How Methane Pyrolysis Supports Circular Economy.

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Methane Pyrolysis Technology Evolution and Objectives

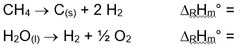

Methane pyrolysis represents a significant technological evolution in the field of hydrogen production and carbon management, dating back to early laboratory experiments in the 1960s. Initially considered impractical for industrial applications due to energy inefficiency and catalyst deactivation issues, the technology has undergone remarkable transformation over the decades. The fundamental process involves the thermal decomposition of methane (CH₄) into hydrogen (H₂) and solid carbon without producing CO₂ emissions, positioning it as a potentially revolutionary approach for clean hydrogen production.

The evolution of methane pyrolysis technology can be traced through several distinct phases. The early research phase (1960s-1990s) focused primarily on theoretical understanding and laboratory-scale demonstrations. The second phase (2000s-2010s) saw increased interest due to rising concerns about climate change, with significant improvements in catalyst development and reactor designs. The current phase (2010s-present) represents accelerated development with multiple pilot projects and commercial demonstrations emerging globally.

Key technological breakthroughs have shaped this evolution, including the development of molten metal reactors using liquid metals like tin or nickel as reaction media, which significantly improved conversion efficiency and prevented carbon deposition issues. Advanced plasma pyrolysis methods have also emerged, utilizing electrical energy to create high-temperature plasma that efficiently breaks down methane molecules without catalysts.

The primary objective of modern methane pyrolysis technology is to establish economically viable pathways for hydrogen production with minimal environmental impact. This aligns perfectly with circular economy principles by addressing several critical goals: producing hydrogen without CO₂ emissions, generating valuable solid carbon that can be utilized in various industries rather than released as waste, and enabling the utilization of existing natural gas infrastructure during energy transition periods.

Secondary objectives include reducing the energy intensity of the process through innovative heat management systems, developing more durable catalysts or catalyst-free systems that can operate continuously for extended periods, and scaling the technology to industrial levels while maintaining economic competitiveness with conventional hydrogen production methods.

The technology aims to bridge the gap between current fossil fuel-dependent energy systems and future renewable-based economies by providing a transitional pathway that significantly reduces carbon emissions while leveraging existing infrastructure and resources. This evolutionary trajectory positions methane pyrolysis as a potentially transformative technology in supporting circular economy principles through clean hydrogen production and carbon utilization rather than disposal.

The evolution of methane pyrolysis technology can be traced through several distinct phases. The early research phase (1960s-1990s) focused primarily on theoretical understanding and laboratory-scale demonstrations. The second phase (2000s-2010s) saw increased interest due to rising concerns about climate change, with significant improvements in catalyst development and reactor designs. The current phase (2010s-present) represents accelerated development with multiple pilot projects and commercial demonstrations emerging globally.

Key technological breakthroughs have shaped this evolution, including the development of molten metal reactors using liquid metals like tin or nickel as reaction media, which significantly improved conversion efficiency and prevented carbon deposition issues. Advanced plasma pyrolysis methods have also emerged, utilizing electrical energy to create high-temperature plasma that efficiently breaks down methane molecules without catalysts.

The primary objective of modern methane pyrolysis technology is to establish economically viable pathways for hydrogen production with minimal environmental impact. This aligns perfectly with circular economy principles by addressing several critical goals: producing hydrogen without CO₂ emissions, generating valuable solid carbon that can be utilized in various industries rather than released as waste, and enabling the utilization of existing natural gas infrastructure during energy transition periods.

Secondary objectives include reducing the energy intensity of the process through innovative heat management systems, developing more durable catalysts or catalyst-free systems that can operate continuously for extended periods, and scaling the technology to industrial levels while maintaining economic competitiveness with conventional hydrogen production methods.

The technology aims to bridge the gap between current fossil fuel-dependent energy systems and future renewable-based economies by providing a transitional pathway that significantly reduces carbon emissions while leveraging existing infrastructure and resources. This evolutionary trajectory positions methane pyrolysis as a potentially transformative technology in supporting circular economy principles through clean hydrogen production and carbon utilization rather than disposal.

