Valuation Of Cryogenic Capture For Industrial Clusters And CCUS Hubs

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Carbon Capture Technology Evolution and Objectives

Cryogenic Carbon Capture (CCC) technology has evolved significantly over the past three decades, transitioning from theoretical concepts to practical applications in industrial settings. Initially developed in the 1990s as a potential method for separating gases at extremely low temperatures, CCC has gained renewed attention in the 2000s as climate change mitigation became a global priority. The fundamental principle behind this technology involves cooling flue gases to temperatures where CO2 solidifies (approximately -140°C), allowing for its physical separation from other gases.

The evolution of CCC technology has been marked by several key milestones. Early laboratory-scale demonstrations in the early 2000s proved the concept's viability, while the 2010s saw significant improvements in energy efficiency and process integration. Recent advancements have focused on reducing the substantial energy requirements that initially limited commercial adoption, with innovations in heat exchange systems and refrigeration cycles yielding energy consumption reductions of approximately 30-45% compared to first-generation designs.

The primary objective of CCC technology development for industrial clusters and CCUS hubs is to achieve cost-effective carbon capture with capture rates exceeding 95% while maintaining energy penalties below 15% of the original process. This represents a significant improvement over conventional amine-based capture systems that typically achieve 85-90% capture rates with higher energy penalties.

Secondary objectives include enhancing operational flexibility to accommodate the variable emission profiles characteristic of industrial clusters, which often contain diverse facilities with different operational patterns and CO2 concentrations. Integration capabilities with existing infrastructure represent another critical goal, as retrofitting rather than replacing industrial assets significantly improves economic feasibility.

The technology roadmap for CCC includes near-term objectives (2023-2025) focused on pilot demonstrations at industrial sites, mid-term goals (2026-2030) targeting commercial-scale implementation within industrial clusters, and long-term ambitions (beyond 2030) aiming for standardized modular systems that can be rapidly deployed across various industrial settings.

From a technical perspective, specific objectives include reducing the temperature required for CO2 desublimation, developing more efficient heat integration systems, and creating advanced materials capable of withstanding cryogenic cycling without degradation. These improvements collectively aim to position CCC as a viable alternative to conventional carbon capture technologies, particularly for industrial clusters where emission sources are concentrated and infrastructure can be shared.

The evolution of CCC technology has been marked by several key milestones. Early laboratory-scale demonstrations in the early 2000s proved the concept's viability, while the 2010s saw significant improvements in energy efficiency and process integration. Recent advancements have focused on reducing the substantial energy requirements that initially limited commercial adoption, with innovations in heat exchange systems and refrigeration cycles yielding energy consumption reductions of approximately 30-45% compared to first-generation designs.

The primary objective of CCC technology development for industrial clusters and CCUS hubs is to achieve cost-effective carbon capture with capture rates exceeding 95% while maintaining energy penalties below 15% of the original process. This represents a significant improvement over conventional amine-based capture systems that typically achieve 85-90% capture rates with higher energy penalties.

Secondary objectives include enhancing operational flexibility to accommodate the variable emission profiles characteristic of industrial clusters, which often contain diverse facilities with different operational patterns and CO2 concentrations. Integration capabilities with existing infrastructure represent another critical goal, as retrofitting rather than replacing industrial assets significantly improves economic feasibility.

The technology roadmap for CCC includes near-term objectives (2023-2025) focused on pilot demonstrations at industrial sites, mid-term goals (2026-2030) targeting commercial-scale implementation within industrial clusters, and long-term ambitions (beyond 2030) aiming for standardized modular systems that can be rapidly deployed across various industrial settings.

From a technical perspective, specific objectives include reducing the temperature required for CO2 desublimation, developing more efficient heat integration systems, and creating advanced materials capable of withstanding cryogenic cycling without degradation. These improvements collectively aim to position CCC as a viable alternative to conventional carbon capture technologies, particularly for industrial clusters where emission sources are concentrated and infrastructure can be shared.

Market Analysis for CCUS in Industrial Clusters

The Carbon Capture, Utilization, and Storage (CCUS) market within industrial clusters represents a significant opportunity for decarbonization efforts globally. Current market assessments indicate that industrial clusters account for approximately 20% of global CO2 emissions, making them prime targets for CCUS implementation. These concentrated emission sources create economies of scale that can substantially reduce the per-ton cost of carbon capture.

