporting that valve-related issues account for at least 15% of their unplanned maintenance activities. This represents a significant pain point and market opportunity for improved solutions.

Regional analysis shows particularly strong demand growth in Asia-Pacific, where methane pyrolysis adoption is accelerating as countries seek to develop blue and turquoise hydrogen production capabilities. North America follows closely, driven by natural gas abundance and increasing investment in low-carbon hydrogen infrastructure.

The market segmentation reveals distinct customer profiles with varying needs. Large-scale industrial hydrogen producers prioritize longevity and minimal maintenance intervals, willing to invest in premium solutions that reduce total cost of ownership. Research facilities and smaller-scale operations tend to focus more on flexibility and adaptability to changing process conditions.

From a product perspective, the highest demand exists for gate valves capable of handling high-temperature carbon-rich environments while maintaining tight sealing properties. Valves incorporating advanced ceramic components, specialized coatings, or novel self-cleaning mechanisms command premium pricing, with customers demonstrating willingness to pay 30-40% above standard industrial valve costs for solutions that extend maintenance intervals.

Market feedback indicates growing interest in smart valve technologies that incorporate condition monitoring capabilities, allowing predictive maintenance approaches rather than scheduled interventions. This trend aligns with broader Industry 4.0 adoption across process industries and represents a potential value-added feature for next-generation valve designs.

The competitive landscape remains fragmented, with specialized valve manufacturers capturing market share from traditional industrial valve suppliers through purpose-built solutions for pyrolysis environments. This creates opportunities for innovation-focused companies to establish leadership positions in this growing niche.

Current Challenges in Gate Valve Maintenance

Gate valve maintenance in methane pyrolysis facilities presents significant challenges due to the harsh operating conditions and critical safety requirements. These valves are exposed to extreme temperatures, often exceeding 1000°C, which accelerates material degradation and reduces operational lifespan. The carbon-rich environment resulting from methane decomposition leads to carbon deposition on valve components, particularly affecting sealing surfaces and stem mechanisms.

Valve seat erosion represents one of the most persistent maintenance challenges, as the high-velocity flow of methane and carbon particles creates abrasive conditions that gradually wear down sealing surfaces. This erosion compromises the valve's ability to provide positive shutoff, leading to leakage and potential safety hazards. Traditional hardening treatments have proven insufficient for long-term protection in these aggressive environments.

Stem packing failures occur frequently due to thermal cycling and carbon infiltration. As facilities cycle between operating and maintenance states, the repeated expansion and contraction of valve components stresses packing materials beyond their design limits. Carbon particles penetrate packing glands, accelerating wear and creating leak paths that compromise both process efficiency and facility safety protocols.

Actuator reliability issues compound maintenance challenges, as pneumatic and electric actuators struggle with the high-temperature environment. Thermal transfer from valve bodies to actuator components leads to premature failure of seals, lubricants, and electronic controls. Maintenance teams often face difficult decisions between more frequent replacement schedules or implementing costly thermal isolation solutions.

Predictive maintenance implementation remains difficult due to limited sensor technology capable of withstanding pyrolysis conditions. Traditional vibration analysis and acoustic monitoring systems frequently fail when exposed to the extreme temperatures and carbon-rich atmosphere. This creates a reactive maintenance environment where failures are addressed after they occur rather than prevented through condition monitoring.

Access constraints further complicate maintenance activities, as gate valves are typically integrated into complex piping systems with limited clearance for maintenance tools and personnel. Complete valve removal often requires extensive system shutdown, cooling periods, and purging procedures, significantly extending maintenance downtime and impacting production schedules.

Material selection presents ongoing challenges as maintenance engineers must balance corrosion resistance, thermal stability, and mechanical strength. While specialized alloys and ceramic components offer improved performance, they significantly increase replacement costs and often require specialized handling techniques during maintenance procedures. The trade-off between maintenance frequency and component cost creates difficult economic decisions for facility operators.

Valve seat erosion represents one of the most persistent maintenance challenges, as the high-velocity flow of methane and carbon particles creates abrasive conditions that gradually wear down sealing surfaces. This erosion compromises the valve's ability to provide positive shutoff, leading to leakage and potential safety hazards. Traditional hardening treatments have proven insufficient for long-term protection in these aggressive environments.

Stem packing failures occur frequently due to thermal cycling and carbon infiltration. As facilities cycle between operating and maintenance states, the repeated expansion and contraction of valve components stresses packing materials beyond their design limits. Carbon particles penetrate packing glands, accelerating wear and creating leak paths that compromise both process efficiency and facility safety protocols.

