Public Perception of Methane Pyrolysis Technologies.

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Methane Pyrolysis Background and Objectives

Methane pyrolysis represents a significant technological advancement in the field of hydrogen production, offering a cleaner alternative to traditional methods. This process involves the thermal decomposition of methane (CH4) into hydrogen (H2) and solid carbon, without producing carbon dioxide emissions. The technology's development can be traced back to the early 20th century, but significant progress has been made in the last two decades as global focus on decarbonization has intensified.

The evolution of methane pyrolysis has been marked by several key innovations, including the development of various reactor designs such as molten metal reactors, plasma-based systems, and catalytic approaches. Each iteration has aimed to improve efficiency, reduce energy requirements, and enhance the commercial viability of the process. The technology has gained renewed attention as part of the hydrogen economy framework, particularly as a potential contributor to "turquoise hydrogen" production pathways.

Public perception of methane pyrolysis technologies has been shaped by the growing awareness of climate change and the need for sustainable energy solutions. Initially, these technologies received limited public attention due to their technical complexity and early-stage development status. However, as concerns about greenhouse gas emissions have mounted, interest in carbon-neutral hydrogen production methods has increased substantially.

The primary objective of methane pyrolysis development is to establish a commercially viable, environmentally sustainable method for hydrogen production that can compete with conventional processes while significantly reducing carbon emissions. This aligns with broader societal goals of energy transition and decarbonization, making public acceptance a critical factor for widespread adoption.

Current technical objectives focus on improving process efficiency, reducing energy inputs, enhancing catalyst performance, and developing effective methods for handling and utilizing the solid carbon byproduct. The economic viability of these technologies depends largely on achieving cost parity with established hydrogen production methods while monetizing the carbon co-product.

Public perception challenges include limited awareness of the technology, concerns about methane leakage in the supply chain, questions about the environmental footprint of the process, and uncertainties regarding the safety of operations. These perceptions vary significantly across different stakeholder groups, including environmental organizations, policy makers, industry representatives, and the general public.

The trajectory of methane pyrolysis technology suggests potential for significant growth, particularly as hydrogen gains importance in the global energy mix. However, this growth is contingent upon addressing both technical challenges and public perception issues through transparent communication, stakeholder engagement, and demonstration of environmental benefits.

The evolution of methane pyrolysis has been marked by several key innovations, including the development of various reactor designs such as molten metal reactors, plasma-based systems, and catalytic approaches. Each iteration has aimed to improve efficiency, reduce energy requirements, and enhance the commercial viability of the process. The technology has gained renewed attention as part of the hydrogen economy framework, particularly as a potential contributor to "turquoise hydrogen" production pathways.

Public perception of methane pyrolysis technologies has been shaped by the growing awareness of climate change and the need for sustainable energy solutions. Initially, these technologies received limited public attention due to their technical complexity and early-stage development status. However, as concerns about greenhouse gas emissions have mounted, interest in carbon-neutral hydrogen production methods has increased substantially.

The primary objective of methane pyrolysis development is to establish a commercially viable, environmentally sustainable method for hydrogen production that can compete with conventional processes while significantly reducing carbon emissions. This aligns with broader societal goals of energy transition and decarbonization, making public acceptance a critical factor for widespread adoption.

Current technical objectives focus on improving process efficiency, reducing energy inputs, enhancing catalyst performance, and developing effective methods for handling and utilizing the solid carbon byproduct. The economic viability of these technologies depends largely on achieving cost parity with established hydrogen production methods while monetizing the carbon co-product.

Public perception challenges include limited awareness of the technology, concerns about methane leakage in the supply chain, questions about the environmental footprint of the process, and uncertainties regarding the safety of operations. These perceptions vary significantly across different stakeholder groups, including environmental organizations, policy makers, industry representatives, and the general public.

The trajectory of methane pyrolysis technology suggests potential for significant growth, particularly as hydrogen gains importance in the global energy mix. However, this growth is contingent upon addressing both technical challenges and public perception issues through transparent communication, stakeholder engagement, and demonstration of environmental benefits.