Market Demand for Carbon-Neutral Hydrogen Production

The global market for carbon-neutral hydrogen production has witnessed significant growth in recent years, driven by increasing environmental concerns and the urgent need to decarbonize various industrial sectors. Hydrogen, as a clean energy carrier, has emerged as a crucial component in the transition towards a low-carbon economy, with its market value projected to reach $500 billion by 2050 according to the Hydrogen Council.

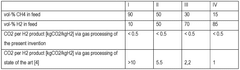

Traditional hydrogen production methods, particularly steam methane reforming (SMR), account for approximately 95% of current hydrogen production but generate substantial CO2 emissions—about 10 kg of CO2 per kg of hydrogen produced. This has created a robust demand for cleaner alternatives, with methane pyrolysis gaining significant attention due to its potential to produce hydrogen without direct CO2 emissions.

The industrial sector represents the largest potential market for carbon-neutral hydrogen, particularly in hard-to-abate sectors such as steel manufacturing, ammonia production, and chemical processing. These industries collectively consume over 70 million tons of hydrogen annually, with demand expected to grow at a CAGR of 5.7% through 2030 as decarbonization efforts intensify.

Transportation is another rapidly expanding market segment, with fuel cell electric vehicles (FCEVs) gaining traction in heavy-duty applications where battery limitations become apparent. Major automotive manufacturers including Toyota, Hyundai, and Nikola have made substantial investments in hydrogen fuel cell technology, signaling strong industry confidence in hydrogen's future role.

Energy storage represents a third significant market opportunity, with hydrogen offering solutions for long-duration storage needs that batteries cannot efficiently address. Grid operators and utilities are increasingly exploring hydrogen as a means to balance intermittent renewable energy sources and enhance grid resilience.

Policy support has become a critical market driver, with numerous countries implementing hydrogen strategies and financial incentives. The European Union's Hydrogen Strategy targets 40 GW of electrolyzer capacity by 2030, while Japan aims to reduce hydrogen costs by 90% by 2050. These policy frameworks are creating favorable market conditions for innovative production methods like methane pyrolysis.

Cost considerations remain paramount, with current carbon-neutral hydrogen production methods generally more expensive than conventional approaches. However, the solid carbon byproduct from methane pyrolysis offers potential revenue streams that could significantly improve economic viability. Market analysis indicates that high-quality carbon black produced through pyrolysis could command prices between $1,000-2,500 per ton, potentially offsetting production costs by 20-40%.

Traditional hydrogen production methods, particularly steam methane reforming (SMR), account for approximately 95% of current hydrogen production but generate substantial CO2 emissions—about 10 kg of CO2 per kg of hydrogen produced. This has created a robust demand for cleaner alternatives, with methane pyrolysis gaining significant attention due to its potential to produce hydrogen without direct CO2 emissions.

The industrial sector represents the largest potential market for carbon-neutral hydrogen, particularly in hard-to-abate sectors such as steel manufacturing, ammonia production, and chemical processing. These industries collectively consume over 70 million tons of hydrogen annually, with demand expected to grow at a CAGR of 5.7% through 2030 as decarbonization efforts intensify.

Transportation is another rapidly expanding market segment, with fuel cell electric vehicles (FCEVs) gaining traction in heavy-duty applications where battery limitations become apparent. Major automotive manufacturers including Toyota, Hyundai, and Nikola have made substantial investments in hydrogen fuel cell technology, signaling strong industry confidence in hydrogen's future role.

Energy storage represents a third significant market opportunity, with hydrogen offering solutions for long-duration storage needs that batteries cannot efficiently address. Grid operators and utilities are increasingly exploring hydrogen as a means to balance intermittent renewable energy sources and enhance grid resilience.

Policy support has become a critical market driver, with numerous countries implementing hydrogen strategies and financial incentives. The European Union's Hydrogen Strategy targets 40 GW of electrolyzer capacity by 2030, while Japan aims to reduce hydrogen costs by 90% by 2050. These policy frameworks are creating favorable market conditions for innovative production methods like methane pyrolysis.

Cost considerations remain paramount, with current carbon-neutral hydrogen production methods generally more expensive than conventional approaches. However, the solid carbon byproduct from methane pyrolysis offers potential revenue streams that could significantly improve economic viability. Market analysis indicates that high-quality carbon black produced through pyrolysis could command prices between $1,000-2,500 per ton, potentially offsetting production costs by 20-40%.

