Comparison Of Cryogenic And Pressure-Swing Capture For High-Concentration Streams

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon Capture Technology Background and Objectives

Carbon capture technology has evolved significantly over the past several decades, driven by increasing global concerns about climate change and greenhouse gas emissions. The concept of capturing carbon dioxide from industrial processes dates back to the 1970s, but has gained substantial momentum since the early 2000s as climate policies have become more stringent worldwide. The technology landscape has progressed from basic absorption techniques to sophisticated systems capable of handling various concentration levels and stream compositions.

The evolution of carbon capture methods has followed distinct pathways, with cryogenic and pressure-swing technologies emerging as particularly promising approaches for high-concentration CO2 streams. Cryogenic carbon capture, which relies on the phase change properties of CO2 at low temperatures, has roots in industrial gas separation dating back several decades but has seen significant refinements in energy efficiency and process integration in recent years. Pressure-swing adsorption/absorption, meanwhile, has developed from basic pressure-cycling systems to highly optimized configurations with advanced sorbent materials.

High-concentration carbon streams, typically found in industries such as ammonia production, ethanol fermentation, and certain natural gas processing operations, present unique opportunities and challenges for capture technologies. These streams, containing CO2 concentrations often exceeding 30%, offer inherent advantages for capture efficiency compared to dilute sources like power plant flue gas (typically 3-15% CO2). The technical objective in addressing these streams is to identify the most energy-efficient, cost-effective, and scalable capture method while maintaining high purity of the captured CO2 for subsequent utilization or storage.

The comparative assessment of cryogenic versus pressure-swing technologies for high-concentration streams aims to establish clear technical and economic benchmarks for implementation across various industrial sectors. This evaluation must consider not only the fundamental thermodynamic and kinetic principles governing each technology but also practical aspects of integration with existing industrial processes, operational flexibility, and scalability potential.

Current technological goals include reducing the energy penalty associated with carbon capture to below 1 GJ/tonne CO2, achieving capture rates exceeding 95%, and developing systems capable of handling fluctuations in feed composition and flow rates. Additionally, there is growing emphasis on developing capture technologies that produce CO2 streams of sufficient purity for direct utilization in value-added applications, thereby creating economic incentives beyond regulatory compliance.

The evolution of carbon capture methods has followed distinct pathways, with cryogenic and pressure-swing technologies emerging as particularly promising approaches for high-concentration CO2 streams. Cryogenic carbon capture, which relies on the phase change properties of CO2 at low temperatures, has roots in industrial gas separation dating back several decades but has seen significant refinements in energy efficiency and process integration in recent years. Pressure-swing adsorption/absorption, meanwhile, has developed from basic pressure-cycling systems to highly optimized configurations with advanced sorbent materials.

High-concentration carbon streams, typically found in industries such as ammonia production, ethanol fermentation, and certain natural gas processing operations, present unique opportunities and challenges for capture technologies. These streams, containing CO2 concentrations often exceeding 30%, offer inherent advantages for capture efficiency compared to dilute sources like power plant flue gas (typically 3-15% CO2). The technical objective in addressing these streams is to identify the most energy-efficient, cost-effective, and scalable capture method while maintaining high purity of the captured CO2 for subsequent utilization or storage.

The comparative assessment of cryogenic versus pressure-swing technologies for high-concentration streams aims to establish clear technical and economic benchmarks for implementation across various industrial sectors. This evaluation must consider not only the fundamental thermodynamic and kinetic principles governing each technology but also practical aspects of integration with existing industrial processes, operational flexibility, and scalability potential.

Current technological goals include reducing the energy penalty associated with carbon capture to below 1 GJ/tonne CO2, achieving capture rates exceeding 95%, and developing systems capable of handling fluctuations in feed composition and flow rates. Additionally, there is growing emphasis on developing capture technologies that produce CO2 streams of sufficient purity for direct utilization in value-added applications, thereby creating economic incentives beyond regulatory compliance.

Market Analysis for High-Concentration CO2 Capture Solutions

The global market for high-concentration CO2 capture technologies is experiencing significant growth, driven by increasing environmental regulations and corporate sustainability commitments. Currently valued at approximately $2.5 billion, this market segment is projected to grow at a CAGR of 7.8% through 2030, with particular acceleration in industrial applications where high-concentration CO2 streams are prevalent.