Actuator reliability issues compound maintenance challenges, as pneumatic and electric actuators struggle with the high-temperature environment. Thermal transfer from valve bodies to actuator components leads to premature failure of seals, lubricants, and electronic controls. Maintenance teams often face difficult decisions between more frequent replacement schedules or implementing costly thermal isolation solutions.

Predictive maintenance implementation remains difficult due to limited sensor technology capable of withstanding pyrolysis conditions. Traditional vibration analysis and acoustic monitoring systems frequently fail when exposed to the extreme temperatures and carbon-rich atmosphere. This creates a reactive maintenance environment where failures are addressed after they occur rather than prevented through condition monitoring.

Access constraints further complicate maintenance activities, as gate valves are typically integrated into complex piping systems with limited clearance for maintenance tools and personnel. Complete valve removal often requires extensive system shutdown, cooling periods, and purging procedures, significantly extending maintenance downtime and impacting production schedules.

Material selection presents ongoing challenges as maintenance engineers must balance corrosion resistance, thermal stability, and mechanical strength. While specialized alloys and ceramic components offer improved performance, they significantly increase replacement costs and often require specialized handling techniques during maintenance procedures. The trade-off between maintenance frequency and component cost creates difficult economic decisions for facility operators.

Current Maintenance Solutions and Protocols

01 Gate valve maintenance tools and equipment

Specialized tools and equipment designed for gate valve maintenance operations, including valve wrenches, maintenance platforms, and automated maintenance devices. These tools are designed to facilitate easier access to valve components, improve maintenance efficiency, and reduce manual labor during maintenance procedures. Some tools are specifically designed for underwater or hard-to-reach valve maintenance scenarios.- Gate valve maintenance tools and equipment: Specialized tools and equipment designed for gate valve maintenance operations, including valve wrenches, maintenance platforms, and automated maintenance devices. These tools facilitate easier access to valve components, improve efficiency of maintenance procedures, and reduce manual labor requirements during valve servicing operations.

- Sealing and lubrication systems for gate valves: Maintenance systems focused on preserving and enhancing the sealing capabilities of gate valves through improved lubrication methods. These systems include specialized lubricant injection mechanisms, sealing surface treatments, and innovative sealing materials that extend valve service life and prevent leakage during operation.

- Automated and remote gate valve maintenance systems: Advanced systems that enable remote monitoring, diagnosis, and maintenance of gate valves. These include sensor-equipped valves that provide real-time operational data, remote control mechanisms for valve adjustment, and automated maintenance scheduling systems that optimize maintenance intervals based on valve performance metrics.

- Gate valve cleaning and debris removal methods: Techniques and devices specifically designed for cleaning gate valves and removing accumulated debris that can affect valve performance. These methods include flushing systems, ultrasonic cleaning technologies, and specialized tools for accessing and cleaning hard-to-reach valve components without complete disassembly.

- Structural improvements for easier gate valve maintenance: Design innovations that make gate valves more accessible and easier to maintain. These include modular valve designs that allow for partial disassembly, quick-release components that reduce maintenance time, and structural modifications that improve access to critical valve parts requiring regular inspection or replacement.

02 Lubrication systems for gate valves

Lubrication systems designed specifically for gate valves to ensure smooth operation and extend service life. These systems include automatic lubrication devices, specialized lubricant delivery mechanisms, and sealed lubrication chambers that protect critical valve components from contamination. Proper lubrication reduces friction between moving parts, prevents corrosion, and minimizes wear during valve operation.Expand Specific Solutions03 Sealing and leakage prevention methods

Methods and systems for maintaining and improving the sealing performance of gate valves to prevent leakage. These include innovative sealing structures, replacement procedures for worn seals, and techniques for detecting and addressing potential leak points. Some solutions involve composite sealing materials or multi-layer sealing designs that can withstand high pressure and temperature variations while maintaining integrity over extended periods.Expand Specific Solutions04 Corrosion prevention and treatment

Techniques and materials for preventing and treating corrosion in gate valves, particularly those used in harsh environments. These include protective coatings, cathodic protection systems, and materials selection strategies to enhance corrosion resistance. Some methods focus on regular inspection and early intervention to address corrosion before it compromises valve functionality, while others involve innovative surface treatments that create a barrier against corrosive elements.Expand Specific Solutions05 Automated and remote maintenance systems

