Refrigeration Cycle Design Choices For Efficient CO2 Desublimation

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Desublimation Technology Background and Objectives

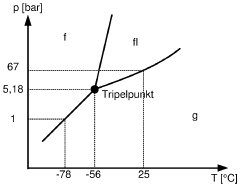

Carbon dioxide (CO2) desublimation, the direct phase transition from gas to solid without passing through the liquid phase, has emerged as a critical technology in various industrial applications. The process has evolved significantly since its initial development in the early 20th century, with major advancements occurring in the past three decades due to increasing environmental concerns and industrial demands for more efficient separation processes.

The historical trajectory of CO2 desublimation technology began with rudimentary cryogenic applications but has since expanded to encompass sophisticated refrigeration cycles specifically designed for optimal phase transition control. Early systems suffered from inefficiencies related to heat transfer limitations and energy consumption, prompting continuous refinement of the underlying thermodynamic principles and engineering designs.

Recent technological evolution has been driven by the global push toward carbon capture and utilization (CCU) technologies, where CO2 desublimation offers advantages in purity and energy efficiency compared to conventional absorption or adsorption methods. The technology has also found applications in food processing, pharmaceutical manufacturing, and semiconductor industries, where high-purity solid CO2 is required.

Current research focuses on optimizing refrigeration cycle designs to enhance the efficiency of the desublimation process. Key parameters under investigation include heat exchanger configurations, refrigerant selection, compression ratios, and expansion valve technologies. The primary technical objectives center on maximizing the desublimation rate while minimizing energy consumption, reducing capital costs, and ensuring operational reliability under varying conditions.

The thermodynamic challenges inherent in CO2 desublimation are substantial, as the process requires precise temperature and pressure control to achieve efficient phase transition. Traditional vapor compression refrigeration cycles have been adapted with specialized modifications to accommodate the unique requirements of CO2 desublimation, including multi-stage compression and custom heat exchanger designs.

Looking forward, the technology aims to achieve several critical objectives: reducing the specific energy consumption per unit of desublimated CO2 by at least 25% compared to current benchmarks; developing scalable systems capable of handling industrial-scale gas volumes; improving heat transfer coefficients in desublimation chambers; and integrating advanced control systems for optimized operation across varying feed compositions and flow rates.

The intersection of refrigeration engineering and CO2 capture technology represents a promising frontier for addressing climate change challenges while meeting industrial needs for efficient separation processes. As global carbon management becomes increasingly important, the refinement of CO2 desublimation technology stands as a key enabler for both environmental sustainability and industrial innovation.

The historical trajectory of CO2 desublimation technology began with rudimentary cryogenic applications but has since expanded to encompass sophisticated refrigeration cycles specifically designed for optimal phase transition control. Early systems suffered from inefficiencies related to heat transfer limitations and energy consumption, prompting continuous refinement of the underlying thermodynamic principles and engineering designs.

Recent technological evolution has been driven by the global push toward carbon capture and utilization (CCU) technologies, where CO2 desublimation offers advantages in purity and energy efficiency compared to conventional absorption or adsorption methods. The technology has also found applications in food processing, pharmaceutical manufacturing, and semiconductor industries, where high-purity solid CO2 is required.

Current research focuses on optimizing refrigeration cycle designs to enhance the efficiency of the desublimation process. Key parameters under investigation include heat exchanger configurations, refrigerant selection, compression ratios, and expansion valve technologies. The primary technical objectives center on maximizing the desublimation rate while minimizing energy consumption, reducing capital costs, and ensuring operational reliability under varying conditions.

The thermodynamic challenges inherent in CO2 desublimation are substantial, as the process requires precise temperature and pressure control to achieve efficient phase transition. Traditional vapor compression refrigeration cycles have been adapted with specialized modifications to accommodate the unique requirements of CO2 desublimation, including multi-stage compression and custom heat exchanger designs.