Industrial sectors generating high-concentration CO2 streams represent the primary market for specialized capture technologies. These include natural gas processing (CO2 concentrations of 30-70%), ethanol production (>95% CO2 purity), ammonia manufacturing (30-40% CO2), and hydrogen production via steam methane reforming (15-60% CO2). The cement industry, with exhaust gases containing 15-30% CO2, also presents a substantial addressable market.

Regional analysis reveals that North America currently dominates the high-concentration CO2 capture market with 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to demonstrate the fastest growth rate due to rapid industrialization in China and India, coupled with emerging carbon pricing mechanisms.

Market demand is increasingly bifurcated between cost-sensitive industrial applications and premium markets where captured CO2 quality is paramount. For cryogenic technologies, the market is primarily driven by applications requiring high-purity CO2, such as food and beverage industries, enhanced oil recovery, and specialized manufacturing. These sectors value the 99.9%+ purity levels achievable through cryogenic separation despite higher energy requirements.

Pressure-swing technologies dominate in cost-sensitive applications where moderate purity (95-99%) is acceptable, including greenhouse enrichment, urea manufacturing, and certain EOR operations. The lower capital expenditure and operational flexibility of pressure-swing systems have secured approximately 65% of the current high-concentration capture market.

Economic analysis indicates that the levelized cost of CO2 capture ranges from $25-45 per ton for pressure-swing technologies and $35-60 per ton for cryogenic systems when applied to high-concentration streams. This cost differential narrows significantly as concentration levels increase above 70%, where cryogenic efficiency improves dramatically.

Market forecasts suggest that integration with utilization pathways will be a key driver of future growth. The CO2-to-value market is expected to reach $70 billion by 2030, creating pull-through demand for high-purity capture technologies. This synergy is particularly evident in emerging applications such as synthetic fuels, building materials, and polymers, where CO2 feedstock quality directly impacts product value.

Industrial sectors generating high-concentration CO2 streams represent the primary market for specialized capture technologies. These include natural gas processing (CO2 concentrations of 30-70%), ethanol production (>95% CO2 purity), ammonia manufacturing (30-40% CO2), and hydrogen production via steam methane reforming (15-60% CO2). The cement industry, with exhaust gases containing 15-30% CO2, also presents a substantial addressable market.

Regional analysis reveals that North America currently dominates the high-concentration CO2 capture market with 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to demonstrate the fastest growth rate due to rapid industrialization in China and India, coupled with emerging carbon pricing mechanisms.

Market demand is increasingly bifurcated between cost-sensitive industrial applications and premium markets where captured CO2 quality is paramount. For cryogenic technologies, the market is primarily driven by applications requiring high-purity CO2, such as food and beverage industries, enhanced oil recovery, and specialized manufacturing. These sectors value the 99.9%+ purity levels achievable through cryogenic separation despite higher energy requirements.

Pressure-swing technologies dominate in cost-sensitive applications where moderate purity (95-99%) is acceptable, including greenhouse enrichment, urea manufacturing, and certain EOR operations. The lower capital expenditure and operational flexibility of pressure-swing systems have secured approximately 65% of the current high-concentration capture market.

Economic analysis indicates that the levelized cost of CO2 capture ranges from $25-45 per ton for pressure-swing technologies and $35-60 per ton for cryogenic systems when applied to high-concentration streams. This cost differential narrows significantly as concentration levels increase above 70%, where cryogenic efficiency improves dramatically.

Market forecasts suggest that integration with utilization pathways will be a key driver of future growth. The CO2-to-value market is expected to reach $70 billion by 2030, creating pull-through demand for high-purity capture technologies. This synergy is particularly evident in emerging applications such as synthetic fuels, building materials, and polymers, where CO2 feedstock quality directly impacts product value.

Current Status and Technical Challenges in Carbon Capture

Carbon capture technologies have evolved significantly over the past decades, with various approaches being developed to address the growing concern of greenhouse gas emissions. Currently, two dominant technologies for high-concentration CO2 streams are cryogenic capture and pressure-swing adsorption (PSA). The global carbon capture market reached approximately $2.5 billion in 2022 and is projected to grow at a CAGR of 15-20% through 2030, driven by stringent emission regulations and increasing corporate sustainability commitments.

Cryogenic carbon capture has achieved capture rates of 90-99% in high-concentration streams, particularly in industrial applications where CO2 concentrations exceed 30%. This technology operates at extremely low temperatures (typically below -100°C), allowing CO2 to be separated through phase change processes. Recent advancements have reduced energy requirements from 1.8 MJ/kg CO2 to approximately 1.2 MJ/kg CO2, representing a significant efficiency improvement.