Advanced systems that enable automated or remote maintenance of gate valves, reducing the need for direct human intervention. These systems incorporate sensors for condition monitoring, diagnostic capabilities for identifying maintenance needs, and mechanisms for performing maintenance tasks remotely. Some solutions include robotic maintenance devices that can operate in hazardous environments or underwater conditions, while others focus on predictive maintenance using data analytics to optimize maintenance scheduling.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The methane pyrolysis gate valve maintenance market is currently in a growth phase, driven by increasing adoption of hydrogen production technologies. The market size is expanding as methane pyrolysis emerges as a cleaner alternative for hydrogen production, with projections showing significant growth over the next decade. Technologically, the field demonstrates varying maturity levels across players. Industry leaders like Air Liquide and PetroChina have developed advanced valve maintenance solutions for high-temperature environments, while specialized valve manufacturers such as OMB SALERI and Safoco are focusing on methane-specific innovations. Applied Materials and Tokyo Electron contribute expertise in high-precision components, while companies like Wanhua Chemical and Beijing Aerospace Petrochemical are advancing materials science for valve durability in pyrolysis conditions.

Beijing Aerospace Petrochemical Tech Equipment Eng Co., Ltd.

Technical Solution: Beijing Aerospace Petrochemical has developed specialized high-temperature resistant gate valves specifically engineered for methane pyrolysis environments. Their maintenance solution incorporates a dual-seal system with graphite and metal composite seals that can withstand temperatures up to 1000°C while maintaining integrity in carbon-rich environments. The company's maintenance protocol includes ultrasonic inspection technology to detect carbon deposits and material degradation without system shutdown. Their proprietary cleaning system uses controlled plasma pulses to remove carbon deposits from valve seats and gates without disassembly, significantly reducing maintenance downtime in continuous pyrolysis operations.

Strengths: Specialized high-temperature materials expertise; non-invasive inspection capabilities; minimal downtime maintenance procedures. Weaknesses: Higher initial implementation costs; requires specialized training for maintenance personnel; limited global service network outside of Asia.

PetroChina Co., Ltd.

Technical Solution: PetroChina has developed a comprehensive gate valve maintenance system for methane pyrolysis facilities that focuses on extending operational life in carbon-rich environments. Their approach integrates specialized valve designs with tungsten carbide and silicon nitride coatings on critical sealing surfaces to resist carbon buildup and erosion. PetroChina's maintenance protocol employs acoustic emission monitoring to detect early signs of valve degradation before failure occurs. Their system includes proprietary cleaning procedures using controlled thermal cycling and mechanical vibration to dislodge carbon deposits without disassembly. For severe fouling, they've engineered specialized tools for in-situ machining of valve seats and gates that can be deployed through access ports, minimizing system downtime and exposure to oxygen that could create hazardous conditions in carbon-rich environments.

Strengths: Extensive experience with large-scale methane processing facilities; advanced non-destructive testing capabilities; comprehensive maintenance documentation and training programs. Weaknesses: Some maintenance procedures require specialized equipment with limited availability; higher initial costs compared to standard valve maintenance systems; longer lead times for replacement components.

Critical Patents and Technical Literature Review

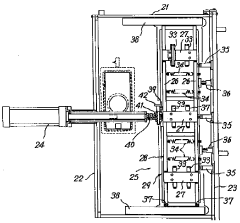

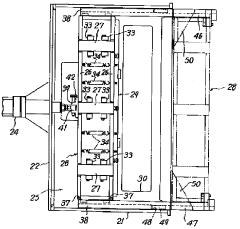

Gate valve and maintenance method for it

PatentInactiveJP1994129549A

Innovation

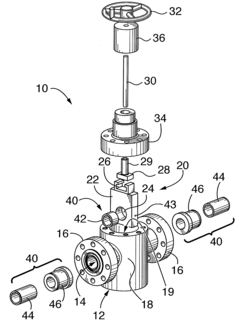

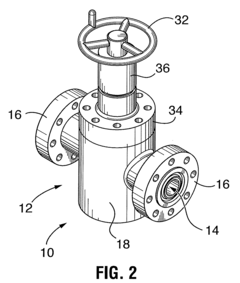

- The gate valve design allows the valve body to be horizontally movable, with detachable flanges and rails for easy disassembly and assembly, enabling maintenance without disconnecting the drive body, and includes a stopper mechanism for fixing the valve body during maintenance.

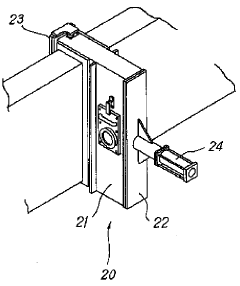

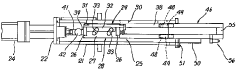

Gate valve with replaceable inserts and method of refurbishing same

PatentInactiveUS20090095933A1

Innovation

- A gate valve design featuring a replaceable wear-resistant flow-path liner with cylindrical steel valve seats, wear sleeves, and a gate insert, which can be easily inspected and replaced to maintain the valve's original specifications, reducing the need for costly rebuilding.

