Sustaining Competitive Advantage through Methane Pyrolysis.

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Methane Pyrolysis Technology Evolution and Objectives

Methane pyrolysis represents a significant technological evolution in the field of hydrogen production and carbon management. The process, which involves the thermal decomposition of methane into hydrogen and solid carbon without direct CO2 emissions, has roots dating back to the early 20th century. However, it has gained renewed attention in recent decades as environmental concerns and energy transition imperatives have intensified.

The technology's evolution can be traced through several distinct phases. Initially, methane pyrolysis was primarily a laboratory curiosity, with early experiments focusing on fundamental reaction mechanisms. The 1960s-1980s saw increased interest in the process as a potential industrial method, though economic viability remained elusive due to high energy requirements and limited applications for the carbon byproduct.

A significant shift occurred in the early 2000s when climate change concerns elevated interest in hydrogen as a clean energy carrier. This period marked the beginning of modern methane pyrolysis development, characterized by innovations in reactor design, catalyst formulations, and process integration. The 2010s witnessed accelerated development with breakthrough technologies including molten metal reactors, plasma-assisted pyrolysis, and advanced catalytic systems.

Current technological objectives for methane pyrolysis center around several key areas. Energy efficiency remains paramount, with researchers aiming to reduce the thermal energy requirements through improved heat transfer mechanisms and catalyst performance. Reactor design innovation focuses on continuous operation capabilities, scalability, and integration with existing natural gas infrastructure.

Carbon valorization represents another critical objective, as the economic viability of methane pyrolysis depends significantly on developing high-value applications for the solid carbon byproduct. This includes carbon materials for batteries, construction materials, and advanced composites.

Process intensification efforts aim to increase hydrogen yield while maintaining product purity and reducing capital costs. Additionally, integration with renewable energy sources for process heating represents a frontier objective to further reduce the carbon footprint of the technology.

The long-term technological trajectory points toward modular, distributed hydrogen production systems that can leverage existing natural gas infrastructure while providing a bridge to a fully renewable hydrogen economy. This evolution aligns with broader energy transition goals while offering a pragmatic pathway that acknowledges current infrastructure constraints.

The ultimate objective is to position methane pyrolysis as a competitive, environmentally superior alternative to conventional hydrogen production methods, particularly steam methane reforming, which currently dominates industrial hydrogen production but generates significant CO2 emissions.

The technology's evolution can be traced through several distinct phases. Initially, methane pyrolysis was primarily a laboratory curiosity, with early experiments focusing on fundamental reaction mechanisms. The 1960s-1980s saw increased interest in the process as a potential industrial method, though economic viability remained elusive due to high energy requirements and limited applications for the carbon byproduct.

A significant shift occurred in the early 2000s when climate change concerns elevated interest in hydrogen as a clean energy carrier. This period marked the beginning of modern methane pyrolysis development, characterized by innovations in reactor design, catalyst formulations, and process integration. The 2010s witnessed accelerated development with breakthrough technologies including molten metal reactors, plasma-assisted pyrolysis, and advanced catalytic systems.

Current technological objectives for methane pyrolysis center around several key areas. Energy efficiency remains paramount, with researchers aiming to reduce the thermal energy requirements through improved heat transfer mechanisms and catalyst performance. Reactor design innovation focuses on continuous operation capabilities, scalability, and integration with existing natural gas infrastructure.

Carbon valorization represents another critical objective, as the economic viability of methane pyrolysis depends significantly on developing high-value applications for the solid carbon byproduct. This includes carbon materials for batteries, construction materials, and advanced composites.

Process intensification efforts aim to increase hydrogen yield while maintaining product purity and reducing capital costs. Additionally, integration with renewable energy sources for process heating represents a frontier objective to further reduce the carbon footprint of the technology.

The long-term technological trajectory points toward modular, distributed hydrogen production systems that can leverage existing natural gas infrastructure while providing a bridge to a fully renewable hydrogen economy. This evolution aligns with broader energy transition goals while offering a pragmatic pathway that acknowledges current infrastructure constraints.

The ultimate objective is to position methane pyrolysis as a competitive, environmentally superior alternative to conventional hydrogen production methods, particularly steam methane reforming, which currently dominates industrial hydrogen production but generates significant CO2 emissions.