Pressure-swing adsorption systems, meanwhile, have demonstrated capture efficiencies of 85-95% in similar high-concentration applications. These systems utilize specialized adsorbent materials that selectively capture CO2 under pressure, then release it when pressure is reduced. Current PSA systems require energy inputs of 1.0-1.5 MJ/kg CO2, with recent innovations in adsorbent materials showing promise for further reductions.

Despite these advancements, both technologies face substantial challenges. For cryogenic systems, the primary limitations include high capital costs (typically 30-40% higher than PSA systems), significant energy requirements for refrigeration, and operational complexities related to managing extremely low temperatures. Material embrittlement at cryogenic temperatures also presents ongoing maintenance challenges and safety concerns.

PSA systems contend with different obstacles, including adsorbent degradation over time (typically losing 5-10% capacity annually), lower capture rates for dilute streams, and challenges in scaling to very large industrial applications. The selectivity of adsorbents remains problematic when dealing with complex gas mixtures containing impurities like SOx and NOx.

Geographically, North America and Europe lead in cryogenic capture technology development, with companies like Air Liquide and Linde advancing proprietary systems. Asia-Pacific regions, particularly China and Japan, have made significant strides in PSA technology, with several demonstration projects achieving commercial scale in the past five years.

The integration of these capture technologies with existing industrial infrastructure presents another significant challenge, often requiring substantial retrofitting and process modifications. This integration challenge has limited widespread adoption despite the technical readiness of both approaches for high-concentration applications.

Cryogenic carbon capture has achieved capture rates of 90-99% in high-concentration streams, particularly in industrial applications where CO2 concentrations exceed 30%. This technology operates at extremely low temperatures (typically below -100°C), allowing CO2 to be separated through phase change processes. Recent advancements have reduced energy requirements from 1.8 MJ/kg CO2 to approximately 1.2 MJ/kg CO2, representing a significant efficiency improvement.

Pressure-swing adsorption systems, meanwhile, have demonstrated capture efficiencies of 85-95% in similar high-concentration applications. These systems utilize specialized adsorbent materials that selectively capture CO2 under pressure, then release it when pressure is reduced. Current PSA systems require energy inputs of 1.0-1.5 MJ/kg CO2, with recent innovations in adsorbent materials showing promise for further reductions.

Despite these advancements, both technologies face substantial challenges. For cryogenic systems, the primary limitations include high capital costs (typically 30-40% higher than PSA systems), significant energy requirements for refrigeration, and operational complexities related to managing extremely low temperatures. Material embrittlement at cryogenic temperatures also presents ongoing maintenance challenges and safety concerns.

PSA systems contend with different obstacles, including adsorbent degradation over time (typically losing 5-10% capacity annually), lower capture rates for dilute streams, and challenges in scaling to very large industrial applications. The selectivity of adsorbents remains problematic when dealing with complex gas mixtures containing impurities like SOx and NOx.

Geographically, North America and Europe lead in cryogenic capture technology development, with companies like Air Liquide and Linde advancing proprietary systems. Asia-Pacific regions, particularly China and Japan, have made significant strides in PSA technology, with several demonstration projects achieving commercial scale in the past five years.

The integration of these capture technologies with existing industrial infrastructure presents another significant challenge, often requiring substantial retrofitting and process modifications. This integration challenge has limited widespread adoption despite the technical readiness of both approaches for high-concentration applications.

Technical Comparison of Cryogenic vs Pressure-Swing Methods

01 Cryogenic capture technology efficiency

Cryogenic capture technology utilizes low-temperature processes to separate and capture gases, particularly carbon dioxide. This method achieves high capture efficiency by cooling gas streams to temperatures where target compounds condense or solidify, allowing for their separation. The technology offers advantages in energy consumption and capture rates compared to conventional methods, with efficiency improvements through heat integration and optimized cooling cycles.- Cryogenic capture technology efficiency factors: Cryogenic capture technologies achieve high efficiency through controlled temperature reduction processes that cause target gases to condense or solidify for separation. The efficiency depends on optimized heat exchange systems, precise temperature control, and energy recovery mechanisms. Advanced cryogenic systems can achieve capture rates exceeding 90% for certain gases while minimizing energy consumption through regenerative cooling cycles and thermal integration with other processes.

