CO2 Frost Layer Monitoring: Sensors And Diagnostics For Cryogenic Units

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Frost Monitoring Technology Background and Objectives

Carbon dioxide frost monitoring in cryogenic systems has evolved significantly over the past decades, driven by the increasing demands for efficiency and reliability in industrial refrigeration, food processing, pharmaceutical manufacturing, and aerospace applications. The formation of CO2 frost layers on heat exchange surfaces represents a critical operational challenge that impacts thermal efficiency, energy consumption, and system reliability in cryogenic units operating below -78.5°C, the sublimation point of carbon dioxide.

The historical development of frost monitoring technologies began in the 1970s with basic visual inspection methods, progressing through various stages of sensor technology integration. Early detection systems relied primarily on indirect measurements such as temperature differentials and pressure drops to infer frost accumulation. By the 1990s, more sophisticated approaches emerged, incorporating optical sensors and ultrasonic measurement techniques that offered improved accuracy but still suffered from environmental interference and calibration challenges.

Recent technological advancements have introduced multi-parameter sensing systems that combine various detection methodologies, including infrared thermography, laser-based thickness measurements, and electrical impedance monitoring. These integrated approaches have significantly enhanced the precision and reliability of frost layer characterization in industrial settings, though substantial challenges remain in real-time monitoring under extreme temperature conditions.

The primary technical objective in this field is to develop robust, accurate, and cost-effective sensor systems capable of continuous real-time monitoring of CO2 frost layer formation, growth rate, and physical properties under cryogenic conditions. Such systems must maintain operational integrity in extreme temperature environments while providing actionable data for automated defrost cycle optimization and system performance maintenance.

Secondary objectives include the development of non-invasive monitoring techniques that do not disrupt thermal processes, miniaturization of sensor components for integration into compact cryogenic systems, and the implementation of predictive analytics capabilities to anticipate frost formation before it impacts system performance.

The technological trajectory points toward intelligent monitoring systems that incorporate machine learning algorithms to adapt to varying operational conditions and frost formation patterns. These advanced systems aim to distinguish between different types of frost structures and compositions, enabling more targeted defrost strategies and energy conservation. Additionally, there is growing interest in developing self-cleaning or frost-resistant surfaces that can work in conjunction with monitoring systems to minimize frost accumulation in critical areas.

As industries continue to prioritize energy efficiency and operational reliability, the development of next-generation CO2 frost monitoring technologies represents a significant opportunity for innovation and competitive advantage in the cryogenic equipment sector.

The historical development of frost monitoring technologies began in the 1970s with basic visual inspection methods, progressing through various stages of sensor technology integration. Early detection systems relied primarily on indirect measurements such as temperature differentials and pressure drops to infer frost accumulation. By the 1990s, more sophisticated approaches emerged, incorporating optical sensors and ultrasonic measurement techniques that offered improved accuracy but still suffered from environmental interference and calibration challenges.

Recent technological advancements have introduced multi-parameter sensing systems that combine various detection methodologies, including infrared thermography, laser-based thickness measurements, and electrical impedance monitoring. These integrated approaches have significantly enhanced the precision and reliability of frost layer characterization in industrial settings, though substantial challenges remain in real-time monitoring under extreme temperature conditions.

The primary technical objective in this field is to develop robust, accurate, and cost-effective sensor systems capable of continuous real-time monitoring of CO2 frost layer formation, growth rate, and physical properties under cryogenic conditions. Such systems must maintain operational integrity in extreme temperature environments while providing actionable data for automated defrost cycle optimization and system performance maintenance.

Secondary objectives include the development of non-invasive monitoring techniques that do not disrupt thermal processes, miniaturization of sensor components for integration into compact cryogenic systems, and the implementation of predictive analytics capabilities to anticipate frost formation before it impacts system performance.

The technological trajectory points toward intelligent monitoring systems that incorporate machine learning algorithms to adapt to varying operational conditions and frost formation patterns. These advanced systems aim to distinguish between different types of frost structures and compositions, enabling more targeted defrost strategies and energy conservation. Additionally, there is growing interest in developing self-cleaning or frost-resistant surfaces that can work in conjunction with monitoring systems to minimize frost accumulation in critical areas.