Looking forward, the technology aims to achieve several critical objectives: reducing the specific energy consumption per unit of desublimated CO2 by at least 25% compared to current benchmarks; developing scalable systems capable of handling industrial-scale gas volumes; improving heat transfer coefficients in desublimation chambers; and integrating advanced control systems for optimized operation across varying feed compositions and flow rates.

The intersection of refrigeration engineering and CO2 capture technology represents a promising frontier for addressing climate change challenges while meeting industrial needs for efficient separation processes. As global carbon management becomes increasingly important, the refinement of CO2 desublimation technology stands as a key enabler for both environmental sustainability and industrial innovation.

Market Analysis for CO2 Capture Technologies

The global CO2 capture technology market is experiencing significant growth, driven by increasing environmental regulations and corporate sustainability commitments. Current market valuations indicate the carbon capture and storage (CCS) sector reached approximately $7 billion in 2022, with projections suggesting expansion to $35 billion by 2030, representing a compound annual growth rate of 19.6%. This growth trajectory is particularly relevant for CO2 desublimation technologies, which are gaining attention as an alternative to traditional absorption methods.

Demand for efficient CO2 capture solutions spans multiple industries, with power generation, cement production, and chemical manufacturing representing the largest market segments. The power generation sector alone accounts for roughly 40% of the current market share, as coal and natural gas plants face mounting pressure to reduce emissions. Industrial processes contribute approximately 25% of global CO2 emissions, creating substantial market potential for desublimation-based capture systems.

Regional analysis reveals varying market dynamics, with North America and Europe leading adoption due to stringent regulatory frameworks. The European Union's commitment to carbon neutrality by 2050 has accelerated investment in capture technologies, with approximately €10 billion allocated through the Innovation Fund for low-carbon technologies. Meanwhile, Asia-Pacific represents the fastest-growing market, with China's recent climate commitments driving substantial investment in carbon capture infrastructure.

Customer requirements are evolving toward solutions offering lower energy penalties and operational costs. Current liquid absorption technologies typically impose energy penalties of 20-30% on power plants, creating strong market demand for more efficient alternatives like optimized desublimation cycles. End-users increasingly prioritize systems with energy consumption below 1 MWh per ton of CO2 captured, a threshold that advanced refrigeration cycle designs for CO2 desublimation could potentially achieve.

Market barriers include high capital expenditure requirements and uncertain regulatory frameworks in developing economies. The average cost for implementing carbon capture systems ranges from $40-120 per ton of CO2 captured, depending on the industry and technology employed. However, carbon pricing mechanisms are creating favorable economics in certain regions, with European carbon prices exceeding €80 per ton in 2022, improving the business case for investment in advanced capture technologies.

Competitive analysis indicates that while traditional chemical absorption dominates current installations with approximately 75% market share, physical separation methods including cryogenic approaches are gaining traction, particularly for high-concentration CO2 streams. This trend creates a significant market opportunity for refrigeration cycle innovations that can enhance the efficiency of CO2 desublimation processes.

Demand for efficient CO2 capture solutions spans multiple industries, with power generation, cement production, and chemical manufacturing representing the largest market segments. The power generation sector alone accounts for roughly 40% of the current market share, as coal and natural gas plants face mounting pressure to reduce emissions. Industrial processes contribute approximately 25% of global CO2 emissions, creating substantial market potential for desublimation-based capture systems.

Regional analysis reveals varying market dynamics, with North America and Europe leading adoption due to stringent regulatory frameworks. The European Union's commitment to carbon neutrality by 2050 has accelerated investment in capture technologies, with approximately €10 billion allocated through the Innovation Fund for low-carbon technologies. Meanwhile, Asia-Pacific represents the fastest-growing market, with China's recent climate commitments driving substantial investment in carbon capture infrastructure.