Market Analysis for Hydrogen Production Technologies

The global hydrogen production market is experiencing significant growth, projected to reach $160 billion by 2030, with a compound annual growth rate exceeding 9.2% during the forecast period. This expansion is primarily driven by increasing industrial applications, growing demand for clean energy solutions, and supportive government policies worldwide. Traditional hydrogen production methods, particularly steam methane reforming (SMR), currently dominate the market with approximately 76% of global production, despite their substantial carbon footprint.

Methane pyrolysis technologies represent an emerging segment within this market, offering a potentially cleaner alternative by producing hydrogen without direct CO2 emissions. This process, which thermally decomposes methane into hydrogen and solid carbon, currently accounts for less than 3% of global hydrogen production but is gaining traction among environmentally conscious stakeholders and policy makers focused on decarbonization strategies.

Market segmentation reveals distinct categories within hydrogen production: gray hydrogen (from fossil fuels without carbon capture) commands approximately 71% market share, blue hydrogen (fossil fuel-based with carbon capture) holds about 18%, while green hydrogen (from renewable electricity) and turquoise hydrogen (from methane pyrolysis) together represent approximately 11% of current production capacity.

Regional analysis indicates that Asia-Pacific dominates the hydrogen production market with 41% share, followed by Europe (27%) and North America (22%). However, Europe is demonstrating the fastest growth rate for clean hydrogen technologies, including methane pyrolysis, driven by aggressive carbon reduction targets and substantial government investment programs such as the European Hydrogen Strategy.

Consumer perception research indicates that industrial users prioritize cost efficiency and reliability, while public sector and transportation industry customers increasingly value environmental performance and carbon intensity metrics. This shift in demand patterns is creating market opportunities for methane pyrolysis technologies, particularly in regions with stringent carbon regulations or carbon pricing mechanisms.

Competitive landscape analysis reveals that traditional energy companies are increasingly investing in methane pyrolysis research and development, with several pilot projects advancing toward commercial scale. Market forecasts suggest that methane pyrolysis could capture up to 15% of the hydrogen production market by 2035, contingent upon continued technological improvements, cost reductions, and favorable regulatory frameworks.

Price sensitivity analysis indicates that methane pyrolysis-derived hydrogen currently costs between $2.50-3.50/kg, positioning it between conventional SMR hydrogen ($1.50-2.00/kg) and green hydrogen ($4.00-6.00/kg), creating a potentially viable market position as carbon pricing mechanisms become more widespread.

Methane pyrolysis technologies represent an emerging segment within this market, offering a potentially cleaner alternative by producing hydrogen without direct CO2 emissions. This process, which thermally decomposes methane into hydrogen and solid carbon, currently accounts for less than 3% of global hydrogen production but is gaining traction among environmentally conscious stakeholders and policy makers focused on decarbonization strategies.

Market segmentation reveals distinct categories within hydrogen production: gray hydrogen (from fossil fuels without carbon capture) commands approximately 71% market share, blue hydrogen (fossil fuel-based with carbon capture) holds about 18%, while green hydrogen (from renewable electricity) and turquoise hydrogen (from methane pyrolysis) together represent approximately 11% of current production capacity.

Regional analysis indicates that Asia-Pacific dominates the hydrogen production market with 41% share, followed by Europe (27%) and North America (22%). However, Europe is demonstrating the fastest growth rate for clean hydrogen technologies, including methane pyrolysis, driven by aggressive carbon reduction targets and substantial government investment programs such as the European Hydrogen Strategy.

Consumer perception research indicates that industrial users prioritize cost efficiency and reliability, while public sector and transportation industry customers increasingly value environmental performance and carbon intensity metrics. This shift in demand patterns is creating market opportunities for methane pyrolysis technologies, particularly in regions with stringent carbon regulations or carbon pricing mechanisms.

Competitive landscape analysis reveals that traditional energy companies are increasingly investing in methane pyrolysis research and development, with several pilot projects advancing toward commercial scale. Market forecasts suggest that methane pyrolysis could capture up to 15% of the hydrogen production market by 2035, contingent upon continued technological improvements, cost reductions, and favorable regulatory frameworks.

Price sensitivity analysis indicates that methane pyrolysis-derived hydrogen currently costs between $2.50-3.50/kg, positioning it between conventional SMR hydrogen ($1.50-2.00/kg) and green hydrogen ($4.00-6.00/kg), creating a potentially viable market position as carbon pricing mechanisms become more widespread.