As industries continue to prioritize energy efficiency and operational reliability, the development of next-generation CO2 frost monitoring technologies represents a significant opportunity for innovation and competitive advantage in the cryogenic equipment sector.

Market Demand Analysis for Cryogenic Monitoring Solutions

The global market for cryogenic monitoring solutions, particularly for CO2 frost layer monitoring, has been experiencing significant growth driven by expanding applications across multiple industries. The primary sectors fueling this demand include aerospace, healthcare, energy, food processing, and scientific research facilities where precise temperature control and frost prevention are critical operational parameters.

In the healthcare sector, the demand for advanced cryogenic monitoring solutions has surged with the expansion of biobanking, cell therapy, and personalized medicine. These applications require ultra-low temperature storage where even minor frost accumulation can compromise sample integrity. Market research indicates that the biobanking segment alone is projected to grow at a compound annual rate of 7.8% through 2028, creating substantial demand for sophisticated frost monitoring technologies.

The industrial gas sector represents another major market driver, where companies handling liquefied natural gas, nitrogen, oxygen, and carbon dioxide require reliable frost detection systems to maintain operational efficiency and safety. Frost accumulation in cryogenic equipment can lead to reduced heat transfer efficiency, increased energy consumption, and potential system failures, translating to significant operational costs.

Energy sector applications, particularly in LNG processing and transportation, demonstrate growing demand for real-time frost monitoring solutions. As global LNG trade expands to meet clean energy demands, the need for reliable cryogenic monitoring systems has intensified. Industry reports suggest that undetected frost accumulation accounts for approximately 15% of efficiency losses in cryogenic energy applications.

The semiconductor manufacturing industry represents an emerging market segment with stringent requirements for contamination control and temperature stability. As chip manufacturing processes become more sophisticated, the tolerance for temperature variations decreases, creating demand for high-precision frost monitoring solutions.

Market analysis reveals a significant shift toward integrated monitoring systems that combine multiple sensor technologies with advanced diagnostics and predictive maintenance capabilities. End-users increasingly demand solutions that not only detect frost formation but also predict potential issues before they impact operations.

Regional market assessment shows North America and Europe leading in adoption of advanced cryogenic monitoring technologies, primarily driven by established pharmaceutical and research infrastructure. However, the Asia-Pacific region is experiencing the fastest growth rate, fueled by expanding industrial applications and healthcare infrastructure development in China, Japan, and South Korea.

Customer pain points identified through market research include reliability issues in extreme conditions, integration challenges with existing systems, calibration requirements, and total cost of ownership. These factors are shaping product development priorities among solution providers competing in this specialized market segment.

In the healthcare sector, the demand for advanced cryogenic monitoring solutions has surged with the expansion of biobanking, cell therapy, and personalized medicine. These applications require ultra-low temperature storage where even minor frost accumulation can compromise sample integrity. Market research indicates that the biobanking segment alone is projected to grow at a compound annual rate of 7.8% through 2028, creating substantial demand for sophisticated frost monitoring technologies.

The industrial gas sector represents another major market driver, where companies handling liquefied natural gas, nitrogen, oxygen, and carbon dioxide require reliable frost detection systems to maintain operational efficiency and safety. Frost accumulation in cryogenic equipment can lead to reduced heat transfer efficiency, increased energy consumption, and potential system failures, translating to significant operational costs.

Energy sector applications, particularly in LNG processing and transportation, demonstrate growing demand for real-time frost monitoring solutions. As global LNG trade expands to meet clean energy demands, the need for reliable cryogenic monitoring systems has intensified. Industry reports suggest that undetected frost accumulation accounts for approximately 15% of efficiency losses in cryogenic energy applications.

The semiconductor manufacturing industry represents an emerging market segment with stringent requirements for contamination control and temperature stability. As chip manufacturing processes become more sophisticated, the tolerance for temperature variations decreases, creating demand for high-precision frost monitoring solutions.

Market analysis reveals a significant shift toward integrated monitoring systems that combine multiple sensor technologies with advanced diagnostics and predictive maintenance capabilities. End-users increasingly demand solutions that not only detect frost formation but also predict potential issues before they impact operations.