- Pressure-swing adsorption capture mechanisms: Pressure-swing adsorption (PSA) technologies utilize pressure differentials to selectively capture target gases on specialized adsorbent materials. The efficiency of PSA systems is determined by adsorbent selectivity, pressure cycling parameters, and bed configuration. Multi-bed PSA systems with rapid cycling can achieve high capture efficiencies while reducing energy requirements through pressure recovery techniques and optimized valve sequencing, making them particularly effective for gas separation applications.

- Hybrid capture systems combining cryogenic and pressure-swing technologies: Hybrid systems that integrate cryogenic and pressure-swing technologies leverage the strengths of both approaches to enhance overall capture efficiency. These systems typically use pressure-swing processes for initial concentration followed by cryogenic separation for final purification. The synergistic combination allows for reduced energy consumption compared to standalone technologies while maintaining high capture rates. Advanced control systems optimize the transition between capture modes to maximize efficiency across varying operating conditions.

- Energy optimization in capture technologies: Energy consumption significantly impacts the overall efficiency of both cryogenic and pressure-swing capture technologies. Advanced heat integration, waste heat recovery, and process optimization techniques can substantially improve capture efficiency. Innovations include multi-stage compression with intercooling, pressure recovery turbines, and thermal energy storage systems. These approaches can reduce energy penalties by 20-40% compared to conventional designs while maintaining or improving capture rates.

- Monitoring and control systems for capture efficiency: Advanced monitoring and control systems play a crucial role in maximizing the efficiency of capture technologies. Real-time sensors, predictive analytics, and adaptive control algorithms optimize operating parameters based on changing conditions. Machine learning approaches can identify optimal pressure and temperature profiles for specific gas compositions. Integrated digital twins enable simulation-based optimization and predictive maintenance, ensuring consistent high-efficiency operation while reducing downtime and energy consumption.

02 Pressure-swing adsorption capture efficiency

Pressure-swing adsorption (PSA) technology captures gases by utilizing pressure differentials to adsorb target compounds onto specialized materials. The efficiency of PSA systems depends on adsorbent selection, cycle time optimization, and pressure range. Recent advancements have improved capture efficiency through multi-bed configurations, novel adsorbent materials, and enhanced regeneration processes, resulting in higher purity products and reduced energy requirements.Expand Specific Solutions03 Hybrid capture systems combining cryogenic and pressure-swing technologies

Hybrid systems that integrate cryogenic and pressure-swing technologies leverage the strengths of both approaches to achieve superior capture efficiency. These combined systems utilize pressure-swing processes for initial separation followed by cryogenic refinement, or vice versa. The synergistic effect reduces overall energy consumption while maintaining high capture rates. Advanced control systems optimize the transition between technologies, adapting to changing input conditions to maintain peak efficiency.Expand Specific Solutions04 Energy optimization in capture technologies

Energy optimization is crucial for improving the efficiency of both cryogenic and pressure-swing capture technologies. Advanced heat integration, waste heat recovery, and process intensification techniques significantly reduce energy consumption. Innovations include multi-stage compression with intercooling, variable pressure operation based on feed composition, and optimized regeneration cycles. These improvements enhance capture efficiency while minimizing the parasitic energy load that traditionally impacts the economic viability of capture systems.Expand Specific Solutions05 Monitoring and control systems for capture efficiency

Advanced monitoring and control systems play a critical role in maximizing the efficiency of cryogenic and pressure-swing capture technologies. Real-time sensors and predictive analytics enable dynamic adjustments to process parameters based on changing input conditions. Machine learning algorithms optimize operational parameters to maintain peak capture efficiency while minimizing energy consumption. These systems provide continuous performance assessment, early fault detection, and automated optimization of capture processes.Expand Specific Solutions