Market demand for CCUS solutions in industrial clusters is being driven by increasingly stringent emissions regulations, carbon pricing mechanisms, and corporate sustainability commitments. The International Energy Agency projects that CCUS capacity needs to increase from current levels of around 40 million tonnes per year to over 5.6 billion tonnes by 2050 to meet climate goals. Industrial clusters, particularly those with high-emission industries like cement, steel, and chemicals, represent the most economically viable early adoption markets.

Regional market analysis reveals varying levels of CCUS development. Europe leads with several advanced industrial cluster projects, particularly in the North Sea region where existing infrastructure and supportive policy frameworks accelerate deployment. The Port of Rotterdam's Porthos project and the UK's Net Zero Teesside exemplify this trend. In North America, the Gulf Coast industrial corridor presents significant opportunities due to its concentration of petrochemical facilities and proximity to geological storage sites.

The Asia-Pacific region shows the highest growth potential, with China and India's expanding industrial bases creating substantial demand for decarbonization solutions. Japan and South Korea are investing heavily in CCUS technologies to meet their climate commitments while maintaining industrial competitiveness.

Market segmentation within industrial clusters reveals that cryogenic capture technologies are particularly well-suited for facilities with high-purity CO2 streams, such as hydrogen production, natural gas processing, and certain chemical manufacturing processes. The technology's ability to produce high-purity liquid CO2 creates additional value streams through potential utilization pathways.

Financial analysis indicates that the total addressable market for CCUS in industrial clusters could reach $200 billion by 2030. However, market penetration remains contingent on continued cost reductions, with current capture costs ranging from $50-150 per ton depending on the application and concentration of CO2 in flue gas streams.

Customer demand is increasingly driven by the concept of "green premiums" for low-carbon industrial products. Major corporations in sectors from automotive to consumer goods are willing to pay premium prices for materials produced with lower carbon footprints, creating pull-through demand for CCUS-enabled industrial production.

Market demand for CCUS solutions in industrial clusters is being driven by increasingly stringent emissions regulations, carbon pricing mechanisms, and corporate sustainability commitments. The International Energy Agency projects that CCUS capacity needs to increase from current levels of around 40 million tonnes per year to over 5.6 billion tonnes by 2050 to meet climate goals. Industrial clusters, particularly those with high-emission industries like cement, steel, and chemicals, represent the most economically viable early adoption markets.

Regional market analysis reveals varying levels of CCUS development. Europe leads with several advanced industrial cluster projects, particularly in the North Sea region where existing infrastructure and supportive policy frameworks accelerate deployment. The Port of Rotterdam's Porthos project and the UK's Net Zero Teesside exemplify this trend. In North America, the Gulf Coast industrial corridor presents significant opportunities due to its concentration of petrochemical facilities and proximity to geological storage sites.

The Asia-Pacific region shows the highest growth potential, with China and India's expanding industrial bases creating substantial demand for decarbonization solutions. Japan and South Korea are investing heavily in CCUS technologies to meet their climate commitments while maintaining industrial competitiveness.

Market segmentation within industrial clusters reveals that cryogenic capture technologies are particularly well-suited for facilities with high-purity CO2 streams, such as hydrogen production, natural gas processing, and certain chemical manufacturing processes. The technology's ability to produce high-purity liquid CO2 creates additional value streams through potential utilization pathways.

Financial analysis indicates that the total addressable market for CCUS in industrial clusters could reach $200 billion by 2030. However, market penetration remains contingent on continued cost reductions, with current capture costs ranging from $50-150 per ton depending on the application and concentration of CO2 in flue gas streams.

Customer demand is increasingly driven by the concept of "green premiums" for low-carbon industrial products. Major corporations in sectors from automotive to consumer goods are willing to pay premium prices for materials produced with lower carbon footprints, creating pull-through demand for CCUS-enabled industrial production.

Cryogenic Capture Technical Challenges and Global Status

Cryogenic carbon capture (CCC) technology faces several significant technical challenges despite its promising potential for industrial decarbonization. The primary challenge lies in the high energy consumption required for cooling flue gases to cryogenic temperatures, typically between -100°C and -140°C, which substantially impacts the overall energy efficiency of the capture process. This energy penalty remains a critical barrier to widespread commercial adoption, particularly in energy-intensive industrial clusters.