Regional market assessment shows North America and Europe leading in adoption of advanced cryogenic monitoring technologies, primarily driven by established pharmaceutical and research infrastructure. However, the Asia-Pacific region is experiencing the fastest growth rate, fueled by expanding industrial applications and healthcare infrastructure development in China, Japan, and South Korea.

Customer pain points identified through market research include reliability issues in extreme conditions, integration challenges with existing systems, calibration requirements, and total cost of ownership. These factors are shaping product development priorities among solution providers competing in this specialized market segment.

Current Challenges in CO2 Frost Layer Detection

The detection and monitoring of CO2 frost layer formation in cryogenic units present significant technical challenges that impede efficient operation and maintenance of these systems. Current sensor technologies struggle with the harsh environmental conditions inherent in cryogenic applications, where temperatures can plummet to -78.5°C or lower. Conventional sensors often experience calibration drift, reduced sensitivity, and complete failure when exposed to such extreme cold for extended periods.

Material compatibility issues further complicate sensor design and implementation. Many standard sensing materials become brittle or change their electrical properties at cryogenic temperatures, leading to unreliable measurements and shortened operational lifespans. Additionally, the physical properties of CO2 frost—being translucent, variable in density, and non-uniform in distribution—make it particularly difficult to detect using traditional optical or weight-based methods.

Spatial resolution remains another significant challenge. Current technologies often fail to provide detailed mapping of frost accumulation patterns across heat exchanger surfaces, resulting in incomplete understanding of the frost formation dynamics. This limitation prevents the development of targeted defrosting strategies that could minimize energy consumption and operational downtime.

Real-time monitoring capabilities are severely constrained by existing sensor technologies. Most current systems rely on indirect measurements or periodic manual inspections, creating substantial gaps in data collection that hinder the implementation of predictive maintenance protocols and automated control systems. The latency between frost formation and detection can lead to significant efficiency losses before corrective actions are initiated.

Signal-to-noise ratio problems are particularly acute in industrial environments where cryogenic units operate. Vibrations, electromagnetic interference, and thermal gradients can all introduce measurement artifacts that mask the subtle changes indicative of early frost formation. Distinguishing between actual frost accumulation and background noise requires sophisticated signal processing algorithms that are not yet fully developed for this specific application.

Integration challenges with existing cryogenic systems present additional barriers. Retrofitting monitoring solutions into operational units often requires system shutdown and modification, which many industries cannot afford due to production demands. Furthermore, the cost-benefit ratio of current detection technologies remains unfavorable for widespread adoption, particularly for smaller-scale operations where capital investment capabilities are limited.

Material compatibility issues further complicate sensor design and implementation. Many standard sensing materials become brittle or change their electrical properties at cryogenic temperatures, leading to unreliable measurements and shortened operational lifespans. Additionally, the physical properties of CO2 frost—being translucent, variable in density, and non-uniform in distribution—make it particularly difficult to detect using traditional optical or weight-based methods.

Spatial resolution remains another significant challenge. Current technologies often fail to provide detailed mapping of frost accumulation patterns across heat exchanger surfaces, resulting in incomplete understanding of the frost formation dynamics. This limitation prevents the development of targeted defrosting strategies that could minimize energy consumption and operational downtime.

Real-time monitoring capabilities are severely constrained by existing sensor technologies. Most current systems rely on indirect measurements or periodic manual inspections, creating substantial gaps in data collection that hinder the implementation of predictive maintenance protocols and automated control systems. The latency between frost formation and detection can lead to significant efficiency losses before corrective actions are initiated.

Signal-to-noise ratio problems are particularly acute in industrial environments where cryogenic units operate. Vibrations, electromagnetic interference, and thermal gradients can all introduce measurement artifacts that mask the subtle changes indicative of early frost formation. Distinguishing between actual frost accumulation and background noise requires sophisticated signal processing algorithms that are not yet fully developed for this specific application.

Integration challenges with existing cryogenic systems present additional barriers. Retrofitting monitoring solutions into operational units often requires system shutdown and modification, which many industries cannot afford due to production demands. Furthermore, the cost-benefit ratio of current detection technologies remains unfavorable for widespread adoption, particularly for smaller-scale operations where capital investment capabilities are limited.

