Stress Analysis in Methane Pyrolysis Reactors.

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Methane Pyrolysis Reactor Stress Analysis Background and Objectives

Methane pyrolysis has emerged as a promising technology for hydrogen production with significantly reduced carbon emissions compared to traditional steam methane reforming processes. The evolution of this technology dates back to the early 20th century, but has gained renewed interest in recent decades due to increasing focus on decarbonization strategies and clean energy transitions. The technical trajectory has shifted from basic thermal decomposition methods to more sophisticated catalytic and plasma-assisted approaches, each presenting unique stress profiles within reactor systems.

The structural integrity of methane pyrolysis reactors represents a critical engineering challenge due to the extreme operating conditions these systems must withstand. Typical operating temperatures range from 700°C to 1200°C, creating substantial thermal expansion stresses across reactor components. Additionally, the carbon deposition inherent to the process introduces mechanical stresses that evolve throughout operational cycles, potentially leading to material fatigue and premature failure.

Current technological development aims to optimize reactor designs that can maintain structural integrity while maximizing hydrogen yield and minimizing energy inputs. The primary objective of stress analysis in these systems is to identify critical stress points, predict failure modes, and develop mitigation strategies that extend reactor lifespan while maintaining operational efficiency. This requires sophisticated modeling approaches that account for the complex interplay between thermal gradients, mechanical loads, and material degradation mechanisms.

Recent advancements in computational modeling have enabled more accurate prediction of stress distributions within these complex reactor geometries. Finite element analysis (FEA) coupled with computational fluid dynamics (CFD) has become instrumental in visualizing stress concentrations under various operating conditions. These simulation capabilities represent a significant leap forward from earlier empirical approaches that relied heavily on post-failure analysis.

The technical objectives for advancing stress analysis in methane pyrolysis reactors include developing multi-physics models that can accurately predict stress evolution during operational cycles, identifying novel materials with enhanced high-temperature mechanical properties, and designing innovative reactor geometries that better distribute thermal and mechanical loads. Additionally, there is growing interest in real-time monitoring systems that can detect stress anomalies before catastrophic failure occurs.

Industry trends indicate a movement toward modular reactor designs that can be more easily maintained and replaced, reducing the economic impact of stress-induced failures. Simultaneously, research is focusing on novel catalyst supports and reactor wall materials that resist carbon fouling, thereby reducing one of the primary sources of mechanical stress in these systems. The ultimate goal remains developing methane pyrolysis technology that offers both economic viability and operational reliability for clean hydrogen production at industrial scales.

The structural integrity of methane pyrolysis reactors represents a critical engineering challenge due to the extreme operating conditions these systems must withstand. Typical operating temperatures range from 700°C to 1200°C, creating substantial thermal expansion stresses across reactor components. Additionally, the carbon deposition inherent to the process introduces mechanical stresses that evolve throughout operational cycles, potentially leading to material fatigue and premature failure.

Current technological development aims to optimize reactor designs that can maintain structural integrity while maximizing hydrogen yield and minimizing energy inputs. The primary objective of stress analysis in these systems is to identify critical stress points, predict failure modes, and develop mitigation strategies that extend reactor lifespan while maintaining operational efficiency. This requires sophisticated modeling approaches that account for the complex interplay between thermal gradients, mechanical loads, and material degradation mechanisms.

Recent advancements in computational modeling have enabled more accurate prediction of stress distributions within these complex reactor geometries. Finite element analysis (FEA) coupled with computational fluid dynamics (CFD) has become instrumental in visualizing stress concentrations under various operating conditions. These simulation capabilities represent a significant leap forward from earlier empirical approaches that relied heavily on post-failure analysis.

The technical objectives for advancing stress analysis in methane pyrolysis reactors include developing multi-physics models that can accurately predict stress evolution during operational cycles, identifying novel materials with enhanced high-temperature mechanical properties, and designing innovative reactor geometries that better distribute thermal and mechanical loads. Additionally, there is growing interest in real-time monitoring systems that can detect stress anomalies before catastrophic failure occurs.

Industry trends indicate a movement toward modular reactor designs that can be more easily maintained and replaced, reducing the economic impact of stress-induced failures. Simultaneously, research is focusing on novel catalyst supports and reactor wall materials that resist carbon fouling, thereby reducing one of the primary sources of mechanical stress in these systems. The ultimate goal remains developing methane pyrolysis technology that offers both economic viability and operational reliability for clean hydrogen production at industrial scales.