Safety Standards and Compliance Requirements

Methane pyrolysis facilities operate under stringent safety regulations due to the hazardous nature of their processes. Compliance with international standards such as ISO 14001, ISO 45001, and industry-specific guidelines like API 598 for valve testing is mandatory for gate valve maintenance operations. These standards establish minimum requirements for inspection frequencies, testing procedures, and documentation protocols that must be rigorously followed to ensure operational safety and environmental protection.

The National Fire Protection Association (NFPA) codes, particularly NFPA 54 and NFPA 58, provide comprehensive guidelines for handling methane and other flammable gases. Maintenance personnel must adhere to these standards when servicing gate valves to prevent potential fire hazards. Additionally, the Occupational Safety and Health Administration (OSHA) regulations, specifically 29 CFR 1910.119 Process Safety Management of Highly Hazardous Chemicals, mandate detailed risk assessments and safety protocols for maintenance activities in pyrolysis facilities.

Environmental compliance requirements add another layer of complexity to gate valve maintenance. The Environmental Protection Agency (EPA) regulations under the Clean Air Act impose strict emission control standards that directly impact valve maintenance procedures. Leak Detection and Repair (LDAR) programs require regular monitoring of valve integrity to prevent methane leakage, with specific requirements for documentation and reporting of maintenance activities.

Regional variations in compliance requirements present significant challenges for global operators. European facilities must comply with ATEX Directive 2014/34/EU for equipment used in potentially explosive atmospheres, while facilities in Asia-Pacific regions often follow modified versions of international standards with additional local requirements. This regulatory diversity necessitates customized maintenance protocols based on facility location.

Recent regulatory developments have introduced more stringent requirements for predictive maintenance and real-time monitoring of critical components like gate valves. The Industrial Emissions Directive (IED) in Europe and similar regulations worldwide increasingly emphasize preventive approaches to maintenance rather than reactive responses to failures. These evolving standards require facilities to implement advanced monitoring technologies and maintain comprehensive digital records of all maintenance activities.

Certification requirements for maintenance personnel have also become more demanding, with specialized training now mandatory for technicians working on high-pressure methane systems. Organizations such as the American Society of Mechanical Engineers (ASME) provide certification programs specifically designed for valve maintenance in hazardous environments, ensuring that only qualified personnel perform critical maintenance tasks on gate valves in methane pyrolysis facilities.

The National Fire Protection Association (NFPA) codes, particularly NFPA 54 and NFPA 58, provide comprehensive guidelines for handling methane and other flammable gases. Maintenance personnel must adhere to these standards when servicing gate valves to prevent potential fire hazards. Additionally, the Occupational Safety and Health Administration (OSHA) regulations, specifically 29 CFR 1910.119 Process Safety Management of Highly Hazardous Chemicals, mandate detailed risk assessments and safety protocols for maintenance activities in pyrolysis facilities.

Environmental compliance requirements add another layer of complexity to gate valve maintenance. The Environmental Protection Agency (EPA) regulations under the Clean Air Act impose strict emission control standards that directly impact valve maintenance procedures. Leak Detection and Repair (LDAR) programs require regular monitoring of valve integrity to prevent methane leakage, with specific requirements for documentation and reporting of maintenance activities.

Regional variations in compliance requirements present significant challenges for global operators. European facilities must comply with ATEX Directive 2014/34/EU for equipment used in potentially explosive atmospheres, while facilities in Asia-Pacific regions often follow modified versions of international standards with additional local requirements. This regulatory diversity necessitates customized maintenance protocols based on facility location.

Recent regulatory developments have introduced more stringent requirements for predictive maintenance and real-time monitoring of critical components like gate valves. The Industrial Emissions Directive (IED) in Europe and similar regulations worldwide increasingly emphasize preventive approaches to maintenance rather than reactive responses to failures. These evolving standards require facilities to implement advanced monitoring technologies and maintain comprehensive digital records of all maintenance activities.

Certification requirements for maintenance personnel have also become more demanding, with specialized training now mandatory for technicians working on high-pressure methane systems. Organizations such as the American Society of Mechanical Engineers (ASME) provide certification programs specifically designed for valve maintenance in hazardous environments, ensuring that only qualified personnel perform critical maintenance tasks on gate valves in methane pyrolysis facilities.