Market Demand Analysis for Carbon-Neutral Hydrogen

The global hydrogen market is experiencing a significant shift towards carbon-neutral production methods, with carbon-neutral hydrogen demand projected to grow substantially over the next decade. Current estimates indicate that the global hydrogen market, valued at approximately 150 billion USD in 2022, is expected to reach 600 billion USD by 2050, with carbon-neutral hydrogen comprising an increasingly significant portion of this market.

This growth is primarily driven by intensifying global decarbonization efforts, with over 75 countries having established net-zero emissions targets. Industries traditionally reliant on fossil fuels are actively seeking cleaner alternatives, positioning hydrogen as a crucial component in the transition to a low-carbon economy. The industrial sector, particularly steel manufacturing, chemical production, and refining, represents the largest potential market for carbon-neutral hydrogen, accounting for nearly 45% of projected demand.

Transportation emerges as another significant demand driver, with hydrogen fuel cell vehicles gaining traction in heavy-duty transport, shipping, and potentially aviation. Major automotive manufacturers have announced substantial investments in hydrogen technology, with several commercial hydrogen-powered truck models already entering markets in Europe, Asia, and North America.

Energy storage applications present a growing opportunity for hydrogen utilization, addressing the intermittency challenges associated with renewable energy sources. Grid-scale hydrogen storage projects are being developed in multiple regions, with capacity expected to increase tenfold by 2030 compared to current levels.

Regional analysis reveals varying adoption patterns, with Europe leading policy support for hydrogen development through its Hydrogen Strategy, which targets 40 GW of electrolyzer capacity by 2030. Asia-Pacific, particularly Japan, South Korea, and increasingly China, demonstrates strong commitment to hydrogen infrastructure development, while North America shows growing interest driven by both federal initiatives and state-level programs.

Cost considerations remain central to market development, with carbon-neutral hydrogen currently priced between 3-8 USD/kg depending on production method and location, compared to 1-2 USD/kg for conventional hydrogen. However, production costs for green and turquoise hydrogen (from methane pyrolysis) are projected to decrease by 50-60% by 2030 due to technological improvements, economies of scale, and supportive policy frameworks.

Consumer willingness to pay premium prices for carbon-neutral products is increasing, particularly in sectors facing stringent emissions regulations. This trend is reinforced by corporate sustainability commitments, with over 300 major global companies having pledged to achieve carbon neutrality, creating substantial demand for decarbonization solutions including carbon-neutral hydrogen.

This growth is primarily driven by intensifying global decarbonization efforts, with over 75 countries having established net-zero emissions targets. Industries traditionally reliant on fossil fuels are actively seeking cleaner alternatives, positioning hydrogen as a crucial component in the transition to a low-carbon economy. The industrial sector, particularly steel manufacturing, chemical production, and refining, represents the largest potential market for carbon-neutral hydrogen, accounting for nearly 45% of projected demand.

Transportation emerges as another significant demand driver, with hydrogen fuel cell vehicles gaining traction in heavy-duty transport, shipping, and potentially aviation. Major automotive manufacturers have announced substantial investments in hydrogen technology, with several commercial hydrogen-powered truck models already entering markets in Europe, Asia, and North America.

Energy storage applications present a growing opportunity for hydrogen utilization, addressing the intermittency challenges associated with renewable energy sources. Grid-scale hydrogen storage projects are being developed in multiple regions, with capacity expected to increase tenfold by 2030 compared to current levels.

Regional analysis reveals varying adoption patterns, with Europe leading policy support for hydrogen development through its Hydrogen Strategy, which targets 40 GW of electrolyzer capacity by 2030. Asia-Pacific, particularly Japan, South Korea, and increasingly China, demonstrates strong commitment to hydrogen infrastructure development, while North America shows growing interest driven by both federal initiatives and state-level programs.

Cost considerations remain central to market development, with carbon-neutral hydrogen currently priced between 3-8 USD/kg depending on production method and location, compared to 1-2 USD/kg for conventional hydrogen. However, production costs for green and turquoise hydrogen (from methane pyrolysis) are projected to decrease by 50-60% by 2030 due to technological improvements, economies of scale, and supportive policy frameworks.