Market Demand for Advanced Pyrolysis Reactor Technologies

The global market for advanced methane pyrolysis reactor technologies is experiencing significant growth, driven by the increasing demand for clean hydrogen production methods. As countries worldwide commit to carbon neutrality targets, the need for decarbonized hydrogen production has become paramount, positioning methane pyrolysis as a promising alternative to traditional steam methane reforming processes which generate substantial CO2 emissions.

Market analysis indicates that the industrial hydrogen sector, valued at approximately 150 billion USD globally, is undergoing a transformation toward greener production methods. Methane pyrolysis, which produces hydrogen without direct CO2 emissions, is attracting substantial investment from both energy companies and governments seeking to reduce their carbon footprint while maintaining energy security.

The petrochemical industry represents another significant market segment demanding advanced pyrolysis reactors. These companies are increasingly interested in technologies that can efficiently convert methane into valuable solid carbon products while producing hydrogen, creating dual revenue streams. This market driver is particularly strong in regions with abundant natural gas resources but strict environmental regulations.

Research institutions and technology developers are responding to this market pull by focusing on stress-resistant reactor designs. The demand for reactors capable of withstanding extreme thermal conditions while maintaining structural integrity over extended operational periods has created a specialized niche market estimated to grow at a compound annual rate of 25% through 2030.

Geographically, North America and Europe lead in adoption of advanced pyrolysis technologies, primarily due to their aggressive decarbonization policies and substantial research funding. However, the Asia-Pacific region is expected to witness the fastest growth rate as countries like Japan, South Korea, and China invest heavily in hydrogen infrastructure development.

End-user industries are increasingly specifying requirements for pyrolysis reactors with enhanced stress management capabilities, longer operational lifespans, and reduced maintenance needs. This market demand is driving innovation in materials science and reactor design, with particular emphasis on managing thermal stress in high-temperature environments.

The market is also seeing growing demand for modular and scalable pyrolysis reactor systems that can be deployed in distributed energy networks. This trend reflects the broader shift toward decentralized energy production and the need for flexible hydrogen generation capabilities that can be integrated with renewable energy sources.

Investors and venture capital firms have recognized this market potential, with funding for advanced pyrolysis technologies increasing by over 200% in the past three years. This capital influx is accelerating commercialization efforts and enabling more rapid technology deployment to meet the growing market demand.

Market analysis indicates that the industrial hydrogen sector, valued at approximately 150 billion USD globally, is undergoing a transformation toward greener production methods. Methane pyrolysis, which produces hydrogen without direct CO2 emissions, is attracting substantial investment from both energy companies and governments seeking to reduce their carbon footprint while maintaining energy security.

The petrochemical industry represents another significant market segment demanding advanced pyrolysis reactors. These companies are increasingly interested in technologies that can efficiently convert methane into valuable solid carbon products while producing hydrogen, creating dual revenue streams. This market driver is particularly strong in regions with abundant natural gas resources but strict environmental regulations.

Research institutions and technology developers are responding to this market pull by focusing on stress-resistant reactor designs. The demand for reactors capable of withstanding extreme thermal conditions while maintaining structural integrity over extended operational periods has created a specialized niche market estimated to grow at a compound annual rate of 25% through 2030.

Geographically, North America and Europe lead in adoption of advanced pyrolysis technologies, primarily due to their aggressive decarbonization policies and substantial research funding. However, the Asia-Pacific region is expected to witness the fastest growth rate as countries like Japan, South Korea, and China invest heavily in hydrogen infrastructure development.

End-user industries are increasingly specifying requirements for pyrolysis reactors with enhanced stress management capabilities, longer operational lifespans, and reduced maintenance needs. This market demand is driving innovation in materials science and reactor design, with particular emphasis on managing thermal stress in high-temperature environments.

The market is also seeing growing demand for modular and scalable pyrolysis reactor systems that can be deployed in distributed energy networks. This trend reflects the broader shift toward decentralized energy production and the need for flexible hydrogen generation capabilities that can be integrated with renewable energy sources.

Investors and venture capital firms have recognized this market potential, with funding for advanced pyrolysis technologies increasing by over 200% in the past three years. This capital influx is accelerating commercialization efforts and enabling more rapid technology deployment to meet the growing market demand.