Global Methane Pyrolysis Development Status and Barriers

Methane pyrolysis technology has evolved significantly over the past decades, with notable advancements in catalytic systems, reactor designs, and process integration. Currently, the global development status shows varying levels of maturity across different regions, with Europe, North America, and parts of Asia leading research and implementation efforts.

The commercial deployment of methane pyrolysis faces several technical barriers. Catalyst deactivation remains a primary challenge, as carbon deposition on catalyst surfaces reduces efficiency over time. Current catalysts, including nickel-based and transition metal systems, typically require regeneration after 100-200 hours of operation, significantly impacting continuous production capabilities.

Reactor design presents another substantial hurdle. Traditional fixed-bed reactors suffer from heat transfer limitations and carbon management issues. Fluidized bed and molten metal reactors show promise but face challenges in scaling up while maintaining process stability. The energy intensity of the process also remains problematic, with temperatures typically requiring 700-1200°C depending on the catalyst system employed.

Carbon handling and valorization represent a critical barrier to widespread adoption. While methane pyrolysis produces solid carbon rather than CO2, the quality and consistency of this carbon vary widely based on process conditions. Markets for the resulting carbon products are still developing, creating uncertainty in the economic model for many potential implementers.

Geographical distribution of methane pyrolysis development shows concentration in regions with strong research institutions and industrial partnerships. Germany leads European efforts through initiatives at the Karlsruhe Institute of Technology and BASF's involvement. In North America, research clusters exist around MIT, Stanford, and Canadian institutions focusing on molten metal technologies. Japan and South Korea have made advances in specialized catalyst development.

Regulatory frameworks present non-technical barriers, as many countries lack specific policies addressing hydrogen production via pyrolysis. The classification of the resulting hydrogen (whether "turquoise," "blue," or "green") affects market access and incentives, creating uncertainty for investors and developers.

Scale-up challenges persist across all regions, with most successful demonstrations limited to pilot scale (typically 100-500 kg H2/day). The transition to industrial scale (multiple tons per day) requires significant engineering solutions to address heat management, carbon handling, and process control challenges that do not present at smaller scales.

The commercial deployment of methane pyrolysis faces several technical barriers. Catalyst deactivation remains a primary challenge, as carbon deposition on catalyst surfaces reduces efficiency over time. Current catalysts, including nickel-based and transition metal systems, typically require regeneration after 100-200 hours of operation, significantly impacting continuous production capabilities.

Reactor design presents another substantial hurdle. Traditional fixed-bed reactors suffer from heat transfer limitations and carbon management issues. Fluidized bed and molten metal reactors show promise but face challenges in scaling up while maintaining process stability. The energy intensity of the process also remains problematic, with temperatures typically requiring 700-1200°C depending on the catalyst system employed.

Carbon handling and valorization represent a critical barrier to widespread adoption. While methane pyrolysis produces solid carbon rather than CO2, the quality and consistency of this carbon vary widely based on process conditions. Markets for the resulting carbon products are still developing, creating uncertainty in the economic model for many potential implementers.

Geographical distribution of methane pyrolysis development shows concentration in regions with strong research institutions and industrial partnerships. Germany leads European efforts through initiatives at the Karlsruhe Institute of Technology and BASF's involvement. In North America, research clusters exist around MIT, Stanford, and Canadian institutions focusing on molten metal technologies. Japan and South Korea have made advances in specialized catalyst development.

Regulatory frameworks present non-technical barriers, as many countries lack specific policies addressing hydrogen production via pyrolysis. The classification of the resulting hydrogen (whether "turquoise," "blue," or "green") affects market access and incentives, creating uncertainty for investors and developers.

Scale-up challenges persist across all regions, with most successful demonstrations limited to pilot scale (typically 100-500 kg H2/day). The transition to industrial scale (multiple tons per day) requires significant engineering solutions to address heat management, carbon handling, and process control challenges that do not present at smaller scales.