Consumer willingness to pay premium prices for carbon-neutral products is increasing, particularly in sectors facing stringent emissions regulations. This trend is reinforced by corporate sustainability commitments, with over 300 major global companies having pledged to achieve carbon neutrality, creating substantial demand for decarbonization solutions including carbon-neutral hydrogen.

Global Methane Pyrolysis Development Status and Barriers

Methane pyrolysis technology has gained significant attention globally as a promising pathway for clean hydrogen production. Currently, the global development status shows varying degrees of progress across different regions. In North America, particularly the United States, substantial research funding has been allocated to methane pyrolysis projects, with several pilot plants demonstrating technical feasibility. The European Union has positioned itself as a leader in this field, with countries like Germany and the Netherlands investing heavily in research infrastructure and industrial-scale demonstrations.

In Asia, Japan and South Korea have made notable advancements in catalyst development for methane pyrolysis, while China has focused on scaling up the technology to meet its ambitious decarbonization goals. However, the Middle East, despite being a major natural gas producer, has shown relatively limited progress in methane pyrolysis technology development, primarily focusing on conventional hydrogen production methods.

Despite these advancements, several significant barriers impede the widespread adoption of methane pyrolysis technology. Technical challenges remain paramount, particularly regarding reactor design optimization and catalyst stability. Current reactors struggle with carbon deposition issues that reduce efficiency and increase maintenance requirements. Additionally, achieving continuous operation at industrial scale remains problematic, with most successful demonstrations limited to batch processing or smaller throughputs.

Economic barriers present another major hurdle. The capital expenditure for methane pyrolysis facilities remains high compared to conventional hydrogen production methods. Without substantial carbon pricing mechanisms or incentives, the economic case for methane pyrolysis is challenging in many markets. Furthermore, the commercialization pathway requires significant investment in scaling up from laboratory to industrial implementation.

Regulatory frameworks and standards represent another critical barrier. The lack of unified global standards for turquoise hydrogen (produced via methane pyrolysis) creates market uncertainty. Additionally, carbon accounting methodologies for this process are still evolving, complicating efforts to monetize its environmental benefits.

Infrastructure limitations also constrain development. The technology requires integration with existing natural gas infrastructure while simultaneously needing new systems for solid carbon handling and storage. This dual requirement creates logistical challenges that few regions are equipped to address comprehensively.

Market acceptance remains uncertain, with potential customers requiring assurances about hydrogen purity, reliability of supply, and long-term viability of the technology before making significant commitments. These combined barriers create a complex landscape that requires coordinated efforts across technical innovation, policy development, and market creation to overcome.

In Asia, Japan and South Korea have made notable advancements in catalyst development for methane pyrolysis, while China has focused on scaling up the technology to meet its ambitious decarbonization goals. However, the Middle East, despite being a major natural gas producer, has shown relatively limited progress in methane pyrolysis technology development, primarily focusing on conventional hydrogen production methods.

Despite these advancements, several significant barriers impede the widespread adoption of methane pyrolysis technology. Technical challenges remain paramount, particularly regarding reactor design optimization and catalyst stability. Current reactors struggle with carbon deposition issues that reduce efficiency and increase maintenance requirements. Additionally, achieving continuous operation at industrial scale remains problematic, with most successful demonstrations limited to batch processing or smaller throughputs.

Economic barriers present another major hurdle. The capital expenditure for methane pyrolysis facilities remains high compared to conventional hydrogen production methods. Without substantial carbon pricing mechanisms or incentives, the economic case for methane pyrolysis is challenging in many markets. Furthermore, the commercialization pathway requires significant investment in scaling up from laboratory to industrial implementation.

Regulatory frameworks and standards represent another critical barrier. The lack of unified global standards for turquoise hydrogen (produced via methane pyrolysis) creates market uncertainty. Additionally, carbon accounting methodologies for this process are still evolving, complicating efforts to monetize its environmental benefits.

Infrastructure limitations also constrain development. The technology requires integration with existing natural gas infrastructure while simultaneously needing new systems for solid carbon handling and storage. This dual requirement creates logistical challenges that few regions are equipped to address comprehensively.

Market acceptance remains uncertain, with potential customers requiring assurances about hydrogen purity, reliability of supply, and long-term viability of the technology before making significant commitments. These combined barriers create a complex landscape that requires coordinated efforts across technical innovation, policy development, and market creation to overcome.