Material selection presents another substantial challenge, as components must withstand extreme temperature cycling while maintaining structural integrity. Conventional materials often become brittle or lose mechanical properties at cryogenic temperatures, necessitating specialized alloys and composites that significantly increase capital costs. Additionally, thermal stress management during temperature transitions requires sophisticated engineering solutions to prevent system failures.

Process integration complexity emerges when implementing cryogenic capture within existing industrial facilities. The technology requires substantial physical footprint and auxiliary systems, creating spatial constraints in brownfield industrial sites. Furthermore, the integration of heat recovery systems to improve energy efficiency adds another layer of complexity to system design and operation.

Globally, cryogenic carbon capture technology remains predominantly at the pilot and demonstration scale. The United States leads research efforts through initiatives at Brigham Young University and Sustainable Energy Solutions (SES), which have developed proprietary CCC processes achieving over 95% CO2 capture rates in controlled environments. Their Cryogenic Carbon Capture™ technology has progressed to small-scale field testing at coal-fired power plants.

In Europe, research consortia in Norway, Germany, and the Netherlands are advancing cryogenic separation technologies with particular focus on industrial applications. The EU's Horizon Europe program has funded several demonstration projects targeting cement and steel production facilities, though most remain at Technology Readiness Level (TRL) 5-6.

Asian development is accelerating, particularly in China and South Korea, where government-backed initiatives are exploring cryogenic capture for industrial clusters. Japan's NEDO (New Energy and Industrial Technology Development Organization) has invested in cryogenic separation research specifically tailored for densely packed industrial zones where space constraints limit other capture technologies.

Despite these global efforts, full-scale commercial deployment remains limited. Current installations primarily serve as technology validation platforms rather than operational carbon management solutions. The technology shows particular promise for industrial clusters and CCUS hubs due to potential economies of scale and shared infrastructure, but requires further advancement in energy efficiency and cost reduction before achieving widespread commercial viability.

Material selection presents another substantial challenge, as components must withstand extreme temperature cycling while maintaining structural integrity. Conventional materials often become brittle or lose mechanical properties at cryogenic temperatures, necessitating specialized alloys and composites that significantly increase capital costs. Additionally, thermal stress management during temperature transitions requires sophisticated engineering solutions to prevent system failures.

Process integration complexity emerges when implementing cryogenic capture within existing industrial facilities. The technology requires substantial physical footprint and auxiliary systems, creating spatial constraints in brownfield industrial sites. Furthermore, the integration of heat recovery systems to improve energy efficiency adds another layer of complexity to system design and operation.

Globally, cryogenic carbon capture technology remains predominantly at the pilot and demonstration scale. The United States leads research efforts through initiatives at Brigham Young University and Sustainable Energy Solutions (SES), which have developed proprietary CCC processes achieving over 95% CO2 capture rates in controlled environments. Their Cryogenic Carbon Capture™ technology has progressed to small-scale field testing at coal-fired power plants.

In Europe, research consortia in Norway, Germany, and the Netherlands are advancing cryogenic separation technologies with particular focus on industrial applications. The EU's Horizon Europe program has funded several demonstration projects targeting cement and steel production facilities, though most remain at Technology Readiness Level (TRL) 5-6.

Asian development is accelerating, particularly in China and South Korea, where government-backed initiatives are exploring cryogenic capture for industrial clusters. Japan's NEDO (New Energy and Industrial Technology Development Organization) has invested in cryogenic separation research specifically tailored for densely packed industrial zones where space constraints limit other capture technologies.

Despite these global efforts, full-scale commercial deployment remains limited. Current installations primarily serve as technology validation platforms rather than operational carbon management solutions. The technology shows particular promise for industrial clusters and CCUS hubs due to potential economies of scale and shared infrastructure, but requires further advancement in energy efficiency and cost reduction before achieving widespread commercial viability.

Current Cryogenic Capture Implementation Approaches

01 Economic valuation of carbon capture technologies

Economic models and methodologies for valuing carbon capture technologies, particularly cryogenic capture systems. These approaches include cost-benefit analysis, risk assessment frameworks, and financial modeling techniques that help quantify the economic viability of implementing cryogenic carbon capture solutions. The valuation considers factors such as operational costs, capital investment requirements, and potential revenue streams from carbon credits or tax incentives.- Carbon capture valuation methods: Various methods for valuing carbon capture technologies in cryogenic systems, including financial modeling approaches that assess the economic viability of carbon capture investments. These methods incorporate factors such as operational costs, efficiency metrics, and potential revenue streams from captured carbon. The valuation frameworks help stakeholders make informed decisions about implementing cryogenic carbon capture technologies by quantifying their economic benefits and risks.