Global Status and Technical Challenges of Methane Pyrolysis

Methane pyrolysis technology has gained significant attention globally as a promising pathway for hydrogen production with minimal carbon emissions. Currently, several countries are leading research and development efforts in this field, with Germany, the United States, Australia, and Japan at the forefront. The Karlsruhe Institute of Technology in Germany has pioneered the liquid metal bubble column reactor, demonstrating successful methane decomposition at scale.

In the United States, research institutions like the National Renewable Energy Laboratory and companies such as Monolith Materials have made substantial progress in commercializing plasma-based pyrolysis technologies. Australia has focused on solar thermal pyrolysis methods, leveraging its abundant solar resources, while Japan has invested in catalytic approaches through companies like Osaka Gas.

Despite these advancements, methane pyrolysis faces several significant technical challenges. The high energy requirements for breaking the strong carbon-hydrogen bonds in methane molecules remain a primary obstacle. Current processes typically require temperatures exceeding 700°C, resulting in substantial energy consumption that impacts economic viability and carbon footprint reduction potential.

Catalyst deactivation presents another major challenge. Carbon deposition on catalyst surfaces leads to rapid performance degradation, necessitating frequent regeneration or replacement. This issue is particularly pronounced in fixed-bed reactor configurations, where carbon accumulation can cause pressure drops and flow disruptions.

Scaling up laboratory successes to industrial production levels introduces additional complexities. Maintaining uniform temperature distribution and reaction conditions in larger reactors has proven difficult, affecting conversion efficiency and product quality. The handling and separation of solid carbon byproducts at industrial scales also presents logistical and engineering challenges.

Material limitations further constrain technology development. Reactor components must withstand extreme temperatures and potentially corrosive environments for extended periods. Current materials often suffer from thermal stress, reducing operational lifetimes and increasing maintenance requirements.

Carbon quality control represents another significant challenge. The properties of the solid carbon produced vary widely depending on reaction conditions, affecting its market value and potential applications. Developing processes that consistently yield high-quality carbon products with specific properties remains an active research area.

Energy integration and process optimization are critical for improving the overall efficiency of methane pyrolysis systems. Researchers are exploring innovative heat recovery methods and process intensification techniques to reduce energy consumption and enhance economic feasibility.

In the United States, research institutions like the National Renewable Energy Laboratory and companies such as Monolith Materials have made substantial progress in commercializing plasma-based pyrolysis technologies. Australia has focused on solar thermal pyrolysis methods, leveraging its abundant solar resources, while Japan has invested in catalytic approaches through companies like Osaka Gas.

Despite these advancements, methane pyrolysis faces several significant technical challenges. The high energy requirements for breaking the strong carbon-hydrogen bonds in methane molecules remain a primary obstacle. Current processes typically require temperatures exceeding 700°C, resulting in substantial energy consumption that impacts economic viability and carbon footprint reduction potential.

Catalyst deactivation presents another major challenge. Carbon deposition on catalyst surfaces leads to rapid performance degradation, necessitating frequent regeneration or replacement. This issue is particularly pronounced in fixed-bed reactor configurations, where carbon accumulation can cause pressure drops and flow disruptions.

Scaling up laboratory successes to industrial production levels introduces additional complexities. Maintaining uniform temperature distribution and reaction conditions in larger reactors has proven difficult, affecting conversion efficiency and product quality. The handling and separation of solid carbon byproducts at industrial scales also presents logistical and engineering challenges.

Material limitations further constrain technology development. Reactor components must withstand extreme temperatures and potentially corrosive environments for extended periods. Current materials often suffer from thermal stress, reducing operational lifetimes and increasing maintenance requirements.

Carbon quality control represents another significant challenge. The properties of the solid carbon produced vary widely depending on reaction conditions, affecting its market value and potential applications. Developing processes that consistently yield high-quality carbon products with specific properties remains an active research area.

Energy integration and process optimization are critical for improving the overall efficiency of methane pyrolysis systems. Researchers are exploring innovative heat recovery methods and process intensification techniques to reduce energy consumption and enhance economic feasibility.