Current Methane Pyrolysis Reactor Designs and Processes

01 Environmental benefits of methane pyrolysis

Methane pyrolysis offers significant environmental advantages as a hydrogen production method by producing solid carbon instead of CO2 emissions. This process effectively decarbonizes natural gas while generating valuable carbon materials as byproducts. The technology represents a cleaner alternative to traditional steam methane reforming, potentially reducing greenhouse gas emissions and contributing to climate change mitigation strategies.- Environmental benefits and carbon reduction: Methane pyrolysis offers significant environmental advantages by producing hydrogen without CO2 emissions, unlike traditional methods such as steam methane reforming. This process directly decomposes methane into hydrogen and solid carbon, avoiding greenhouse gas emissions. The environmental benefits provide a competitive advantage in markets with strict carbon regulations and for companies with sustainability goals, positioning methane pyrolysis as a cleaner alternative for hydrogen production in the transition to low-carbon energy systems.

- Economic efficiency and cost advantages: Methane pyrolysis presents economic advantages through reduced operational costs compared to conventional hydrogen production methods. The process requires less energy input and eliminates the need for carbon capture infrastructure. Additionally, the solid carbon byproduct can be sold as a valuable material for various applications, creating a secondary revenue stream. These economic efficiencies make methane pyrolysis financially competitive, especially as carbon pricing mechanisms become more widespread and energy markets evolve toward cleaner solutions.

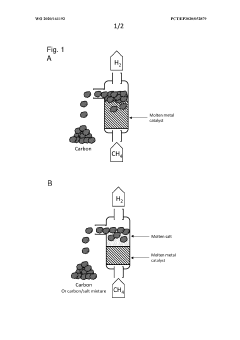

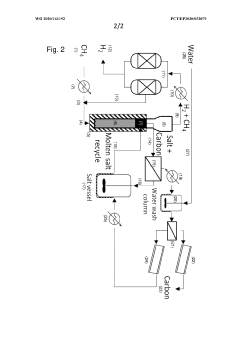

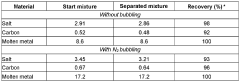

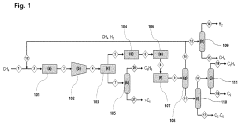

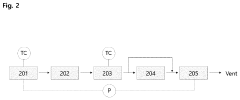

- Technological innovations in reactor design: Advanced reactor designs for methane pyrolysis provide competitive advantages through improved efficiency and scalability. Innovations include molten metal catalysts, plasma-assisted decomposition, and specialized heating methods that enhance conversion rates and reduce energy requirements. These technological developments allow for more efficient methane cracking at lower temperatures, continuous operation, and better carbon handling. The novel reactor designs enable more compact installations and improved process control, creating significant competitive differentiation in the hydrogen production market.

- Integration with renewable energy systems: Methane pyrolysis can be effectively integrated with renewable energy sources, creating a competitive advantage in the green hydrogen market. The process can utilize intermittent renewable electricity for heating, enabling flexible operation that complements variable renewable generation. This integration pathway allows for the production of low-carbon hydrogen while providing grid balancing services. The synergy between methane pyrolysis and renewable energy systems offers a practical transition solution that combines the reliability of natural gas infrastructure with the environmental benefits of renewable energy.

- Value-added carbon byproducts: A key competitive advantage of methane pyrolysis is the production of solid carbon as a valuable byproduct rather than CO2 emissions. This solid carbon can be processed into various high-value materials including carbon black, carbon nanotubes, graphene, and activated carbon for use in manufacturing, electronics, and advanced materials. The ability to convert what would otherwise be a waste product into marketable materials creates additional revenue streams and improves the overall economics of hydrogen production, distinguishing methane pyrolysis from other hydrogen production methods.