Customer requirements are evolving toward solutions offering lower energy penalties and operational costs. Current liquid absorption technologies typically impose energy penalties of 20-30% on power plants, creating strong market demand for more efficient alternatives like optimized desublimation cycles. End-users increasingly prioritize systems with energy consumption below 1 MWh per ton of CO2 captured, a threshold that advanced refrigeration cycle designs for CO2 desublimation could potentially achieve.

Market barriers include high capital expenditure requirements and uncertain regulatory frameworks in developing economies. The average cost for implementing carbon capture systems ranges from $40-120 per ton of CO2 captured, depending on the industry and technology employed. However, carbon pricing mechanisms are creating favorable economics in certain regions, with European carbon prices exceeding €80 per ton in 2022, improving the business case for investment in advanced capture technologies.

Competitive analysis indicates that while traditional chemical absorption dominates current installations with approximately 75% market share, physical separation methods including cryogenic approaches are gaining traction, particularly for high-concentration CO2 streams. This trend creates a significant market opportunity for refrigeration cycle innovations that can enhance the efficiency of CO2 desublimation processes.

Current Refrigeration Cycle Technologies and Challenges

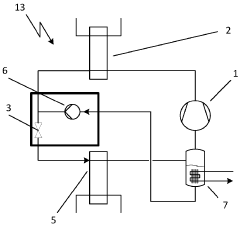

Refrigeration cycles are fundamental to CO2 desublimation processes, with several established technologies currently dominating the market. Vapor compression refrigeration cycles remain the most widely implemented solution, utilizing compressors to increase refrigerant pressure and temperature before condensation and subsequent expansion. These systems typically achieve coefficients of performance (COP) between 2.5-4.5 depending on operating conditions and refrigerant selection. However, when applied to CO2 desublimation, traditional vapor compression cycles face significant challenges due to the high pressure requirements and the substantial latent heat associated with the phase transition from gas to solid.

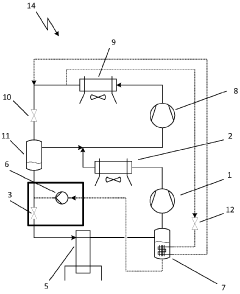

Cascade refrigeration systems have emerged as a viable alternative for CO2 desublimation applications, employing multiple refrigeration cycles operating at different temperature levels. This configuration allows for more efficient heat rejection at the required ultra-low temperatures (typically below -78.5°C for CO2 desublimation). While effective, cascade systems introduce additional complexity, higher capital costs, and increased maintenance requirements compared to single-stage systems.

Transcritical CO2 refrigeration cycles represent another technological approach gaining traction in this field. These systems operate above the critical point of CO2 on the high-pressure side, eliminating the traditional condensation process. When applied to CO2 desublimation, these systems face challenges related to the high operating pressures (often exceeding 73.8 bar) and the need for specialized components capable of withstanding these conditions.

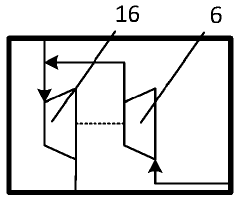

A significant technical challenge across all refrigeration technologies for CO2 desublimation is the management of frost formation on heat exchange surfaces. As solid CO2 accumulates, it creates an insulating layer that progressively reduces heat transfer efficiency, necessitating periodic defrosting cycles that compromise overall system performance and energy efficiency. Current solutions include mechanical scraping mechanisms, thermal cycling, and specialized surface treatments, though none have proven universally effective.

Energy efficiency remains a paramount concern, with conventional systems requiring substantial power input to achieve and maintain the low temperatures necessary for CO2 desublimation. This challenge is compounded by the thermodynamic inefficiencies inherent in operating refrigeration cycles across large temperature differentials. Recent research has focused on advanced heat recovery systems and multi-stage compression with intercooling to mitigate these inefficiencies.

Material limitations present another significant hurdle, as components must withstand both extremely low temperatures and, in some configurations, high pressures. Conventional materials often become brittle or lose their mechanical properties under these conditions, necessitating the use of specialized alloys and composites that add to system cost and complexity.