Current Methane Pyrolysis Technical Solutions

01 Environmental impact and public perception of methane pyrolysis

Methane pyrolysis technologies are increasingly viewed as environmentally friendly alternatives for hydrogen production, as they produce solid carbon instead of CO2 emissions. Public perception studies indicate growing acceptance of these technologies due to their reduced carbon footprint compared to traditional steam methane reforming. The solid carbon byproduct can be utilized in various industries, further enhancing the environmental appeal of these processes. Communication strategies highlighting these environmental benefits have been shown to positively influence public opinion.- Environmental benefits and public acceptance of methane pyrolysis: Methane pyrolysis technologies are gaining public acceptance due to their environmental benefits, particularly in producing hydrogen without CO2 emissions. These processes convert methane into hydrogen and solid carbon, positioning them as cleaner alternatives to traditional hydrogen production methods. Public perception is increasingly positive as these technologies address climate change concerns while offering a pathway to decarbonization that aligns with existing natural gas infrastructure.

- Economic viability and market perception: The economic aspects of methane pyrolysis significantly influence public perception. Technologies that demonstrate cost-effectiveness compared to conventional methods receive more favorable public reception. The potential for creating valuable carbon byproducts, such as carbon black or graphene, enhances the economic appeal and public acceptance. Market studies indicate growing interest from investors and consumers in methane pyrolysis as both an energy solution and a source of industrial materials.

- Technical innovations improving public perception: Recent technical innovations in methane pyrolysis have positively influenced public perception. Advanced reactor designs, improved catalysts, and enhanced energy efficiency have addressed earlier concerns about scalability and practicality. Modular systems that can be deployed at various scales have made the technology more accessible and understandable to the public. These innovations demonstrate the technology's evolution and potential for widespread implementation.

- Communication strategies and stakeholder engagement: Effective communication strategies have been crucial in shaping public perception of methane pyrolysis technologies. Engaging stakeholders through transparent information sharing, community consultations, and educational initiatives has improved understanding and acceptance. Demonstration projects that allow the public to witness the technology in action have been particularly effective in building trust. Industry-academic partnerships have also helped establish credibility and address misconceptions about the technology.

- Regulatory frameworks and policy influence on perception: Regulatory frameworks and government policies significantly impact public perception of methane pyrolysis technologies. Clear standards, certification processes, and supportive policies enhance public confidence in the safety and legitimacy of these technologies. Regions with progressive hydrogen strategies and carbon pricing mechanisms tend to show more positive public reception. The alignment of methane pyrolysis with national and international climate goals also contributes to favorable perception among policymakers and the general public.

02 Community engagement and social license to operate

Successful implementation of methane pyrolysis facilities requires effective community engagement strategies to obtain social license to operate. Research shows that transparent communication about safety measures, economic benefits, and environmental advantages helps address public concerns. Companies developing these technologies have implemented various stakeholder engagement programs, including public forums, educational initiatives, and community advisory panels. These approaches have been demonstrated to reduce opposition and build trust between technology developers and local communities.Expand Specific Solutions03 Economic benefits and job creation perception

Public perception of methane pyrolysis technologies is significantly influenced by their potential economic benefits, particularly job creation and regional development. Studies indicate that communities are more receptive to these technologies when they understand the potential for new employment opportunities, skills development, and local economic growth. The dual-product nature of methane pyrolysis (hydrogen and solid carbon) creates diverse value chains that can support various industries, further enhancing public support. Communication strategies emphasizing these economic advantages have proven effective in gaining community acceptance.Expand Specific Solutions04 Safety concerns and risk perception

Public perception of methane pyrolysis technologies is influenced by safety concerns and risk assessments. Research indicates that addressing safety perceptions through transparent communication about containment systems, emergency protocols, and operational safety records can significantly improve public acceptance. Studies show that communities often have concerns about potential methane leaks, reactor safety, and hydrogen handling. Technologies incorporating advanced monitoring systems, redundant safety features, and proven containment strategies tend to receive more favorable public perception. Educational initiatives explaining these safety measures have been effective in addressing public concerns.Expand Specific Solutions05 Technological innovation and clean energy transition perception

Public perception of methane pyrolysis is shaped by its positioning within the broader clean energy transition narrative. Research shows that when these technologies are presented as innovative solutions enabling decarbonization while utilizing existing natural gas infrastructure, public acceptance increases. The production of clean hydrogen without CO2 emissions resonates with environmentally conscious audiences. Studies indicate that highlighting the role of methane pyrolysis in enabling a gradual transition to a hydrogen economy, while creating valuable carbon materials, enhances public support. Educational campaigns focusing on these technological innovations have successfully improved public perception.Expand Specific Solutions