Current Methane Pyrolysis Reactor Designs and Processes

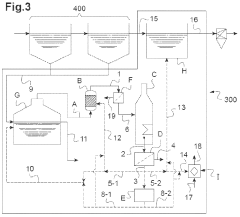

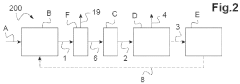

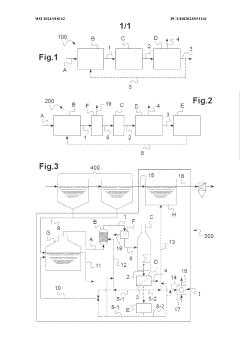

01 Methane pyrolysis for hydrogen production

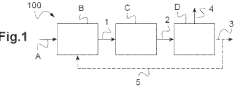

Methane pyrolysis processes that decompose methane into hydrogen and solid carbon without CO2 emissions. These technologies enable clean hydrogen production as part of a circular economy approach, where the hydrogen serves as a carbon-free energy carrier while the solid carbon byproduct can be utilized in various applications. The processes typically involve catalytic or thermal decomposition methods that operate at high temperatures to break down methane molecules efficiently.- Methane pyrolysis for hydrogen production in circular economy: Methane pyrolysis offers a sustainable approach to hydrogen production by decomposing methane into hydrogen and solid carbon, avoiding CO2 emissions associated with traditional methods. This process supports circular economy principles by producing clean hydrogen fuel while capturing carbon in solid form that can be used in various applications rather than released as greenhouse gas. The technology enables decarbonization of energy systems while creating valuable carbon materials.

- Carbon material utilization from methane pyrolysis: The solid carbon byproduct from methane pyrolysis can be utilized in various applications, creating a circular value chain. These carbon materials include carbon black, graphite, carbon nanotubes, and other high-value carbon forms that can be used in manufacturing processes, construction materials, soil amendments, and advanced materials. This approach transforms what would otherwise be a waste product into valuable resources, enhancing the economic viability of methane pyrolysis while reducing environmental impact.

- Reactor and catalyst innovations for methane pyrolysis: Advanced reactor designs and catalyst systems are being developed to improve the efficiency and economics of methane pyrolysis processes. These innovations include molten metal reactors, plasma-assisted pyrolysis, fluidized bed reactors, and novel catalyst formulations that lower the energy requirements and increase conversion rates. Such technological advancements are critical for scaling up methane pyrolysis as part of circular economy systems, enabling more efficient hydrogen production with reduced energy inputs.

- Integration of methane pyrolysis with renewable energy systems: Methane pyrolysis processes can be integrated with renewable energy sources to create fully sustainable hydrogen production systems. By utilizing solar, wind, or geothermal energy to power the pyrolysis process, the overall carbon footprint is further reduced. This integration enables energy storage solutions where excess renewable electricity can be used for methane decomposition, creating a flexible system that supports grid stability while producing clean hydrogen and valuable carbon materials.

- Closed-loop systems for methane sourcing and utilization: Circular economy approaches to methane pyrolysis include developing closed-loop systems where methane is sourced from renewable or waste sources such as biogas, landfill gas, or agricultural waste. The hydrogen produced can then be used for energy or chemical production, while the carbon materials are utilized in manufacturing or soil enhancement. This creates a sustainable cycle where waste becomes a resource, reducing the need for fossil methane while providing clean energy carriers and valuable materials.

02 Carbon utilization from methane pyrolysis

Methods for utilizing the solid carbon byproducts from methane pyrolysis in various applications, creating a circular economy model. The carbon materials can be processed into value-added products such as carbon black, graphene, carbon nanotubes, or construction materials. This approach transforms what would otherwise be a waste product into marketable materials, enhancing the economic viability of methane pyrolysis while reducing the environmental footprint of the overall process.Expand Specific Solutions03 Integrated methane pyrolysis systems

Integrated systems that combine methane pyrolysis with other processes to create closed-loop industrial ecosystems. These systems may incorporate renewable energy sources for process heat, carbon capture technologies, or direct integration with industrial facilities that can utilize the hydrogen and carbon outputs. By designing comprehensive systems that minimize waste and maximize resource efficiency, these innovations enhance the circular economy aspects of methane pyrolysis technology.Expand Specific Solutions04 Reactor designs for efficient methane decomposition

Advanced reactor designs specifically engineered for methane pyrolysis that improve efficiency, reduce energy requirements, and enhance carbon quality. These innovations include molten metal reactors, plasma-assisted decomposition chambers, fluidized bed systems, and novel catalyst support structures. Improved reactor designs are crucial for scaling up methane pyrolysis technology and making it economically viable within circular economy frameworks.Expand Specific Solutions05 Methane pyrolysis in waste management