Control system optimization represents a frontier challenge, as the dynamic nature of CO2 desublimation processes requires sophisticated monitoring and adjustment capabilities to maintain optimal operating conditions while adapting to varying input parameters and environmental conditions.

Cascade refrigeration systems have emerged as a viable alternative for CO2 desublimation applications, employing multiple refrigeration cycles operating at different temperature levels. This configuration allows for more efficient heat rejection at the required ultra-low temperatures (typically below -78.5°C for CO2 desublimation). While effective, cascade systems introduce additional complexity, higher capital costs, and increased maintenance requirements compared to single-stage systems.

Transcritical CO2 refrigeration cycles represent another technological approach gaining traction in this field. These systems operate above the critical point of CO2 on the high-pressure side, eliminating the traditional condensation process. When applied to CO2 desublimation, these systems face challenges related to the high operating pressures (often exceeding 73.8 bar) and the need for specialized components capable of withstanding these conditions.

A significant technical challenge across all refrigeration technologies for CO2 desublimation is the management of frost formation on heat exchange surfaces. As solid CO2 accumulates, it creates an insulating layer that progressively reduces heat transfer efficiency, necessitating periodic defrosting cycles that compromise overall system performance and energy efficiency. Current solutions include mechanical scraping mechanisms, thermal cycling, and specialized surface treatments, though none have proven universally effective.

Energy efficiency remains a paramount concern, with conventional systems requiring substantial power input to achieve and maintain the low temperatures necessary for CO2 desublimation. This challenge is compounded by the thermodynamic inefficiencies inherent in operating refrigeration cycles across large temperature differentials. Recent research has focused on advanced heat recovery systems and multi-stage compression with intercooling to mitigate these inefficiencies.

Material limitations present another significant hurdle, as components must withstand both extremely low temperatures and, in some configurations, high pressures. Conventional materials often become brittle or lose their mechanical properties under these conditions, necessitating the use of specialized alloys and composites that add to system cost and complexity.

Control system optimization represents a frontier challenge, as the dynamic nature of CO2 desublimation processes requires sophisticated monitoring and adjustment capabilities to maintain optimal operating conditions while adapting to varying input parameters and environmental conditions.

Existing Refrigeration Cycle Designs for CO2 Desublimation

01 Advanced refrigerant compositions

Innovative refrigerant compositions can significantly improve refrigeration cycle efficiency. These include environmentally friendly refrigerants with low global warming potential, refrigerant mixtures with optimized thermodynamic properties, and natural refrigerants. These compositions can reduce energy consumption while maintaining or improving cooling performance, leading to more efficient refrigeration systems with reduced environmental impact.- Advanced refrigerant compositions: Innovative refrigerant compositions can significantly improve refrigeration cycle efficiency. These include environmentally friendly refrigerants with low global warming potential (GWP) and ozone depletion potential (ODP). Advanced refrigerant mixtures can enhance heat transfer properties, reduce energy consumption, and improve overall system performance while meeting environmental regulations. These compositions are designed to operate efficiently across various temperature ranges and pressure conditions.

- Compressor optimization techniques: Optimizing compressor design and operation is crucial for refrigeration cycle efficiency. Techniques include variable speed compressors, improved valve designs, enhanced lubrication systems, and advanced motor efficiency. Innovations in compressor technology focus on reducing mechanical losses, improving compression ratios, and minimizing energy consumption during partial load conditions. These optimizations contribute significantly to the overall coefficient of performance (COP) of refrigeration systems.

- Heat exchanger enhancements: Enhanced heat exchanger designs improve thermal transfer efficiency in refrigeration cycles. Innovations include microchannel heat exchangers, advanced fin designs, improved tube geometries, and novel surface treatments that enhance heat transfer coefficients. These enhancements reduce temperature differences required for heat transfer, minimize pressure drops, and improve overall system efficiency. More efficient heat exchangers allow for smaller system footprints while maintaining or improving cooling capacity.