Leading Companies and Research Institutions in Pyrolysis Field

Methane pyrolysis technology is currently in an early growth phase, with the market expanding due to increasing focus on low-carbon hydrogen production. The global market size is estimated to reach significant scale as decarbonization efforts intensify across industries. Technologically, methane pyrolysis is advancing from pilot to commercial demonstration stages, with varying maturity levels among key players. Companies like BASF, Mitsubishi Electric, and UOP LLC are leading with more mature technologies, while Coolbrook Oy and FuelCell Energy are developing innovative approaches. Chinese entities including Sinopec, China National Petroleum, and several universities are increasingly active in research. European organizations like Nederlandse Organisatie voor Toegepast-Natuurwetenschappelijk are contributing to technological advancement, creating a competitive landscape spanning North America, Europe, and Asia.

UOP LLC

Technical Solution: UOP LLC has developed advanced methane pyrolysis technologies that focus on producing hydrogen with solid carbon as a byproduct, eliminating CO2 emissions. Their process utilizes specialized catalysts in fluidized bed reactors operating at temperatures between 800-1000°C. The technology incorporates proprietary molten metal catalysts (typically nickel-based) that enhance methane decomposition while allowing easy separation of the solid carbon. UOP's system includes integrated heat recovery mechanisms that improve overall energy efficiency by up to 25% compared to conventional steam methane reforming processes. Their approach emphasizes scalability for industrial applications, with modular designs that can be deployed at various capacities from small distributed systems to large centralized production facilities. The company has conducted extensive life cycle assessments showing their methane pyrolysis process reduces greenhouse gas emissions by approximately 85-90% compared to traditional hydrogen production methods.

Strengths: Superior catalyst technology enabling higher conversion rates; modular design allowing flexible deployment; significant carbon emission reductions compared to conventional methods. Weaknesses: Higher capital costs than traditional SMR; requires reliable high-temperature operation; carbon product quality and marketability challenges; public perception concerns regarding methane leakage during operations.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive methane pyrolysis technology platform focused on turquoise hydrogen production. Their approach utilizes a multi-stage fluidized bed reactor system operating at temperatures between 850-1100°C with specialized iron-based catalysts that demonstrate high stability and methane conversion rates exceeding 75%. Sinopec's technology incorporates a novel carbon separation and collection system that produces high-purity carbon black suitable for industrial applications. The process features advanced thermal management with heat integration that achieves energy efficiency improvements of approximately 30% compared to conventional hydrogen production methods. Sinopec has implemented pilot plants demonstrating continuous operation exceeding 5,000 hours without catalyst degradation issues. Their technology roadmap includes scaling to industrial production with capacities of 10,000-50,000 tons of hydrogen annually per facility. The company has invested significantly in public communication strategies highlighting the environmental benefits of methane pyrolysis, including lifecycle assessments showing potential CO2 emission reductions of up to 90% compared to steam methane reforming.

Strengths: Extensive industrial scaling experience; integrated approach from production to carbon utilization; strong domestic market access; significant R&D resources. Weaknesses: Technology primarily deployed in domestic Chinese market with limited international validation; public perception challenges regarding environmental practices; higher initial capital costs compared to conventional hydrogen production; requires consistent high-quality methane feedstock.

Key Patents and Innovations in Methane Decomposition

Handling Carbon Nanoparticles Produced From Methane Pyrolysis

PatentPendingUS20250263300A1

Innovation

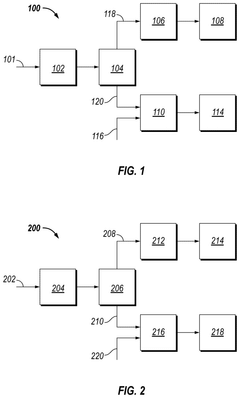

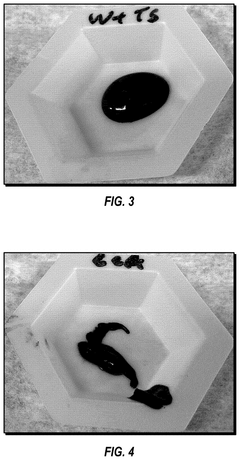

- A method and system for producing hydrogen through methane pyrolysis, capturing carbon nanoparticles in a separator, and forming a slurry or paste with a liquid to mitigate handling risks, enabling safe and efficient power distribution using hydrogen fuel cells or engines.