Current Challenges in High-Temperature Reactor Stress Management

Methane pyrolysis reactors operate under extreme conditions, with temperatures often exceeding 1000°C to facilitate the thermal decomposition of methane into hydrogen and solid carbon. These high-temperature environments create significant challenges for reactor materials and structural integrity management. Current reactor designs struggle with thermal expansion issues, where different components expand at varying rates, creating internal stresses that can lead to material fatigue and eventual failure.

Material degradation presents another critical challenge, as prolonged exposure to high temperatures accelerates creep deformation and reduces material strength over time. This is particularly problematic at the reactor's hottest zones, where materials may operate near their thermal limits. The carbon deposition process itself introduces additional stress factors, as solid carbon accumulation on reactor walls creates uneven thermal distribution and mechanical pressure points.

Thermal cycling during operational start-up and shutdown sequences generates significant thermal shock, subjecting reactor materials to rapid temperature changes that induce stress concentration at critical junctions. These cyclic stresses contribute substantially to component fatigue and can initiate crack formation even in high-performance alloys and ceramics designed for extreme environments.

Computational modeling of these complex stress patterns remains inadequate, as current simulation tools struggle to accurately predict the combined effects of thermal, mechanical, and chemical stresses in real-time operating conditions. The multiphysics nature of the problem, involving heat transfer, fluid dynamics, and structural mechanics, creates significant computational challenges that limit predictive capabilities.

Monitoring technologies for real-time stress assessment in high-temperature environments are similarly underdeveloped. Conventional sensors often fail under pyrolysis conditions, creating blind spots in operational awareness and preventive maintenance strategies. This limitation forces operators to rely on conservative operational parameters that reduce efficiency and hydrogen production rates.

Material selection represents a fundamental challenge, as the ideal material would need to combine high-temperature strength, thermal shock resistance, chemical inertness to carbon deposition, and long-term durability—a combination that current materials science has yet to fully deliver. Advanced ceramics and specialized metal alloys show promise but come with significant cost implications and manufacturing complexities.

Scaling reactor designs from laboratory to industrial scale introduces additional stress management challenges, as thermal gradients and mechanical stresses behave differently at larger dimensions. This scaling problem has slowed commercial deployment of methane pyrolysis technologies despite their promising role in clean hydrogen production pathways.

Material degradation presents another critical challenge, as prolonged exposure to high temperatures accelerates creep deformation and reduces material strength over time. This is particularly problematic at the reactor's hottest zones, where materials may operate near their thermal limits. The carbon deposition process itself introduces additional stress factors, as solid carbon accumulation on reactor walls creates uneven thermal distribution and mechanical pressure points.

Thermal cycling during operational start-up and shutdown sequences generates significant thermal shock, subjecting reactor materials to rapid temperature changes that induce stress concentration at critical junctions. These cyclic stresses contribute substantially to component fatigue and can initiate crack formation even in high-performance alloys and ceramics designed for extreme environments.

Computational modeling of these complex stress patterns remains inadequate, as current simulation tools struggle to accurately predict the combined effects of thermal, mechanical, and chemical stresses in real-time operating conditions. The multiphysics nature of the problem, involving heat transfer, fluid dynamics, and structural mechanics, creates significant computational challenges that limit predictive capabilities.

Monitoring technologies for real-time stress assessment in high-temperature environments are similarly underdeveloped. Conventional sensors often fail under pyrolysis conditions, creating blind spots in operational awareness and preventive maintenance strategies. This limitation forces operators to rely on conservative operational parameters that reduce efficiency and hydrogen production rates.

Material selection represents a fundamental challenge, as the ideal material would need to combine high-temperature strength, thermal shock resistance, chemical inertness to carbon deposition, and long-term durability—a combination that current materials science has yet to fully deliver. Advanced ceramics and specialized metal alloys show promise but come with significant cost implications and manufacturing complexities.

Scaling reactor designs from laboratory to industrial scale introduces additional stress management challenges, as thermal gradients and mechanical stresses behave differently at larger dimensions. This scaling problem has slowed commercial deployment of methane pyrolysis technologies despite their promising role in clean hydrogen production pathways.