- System control and optimization strategies: Advanced control strategies optimize refrigeration cycle efficiency through intelligent system management. These include adaptive control algorithms, predictive maintenance systems, load-based operation adjustments, and multi-variable optimization techniques. Smart controls can dynamically adjust operating parameters based on ambient conditions, cooling demand, and energy costs. Integration of sensors and IoT technology enables real-time monitoring and optimization of system performance, reducing energy consumption while maintaining desired cooling effects.

- Energy recovery and hybrid systems: Energy recovery mechanisms and hybrid system designs capture and reuse waste heat from refrigeration cycles to improve overall efficiency. These include heat recovery systems, cascade refrigeration cycles, absorption-compression hybrid systems, and integration with renewable energy sources. Waste heat can be utilized for water heating, space heating, or other processes. Hybrid systems combine different refrigeration technologies to optimize performance across varying operating conditions, significantly improving energy efficiency and reducing operational costs.

02 Enhanced heat exchange components

Improved heat exchanger designs and components play a crucial role in refrigeration cycle efficiency. Advanced evaporator and condenser designs with optimized surface areas, microchannel heat exchangers, and enhanced heat transfer surfaces can significantly reduce thermal resistance. These innovations allow for more effective heat transfer, reducing the temperature difference required for operation and thereby improving the overall coefficient of performance of the refrigeration system.Expand Specific Solutions03 Compressor technology improvements

Advanced compressor technologies can substantially increase refrigeration cycle efficiency. Innovations include variable speed compressors that adjust to cooling demand, scroll compressors with reduced friction losses, and compressors with improved valve designs. These technologies reduce energy consumption by minimizing compression losses and allowing the system to operate at optimal conditions across varying loads, resulting in significant efficiency gains throughout the refrigeration cycle.Expand Specific Solutions04 System control and optimization strategies

Intelligent control systems and optimization strategies can maximize refrigeration cycle efficiency. These include adaptive control algorithms, predictive maintenance systems, and real-time performance monitoring. By continuously adjusting operating parameters based on ambient conditions and cooling demands, these systems ensure that refrigeration cycles operate at their most efficient points. Advanced control strategies can also integrate multiple components to work harmoniously, further enhancing overall system efficiency.Expand Specific Solutions05 Waste heat recovery and subcooling techniques

Waste heat recovery systems and subcooling techniques can significantly improve refrigeration cycle efficiency. These innovations capture and repurpose heat that would otherwise be rejected to the environment, using it for useful purposes or to enhance the refrigeration process itself. Subcooling techniques can increase the cooling capacity without proportionally increasing power consumption, while heat recovery systems can utilize waste heat for other applications, effectively increasing the overall energy utilization of the system.Expand Specific Solutions

Leading Companies in CO2 Capture and Refrigeration

The CO2 desublimation refrigeration cycle design market is currently in a growth phase, with increasing demand driven by environmental regulations and sustainability initiatives. The market is characterized by a mix of established HVAC giants and specialized refrigeration technology providers. Leading players include Mayekawa MFG, Carrier Corp., Mitsubishi Electric, DAIKIN Industries, and Mitsubishi Heavy Industries, who are investing in R&D to improve efficiency and reduce environmental impact. The technology is approaching maturity in industrial applications but still evolving for commercial use, with companies like Gree Green Refrigeration and National Institute of Clean & Low Carbon Energy focusing on innovative solutions. Academic institutions such as Peking University and Xi'an Jiaotong University are contributing fundamental research, creating a competitive landscape where collaboration between industry and academia is driving technological advancement.

Mayekawa MFG Co., Ltd.