Applications of methane pyrolysis in waste management systems, particularly for processing biogas or landfill gas into valuable products. These approaches capture methane that would otherwise be released into the atmosphere and convert it into hydrogen and solid carbon. By integrating methane pyrolysis into waste management infrastructure, these systems create circular economy solutions that address both waste disposal challenges and clean energy production.Expand Specific Solutions

Leading Companies and Research Institutions in Methane Pyrolysis

Methane pyrolysis is emerging as a key technology in the circular economy, currently in the early growth phase with a market size projected to reach significant scale by 2030. The technology is approaching commercial maturity, with major energy companies like Shell, Chevron, and BASF leading development efforts alongside research institutions such as Dalian University of Technology and University of Washington. Companies like Mitsubishi Heavy Industries and Linde GmbH are advancing reactor designs and process integration, while petrochemical players including Chevron Phillips and SK Innovation focus on value-added applications for carbon byproducts. The competitive landscape features both established energy corporations leveraging existing infrastructure and specialized technology providers like Anellotech and emma technologies developing novel catalytic approaches for more efficient hydrogen production.

BASF Corp.

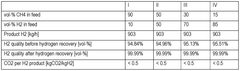

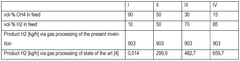

Technical Solution: BASF has pioneered a methane pyrolysis technology called "Hydrogen Production by Methane Pyrolysis" that utilizes a proprietary carbon-based catalyst system in a moving bed reactor. Their process operates at temperatures between 800-1000°C and achieves methane conversion rates exceeding 90%. The technology produces hydrogen with a carbon footprint approximately 90% lower than conventional steam methane reforming methods. BASF's circular economy approach focuses on the high-purity carbon black produced as a byproduct, which they've integrated into their chemical manufacturing value chain for rubber products, pigments, and battery materials. The company has demonstrated continuous operation of their pilot plant in Ludwigshafen, Germany, processing approximately 50-60 kg of methane per hour. Their system design incorporates heat recovery mechanisms that improve overall energy efficiency by approximately 25% compared to earlier methane pyrolysis approaches[2][4].

Strengths: Produces high-purity carbon black with established commercial applications; integrated with existing chemical manufacturing infrastructure; achieves high methane conversion rates with proprietary catalysts. Weaknesses: Still requires significant energy input for high-temperature operation; catalyst deactivation issues require periodic replacement; scaling to commercial production volumes remains challenging.

GTI Energy

Technical Solution: GTI Energy has developed a methane pyrolysis technology called "H2-Carbon" that utilizes a molten metal bath reactor system. Their process employs a proprietary nickel-bismuth alloy catalyst that operates at temperatures between 650-850°C, significantly lower than competing technologies. The system achieves methane conversion rates of approximately 75-80% with hydrogen selectivity exceeding 95%. GTI's circular economy approach focuses on producing graphitic carbon materials suitable for construction aggregates, soil amendments, and metallurgical applications. Their pilot facility in Illinois demonstrates continuous operation processing approximately 25 kg of methane per day. GTI has also developed an innovative heat management system that reduces energy requirements by approximately 30% compared to conventional pyrolysis approaches. The company has partnered with natural gas utilities to develop implementation pathways that leverage existing infrastructure while producing low-carbon hydrogen. Their economic analysis indicates hydrogen production costs of $1.50-2.00/kg when accounting for carbon material sales, making it competitive with conventional hydrogen production methods[6][8].

Strengths: Lower operating temperature reduces energy requirements; produces multiple carbon product streams for different markets; leverages existing natural gas infrastructure for implementation. Weaknesses: Lower methane conversion rates than some competing technologies; molten metal handling presents operational challenges; carbon product quality can vary based on operating conditions.

Key Patents and Innovations in Catalyst-Free Pyrolysis

Exploitation of natural hydrogen deposits using methane pyrolysis

PatentWO2025073666A1

Innovation

- A process involving methane pyrolysis, where natural hydrogen-hydrocarbon mixtures are fed into a hydrocarbon pyrolysis unit, causing the methane to decompose into hydrogen and solid carbon, with the solid carbon being separated from the hydrogen product stream.