- Cryogenic carbon capture technologies: Technical innovations in cryogenic systems designed specifically for carbon capture applications. These technologies utilize low-temperature processes to separate and capture carbon dioxide from industrial emissions or ambient air. The systems employ specialized equipment and processes that cool gas streams to temperatures where CO2 solidifies or liquefies, allowing for efficient separation. These cryogenic approaches offer advantages in capture efficiency and energy consumption compared to conventional carbon capture methods.

- Environmental credit trading systems: Market-based mechanisms that enable the trading of environmental credits generated from carbon capture activities, including those using cryogenic technologies. These systems establish frameworks for quantifying, verifying, and monetizing carbon reduction achievements. The trading platforms facilitate transactions between carbon capturers and entities seeking to offset their emissions, creating financial incentives for implementing cryogenic capture solutions while helping organizations meet regulatory requirements or voluntary sustainability goals.

- Risk assessment frameworks for cryogenic projects: Methodologies for evaluating and managing risks associated with cryogenic carbon capture investments. These frameworks address technical, operational, financial, and regulatory risks specific to low-temperature carbon capture systems. They incorporate probabilistic models, sensitivity analyses, and scenario planning to quantify potential impacts on project valuation. The risk assessment approaches help investors and operators identify mitigation strategies and make more accurate valuations of cryogenic capture initiatives under uncertainty.

- Data analytics for optimizing cryogenic capture value: Advanced data analytics and computational methods that enhance the economic value of cryogenic carbon capture systems. These approaches leverage machine learning, artificial intelligence, and big data processing to optimize operational parameters, predict maintenance needs, and maximize capture efficiency. The analytics platforms integrate real-time monitoring with predictive modeling to improve decision-making and increase the financial returns from cryogenic capture investments through continuous performance optimization.

02 Carbon credit trading and environmental asset valuation

Systems and methods for trading carbon credits and valuing environmental assets related to cryogenic capture technologies. These include market-based approaches for determining the value of carbon reduction achieved through cryogenic capture, platforms for trading carbon credits, and mechanisms for monetizing environmental benefits. The valuation frameworks incorporate regulatory compliance values, voluntary market considerations, and long-term environmental impact assessments.Expand Specific Solutions03 Risk management and insurance for carbon capture projects

Risk assessment and insurance solutions specifically designed for cryogenic carbon capture projects. These include methodologies for identifying, quantifying, and mitigating financial and operational risks associated with implementing cryogenic capture technologies. Insurance products and risk management strategies help protect investments in carbon capture infrastructure while providing frameworks for valuing risk reduction and certainty in project outcomes.Expand Specific Solutions04 Data-driven valuation models for cryogenic technologies

Advanced computational and data-driven approaches for valuing cryogenic capture technologies. These include machine learning algorithms, predictive analytics, and big data processing systems that enhance the accuracy of financial projections and technology valuations. The models incorporate technical performance data, market trends, and regulatory scenarios to provide dynamic valuation frameworks that adapt to changing conditions and technological improvements.Expand Specific Solutions05 Investment frameworks for cryogenic capture infrastructure

Structured investment approaches and financial frameworks specifically designed for funding cryogenic capture infrastructure. These include project finance models, public-private partnership structures, and investment valuation methodologies that address the unique characteristics of carbon capture projects. The frameworks incorporate long-term value creation, stakeholder returns, and sustainable development considerations while providing mechanisms for attracting capital to cryogenic capture initiatives.Expand Specific Solutions

Key Industry Stakeholders in CCUS Hub Development

The cryogenic capture market for industrial clusters and CCUS hubs is in an early growth phase, characterized by increasing technological maturity and expanding applications. The global market is projected to grow significantly as carbon capture becomes essential for emission reduction targets. Leading academic institutions like China University of Mining & Technology and Harbin Institute of Technology are advancing fundamental research, while major energy corporations including China National Petroleum, PetroChina, and ExxonMobil are driving commercial implementation. Specialized technology providers such as Linde GmbH and Sumitomo Cryogenics are developing critical equipment solutions. The competitive landscape features collaboration between research institutions and industry players, with state-owned enterprises in China making substantial investments alongside international oil and gas companies to scale cryogenic carbon capture technologies for industrial decarbonization.