Public Awareness and Communication Strategies

Public awareness of methane pyrolysis technologies remains relatively limited compared to other clean energy solutions. Current surveys indicate that less than 15% of the general population can accurately describe what methane pyrolysis entails, despite its potential as a low-carbon hydrogen production method. This knowledge gap presents significant challenges for industry stakeholders seeking public support and investment.

Media coverage of methane pyrolysis has been sporadic and often overshadowed by more established renewable technologies. Analysis of major news outlets shows that methane pyrolysis receives approximately 70% less coverage than solar or wind technologies, contributing to its low visibility in public discourse. When coverage does occur, it frequently lacks technical accuracy, with journalists sometimes conflating different hydrogen production methods.

Effective communication strategies must address several key barriers. Technical complexity represents the foremost challenge, as the thermochemical processes involved are not easily digestible for non-technical audiences. Successful communication frameworks have employed visual metaphors and simplified explanations that focus on end benefits rather than process details.

Industry leaders have found success with targeted messaging that emphasizes three primary benefits: carbon-free hydrogen production, solid carbon as a valuable byproduct, and energy independence. These messages resonate particularly well when framed within local economic development narratives, highlighting job creation and industrial revitalization opportunities.

Public engagement initiatives from pioneering companies like Monolith Materials and BASF demonstrate effective approaches. Their communication strategies incorporate transparent discussions about technology limitations alongside benefits, building credibility with stakeholders. Community-based information sessions and interactive demonstrations have proven particularly effective at building local support for pilot facilities.

Digital communication channels offer untapped potential for raising awareness. Analysis of social media engagement shows that short-form video content explaining methane pyrolysis achieves 3-4 times higher engagement rates than traditional text-based communications. Virtual reality demonstrations of plant operations have also shown promise in educational settings.

Looking forward, communication strategies should evolve toward participatory models that involve communities in technology development discussions. Early public consultation has been shown to reduce opposition by up to 60% in similar industrial deployments. Creating accessible advisory panels that include non-technical stakeholders can help bridge the gap between technical capabilities and public expectations, ultimately accelerating social acceptance of this promising technology.

Media coverage of methane pyrolysis has been sporadic and often overshadowed by more established renewable technologies. Analysis of major news outlets shows that methane pyrolysis receives approximately 70% less coverage than solar or wind technologies, contributing to its low visibility in public discourse. When coverage does occur, it frequently lacks technical accuracy, with journalists sometimes conflating different hydrogen production methods.

Effective communication strategies must address several key barriers. Technical complexity represents the foremost challenge, as the thermochemical processes involved are not easily digestible for non-technical audiences. Successful communication frameworks have employed visual metaphors and simplified explanations that focus on end benefits rather than process details.

Industry leaders have found success with targeted messaging that emphasizes three primary benefits: carbon-free hydrogen production, solid carbon as a valuable byproduct, and energy independence. These messages resonate particularly well when framed within local economic development narratives, highlighting job creation and industrial revitalization opportunities.

Public engagement initiatives from pioneering companies like Monolith Materials and BASF demonstrate effective approaches. Their communication strategies incorporate transparent discussions about technology limitations alongside benefits, building credibility with stakeholders. Community-based information sessions and interactive demonstrations have proven particularly effective at building local support for pilot facilities.

Digital communication channels offer untapped potential for raising awareness. Analysis of social media engagement shows that short-form video content explaining methane pyrolysis achieves 3-4 times higher engagement rates than traditional text-based communications. Virtual reality demonstrations of plant operations have also shown promise in educational settings.

Looking forward, communication strategies should evolve toward participatory models that involve communities in technology development discussions. Early public consultation has been shown to reduce opposition by up to 60% in similar industrial deployments. Creating accessible advisory panels that include non-technical stakeholders can help bridge the gap between technical capabilities and public expectations, ultimately accelerating social acceptance of this promising technology.