Key Industry Players in Carbon Capture Technologies

The carbon capture market for high-concentration streams is currently in a growth phase, with increasing adoption driven by climate change mitigation efforts. The market is projected to expand significantly as industries seek cost-effective carbon management solutions. Cryogenic capture technology, championed by Air Liquide, Linde, and Air Products, offers high purity but requires substantial energy for gas cooling. Pressure-swing adsorption (PSA), advanced by ExxonMobil, TDA Research, and Praxair, provides more energy-efficient operation with lower capital costs. Academic institutions like Portland State University and Tianjin University are developing hybrid systems combining both technologies' advantages. The competitive landscape is evolving as companies optimize these technologies for specific industrial applications, with Chinese players like SICHUAN TECHAIRS and Hangzhou Oxygen Plant Group rapidly gaining market share through cost-effective solutions.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed advanced cryogenic carbon capture (CCC) technology specifically designed for high-concentration CO2 streams. Their approach utilizes a proprietary anti-sublimation process that prevents solid CO2 formation during cooling, addressing a key challenge in cryogenic capture. The system employs a multi-stage cooling process with heat integration to minimize energy requirements, achieving capture rates exceeding 95% for concentrated streams. Their technology incorporates specialized heat exchangers with enhanced surface treatments to prevent fouling and scaling during extended operation. ExxonMobil's cryogenic system is particularly effective for natural gas processing facilities and hydrogen production plants where CO2 concentrations typically exceed 30%. The company has also developed hybrid systems that combine initial pressure-swing adsorption (PSA) for bulk separation followed by cryogenic polishing for ultra-high purity requirements.

Strengths: Superior energy efficiency for high-concentration streams (>30% CO2) compared to conventional amine scrubbing; produces high-purity liquid CO2 ready for transport; minimal chemical consumption. Weaknesses: Higher capital costs than PSA systems; requires significant cooling infrastructure; less flexible for handling fluctuating feed compositions.

Linde GmbH

Technical Solution: Linde has pioneered a comprehensive portfolio of both cryogenic and pressure-swing technologies for high-concentration CO2 streams. Their RECTISOL® cryogenic process utilizes refrigerated methanol as a physical solvent, operating at temperatures around -40°C to -60°C, achieving CO2 removal efficiencies up to 99.8% for concentrated streams. For pressure-swing applications, Linde's VPSA (Vacuum Pressure Swing Adsorption) technology employs specialized molecular sieves and optimized cycle configurations that reduce power consumption by approximately 25% compared to conventional PSA systems. Their comparative analysis shows cryogenic systems are preferred for streams with CO2 concentrations above 50%, while their advanced PSA systems offer better economics for concentrations between 20-50%. Linde has also developed hybrid solutions that integrate membrane pre-concentration with either cryogenic or PSA final purification, reducing overall energy requirements by up to 30% compared to standalone technologies.

Strengths: Extensive commercial deployment experience across both technologies; proprietary adsorbent materials for PSA with higher CO2 selectivity; modular design allowing capacity expansion. Weaknesses: Cryogenic systems have higher initial capital investment; PSA systems require more frequent adsorbent replacement; both technologies face challenges with impurities like water and hydrocarbons.

Critical Patents and Research in High-Concentration Capture

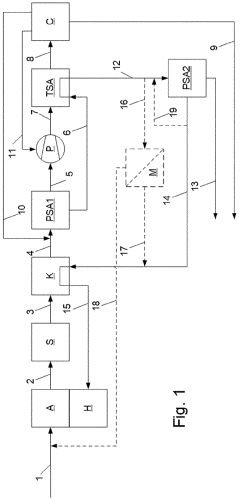

Installation for reducing a carbon dioxide content of a gas flow which contains carbon dioxide and is rich in hydrocarbons, and a corresponding method

PatentInactiveEP2997320A2

Innovation

- A system utilizing two cryogenic separation units with Kryokondensators, where carbon dioxide is deposited in solid form at temperatures and pressures below its triple point, allowing for low residual CO2 levels and efficient regeneration with minimal energy consumption, using cryogenic refrigerants like liquid nitrogen or liquefied natural gas.

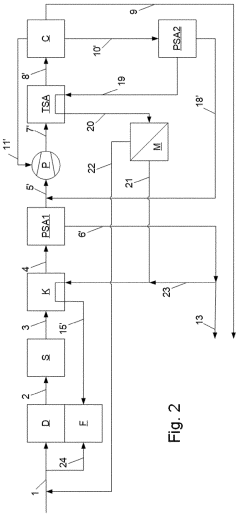

Process for hydrogen production with low carbon dioxide emission

PatentWO2023117130A1

Innovation

- The process involves using a first pressure swing adsorber to separate synthesis gas into carbon dioxide-depleted and enriched fractions, followed by cryogenic gas separation to achieve high carbon capture rates, with additional steps for further purification and recycling to optimize energy use and reduce costs.