China National Petroleum Corp.

Technical Solution: China National Petroleum Corporation (CNPC) has developed a comprehensive cryogenic carbon capture system specifically designed for integration with natural gas processing facilities and refineries. Their technology employs a multi-stage cryogenic separation process that progressively cools flue gases to temperatures around -140°C, allowing for selective condensation and separation of CO2. CNPC's approach incorporates heat integration systems that recover cold energy from the liquefied CO2 stream to pre-cool incoming flue gases, significantly improving energy efficiency. The company has implemented this technology at several of their industrial facilities across China, including the Jilin Oil Field CCUS project, which captures approximately 200,000 tons of CO2 annually for enhanced oil recovery operations. CNPC has further advanced their cryogenic technology by developing specialized materials resistant to the extreme temperature conditions required for operation, reducing maintenance costs and extending equipment lifespan. Their system achieves capture rates of 85-95% while producing high-purity CO2 suitable for industrial applications.

Strengths: Excellent integration with existing oil and gas infrastructure; proven deployment at commercial scale; dual-purpose capability for both sequestration and enhanced oil recovery. Weaknesses: Relatively high energy consumption; primarily optimized for natural gas processing applications; requires significant cooling water resources.

Southwest Research Institute

Technical Solution: Southwest Research Institute (SwRI) has developed an advanced Cryogenic Carbon Capture™ (CCC) technology that utilizes a novel approach to separate CO2 from industrial emissions. Their system employs a proprietary process that rapidly cools flue gases to temperatures where CO2 desublimates directly into solid form while other gases remain vapor. SwRI's technology features a specialized heat exchanger design that recovers over 95% of the cooling energy, dramatically reducing the energy penalty typically associated with cryogenic processes. The institute has demonstrated their technology at pilot scale, achieving capture rates exceeding 95% with energy requirements approximately 30% lower than conventional amine-based systems. Their approach is particularly well-suited for industrial clusters due to its modular design, allowing for scalable implementation across diverse industrial facilities. SwRI has further enhanced their technology by developing specialized CO2 handling systems that efficiently convert the solid CO2 into liquid form for transport to sequestration sites or utilization facilities. The system's compact footprint makes it ideal for retrofitting existing industrial facilities with limited available space, a common challenge in industrial clusters.

Strengths: Exceptional energy efficiency through advanced heat recovery; modular design enabling flexible deployment; high capture rates across variable flue gas compositions. Weaknesses: Limited commercial-scale demonstration compared to larger industry players; higher capital costs for initial deployment; requires specialized training for operational personnel.

Critical Patents and Innovations in Cryogenic Separation

CCUS (carbon capture utilization and storage) system for exploiting thickened oil reservoirs based on optimal flue gas CO<sub>2 </sub>enrichment ratio and working method thereof

PatentActiveUS11208872B2

Innovation

- A CCUS system incorporating a flue gas CO2 enrichment unit with a two-stage air separation process and a boiler injection gas premixed tank to adjust the CO2 and N2 proportions dynamically, optimizing the flue gas CO2 enrichment ratio for reduced energy consumption and enhanced oil production.

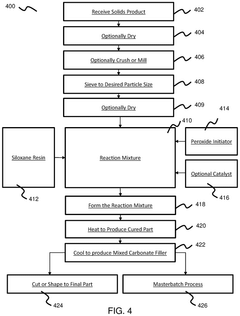

Process for producing a mixed filler

PatentPendingUS20250051538A1

Innovation

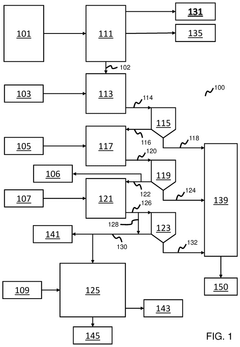

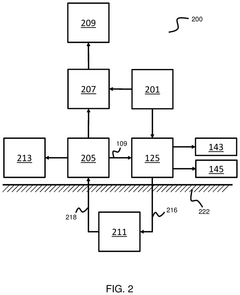

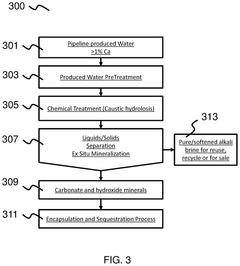

- An integrated CCUS (Carbon Capture, Utilization, and Storage) process that converts CO2 into Group 2 carbonates through mineral carbonation of produced water, followed by an encapsulation and sequestration process to produce a mixed filler from the carbonates, which can be used in construction materials and as a feedstock for chloralkali and hydrogen production.