Current Stress Mitigation Solutions for Pyrolysis Reactors

01 Reactor design for stress management in methane pyrolysis

Specialized reactor designs can effectively manage thermal and mechanical stresses during methane pyrolysis. These designs incorporate features such as reinforced walls, stress-relieving joints, and strategic material selection to withstand the high temperatures and pressures involved in the pyrolysis process. Advanced computational modeling helps optimize these designs to minimize stress concentration points and extend reactor lifespan while maintaining operational efficiency.- Reactor design for stress management in methane pyrolysis: Specialized reactor designs can effectively manage thermal and mechanical stress during methane pyrolysis. These designs incorporate features such as reinforced walls, stress-relieving joints, and strategic material placement to withstand high temperatures and pressure fluctuations. Advanced cooling systems and thermal expansion accommodation mechanisms help maintain structural integrity during the extreme conditions of pyrolysis operations.

- Material selection for stress resistance in pyrolysis reactors: The selection of appropriate materials is crucial for managing stress in methane pyrolysis reactors. High-temperature resistant alloys, ceramic composites, and specialized coatings can withstand the thermal cycling and chemical environment during pyrolysis. These materials offer improved creep resistance, thermal shock tolerance, and resistance to carbon deposition, extending reactor lifespan and maintaining performance under stress conditions.

- Monitoring and control systems for stress management: Advanced monitoring and control systems help manage stress in methane pyrolysis reactors by providing real-time data on temperature gradients, pressure variations, and structural integrity. These systems employ sensors, predictive algorithms, and automated response mechanisms to detect early signs of stress-related issues and make operational adjustments. Continuous monitoring enables preventive maintenance and optimizes reactor performance while minimizing stress-induced failures.

- Innovative heating methods to reduce thermal stress: Novel heating approaches can significantly reduce thermal stress in methane pyrolysis reactors. Technologies such as microwave heating, induction heating, and pulsed heating provide more uniform temperature distribution and better control over heating rates. These methods minimize thermal gradients within reactor components, reducing expansion-related stress and extending the operational lifetime of critical components while maintaining efficient pyrolysis performance.

- Catalytic systems for lower-temperature pyrolysis operation: Catalytic systems enable methane pyrolysis at lower temperatures, significantly reducing thermal stress on reactor components. Advanced catalysts based on transition metals, carbon materials, or novel nanostructures lower the activation energy required for methane decomposition. Operating at reduced temperatures decreases thermal expansion, thermal cycling effects, and associated mechanical stress, while maintaining conversion efficiency and extending the service life of reactor materials.

02 Material selection for stress resistance in pyrolysis reactors

The selection of appropriate materials is crucial for managing stress in methane pyrolysis reactors. High-temperature alloys, ceramic composites, and specialized coatings can significantly improve stress resistance under extreme pyrolysis conditions. These materials exhibit superior thermal expansion properties, creep resistance, and corrosion resistance, which are essential for maintaining structural integrity during the repeated thermal cycling that occurs in pyrolysis operations.Expand Specific Solutions03 Thermal management techniques for stress reduction

Effective thermal management is essential for reducing stress in methane pyrolysis reactors. Techniques include controlled heating and cooling rates, temperature gradient optimization, and strategic insulation placement. Advanced cooling systems, such as liquid metal or molten salt cooling, help maintain uniform temperature distribution and prevent thermal shock. These approaches significantly reduce thermal stress and extend reactor component lifespans while improving overall process efficiency.Expand Specific Solutions04 Monitoring and control systems for stress prevention

Advanced monitoring and control systems play a crucial role in preventing excessive stress in methane pyrolysis reactors. Real-time stress monitoring using sensors, strain gauges, and acoustic emission detection allows for early identification of potential failure points. Integrated control systems can automatically adjust operating parameters to reduce stress during critical phases of operation. Predictive maintenance algorithms analyze operational data to schedule interventions before stress-related failures occur.Expand Specific Solutions05 Novel reactor configurations for distributed stress management

Innovative reactor configurations help distribute and manage stress more effectively during methane pyrolysis. These include fluidized bed reactors, molten metal reactors, and microwave-assisted reactors that provide more uniform heating and reduce localized stress points. Modular designs with smaller reaction chambers connected in series or parallel distribute the thermal and mechanical loads across multiple components. These configurations improve stress management while enhancing process efficiency and catalyst longevity.Expand Specific Solutions