Energy Efficiency and Cost Analysis of Capture Technologies

Energy efficiency and cost considerations are paramount when evaluating carbon capture technologies for high-concentration streams. Cryogenic and pressure-swing capture systems demonstrate distinct energy consumption profiles that significantly impact their economic viability in industrial applications.

Cryogenic capture technologies typically require substantial initial energy input for cooling gas streams to temperatures where CO2 solidifies or liquefies (approximately -78.5°C or lower). This process demands significant electricity consumption for refrigeration systems, with energy requirements ranging from 0.4 to 1.2 MWh per ton of CO2 captured, depending on system configuration and stream concentration. However, for high-concentration streams (>30% CO2), cryogenic systems demonstrate improved efficiency ratios, as less energy is wasted cooling non-CO2 components.

Pressure-swing adsorption (PSA) systems, conversely, operate primarily through compression energy rather than cooling. These systems typically consume between 0.3 and 0.8 MWh per ton of CO2 captured from high-concentration streams. The energy efficiency advantage becomes particularly evident when waste heat from industrial processes can be integrated into the system, potentially reducing net energy requirements by 15-25%.

Capital expenditure profiles differ significantly between these technologies. Cryogenic systems require substantial upfront investment in specialized refrigeration equipment, insulation systems, and cryogenic-grade materials, typically ranging from $1,500-2,500 per ton of annual capture capacity. PSA systems generally present lower initial capital costs ($800-1,800 per ton of annual capacity) but may incur higher operational expenses through adsorbent replacement and more frequent maintenance cycles.

Operational costs reveal further distinctions. Cryogenic systems benefit from lower maintenance requirements and longer equipment lifespans (typically 20+ years), with minimal consumable materials. PSA systems require periodic adsorbent replacement (every 2-5 years) and more frequent valve maintenance, though individual component costs are generally lower than specialized cryogenic equipment repairs.

Scale economics favor cryogenic systems for very large installations (>500,000 tons CO2/year), where the efficiency of industrial-scale refrigeration improves dramatically. PSA systems demonstrate better cost-scaling at small to medium capacities, making them more suitable for distributed capture applications or facilities with variable output streams.

Recent technological innovations have narrowed the efficiency gap, with hybrid systems emerging that leverage the strengths of both approaches. Advanced heat integration in cryogenic systems has reduced energy penalties by up to 30% in pilot demonstrations, while next-generation adsorbents have improved PSA efficiency by 15-25% compared to conventional materials.

Cryogenic capture technologies typically require substantial initial energy input for cooling gas streams to temperatures where CO2 solidifies or liquefies (approximately -78.5°C or lower). This process demands significant electricity consumption for refrigeration systems, with energy requirements ranging from 0.4 to 1.2 MWh per ton of CO2 captured, depending on system configuration and stream concentration. However, for high-concentration streams (>30% CO2), cryogenic systems demonstrate improved efficiency ratios, as less energy is wasted cooling non-CO2 components.

Pressure-swing adsorption (PSA) systems, conversely, operate primarily through compression energy rather than cooling. These systems typically consume between 0.3 and 0.8 MWh per ton of CO2 captured from high-concentration streams. The energy efficiency advantage becomes particularly evident when waste heat from industrial processes can be integrated into the system, potentially reducing net energy requirements by 15-25%.

Capital expenditure profiles differ significantly between these technologies. Cryogenic systems require substantial upfront investment in specialized refrigeration equipment, insulation systems, and cryogenic-grade materials, typically ranging from $1,500-2,500 per ton of annual capture capacity. PSA systems generally present lower initial capital costs ($800-1,800 per ton of annual capacity) but may incur higher operational expenses through adsorbent replacement and more frequent maintenance cycles.

Operational costs reveal further distinctions. Cryogenic systems benefit from lower maintenance requirements and longer equipment lifespans (typically 20+ years), with minimal consumable materials. PSA systems require periodic adsorbent replacement (every 2-5 years) and more frequent valve maintenance, though individual component costs are generally lower than specialized cryogenic equipment repairs.

Scale economics favor cryogenic systems for very large installations (>500,000 tons CO2/year), where the efficiency of industrial-scale refrigeration improves dramatically. PSA systems demonstrate better cost-scaling at small to medium capacities, making them more suitable for distributed capture applications or facilities with variable output streams.

Recent technological innovations have narrowed the efficiency gap, with hybrid systems emerging that leverage the strengths of both approaches. Advanced heat integration in cryogenic systems has reduced energy penalties by up to 30% in pilot demonstrations, while next-generation adsorbents have improved PSA efficiency by 15-25% compared to conventional materials.