Economic Feasibility Assessment of Cryogenic Capture

The economic feasibility of cryogenic carbon capture technology for industrial clusters and CCUS hubs depends on several critical factors that must be carefully evaluated. Initial capital expenditure represents a significant barrier, with cryogenic systems requiring substantial investment in specialized equipment such as heat exchangers, cryogenic vessels, and compression systems. Current estimates place these costs between $60-80 per tonne of CO2 captured, which remains higher than some competing technologies like amine-based systems.

Operational expenses present another crucial consideration, primarily dominated by energy consumption. Cryogenic processes require significant cooling power, typically consuming 0.8-1.2 MWh per tonne of CO2 captured. However, when integrated within industrial clusters, waste heat recovery and energy integration opportunities can potentially reduce these costs by 15-25%, improving the overall economics substantially.

Scale economies play a pivotal role in determining feasibility. Analysis of industrial clusters indicates that cryogenic capture becomes increasingly competitive at larger scales, with the levelized cost of capture decreasing by approximately 30% when scaling from 100,000 to 1 million tonnes of CO2 annually. This makes the technology particularly attractive for large industrial hubs where multiple emission sources can be aggregated.

The technology's compatibility with existing infrastructure represents a significant advantage. Unlike some alternative capture methods, cryogenic systems can be retrofitted to existing facilities with minimal disruption to ongoing operations. This adaptability reduces implementation costs by an estimated 10-15% compared to technologies requiring more extensive modifications.

Market conditions and carbon pricing mechanisms heavily influence economic viability. Current carbon prices in major markets range from $25-85 per tonne, with projections suggesting increases to $100-150 by 2030. Sensitivity analysis indicates that cryogenic capture becomes economically viable without subsidies when carbon prices exceed approximately $70-80 per tonne, depending on specific implementation conditions.

Transportation and storage costs must also be factored into comprehensive economic assessments. The high-purity CO2 stream produced by cryogenic capture (typically >99%) reduces downstream purification requirements, potentially saving $5-10 per tonne in transportation and storage costs compared to lower-purity capture methods. This advantage becomes particularly valuable in hub configurations where transportation infrastructure costs can be shared among multiple emitters.

Operational expenses present another crucial consideration, primarily dominated by energy consumption. Cryogenic processes require significant cooling power, typically consuming 0.8-1.2 MWh per tonne of CO2 captured. However, when integrated within industrial clusters, waste heat recovery and energy integration opportunities can potentially reduce these costs by 15-25%, improving the overall economics substantially.

Scale economies play a pivotal role in determining feasibility. Analysis of industrial clusters indicates that cryogenic capture becomes increasingly competitive at larger scales, with the levelized cost of capture decreasing by approximately 30% when scaling from 100,000 to 1 million tonnes of CO2 annually. This makes the technology particularly attractive for large industrial hubs where multiple emission sources can be aggregated.

The technology's compatibility with existing infrastructure represents a significant advantage. Unlike some alternative capture methods, cryogenic systems can be retrofitted to existing facilities with minimal disruption to ongoing operations. This adaptability reduces implementation costs by an estimated 10-15% compared to technologies requiring more extensive modifications.

Market conditions and carbon pricing mechanisms heavily influence economic viability. Current carbon prices in major markets range from $25-85 per tonne, with projections suggesting increases to $100-150 by 2030. Sensitivity analysis indicates that cryogenic capture becomes economically viable without subsidies when carbon prices exceed approximately $70-80 per tonne, depending on specific implementation conditions.

Transportation and storage costs must also be factored into comprehensive economic assessments. The high-purity CO2 stream produced by cryogenic capture (typically >99%) reduces downstream purification requirements, potentially saving $5-10 per tonne in transportation and storage costs compared to lower-purity capture methods. This advantage becomes particularly valuable in hub configurations where transportation infrastructure costs can be shared among multiple emitters.