Technical Solution: Mayekawa has developed advanced CO2 desublimation systems utilizing their NewTon refrigeration technology. Their approach incorporates a cascade refrigeration cycle where CO2 is used as both refrigerant and target for desublimation. The system employs precise temperature control mechanisms in the desublimation chamber, maintaining conditions between -78.5°C and -56.6°C (the CO2 triple point). Mayekawa's design features specialized heat exchangers with enhanced surface area and controlled nucleation sites to optimize the solid CO2 formation process. Their technology incorporates intelligent defrosting cycles to manage solid CO2 buildup without disrupting the continuous operation. The system also utilizes waste heat recovery to improve overall energy efficiency, reducing power consumption by approximately 30% compared to conventional systems.

Strengths: Superior energy efficiency with proven industrial-scale implementation; excellent temperature stability control; integrated heat recovery systems. Weaknesses: Higher initial capital investment; requires specialized maintenance expertise; system complexity can lead to operational challenges in certain environments.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has pioneered a two-stage compression CO2 refrigeration cycle specifically optimized for desublimation processes. Their system utilizes an internal heat exchanger between the high and low-pressure sides to maximize efficiency. The design incorporates precise electronic expansion valve control to maintain optimal gas cooler outlet temperatures based on ambient conditions. For CO2 desublimation applications, Mitsubishi has developed specialized heat exchangers with controlled surface temperatures to promote uniform solid CO2 formation. Their system employs variable-speed compressors that adjust capacity based on load requirements, significantly improving part-load efficiency. The technology also features advanced oil management systems to ensure reliable operation despite the challenging conditions of CO2 refrigeration cycles operating near the triple point. Mitsubishi's approach achieves COP values approximately 20-30% higher than conventional systems when operating in desublimation conditions.

Strengths: Highly efficient two-stage compression technology; sophisticated electronic control systems; proven reliability in industrial applications. Weaknesses: Complex system architecture requires specialized installation and maintenance; higher initial cost compared to conventional systems; performance advantages diminish in extremely high ambient temperature environments.

Key Technical Innovations in Cryogenic CO2 Capture

cycle process for the provision of refrigeration with carbon dioxide as a refrigerant and refrigeration system for carrying out the process

PatentInactiveDE102015111183A1

Innovation

- A CO2-Solid cycle method involving CO2 pressurization, recooling, mixing with a carrier fluid, and expansion below the triple point to prevent solid CO2 agglomeration, utilizing the enthalpy of solution for additional cooling, and employing a refrigeration system with a compressor, heat exchanger, mixing device, expansion device, and separator.

Carbon dioxide co-fluid

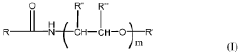

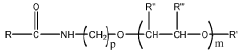

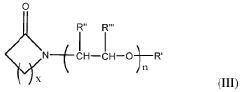

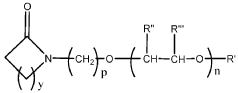

PatentWO2017189897A1

Innovation

- A carbon dioxide/co-fluid mixture with 50% to 99% co-fluid and 1% to 50% carbon dioxide, utilizing alkoxylated carboxylic amides such as N-2,5,8,11-tetraoxadodecyl-2-pyrrolidinone and its homologs, which exhibit high desorption rates at lower temperatures, is used in refrigeration cycles, along with pumps or compressors containing the co-fluid as a lubricant, and ultrasonic transducers to increase desorption efficiency.

Environmental Impact Assessment of Desublimation Technologies

The environmental impact of desublimation technologies, particularly in CO2 capture systems, represents a critical consideration in their implementation and scaling. When evaluating refrigeration cycle design choices for CO2 desublimation, environmental assessment must account for both direct and indirect ecological footprints across the technology lifecycle.

Primary environmental concerns include energy consumption patterns, which directly correlate with greenhouse gas emissions when non-renewable energy sources power these systems. Current desublimation technologies typically require significant cooling energy, with estimates suggesting energy requirements between 0.5-1.2 MWh per ton of CO2 captured, depending on system design efficiency and operating conditions.