02 Economic advantages of methane pyrolysis processes

Methane pyrolysis presents economic benefits through the production of high-value carbon materials alongside hydrogen. The process requires less energy input compared to electrolysis and can utilize existing natural gas infrastructure. Additionally, the solid carbon byproduct can be marketed as a commodity in various industries, creating a secondary revenue stream that improves the overall economics of hydrogen production.Expand Specific Solutions03 Technological innovations in methane pyrolysis reactors

Recent technological advancements in methane pyrolysis reactor designs have improved process efficiency and scalability. Innovations include molten metal catalysts, plasma-assisted decomposition, and specialized reactor configurations that enhance heat transfer and carbon separation. These developments address previous limitations in reaction kinetics and carbon handling, enabling more efficient conversion of methane to hydrogen and solid carbon.Expand Specific Solutions04 Integration with renewable energy systems

Methane pyrolysis can be strategically integrated with renewable energy sources to create hybrid energy systems. By utilizing renewable electricity for process heating, the carbon intensity of hydrogen production can be further reduced. This integration enables energy storage solutions and grid balancing capabilities, providing flexibility in energy management and supporting the transition to renewable energy infrastructure.Expand Specific Solutions05 Market positioning and competitive strategy

Companies deploying methane pyrolysis technology can gain competitive advantages through strategic market positioning. By emphasizing the production of clean hydrogen without CO2 emissions, businesses can target environmentally conscious markets and potentially command premium pricing. The technology also offers flexibility in scale, allowing for both centralized and distributed hydrogen production models that can serve diverse market segments and applications.Expand Specific Solutions

Leading Companies and Research Institutions in Methane Pyrolysis

Methane pyrolysis is currently in an early growth phase within the clean hydrogen production market, with increasing interest due to its potential for low-carbon hydrogen production. The global market is expanding rapidly, projected to reach significant scale as decarbonization efforts intensify. Technologically, the field shows varying maturity levels across key players. Industry leaders like Sinopec, BASF, Air Liquide, and Linde are advancing commercial-scale implementations, while research institutions such as Dalian University of Technology and PARC are developing next-generation catalysts and reactor designs. Emerging companies like Hazer Group and Modern Hydrogen are introducing innovative approaches to methane decomposition. The competitive landscape is characterized by strategic partnerships between established petrochemical companies and technology developers, with increasing investment in pilot projects demonstrating technical feasibility and economic viability.

BASF Corp.

Technical Solution: BASF has developed an innovative methane pyrolysis technology that utilizes a molten metal bubble column reactor system. Their approach employs a tin-based liquid metal catalyst that enables efficient methane decomposition at temperatures around 600-700°C. The process features a unique reactor design that maximizes gas-liquid contact area while minimizing energy requirements. BASF's technology incorporates advanced carbon separation mechanisms that allow for continuous carbon removal as a valuable byproduct. The company has integrated their pyrolysis system with existing chemical manufacturing infrastructure to create synergistic production opportunities. Their process achieves hydrogen production with over 95% purity directly from the reactor, minimizing downstream purification requirements. BASF has demonstrated the technology at pilot scale and is currently scaling up for industrial implementation, with projected hydrogen production costs competitive with conventional methods when accounting for carbon pricing.

Strengths: Chemical industry expertise enables effective integration with existing processes; molten metal approach offers good energy efficiency; continuous carbon removal system improves operational reliability. Weaknesses: Liquid metal handling presents materials compatibility challenges; carbon quality control needs further development; scaling economics still being validated at larger scales.

Hazer Group Ltd.

Technical Solution: Hazer Group has developed a proprietary methane pyrolysis technology called the HAZER Process that uses iron ore as a catalyst to convert natural gas into hydrogen and high-quality graphite. Their approach enables the production of clean hydrogen with significantly lower carbon emissions compared to traditional methods. The process operates at moderate temperatures (700-900°C) and utilizes a fluidized bed reactor system that enhances efficiency and scalability. Hazer has successfully demonstrated their technology at pilot scale and is currently working on commercial-scale implementation. Their process achieves approximately 80% conversion efficiency of methane to hydrogen while capturing carbon as solid graphite rather than CO2, effectively eliminating greenhouse gas emissions from the hydrogen production process.

Strengths: Produces valuable graphite as a co-product which improves economics; zero-CO2 emissions process; uses widely available iron ore catalysts. Weaknesses: Still scaling to commercial deployment; requires consistent catalyst management; energy intensity of the process remains a challenge for large-scale implementation.

Critical Patents and Innovations in Catalyst-Free Pyrolysis

Use of molten salt to separate carbon from a molten metal catalyst

PatentWO2020161192A1

Innovation

- The use of molten salt with a lower density than molten metal to physically separate solid carbon, allowing it to accumulate on top and be collected with the salt, facilitating easy separation and maintaining the catalytic activity of the molten metal.