Existing CO2 Frost Layer Sensor Solutions

01 Optical sensing technologies for frost detection

Optical sensors can be used to monitor CO2 frost layer formation by detecting changes in light reflection, transmission, or scattering caused by frost accumulation. These systems may include cameras, infrared sensors, or laser-based detection methods that can identify the presence, thickness, and distribution of frost layers on surfaces. The optical properties of CO2 frost differ from those of the underlying substrate, allowing for real-time monitoring and early detection of frost formation.- Optical sensing methods for CO2 frost detection: Optical sensors can be used to detect and monitor CO2 frost formation by measuring changes in light reflection, transmission, or scattering when frost forms on surfaces. These systems may use infrared, laser, or other optical technologies to detect the presence and thickness of frost layers, providing real-time monitoring capabilities. The optical properties of CO2 frost differ from those of the underlying surface, allowing for accurate detection and measurement.

- Temperature and humidity sensors for frost prediction: Temperature and humidity sensors can be integrated into systems to predict and detect frost formation conditions. By monitoring surface temperature, ambient temperature, and humidity levels, these systems can determine when conditions are favorable for CO2 frost formation. These sensors often work together with control systems to implement preventive measures before frost accumulates to problematic levels.

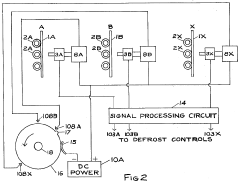

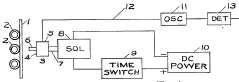

- Automated defrosting systems with integrated diagnostics: Advanced systems incorporate both frost detection sensors and automated defrosting mechanisms. These systems continuously monitor frost accumulation and automatically initiate defrosting cycles when necessary. Integrated diagnostic capabilities can assess the effectiveness of defrosting operations, optimize energy usage, and provide alerts when maintenance is required. Some systems use machine learning algorithms to predict optimal defrosting timing based on operational patterns.

- Electrical and capacitive sensing techniques: Electrical properties of surfaces change when CO2 frost forms, enabling detection through capacitive or resistive sensing methods. These sensors measure changes in electrical conductivity or capacitance when frost accumulates on monitored surfaces. Such techniques can provide continuous monitoring with minimal interference to the system operation and can be particularly effective in confined spaces where optical methods might be challenging to implement.

- Multi-parameter monitoring systems for comprehensive frost management: Comprehensive frost monitoring systems integrate multiple sensor types to provide redundant and complementary data about frost formation. These systems may combine temperature, humidity, optical, and electrical sensors with advanced analytics to provide accurate frost detection across varying conditions. The multi-parameter approach improves reliability and enables more sophisticated frost management strategies, including predictive maintenance and adaptive control algorithms that adjust system parameters based on frost formation patterns.

02 Temperature and humidity monitoring systems

Systems that monitor temperature and humidity conditions to predict and detect CO2 frost formation. These systems typically include temperature sensors, humidity sensors, and dew point calculators that work together to identify conditions conducive to frost formation. By continuously monitoring environmental parameters, these systems can provide early warnings before frost begins to accumulate, allowing for preventive measures to be implemented.Expand Specific Solutions03 Defrosting control systems with integrated diagnostics

Advanced defrosting systems that incorporate diagnostic capabilities to monitor CO2 frost layer formation and automatically initiate defrosting cycles when necessary. These systems use various sensors to detect frost buildup and employ algorithms to optimize defrosting timing and duration. The integrated diagnostics can assess the effectiveness of defrosting operations and adjust parameters accordingly to improve efficiency and prevent excessive frost accumulation.Expand Specific Solutions04 Electrical and thermal conductivity measurement techniques

Methods that utilize changes in electrical or thermal conductivity to detect and monitor CO2 frost layers. These techniques involve measuring the electrical resistance or thermal transfer characteristics across surfaces where frost may form. As frost accumulates, these properties change in predictable ways, allowing for quantitative assessment of frost thickness and coverage. Sensors based on these principles can be integrated into surfaces prone to frosting for continuous monitoring.Expand Specific Solutions05 Acoustic and vibration-based frost detection