Refrigerant selection presents another significant environmental consideration. Traditional refrigeration cycles often employ hydrofluorocarbons (HFCs) with high global warming potential (GWP). Alternative natural refrigerants like ammonia or CO2 itself (transcritical CO2 cycles) offer substantially lower environmental impact, though they present different engineering challenges regarding pressure requirements and system safety.

Water consumption represents a frequently overlooked environmental factor in desublimation processes. Systems requiring water for cooling towers or other auxiliary functions may place additional stress on local water resources, particularly in water-scarce regions. Closed-loop designs and air-cooled alternatives can mitigate these impacts but often at the cost of reduced energy efficiency.

Material selection for heat exchangers and other system components carries embedded environmental impacts through manufacturing processes and resource extraction. Advanced materials like specialized aluminum alloys or composite materials may offer performance advantages but require careful lifecycle assessment to ensure their environmental benefits outweigh production impacts.

Noise pollution and land use requirements constitute additional environmental considerations, particularly for large-scale industrial implementations. Compact system designs with appropriate acoustic insulation can minimize these impacts in sensitive environments or populated areas.

The environmental benefits of CO2 desublimation must be weighed against these impacts through comprehensive lifecycle assessment. When designed optimally, these systems can achieve net environmental benefits by enabling carbon capture with minimized auxiliary environmental impacts. Recent technological innovations have demonstrated potential efficiency improvements of 15-30% compared to first-generation systems, significantly improving the environmental profile of desublimation technologies.

Future environmental impact reductions will likely come through integration with renewable energy sources, advanced heat recovery systems, and continued refinement of system components to maximize efficiency while minimizing resource requirements.

Primary environmental concerns include energy consumption patterns, which directly correlate with greenhouse gas emissions when non-renewable energy sources power these systems. Current desublimation technologies typically require significant cooling energy, with estimates suggesting energy requirements between 0.5-1.2 MWh per ton of CO2 captured, depending on system design efficiency and operating conditions.

Refrigerant selection presents another significant environmental consideration. Traditional refrigeration cycles often employ hydrofluorocarbons (HFCs) with high global warming potential (GWP). Alternative natural refrigerants like ammonia or CO2 itself (transcritical CO2 cycles) offer substantially lower environmental impact, though they present different engineering challenges regarding pressure requirements and system safety.

Water consumption represents a frequently overlooked environmental factor in desublimation processes. Systems requiring water for cooling towers or other auxiliary functions may place additional stress on local water resources, particularly in water-scarce regions. Closed-loop designs and air-cooled alternatives can mitigate these impacts but often at the cost of reduced energy efficiency.

Material selection for heat exchangers and other system components carries embedded environmental impacts through manufacturing processes and resource extraction. Advanced materials like specialized aluminum alloys or composite materials may offer performance advantages but require careful lifecycle assessment to ensure their environmental benefits outweigh production impacts.

Noise pollution and land use requirements constitute additional environmental considerations, particularly for large-scale industrial implementations. Compact system designs with appropriate acoustic insulation can minimize these impacts in sensitive environments or populated areas.

The environmental benefits of CO2 desublimation must be weighed against these impacts through comprehensive lifecycle assessment. When designed optimally, these systems can achieve net environmental benefits by enabling carbon capture with minimized auxiliary environmental impacts. Recent technological innovations have demonstrated potential efficiency improvements of 15-30% compared to first-generation systems, significantly improving the environmental profile of desublimation technologies.

Future environmental impact reductions will likely come through integration with renewable energy sources, advanced heat recovery systems, and continued refinement of system components to maximize efficiency while minimizing resource requirements.

Energy Optimization Strategies for Industrial Implementation

Energy optimization in CO2 desublimation processes represents a critical frontier for industries seeking to reduce operational costs while meeting increasingly stringent environmental regulations. The implementation of optimized refrigeration cycles for CO2 capture requires strategic approaches that balance technical feasibility with economic viability.