Environmental Impact and Sustainability Considerations

Methane pyrolysis facilities represent a promising pathway for hydrogen production with significantly reduced carbon emissions compared to traditional steam methane reforming. The environmental impact and sustainability considerations of gate valve maintenance in these facilities are multifaceted and deserve careful examination.

The maintenance of gate valves in methane pyrolysis facilities directly impacts carbon emissions through several mechanisms. When valves fail or require emergency maintenance, process shutdowns may necessitate methane flaring, resulting in direct CO2 emissions. Properly maintained valves minimize leakage of methane, a greenhouse gas with warming potential approximately 25 times greater than CO2 over a 100-year period. Research indicates that valve-related methane leakage can account for 5-8% of total facility emissions when maintenance protocols are suboptimal.

Water conservation presents another critical environmental consideration. Traditional valve maintenance procedures often utilize water-intensive cleaning processes. In regions facing water scarcity, this creates additional environmental pressure. Advanced maintenance techniques incorporating dry cleaning methods and water recycling systems can reduce water consumption by up to 60% compared to conventional approaches, significantly enhancing the sustainability profile of maintenance operations.

The chemical compounds used in valve maintenance also warrant attention. Traditional lubricants and cleaning agents may contain volatile organic compounds (VOCs) and other environmentally persistent substances. The transition to bio-based lubricants and environmentally benign cleaning agents represents an important sustainability advancement, reducing both worker exposure to hazardous substances and environmental contamination risk.

Energy efficiency during maintenance procedures directly affects the carbon footprint of pyrolysis operations. Predictive maintenance technologies powered by renewable energy sources can reduce maintenance-related energy consumption by 30-40% compared to reactive maintenance approaches. This aligns with broader industry goals of minimizing the carbon intensity of hydrogen production through methane pyrolysis.

Waste management considerations extend to the disposal or recycling of valve components at end-of-life. The implementation of circular economy principles in valve maintenance—including refurbishment, remanufacturing, and materials recovery—can divert up to 85% of valve-related waste from landfills. Several leading facilities have pioneered valve component recycling programs that recover valuable metals while minimizing environmental impact.

The life cycle assessment (LCA) of different valve maintenance strategies reveals significant variations in environmental footprint. Proactive maintenance regimes typically demonstrate 25-35% lower lifetime environmental impact compared to reactive approaches, primarily due to extended valve service life, reduced emergency interventions, and optimized resource utilization throughout the maintenance cycle.

The maintenance of gate valves in methane pyrolysis facilities directly impacts carbon emissions through several mechanisms. When valves fail or require emergency maintenance, process shutdowns may necessitate methane flaring, resulting in direct CO2 emissions. Properly maintained valves minimize leakage of methane, a greenhouse gas with warming potential approximately 25 times greater than CO2 over a 100-year period. Research indicates that valve-related methane leakage can account for 5-8% of total facility emissions when maintenance protocols are suboptimal.

Water conservation presents another critical environmental consideration. Traditional valve maintenance procedures often utilize water-intensive cleaning processes. In regions facing water scarcity, this creates additional environmental pressure. Advanced maintenance techniques incorporating dry cleaning methods and water recycling systems can reduce water consumption by up to 60% compared to conventional approaches, significantly enhancing the sustainability profile of maintenance operations.

The chemical compounds used in valve maintenance also warrant attention. Traditional lubricants and cleaning agents may contain volatile organic compounds (VOCs) and other environmentally persistent substances. The transition to bio-based lubricants and environmentally benign cleaning agents represents an important sustainability advancement, reducing both worker exposure to hazardous substances and environmental contamination risk.

Energy efficiency during maintenance procedures directly affects the carbon footprint of pyrolysis operations. Predictive maintenance technologies powered by renewable energy sources can reduce maintenance-related energy consumption by 30-40% compared to reactive maintenance approaches. This aligns with broader industry goals of minimizing the carbon intensity of hydrogen production through methane pyrolysis.

Waste management considerations extend to the disposal or recycling of valve components at end-of-life. The implementation of circular economy principles in valve maintenance—including refurbishment, remanufacturing, and materials recovery—can divert up to 85% of valve-related waste from landfills. Several leading facilities have pioneered valve component recycling programs that recover valuable metals while minimizing environmental impact.

The life cycle assessment (LCA) of different valve maintenance strategies reveals significant variations in environmental footprint. Proactive maintenance regimes typically demonstrate 25-35% lower lifetime environmental impact compared to reactive approaches, primarily due to extended valve service life, reduced emergency interventions, and optimized resource utilization throughout the maintenance cycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!