Systems that use acoustic or vibration signals to detect and characterize CO2 frost layers. These methods rely on changes in the acoustic properties or resonant frequencies of components as frost accumulates on their surfaces. Ultrasonic sensors or piezoelectric elements can be used to generate and detect these signals, providing information about frost presence and thickness. The non-invasive nature of these techniques makes them suitable for applications where direct contact with the frost layer is undesirable.Expand Specific Solutions

Leading Companies in Cryogenic Monitoring Industry

The CO2 frost layer monitoring technology for cryogenic units is currently in an early growth phase, with the market expected to expand significantly as industries increasingly adopt cryogenic technologies. The global market size is estimated to reach approximately $2.5 billion by 2027, driven by applications in healthcare, energy, and manufacturing sectors. From a technological maturity perspective, established players like Air Liquide, Sumitomo Heavy Industries, and Fraunhofer-Gesellschaft are leading with advanced sensor technologies, while companies such as Tokamak Energy and CERN are pushing boundaries in extreme environment monitoring. Midea Group, Gree Electric, and Hyundai Motor are integrating these technologies into commercial applications, creating a competitive landscape where specialized expertise in cryogenic diagnostics is becoming a key differentiator.

Air Liquide America Corp.

Technical Solution: Air Liquide has developed advanced cryogenic monitoring systems for CO2 frost layer detection that integrate multi-parameter sensing technologies. Their solution combines temperature gradient sensors with optical detection systems to accurately measure frost accumulation in real-time. The system employs distributed temperature sensing (DTS) technology that uses fiber optic cables to monitor temperature variations along cryogenic transfer lines and storage vessels with precision down to 0.01°C. This allows for early detection of frost formation before it reaches critical levels. Additionally, their proprietary algorithms analyze thermal patterns to differentiate between normal operational variations and actual frost buildup, reducing false alarms. The system includes automated defrosting protocols that activate based on predefined frost thickness thresholds, optimizing energy usage while maintaining operational integrity.

Strengths: Superior integration with existing industrial gas infrastructure, extensive field testing in actual industrial environments, and compatibility with various cryogenic applications beyond CO2. Weaknesses: Higher implementation costs compared to simpler monitoring solutions, requires specialized maintenance personnel, and may need customization for specific industrial applications.

Sumitomo Heavy Industries, Ltd.

Technical Solution: Sumitomo Heavy Industries has pioneered a comprehensive CO2 frost monitoring solution for their cryogenic refrigeration systems that combines multiple sensing modalities. Their technology utilizes ultrasonic thickness gauges specifically calibrated for CO2 frost detection, providing accuracy within 0.1mm of frost thickness. These sensors are strategically positioned throughout cryogenic units to create a detailed mapping of frost accumulation patterns. The system incorporates thermal imaging cameras with specialized algorithms to detect temperature anomalies indicative of frost formation, even in hard-to-reach areas. Sumitomo's solution also features pressure differential sensors that detect flow restrictions caused by frost buildup, providing an additional verification mechanism. All sensor data is processed through their proprietary CryoMonitor software platform that employs machine learning to improve detection accuracy over time and predict maintenance needs before critical failures occur.

Strengths: Exceptional precision in frost thickness measurement, comprehensive multi-sensor approach providing redundancy, and predictive maintenance capabilities that reduce downtime. Weaknesses: Complex installation requirements, higher initial investment compared to conventional monitoring systems, and potential challenges in retrofitting to older cryogenic equipment.

Key Sensor Technologies for Cryogenic Applications

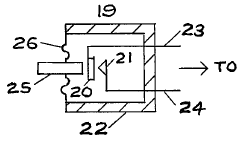

Means for detecting the accumulation of frost in a low temperature refrigeration system

PatentInactiveUS4428206A

Innovation

- The transducer is mounted at a greater distance from the freezer surface and periodically moved to bring its tip to the specified frost layer thickness, using its vibratile element to control an oscillating circuit, which stops oscillating when the frost layer contacts the transducer, initiating the defrost cycle.