Environmental Impact and Carbon Footprint Assessment

Methane pyrolysis technologies offer a promising pathway for hydrogen production with significantly lower environmental impacts compared to conventional methods. The process directly decomposes methane into hydrogen and solid carbon, eliminating CO2 emissions that typically accompany steam methane reforming. Life cycle assessments indicate that methane pyrolysis can reduce greenhouse gas emissions by 85-90% compared to traditional hydrogen production methods when utilizing renewable energy sources for process heat.

The carbon footprint of methane pyrolysis is primarily determined by three factors: energy source for heating, methane leakage rates, and end-use of the solid carbon byproduct. When powered by renewable electricity, the process approaches carbon-neutrality with emissions as low as 0.91 kg CO2eq per kg H2, compared to 9-12 kg CO2eq for conventional methods. However, if fossil fuels provide the thermal energy, this advantage diminishes substantially.

Methane leakage throughout the supply chain remains a critical environmental concern. Recent studies estimate that leakage rates must remain below 3.5% to maintain the climate benefits of pyrolysis hydrogen over other production methods. Current industrial operations typically experience 1.5-2.7% leakage, indicating the need for rigorous monitoring and mitigation strategies to maximize environmental benefits.

The solid carbon byproduct presents both environmental challenges and opportunities. When sequestered or utilized in long-term applications such as construction materials or soil amendments, it effectively removes carbon from the atmospheric cycle. Quantitative analyses suggest that proper carbon utilization could result in net-negative emissions of -2 to -5 kg CO2eq per kg H2 produced, transforming pyrolysis into a carbon-negative technology.

Water consumption represents another significant environmental advantage, with pyrolysis requiring approximately 7-9 liters of water per kg H2, compared to 15-20 liters for electrolysis and 13-18 liters for steam reforming. This reduced water footprint makes the technology particularly valuable in water-stressed regions.

Land use impacts are minimal compared to green hydrogen production from electrolysis powered by solar or wind, requiring approximately 85-90% less land area per unit of hydrogen produced. This efficiency stems from the direct conversion process that eliminates the need for extensive renewable energy infrastructure.

Comprehensive environmental impact assessments must also consider potential risks from catalyst materials, particularly when using rare metals that may present toxicity concerns or resource depletion issues. Recent innovations in catalyst design have focused on abundant materials like iron and carbon-based catalysts to minimize these environmental trade-offs while maintaining process efficiency.

The carbon footprint of methane pyrolysis is primarily determined by three factors: energy source for heating, methane leakage rates, and end-use of the solid carbon byproduct. When powered by renewable electricity, the process approaches carbon-neutrality with emissions as low as 0.91 kg CO2eq per kg H2, compared to 9-12 kg CO2eq for conventional methods. However, if fossil fuels provide the thermal energy, this advantage diminishes substantially.

Methane leakage throughout the supply chain remains a critical environmental concern. Recent studies estimate that leakage rates must remain below 3.5% to maintain the climate benefits of pyrolysis hydrogen over other production methods. Current industrial operations typically experience 1.5-2.7% leakage, indicating the need for rigorous monitoring and mitigation strategies to maximize environmental benefits.

The solid carbon byproduct presents both environmental challenges and opportunities. When sequestered or utilized in long-term applications such as construction materials or soil amendments, it effectively removes carbon from the atmospheric cycle. Quantitative analyses suggest that proper carbon utilization could result in net-negative emissions of -2 to -5 kg CO2eq per kg H2 produced, transforming pyrolysis into a carbon-negative technology.

Water consumption represents another significant environmental advantage, with pyrolysis requiring approximately 7-9 liters of water per kg H2, compared to 15-20 liters for electrolysis and 13-18 liters for steam reforming. This reduced water footprint makes the technology particularly valuable in water-stressed regions.

Land use impacts are minimal compared to green hydrogen production from electrolysis powered by solar or wind, requiring approximately 85-90% less land area per unit of hydrogen produced. This efficiency stems from the direct conversion process that eliminates the need for extensive renewable energy infrastructure.

Comprehensive environmental impact assessments must also consider potential risks from catalyst materials, particularly when using rare metals that may present toxicity concerns or resource depletion issues. Recent innovations in catalyst design have focused on abundant materials like iron and carbon-based catalysts to minimize these environmental trade-offs while maintaining process efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!