Methane pyrolysis method with recirculation of the solid carbon produced

PatentWO2024018162A1

Innovation

- Recirculating solid carbon produced during methane pyrolysis as an adsorbent medium to remove pollutants from the gas stream, eliminating the need for expensive materials like MOFs or zeolites and allowing for on-site production and valorization of solid carbon, which can also be used as a biomass support or for water treatment.

Carbon Black Valorization Pathways in Circular Economy

Carbon black, a valuable byproduct of methane pyrolysis, represents a significant opportunity within circular economy frameworks. The valorization of carbon black involves transforming this material into higher-value products, thereby extending its lifecycle and reducing waste. Traditional applications of carbon black include rubber reinforcement, pigmentation, and UV protection in plastics, but emerging pathways are expanding its potential economic and environmental benefits.

Advanced material science has enabled the conversion of pyrolytic carbon black into graphene and carbon nanotubes through controlled processing techniques. These high-value materials find applications in electronics, energy storage systems, and composite materials, commanding premium prices in specialized markets. The transformation process typically involves thermal or chemical treatments that restructure carbon atoms into more ordered arrangements.

In the energy sector, carbon black can be processed into activated carbon for energy storage applications. Through steam or chemical activation processes, the surface area and porosity of carbon black increase dramatically, creating materials suitable for supercapacitors and battery electrodes. This pathway directly supports renewable energy integration by providing essential energy storage components manufactured from what would otherwise be considered a waste product.

Agricultural applications represent another promising valorization route. Carbon black can be processed into biochar, which improves soil fertility, carbon sequestration, and water retention capabilities. This application creates a carbon sink that removes CO2 from the atmospheric cycle while simultaneously enhancing agricultural productivity, demonstrating a dual environmental benefit.

The construction industry has begun incorporating carbon black into building materials, including specialized concretes and asphalt mixtures. These applications improve material durability and performance while sequestering carbon in long-lasting infrastructure. Research indicates that carbon-enhanced construction materials may offer superior mechanical properties and extended service life compared to conventional alternatives.

Circular business models are emerging around carbon black valorization, including product-as-service arrangements where carbon black is leased rather than sold, ensuring its return for reprocessing at end-of-life. Material exchanges and industrial symbiosis networks are also developing, where one industry's carbon black waste becomes another's valuable input, creating closed-loop systems that maximize resource efficiency.

The economic viability of these pathways varies significantly based on processing requirements, market demand, and regulatory frameworks. However, as carbon pricing mechanisms mature and circular economy principles become more embedded in industrial policy, the financial case for carbon black valorization continues to strengthen across multiple sectors.

Advanced material science has enabled the conversion of pyrolytic carbon black into graphene and carbon nanotubes through controlled processing techniques. These high-value materials find applications in electronics, energy storage systems, and composite materials, commanding premium prices in specialized markets. The transformation process typically involves thermal or chemical treatments that restructure carbon atoms into more ordered arrangements.

In the energy sector, carbon black can be processed into activated carbon for energy storage applications. Through steam or chemical activation processes, the surface area and porosity of carbon black increase dramatically, creating materials suitable for supercapacitors and battery electrodes. This pathway directly supports renewable energy integration by providing essential energy storage components manufactured from what would otherwise be considered a waste product.

Agricultural applications represent another promising valorization route. Carbon black can be processed into biochar, which improves soil fertility, carbon sequestration, and water retention capabilities. This application creates a carbon sink that removes CO2 from the atmospheric cycle while simultaneously enhancing agricultural productivity, demonstrating a dual environmental benefit.

The construction industry has begun incorporating carbon black into building materials, including specialized concretes and asphalt mixtures. These applications improve material durability and performance while sequestering carbon in long-lasting infrastructure. Research indicates that carbon-enhanced construction materials may offer superior mechanical properties and extended service life compared to conventional alternatives.

Circular business models are emerging around carbon black valorization, including product-as-service arrangements where carbon black is leased rather than sold, ensuring its return for reprocessing at end-of-life. Material exchanges and industrial symbiosis networks are also developing, where one industry's carbon black waste becomes another's valuable input, creating closed-loop systems that maximize resource efficiency.