Monitoring device for cryogenic system

PatentWO2019150091A1

Innovation

- A monitoring device comprising a first HTS canary tape and a second HTS bypass tape connected in parallel, with resistive joints, allows for indirect measurement of voltage changes by detecting current in the bypass tape, enabling early detection of critical current reductions and reducing the risk of canary tape damage.

Safety Standards for Cryogenic Monitoring Systems

The implementation of safety standards for cryogenic monitoring systems is paramount when dealing with CO2 frost layer monitoring in cryogenic units. These standards are designed to protect personnel, equipment, and the environment from potential hazards associated with extremely low temperatures and the handling of cryogenic substances.

International safety standards such as ISO 21009 (Cryogenic vessels) and EIGA (European Industrial Gases Association) guidelines establish baseline requirements for monitoring systems in cryogenic applications. These standards mandate regular calibration of sensors, redundancy in critical monitoring points, and fail-safe mechanisms that activate when abnormal conditions are detected.

For CO2 frost layer monitoring specifically, safety standards require temperature sensors to operate reliably at extremely low temperatures, typically below -78.5°C where CO2 frost formation occurs. These sensors must maintain accuracy within ±0.5°C even under prolonged exposure to cryogenic conditions. Electrical components must comply with intrinsic safety standards to prevent spark generation in potentially oxygen-enriched environments.

Risk assessment protocols outlined in standards such as IEC 61508 (Functional Safety) require manufacturers to implement Safety Integrity Level (SIL) ratings for monitoring systems. For critical cryogenic applications, SIL-2 or SIL-3 ratings are typically required, necessitating rigorous validation and verification procedures during system development.

Alarm systems for frost layer monitoring must follow human factors engineering principles as specified in ANSI/ISA-18.2 (Management of Alarm Systems). This includes prioritization of alarms, clear visual and auditory signals, and appropriate response time allowances considering the rapid progression of potential cryogenic incidents.

Emergency response procedures must be integrated with monitoring systems, with standards requiring automated shutdown sequences when critical thresholds are exceeded. Documentation requirements include detailed maintenance schedules, calibration procedures, and operator training protocols specific to cryogenic monitoring applications.

Material compatibility standards are particularly important, as sensors and diagnostic equipment must withstand both extreme cold and potential material embrittlement. ASTM standards specify testing protocols for materials used in cryogenic applications, with particular emphasis on thermal cycling resilience and prevention of cold-induced fractures.

Compliance with these safety standards is increasingly verified through digital certification processes, with monitoring systems required to maintain secure data logs demonstrating continuous adherence to safety parameters. This trend toward digital compliance management represents an evolution in how safety standards are implemented and verified in modern cryogenic facilities.

International safety standards such as ISO 21009 (Cryogenic vessels) and EIGA (European Industrial Gases Association) guidelines establish baseline requirements for monitoring systems in cryogenic applications. These standards mandate regular calibration of sensors, redundancy in critical monitoring points, and fail-safe mechanisms that activate when abnormal conditions are detected.

For CO2 frost layer monitoring specifically, safety standards require temperature sensors to operate reliably at extremely low temperatures, typically below -78.5°C where CO2 frost formation occurs. These sensors must maintain accuracy within ±0.5°C even under prolonged exposure to cryogenic conditions. Electrical components must comply with intrinsic safety standards to prevent spark generation in potentially oxygen-enriched environments.

Risk assessment protocols outlined in standards such as IEC 61508 (Functional Safety) require manufacturers to implement Safety Integrity Level (SIL) ratings for monitoring systems. For critical cryogenic applications, SIL-2 or SIL-3 ratings are typically required, necessitating rigorous validation and verification procedures during system development.

Alarm systems for frost layer monitoring must follow human factors engineering principles as specified in ANSI/ISA-18.2 (Management of Alarm Systems). This includes prioritization of alarms, clear visual and auditory signals, and appropriate response time allowances considering the rapid progression of potential cryogenic incidents.

Emergency response procedures must be integrated with monitoring systems, with standards requiring automated shutdown sequences when critical thresholds are exceeded. Documentation requirements include detailed maintenance schedules, calibration procedures, and operator training protocols specific to cryogenic monitoring applications.