Leading Companies and Research Institutions in Reactor Technology

The methane pyrolysis reactor stress analysis market is currently in a growth phase, characterized by increasing demand for clean hydrogen production technologies. The market size is expanding as industries seek carbon-neutral alternatives to traditional hydrogen production methods. Technologically, the field shows varying maturity levels across players. ExxonMobil Chemical and BASF lead with advanced stress modeling capabilities, while China Petroleum & Chemical Corp. and Sinopec Engineering are rapidly advancing their technical expertise. Research institutions like Dalian Institute of Chemical Physics and University of Groningen contribute significant innovations in reactor materials and design. Specialized companies such as Haldor Topsøe and Unitel Technologies offer niche expertise in catalyst integration and reactor optimization, creating a competitive landscape where collaboration between industry and academia drives technological advancement.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced computational fluid dynamics (CFD) models specifically for methane pyrolysis reactors that integrate thermal stress analysis with reaction kinetics. Their approach combines finite element analysis (FEA) with thermochemical modeling to predict stress distribution in reactor walls during high-temperature operations (>1000°C). Sinopec's technology incorporates real-time monitoring systems using distributed fiber optic sensors embedded within reactor linings to detect thermal gradients and mechanical strain. This allows for dynamic adjustment of operating parameters to minimize thermal cycling and extend reactor lifetime. Their proprietary ceramic-metallic composite materials for reactor construction demonstrate superior thermal shock resistance while maintaining structural integrity under the extreme conditions required for methane decomposition to hydrogen and solid carbon.

Strengths: Comprehensive integration of real-time monitoring with predictive modeling allows for proactive maintenance and operational optimization. Their composite materials show exceptional durability in high-temperature hydrogen environments. Weaknesses: The complex monitoring systems require specialized maintenance personnel and increase initial capital costs. The technology is primarily optimized for large-scale industrial applications and may be less cost-effective for smaller operations.

BASF Corp.

Technical Solution: BASF has pioneered a molten metal bubble column reactor design for methane pyrolysis that fundamentally addresses stress-related challenges. Their technology utilizes liquid metal (typically tin or lead-bismuth alloys) as both reaction medium and heat transfer agent, eliminating many traditional solid-wall stress concerns. The reactor features a specialized double-wall construction with active cooling channels that create controlled temperature gradients, minimizing thermal expansion differentials. BASF's approach incorporates computational models that simulate bubble dynamics and their interaction with reactor walls, predicting localized stress concentrations from gas-liquid interfaces. Their design includes sacrificial wear components at high-stress points and utilizes advanced alloys with carefully engineered thermal expansion coefficients. The system operates at moderate pressures (5-15 bar) to balance reaction kinetics with mechanical stress limitations, achieving hydrogen production rates of approximately 60-80 kg H₂/m³ reactor volume per day.

Strengths: The liquid metal medium eliminates carbon fouling issues that plague traditional reactors and provides exceptional heat transfer properties. The system can operate continuously for extended periods without shutdown for carbon removal. Weaknesses: Liquid metal handling introduces safety and containment challenges, particularly at scale. The technology requires specialized materials compatible with both molten metals and high-temperature hydrogen environments, increasing capital costs.

Key Innovations in Material Science for High-Temperature Applications

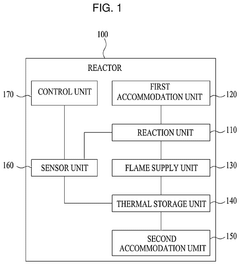

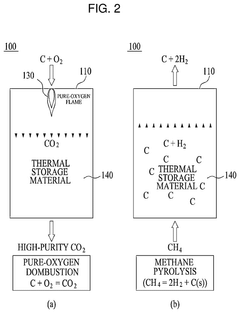

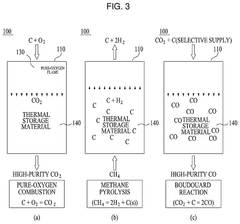

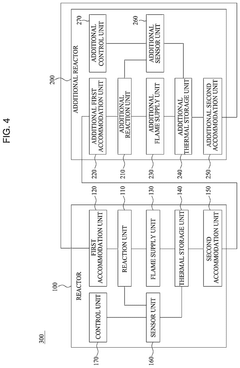

Reactor for producing hydrogen and carbon through pyrolysis of methane by thermal storage method, and combination reactor comprising same

PatentPendingUS20240400386A1

Innovation

- A reactor system that incorporates thermal storage to utilize combustion heat from pure-oxygen combustion of carbon for methane pyrolysis, allowing alternate operation of combustion and pyrolysis in one reactor, and includes a Boudouard reaction to produce high-purity carbon monoxide, with a combination reactor design for efficient carbon utilization and energy management.