The economic viability of these pathways varies significantly based on processing requirements, market demand, and regulatory frameworks. However, as carbon pricing mechanisms mature and circular economy principles become more embedded in industrial policy, the financial case for carbon black valorization continues to strengthen across multiple sectors.

Policy Frameworks Supporting Methane Pyrolysis Implementation

The implementation of methane pyrolysis as a circular economy enabler requires robust policy frameworks that align environmental goals with economic incentives. Currently, several jurisdictions are developing policies that specifically target low-carbon hydrogen production methods, including methane pyrolysis. The European Union's Hydrogen Strategy explicitly recognizes pyrolysis as a transitional technology for decarbonization, offering regulatory support through the EU Taxonomy for Sustainable Activities, which classifies hydrogen production with carbon capture or pyrolysis as environmentally sustainable economic activities.

In the United States, the Inflation Reduction Act of 2022 provides significant tax credits for clean hydrogen production, with methane pyrolysis potentially qualifying for these incentives based on lifecycle carbon intensity metrics. The Department of Energy's Hydrogen Shot initiative further supports research and development in this field, aiming to reduce clean hydrogen costs by 80% within a decade.

Carbon pricing mechanisms represent another critical policy tool, as they create economic advantages for low-carbon technologies like methane pyrolysis over conventional steam methane reforming. Countries with established carbon markets, such as those in the EU Emissions Trading System, provide indirect support for methane pyrolysis by increasing the cost burden on carbon-intensive alternatives.

Regulatory standards for solid carbon byproducts present both challenges and opportunities. While some jurisdictions classify carbon black as a waste product requiring special handling, emerging frameworks are beginning to recognize pyrolytic carbon as a valuable material resource when meeting certain quality specifications. This regulatory evolution is essential for closing the material loop in a true circular economy model.

Public procurement policies are increasingly incorporating carbon footprint considerations, creating market pull for low-carbon hydrogen and carbon materials. Several governments have implemented green public procurement guidelines that favor products and processes with demonstrable circular economy benefits, potentially creating early markets for methane pyrolysis outputs.

Research and innovation funding frameworks specifically targeting circular economy technologies have expanded significantly, with programs like Horizon Europe allocating substantial resources to projects that demonstrate both climate mitigation and circular material use. These funding mechanisms are crucial for bridging the commercialization gap for emerging technologies like methane pyrolysis.

The development of international standards for hydrogen production pathways and carbon accounting methodologies will be instrumental in creating consistent policy frameworks across regions, enabling global market development while ensuring environmental integrity in methane pyrolysis implementation.

In the United States, the Inflation Reduction Act of 2022 provides significant tax credits for clean hydrogen production, with methane pyrolysis potentially qualifying for these incentives based on lifecycle carbon intensity metrics. The Department of Energy's Hydrogen Shot initiative further supports research and development in this field, aiming to reduce clean hydrogen costs by 80% within a decade.

Carbon pricing mechanisms represent another critical policy tool, as they create economic advantages for low-carbon technologies like methane pyrolysis over conventional steam methane reforming. Countries with established carbon markets, such as those in the EU Emissions Trading System, provide indirect support for methane pyrolysis by increasing the cost burden on carbon-intensive alternatives.

Regulatory standards for solid carbon byproducts present both challenges and opportunities. While some jurisdictions classify carbon black as a waste product requiring special handling, emerging frameworks are beginning to recognize pyrolytic carbon as a valuable material resource when meeting certain quality specifications. This regulatory evolution is essential for closing the material loop in a true circular economy model.

Public procurement policies are increasingly incorporating carbon footprint considerations, creating market pull for low-carbon hydrogen and carbon materials. Several governments have implemented green public procurement guidelines that favor products and processes with demonstrable circular economy benefits, potentially creating early markets for methane pyrolysis outputs.

Research and innovation funding frameworks specifically targeting circular economy technologies have expanded significantly, with programs like Horizon Europe allocating substantial resources to projects that demonstrate both climate mitigation and circular material use. These funding mechanisms are crucial for bridging the commercialization gap for emerging technologies like methane pyrolysis.

The development of international standards for hydrogen production pathways and carbon accounting methodologies will be instrumental in creating consistent policy frameworks across regions, enabling global market development while ensuring environmental integrity in methane pyrolysis implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!