Primary among these strategies is heat integration across the industrial system. By identifying opportunities to recover and repurpose waste heat from various process streams, facilities can significantly reduce the energy burden on refrigeration systems. Advanced heat exchangers with enhanced surface designs can facilitate more efficient thermal transfer between process streams, minimizing the temperature differential required for effective operation.

Variable speed drives for compressors and pumps offer another substantial opportunity for energy conservation. These systems allow equipment to operate at precisely the required capacity rather than cycling on and off at fixed speeds, resulting in smoother operation and reduced energy consumption during partial load conditions. Implementation data suggests energy savings of 15-30% compared to conventional fixed-speed systems.

Cascade refrigeration configurations present particularly promising solutions for CO2 desublimation applications. By utilizing multiple refrigerants with complementary thermodynamic properties across different temperature ranges, these systems can achieve higher overall efficiency than single-refrigerant cycles. The upper stages typically employ conventional refrigerants, while lower stages may utilize specialized fluids optimized for the cryogenic temperatures required for CO2 solidification.

Advanced control algorithms represent another frontier in optimization. Model predictive control (MPC) systems that anticipate load changes and adjust operating parameters proactively rather than reactively have demonstrated energy savings of 10-20% in industrial refrigeration applications. These systems continuously optimize compressor sequencing, condenser fan operation, and expansion valve positions based on real-time conditions and forecasted demands.

Material selection for heat exchange surfaces also plays a crucial role in long-term energy efficiency. Surfaces engineered to resist fouling and frost accumulation maintain heat transfer effectiveness over extended operational periods, reducing the frequency of energy-intensive defrost cycles and system downtime.

For industrial implementation, phased deployment approaches often prove most successful. Initial focus on instrumentation upgrades and control system optimization provides immediate efficiency gains while generating operational data to inform subsequent mechanical system modifications. This strategy allows facilities to realize incremental benefits while building the technical and financial case for more substantial capital investments in advanced refrigeration technologies.

Primary among these strategies is heat integration across the industrial system. By identifying opportunities to recover and repurpose waste heat from various process streams, facilities can significantly reduce the energy burden on refrigeration systems. Advanced heat exchangers with enhanced surface designs can facilitate more efficient thermal transfer between process streams, minimizing the temperature differential required for effective operation.

Variable speed drives for compressors and pumps offer another substantial opportunity for energy conservation. These systems allow equipment to operate at precisely the required capacity rather than cycling on and off at fixed speeds, resulting in smoother operation and reduced energy consumption during partial load conditions. Implementation data suggests energy savings of 15-30% compared to conventional fixed-speed systems.

Cascade refrigeration configurations present particularly promising solutions for CO2 desublimation applications. By utilizing multiple refrigerants with complementary thermodynamic properties across different temperature ranges, these systems can achieve higher overall efficiency than single-refrigerant cycles. The upper stages typically employ conventional refrigerants, while lower stages may utilize specialized fluids optimized for the cryogenic temperatures required for CO2 solidification.

Advanced control algorithms represent another frontier in optimization. Model predictive control (MPC) systems that anticipate load changes and adjust operating parameters proactively rather than reactively have demonstrated energy savings of 10-20% in industrial refrigeration applications. These systems continuously optimize compressor sequencing, condenser fan operation, and expansion valve positions based on real-time conditions and forecasted demands.

Material selection for heat exchange surfaces also plays a crucial role in long-term energy efficiency. Surfaces engineered to resist fouling and frost accumulation maintain heat transfer effectiveness over extended operational periods, reducing the frequency of energy-intensive defrost cycles and system downtime.

For industrial implementation, phased deployment approaches often prove most successful. Initial focus on instrumentation upgrades and control system optimization provides immediate efficiency gains while generating operational data to inform subsequent mechanical system modifications. This strategy allows facilities to realize incremental benefits while building the technical and financial case for more substantial capital investments in advanced refrigeration technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!