Process of selectively hydrogenating gas mixture having high acetylene content

PatentActiveUS11858886B2

Innovation

- A selective hydrogenation process using a bimetallic catalyst with Pd and Cu supported on a porous substrate, where the catalysts are prepared by spray impregnation and reduction, allowing for efficient conversion of high-concentration acetylene in methane pyrolysis products to ethylene without external hydrogen supply, optimizing the weight ratio of metals to enhance acetylene conversion and ethylene selectivity.

Environmental Impact Assessment and Carbon Footprint

Methane pyrolysis represents a significant advancement in hydrogen production with potentially lower environmental impacts compared to conventional methods. The environmental assessment of this technology reveals several promising aspects that could contribute to sustainable competitive advantage in the energy transition landscape.

The carbon footprint of methane pyrolysis is substantially lower than traditional steam methane reforming (SMR) processes. While SMR produces approximately 9-12 kg CO2 per kg of hydrogen, methane pyrolysis can reduce these emissions by up to 85% when powered by renewable electricity. This dramatic reduction stems from the process's fundamental chemistry - directly separating methane into hydrogen and solid carbon rather than generating CO2 as a byproduct.

Life cycle assessments indicate that methane pyrolysis facilities have significantly reduced scope 1 and 2 emissions compared to conventional hydrogen production methods. The solid carbon byproduct represents sequestered carbon that would otherwise enter the atmosphere as CO2, effectively creating a carbon sink when the carbon is utilized in durable applications such as construction materials or advanced composites.

Water consumption represents another environmental advantage of methane pyrolysis. Unlike electrolysis, which requires substantial water inputs (approximately 9 liters per kg of hydrogen), methane pyrolysis requires minimal water resources. This reduced water footprint becomes increasingly valuable in water-stressed regions and contributes to the overall sustainability profile of the technology.

Land use requirements for methane pyrolysis facilities are also comparatively modest. The compact nature of reactor designs allows for smaller industrial footprints compared to large-scale electrolysis operations or SMR plants with carbon capture systems. This spatial efficiency enables more flexible siting options and reduced ecosystem disruption.

Regarding air quality impacts, methane pyrolysis eliminates the production of nitrogen oxides and sulfur oxides commonly associated with combustion-based hydrogen production methods. The absence of these pollutants contributes to improved local air quality around production facilities and reduces regulatory compliance burdens related to emissions controls.

The environmental benefits extend to the supply chain when considering methane leakage. By creating value for methane that might otherwise be flared or vented, particularly in oil production regions, methane pyrolysis can incentivize better capture and utilization of this potent greenhouse gas, further enhancing its climate mitigation potential.

The carbon footprint of methane pyrolysis is substantially lower than traditional steam methane reforming (SMR) processes. While SMR produces approximately 9-12 kg CO2 per kg of hydrogen, methane pyrolysis can reduce these emissions by up to 85% when powered by renewable electricity. This dramatic reduction stems from the process's fundamental chemistry - directly separating methane into hydrogen and solid carbon rather than generating CO2 as a byproduct.

Life cycle assessments indicate that methane pyrolysis facilities have significantly reduced scope 1 and 2 emissions compared to conventional hydrogen production methods. The solid carbon byproduct represents sequestered carbon that would otherwise enter the atmosphere as CO2, effectively creating a carbon sink when the carbon is utilized in durable applications such as construction materials or advanced composites.

Water consumption represents another environmental advantage of methane pyrolysis. Unlike electrolysis, which requires substantial water inputs (approximately 9 liters per kg of hydrogen), methane pyrolysis requires minimal water resources. This reduced water footprint becomes increasingly valuable in water-stressed regions and contributes to the overall sustainability profile of the technology.

Land use requirements for methane pyrolysis facilities are also comparatively modest. The compact nature of reactor designs allows for smaller industrial footprints compared to large-scale electrolysis operations or SMR plants with carbon capture systems. This spatial efficiency enables more flexible siting options and reduced ecosystem disruption.

Regarding air quality impacts, methane pyrolysis eliminates the production of nitrogen oxides and sulfur oxides commonly associated with combustion-based hydrogen production methods. The absence of these pollutants contributes to improved local air quality around production facilities and reduces regulatory compliance burdens related to emissions controls.