Safety Standards and Compliance Requirements for Pyrolysis Equipment

Methane pyrolysis reactors must adhere to stringent safety standards and compliance requirements due to the high-temperature operations and potential hazards involved. The International Organization for Standardization (ISO) provides several relevant standards, including ISO 16110 for hydrogen generators using fuel processing technologies and ISO 13577 for industrial furnaces and associated processing equipment, which apply to pyrolysis reactor design and operation.

In the United States, the Occupational Safety and Health Administration (OSHA) mandates Process Safety Management (PSM) standards under 29 CFR 1910.119 for facilities handling hazardous chemicals above threshold quantities. These standards require comprehensive process hazard analyses, written operating procedures, and regular equipment inspections for methane pyrolysis reactors.

The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code Section VIII provides critical guidelines for pressure vessel design, which directly impacts stress management in pyrolysis reactors. Compliance with these codes ensures that reactors can withstand operational stresses without catastrophic failure.

European regulations, particularly the Pressure Equipment Directive (PED) 2014/68/EU and ATEX Directive 2014/34/EU for equipment in explosive atmospheres, establish essential safety requirements for pyrolysis equipment operating in EU markets. These directives necessitate thorough risk assessments and conformity procedures before equipment commissioning.

Material selection standards, such as ASTM A240 for heat-resistant stainless steel and ASTM A213 for alloy steel tubes, provide specifications crucial for stress-resistant components in pyrolysis reactors. Compliance with these material standards ensures structural integrity under extreme thermal conditions.

Emissions standards, including EPA regulations in the US and the Industrial Emissions Directive (IED) 2010/75/EU in Europe, govern the environmental impact of pyrolysis operations. These regulations influence reactor design by requiring effective emission control systems that can withstand operational stresses.

Regular inspection protocols, as outlined in API 510 for pressure vessel inspection and API 570 for piping inspection, are mandatory for maintaining compliance. These inspections specifically target stress-related deterioration, including creep damage, thermal fatigue, and material degradation.

Certification requirements vary by jurisdiction but typically involve third-party verification of design calculations, material certifications, and non-destructive testing results. Documentation of stress analysis calculations and safety factors must be maintained throughout the equipment lifecycle to demonstrate ongoing compliance with applicable standards.

In the United States, the Occupational Safety and Health Administration (OSHA) mandates Process Safety Management (PSM) standards under 29 CFR 1910.119 for facilities handling hazardous chemicals above threshold quantities. These standards require comprehensive process hazard analyses, written operating procedures, and regular equipment inspections for methane pyrolysis reactors.

The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code Section VIII provides critical guidelines for pressure vessel design, which directly impacts stress management in pyrolysis reactors. Compliance with these codes ensures that reactors can withstand operational stresses without catastrophic failure.

European regulations, particularly the Pressure Equipment Directive (PED) 2014/68/EU and ATEX Directive 2014/34/EU for equipment in explosive atmospheres, establish essential safety requirements for pyrolysis equipment operating in EU markets. These directives necessitate thorough risk assessments and conformity procedures before equipment commissioning.

Material selection standards, such as ASTM A240 for heat-resistant stainless steel and ASTM A213 for alloy steel tubes, provide specifications crucial for stress-resistant components in pyrolysis reactors. Compliance with these material standards ensures structural integrity under extreme thermal conditions.

Emissions standards, including EPA regulations in the US and the Industrial Emissions Directive (IED) 2010/75/EU in Europe, govern the environmental impact of pyrolysis operations. These regulations influence reactor design by requiring effective emission control systems that can withstand operational stresses.

Regular inspection protocols, as outlined in API 510 for pressure vessel inspection and API 570 for piping inspection, are mandatory for maintaining compliance. These inspections specifically target stress-related deterioration, including creep damage, thermal fatigue, and material degradation.

Certification requirements vary by jurisdiction but typically involve third-party verification of design calculations, material certifications, and non-destructive testing results. Documentation of stress analysis calculations and safety factors must be maintained throughout the equipment lifecycle to demonstrate ongoing compliance with applicable standards.

Environmental Impact Assessment of Methane Pyrolysis Technologies

Methane pyrolysis technologies represent a promising pathway for hydrogen production with significantly reduced environmental footprint compared to conventional methods. The environmental impact assessment of these technologies reveals several key advantages that position them as potentially transformative in the clean energy landscape.