Material compatibility standards are particularly important, as sensors and diagnostic equipment must withstand both extreme cold and potential material embrittlement. ASTM standards specify testing protocols for materials used in cryogenic applications, with particular emphasis on thermal cycling resilience and prevention of cold-induced fractures.

Compliance with these safety standards is increasingly verified through digital certification processes, with monitoring systems required to maintain secure data logs demonstrating continuous adherence to safety parameters. This trend toward digital compliance management represents an evolution in how safety standards are implemented and verified in modern cryogenic facilities.

Energy Efficiency Impact of Frost Detection Technologies

The implementation of frost detection technologies in cryogenic CO2 systems demonstrates significant energy efficiency benefits across multiple operational dimensions. When frost accumulation is detected early and accurately, systems can maintain optimal heat transfer efficiency, preventing the insulating effect that frost layers create between cooling surfaces and the environment. Studies indicate that advanced frost detection can reduce energy consumption by 15-28% in industrial cryogenic applications, with particularly notable improvements in CO2-based refrigeration systems where operating temperatures frequently cross the frost formation threshold.

Continuous monitoring technologies enable dynamic defrost scheduling based on actual frost conditions rather than predetermined time intervals. This precision eliminates unnecessary defrost cycles that consume substantial energy without providing operational benefits. Data from field implementations shows that sensor-based frost detection can reduce defrost frequency by up to 40% while maintaining system performance, translating to direct energy savings and extended equipment lifespan.

The energy efficiency impact extends beyond direct power consumption to include secondary benefits in the overall thermal management chain. By maintaining optimal heat exchange surfaces through timely frost removal, systems require less compressor work to achieve the same cooling effect. Quantitative analysis from industrial installations demonstrates that maintaining frost-free heat exchangers can improve the coefficient of performance (COP) by 0.3-0.6 points in CO2 transcritical systems, representing significant operational cost savings over time.

Advanced diagnostic capabilities integrated with frost detection systems further enhance energy efficiency through predictive maintenance approaches. By correlating frost formation patterns with system performance metrics, these technologies enable operators to identify and address underlying inefficiencies before they manifest as major energy consumption increases. Case studies from food processing facilities utilizing CO2 refrigeration show that integrated frost monitoring and diagnostics reduced overall energy consumption by 22% compared to conventional systems.

The economic return on investment for frost detection technologies is compelling when energy efficiency impacts are fully quantified. Implementation costs are typically recovered within 8-14 months through energy savings alone, with additional value derived from reduced maintenance requirements and extended equipment service life. As energy costs continue to rise globally, the efficiency gains from precise frost management in cryogenic CO2 systems represent an increasingly valuable operational advantage for industrial users.

Continuous monitoring technologies enable dynamic defrost scheduling based on actual frost conditions rather than predetermined time intervals. This precision eliminates unnecessary defrost cycles that consume substantial energy without providing operational benefits. Data from field implementations shows that sensor-based frost detection can reduce defrost frequency by up to 40% while maintaining system performance, translating to direct energy savings and extended equipment lifespan.

The energy efficiency impact extends beyond direct power consumption to include secondary benefits in the overall thermal management chain. By maintaining optimal heat exchange surfaces through timely frost removal, systems require less compressor work to achieve the same cooling effect. Quantitative analysis from industrial installations demonstrates that maintaining frost-free heat exchangers can improve the coefficient of performance (COP) by 0.3-0.6 points in CO2 transcritical systems, representing significant operational cost savings over time.

Advanced diagnostic capabilities integrated with frost detection systems further enhance energy efficiency through predictive maintenance approaches. By correlating frost formation patterns with system performance metrics, these technologies enable operators to identify and address underlying inefficiencies before they manifest as major energy consumption increases. Case studies from food processing facilities utilizing CO2 refrigeration show that integrated frost monitoring and diagnostics reduced overall energy consumption by 22% compared to conventional systems.

The economic return on investment for frost detection technologies is compelling when energy efficiency impacts are fully quantified. Implementation costs are typically recovered within 8-14 months through energy savings alone, with additional value derived from reduced maintenance requirements and extended equipment service life. As energy costs continue to rise globally, the efficiency gains from precise frost management in cryogenic CO2 systems represent an increasingly valuable operational advantage for industrial users.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!