Environmental Impact and Sustainability Considerations

The environmental impact of carbon capture technologies is a critical consideration in their implementation, particularly for high-concentration CO2 streams. Cryogenic and pressure-swing capture methods present distinct environmental footprints that must be thoroughly evaluated when determining optimal deployment strategies.

Cryogenic capture systems, while energy-intensive during the cooling process, offer significant advantages in terms of water conservation. Unlike many alternative capture technologies, cryogenic methods require minimal water resources, making them particularly valuable in water-stressed regions. However, the substantial energy requirements for achieving ultra-low temperatures translate to higher indirect emissions if powered by fossil fuel sources, potentially undermining the net environmental benefit.

Pressure-swing adsorption (PSA) systems generally demonstrate lower direct energy consumption compared to cryogenic alternatives, resulting in reduced operational carbon footprints when considering electricity generation emissions. Nevertheless, PSA technologies typically require specialized adsorbent materials that may involve energy-intensive manufacturing processes and potentially toxic components, raising concerns about resource depletion and end-of-life disposal challenges.

Life cycle assessment (LCA) studies indicate that the environmental superiority of either technology is highly context-dependent. For industrial applications with access to renewable energy sources, cryogenic systems may offer superior overall environmental performance despite higher energy demands. Conversely, in regions heavily dependent on fossil fuels for electricity generation, PSA systems often present lower lifecycle emissions despite material-related environmental concerns.

The sustainability profile of both technologies can be substantially enhanced through integration with renewable energy sources and waste heat recovery systems. Particularly promising is the potential for cryogenic systems to utilize liquefied captured CO2 for cooling applications in adjacent processes, creating synergistic efficiency improvements across industrial operations.

Regulatory frameworks increasingly emphasize comprehensive environmental impact assessments beyond simple carbon accounting. This includes considerations of land use, ecological disruption, and potential for chemical leakage or accidental releases. PSA systems generally require smaller physical footprints than comparable cryogenic installations, potentially reducing habitat disruption in sensitive areas.

Looking forward, emerging hybrid systems that combine elements of both technologies show promise for optimizing environmental performance across multiple metrics. These integrated approaches aim to leverage the water efficiency of cryogenic methods with the lower energy intensity of pressure-swing processes, potentially establishing new sustainability benchmarks for high-concentration carbon capture applications.

Cryogenic capture systems, while energy-intensive during the cooling process, offer significant advantages in terms of water conservation. Unlike many alternative capture technologies, cryogenic methods require minimal water resources, making them particularly valuable in water-stressed regions. However, the substantial energy requirements for achieving ultra-low temperatures translate to higher indirect emissions if powered by fossil fuel sources, potentially undermining the net environmental benefit.

Pressure-swing adsorption (PSA) systems generally demonstrate lower direct energy consumption compared to cryogenic alternatives, resulting in reduced operational carbon footprints when considering electricity generation emissions. Nevertheless, PSA technologies typically require specialized adsorbent materials that may involve energy-intensive manufacturing processes and potentially toxic components, raising concerns about resource depletion and end-of-life disposal challenges.

Life cycle assessment (LCA) studies indicate that the environmental superiority of either technology is highly context-dependent. For industrial applications with access to renewable energy sources, cryogenic systems may offer superior overall environmental performance despite higher energy demands. Conversely, in regions heavily dependent on fossil fuels for electricity generation, PSA systems often present lower lifecycle emissions despite material-related environmental concerns.

The sustainability profile of both technologies can be substantially enhanced through integration with renewable energy sources and waste heat recovery systems. Particularly promising is the potential for cryogenic systems to utilize liquefied captured CO2 for cooling applications in adjacent processes, creating synergistic efficiency improvements across industrial operations.

Regulatory frameworks increasingly emphasize comprehensive environmental impact assessments beyond simple carbon accounting. This includes considerations of land use, ecological disruption, and potential for chemical leakage or accidental releases. PSA systems generally require smaller physical footprints than comparable cryogenic installations, potentially reducing habitat disruption in sensitive areas.

Looking forward, emerging hybrid systems that combine elements of both technologies show promise for optimizing environmental performance across multiple metrics. These integrated approaches aim to leverage the water efficiency of cryogenic methods with the lower energy intensity of pressure-swing processes, potentially establishing new sustainability benchmarks for high-concentration carbon capture applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!