The primary environmental benefit of methane pyrolysis is the absence of direct CO2 emissions during the hydrogen production process. Unlike steam methane reforming (SMR), which generates 9-12 kg of CO2 per kg of hydrogen produced, pyrolysis produces solid carbon instead of gaseous carbon dioxide. This fundamental difference eliminates the need for carbon capture and storage infrastructure, reducing both costs and environmental risks associated with CO2 transportation and sequestration.

Water consumption represents another significant environmental advantage of methane pyrolysis. Traditional hydrogen production methods require substantial water inputs, with electrolysis consuming approximately 9 kg of water per kg of hydrogen. In contrast, methane pyrolysis requires minimal water, primarily for cooling systems rather than as a process input. This characteristic makes pyrolysis particularly valuable in water-stressed regions where resource competition is intensifying.

The solid carbon byproduct of methane pyrolysis presents both environmental challenges and opportunities. When properly managed, this carbon can be utilized in various applications including construction materials, soil amendments, and advanced materials manufacturing. Life cycle assessments indicate that carbon sequestration in these forms can result in net negative emissions when displacing carbon-intensive materials. However, improper handling could lead to particulate emissions and potential respiratory health impacts in surrounding communities.

Energy efficiency considerations reveal that methane pyrolysis reactors, particularly those utilizing plasma or molten metal catalysts, demonstrate lower overall energy intensity compared to electrolysis. This translates to reduced upstream environmental impacts from electricity generation, though the specific impact profile depends heavily on the energy mix powering the process.

Land use requirements for methane pyrolysis facilities are generally comparable to conventional natural gas processing infrastructure, presenting minimal additional ecological disruption when integrated with existing natural gas supply chains. This contrasts favorably with the extensive land requirements of renewable hydrogen production methods that rely on dedicated solar or wind installations.

Potential environmental risks associated with methane pyrolysis include fugitive methane emissions, which have 25-28 times the global warming potential of CO2 over a 100-year period. Reactor stress analysis plays a critical role in minimizing these risks by ensuring structural integrity and preventing leakage under the high-temperature conditions characteristic of pyrolysis operations.

The primary environmental benefit of methane pyrolysis is the absence of direct CO2 emissions during the hydrogen production process. Unlike steam methane reforming (SMR), which generates 9-12 kg of CO2 per kg of hydrogen produced, pyrolysis produces solid carbon instead of gaseous carbon dioxide. This fundamental difference eliminates the need for carbon capture and storage infrastructure, reducing both costs and environmental risks associated with CO2 transportation and sequestration.

Water consumption represents another significant environmental advantage of methane pyrolysis. Traditional hydrogen production methods require substantial water inputs, with electrolysis consuming approximately 9 kg of water per kg of hydrogen. In contrast, methane pyrolysis requires minimal water, primarily for cooling systems rather than as a process input. This characteristic makes pyrolysis particularly valuable in water-stressed regions where resource competition is intensifying.

The solid carbon byproduct of methane pyrolysis presents both environmental challenges and opportunities. When properly managed, this carbon can be utilized in various applications including construction materials, soil amendments, and advanced materials manufacturing. Life cycle assessments indicate that carbon sequestration in these forms can result in net negative emissions when displacing carbon-intensive materials. However, improper handling could lead to particulate emissions and potential respiratory health impacts in surrounding communities.

Energy efficiency considerations reveal that methane pyrolysis reactors, particularly those utilizing plasma or molten metal catalysts, demonstrate lower overall energy intensity compared to electrolysis. This translates to reduced upstream environmental impacts from electricity generation, though the specific impact profile depends heavily on the energy mix powering the process.

Land use requirements for methane pyrolysis facilities are generally comparable to conventional natural gas processing infrastructure, presenting minimal additional ecological disruption when integrated with existing natural gas supply chains. This contrasts favorably with the extensive land requirements of renewable hydrogen production methods that rely on dedicated solar or wind installations.

Potential environmental risks associated with methane pyrolysis include fugitive methane emissions, which have 25-28 times the global warming potential of CO2 over a 100-year period. Reactor stress analysis plays a critical role in minimizing these risks by ensuring structural integrity and preventing leakage under the high-temperature conditions characteristic of pyrolysis operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!