The environmental benefits extend to the supply chain when considering methane leakage. By creating value for methane that might otherwise be flared or vented, particularly in oil production regions, methane pyrolysis can incentivize better capture and utilization of this potent greenhouse gas, further enhancing its climate mitigation potential.

Economic Viability and Commercialization Pathways

The economic viability of methane pyrolysis as a hydrogen production method hinges on several interconnected factors that determine its commercial potential. Current cost analyses indicate that methane pyrolysis can achieve hydrogen production costs between $1.50-2.50/kg, positioning it competitively against conventional steam methane reforming with carbon capture ($1.70-2.40/kg) while offering superior carbon emission profiles.

Capital expenditure requirements for methane pyrolysis facilities vary significantly based on technology selection, with plasma-based systems typically requiring higher initial investment but offering operational flexibility. Molten metal reactors present a middle-ground option with moderate CAPEX and OPEX profiles. The economic equation is further influenced by solid carbon byproduct valorization, which can potentially offset 15-30% of production costs depending on carbon quality and market access.

Scale economies represent a critical pathway to commercial viability, with modeling suggesting that facilities producing 50,000+ tons of hydrogen annually could achieve cost reductions of 25-40% compared to smaller demonstration plants. This scale advantage must be balanced against market development timelines and infrastructure readiness.

Commercialization pathways for methane pyrolysis technologies follow several distinct trajectories. The industrial cluster approach leverages existing hydrogen demand centers (refineries, chemical plants) to establish initial market footholds without requiring extensive distribution infrastructure. This pathway benefits from predictable offtake agreements but may limit scale potential.

The integrated energy hub model positions methane pyrolysis facilities as multi-product energy centers producing hydrogen, electricity, and carbon materials. This approach maximizes revenue streams but increases operational complexity and market exposure across multiple sectors.

Phased deployment strategies represent perhaps the most pragmatic commercialization approach, beginning with small-scale industrial applications (2,000-5,000 tons/year) before expanding to regional hydrogen networks and eventually grid-scale energy applications. This pathway minimizes initial capital risk while allowing technology optimization through iterative deployment.

Regulatory frameworks significantly impact economic viability, with carbon pricing mechanisms, clean hydrogen production incentives, and carbon credit systems potentially improving project economics by 15-40% depending on jurisdiction. The Inflation Reduction Act in the US and similar policies in the EU have established production tax credits that substantially enhance methane pyrolysis business cases when carbon intensity requirements are met.

Capital expenditure requirements for methane pyrolysis facilities vary significantly based on technology selection, with plasma-based systems typically requiring higher initial investment but offering operational flexibility. Molten metal reactors present a middle-ground option with moderate CAPEX and OPEX profiles. The economic equation is further influenced by solid carbon byproduct valorization, which can potentially offset 15-30% of production costs depending on carbon quality and market access.

Scale economies represent a critical pathway to commercial viability, with modeling suggesting that facilities producing 50,000+ tons of hydrogen annually could achieve cost reductions of 25-40% compared to smaller demonstration plants. This scale advantage must be balanced against market development timelines and infrastructure readiness.

Commercialization pathways for methane pyrolysis technologies follow several distinct trajectories. The industrial cluster approach leverages existing hydrogen demand centers (refineries, chemical plants) to establish initial market footholds without requiring extensive distribution infrastructure. This pathway benefits from predictable offtake agreements but may limit scale potential.

The integrated energy hub model positions methane pyrolysis facilities as multi-product energy centers producing hydrogen, electricity, and carbon materials. This approach maximizes revenue streams but increases operational complexity and market exposure across multiple sectors.

Phased deployment strategies represent perhaps the most pragmatic commercialization approach, beginning with small-scale industrial applications (2,000-5,000 tons/year) before expanding to regional hydrogen networks and eventually grid-scale energy applications. This pathway minimizes initial capital risk while allowing technology optimization through iterative deployment.

Regulatory frameworks significantly impact economic viability, with carbon pricing mechanisms, clean hydrogen production incentives, and carbon credit systems potentially improving project economics by 15-40% depending on jurisdiction. The Inflation Reduction Act in the US and similar policies in the EU have established production tax credits that substantially enhance methane pyrolysis business cases when carbon intensity requirements are met.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!