Policy Frameworks Supporting Industrial CCUS Deployment

The development of effective policy frameworks is crucial for accelerating industrial CCUS deployment, particularly for cryogenic capture technologies within industrial clusters and CCUS hubs. Current policy landscapes across major economies demonstrate varying approaches to incentivizing carbon capture technologies, with significant implications for cryogenic capture valuation.

Carbon pricing mechanisms represent a fundamental policy tool, with the EU Emissions Trading System (ETS) and similar schemes in the UK and Canada providing economic signals that enhance the value proposition of cryogenic capture systems. These mechanisms effectively transform carbon emissions from externalities into quantifiable financial liabilities, improving the cost-benefit analysis for industrial adopters.

Tax incentives have emerged as powerful catalysts for CCUS deployment, with the U.S. 45Q tax credit offering up to $85 per tonne of CO2 permanently sequestered. Similar frameworks in Canada, Norway, and the Netherlands provide substantial financial support that directly impacts the economic viability of cryogenic capture installations within industrial clusters.

Public funding programs targeting research, development, and demonstration projects have accelerated technological advancement and commercial readiness of cryogenic capture systems. The EU Innovation Fund, UK's CCUS Infrastructure Fund, and similar initiatives in Japan and Australia have allocated billions toward scaling industrial decarbonization technologies, creating pathways for cryogenic capture integration into industrial processes.

Regulatory frameworks establishing technical standards, permitting processes, and liability regimes for CO2 transport and storage infrastructure are equally important for enabling industrial CCUS deployment. Countries with well-developed regulatory environments, such as Norway and the UK, demonstrate how policy certainty can facilitate investment in shared infrastructure necessary for industrial clusters and CCUS hubs.

Cross-border cooperation frameworks are increasingly recognized as essential for optimizing CCUS deployment. The London Protocol amendment allowing transboundary CO2 transport for storage purposes and regional initiatives like the North Sea Basin Task Force illustrate how international policy coordination can enhance the economic feasibility of large-scale cryogenic capture projects serving multiple industrial clusters.

Industrial strategy policies that identify priority sectors for decarbonization and establish sectoral emissions reduction targets provide important market signals for cryogenic capture technology providers. These frameworks help create predictable demand trajectories that support investment decisions and technology development pathways aligned with national climate commitments.

Carbon pricing mechanisms represent a fundamental policy tool, with the EU Emissions Trading System (ETS) and similar schemes in the UK and Canada providing economic signals that enhance the value proposition of cryogenic capture systems. These mechanisms effectively transform carbon emissions from externalities into quantifiable financial liabilities, improving the cost-benefit analysis for industrial adopters.

Tax incentives have emerged as powerful catalysts for CCUS deployment, with the U.S. 45Q tax credit offering up to $85 per tonne of CO2 permanently sequestered. Similar frameworks in Canada, Norway, and the Netherlands provide substantial financial support that directly impacts the economic viability of cryogenic capture installations within industrial clusters.

Public funding programs targeting research, development, and demonstration projects have accelerated technological advancement and commercial readiness of cryogenic capture systems. The EU Innovation Fund, UK's CCUS Infrastructure Fund, and similar initiatives in Japan and Australia have allocated billions toward scaling industrial decarbonization technologies, creating pathways for cryogenic capture integration into industrial processes.

Regulatory frameworks establishing technical standards, permitting processes, and liability regimes for CO2 transport and storage infrastructure are equally important for enabling industrial CCUS deployment. Countries with well-developed regulatory environments, such as Norway and the UK, demonstrate how policy certainty can facilitate investment in shared infrastructure necessary for industrial clusters and CCUS hubs.

Cross-border cooperation frameworks are increasingly recognized as essential for optimizing CCUS deployment. The London Protocol amendment allowing transboundary CO2 transport for storage purposes and regional initiatives like the North Sea Basin Task Force illustrate how international policy coordination can enhance the economic feasibility of large-scale cryogenic capture projects serving multiple industrial clusters.

Industrial strategy policies that identify priority sectors for decarbonization and establish sectoral emissions reduction targets provide important market signals for cryogenic capture technology providers. These frameworks help create predictable demand trajectories that support investment decisions and technology development pathways aligned with national climate commitments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!