Instrumenting Cryogenic Capture For Remote And Offshore Operations

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Capture Technology Evolution and Objectives

Cryogenic capture technology has evolved significantly over the past decades, transforming from laboratory-scale experiments to industrial applications. Initially developed for gas separation in petrochemical industries during the 1960s, cryogenic capture systems have progressively expanded into environmental applications, particularly for carbon dioxide capture and storage (CCS). The fundamental principle involves cooling gas streams to temperatures where target components condense or solidify, allowing for their separation and collection.

The evolution of cryogenic capture technology has been marked by several key milestones. In the 1980s, the introduction of more efficient heat exchangers significantly reduced energy requirements. The 1990s saw the development of specialized materials capable of withstanding extreme temperature cycling, enhancing system durability. By the early 2000s, integration with automated control systems enabled more precise operation and monitoring, critical for remote applications.

Recent technological advancements have focused on miniaturization and modularization, making cryogenic systems more adaptable to space-constrained environments such as offshore platforms. Innovations in insulation materials have dramatically improved thermal efficiency, reducing operational costs and expanding the feasibility of deployment in challenging locations.

The primary objective of instrumenting cryogenic capture for remote and offshore operations is to develop robust, autonomous systems capable of functioning reliably in harsh environments with minimal human intervention. This includes creating sensor networks that can withstand extreme temperature gradients while providing accurate, real-time data on system performance and captured material composition.

Secondary objectives include reducing the energy footprint of cryogenic capture processes, as energy availability is often limited in remote and offshore settings. This necessitates the development of more efficient cooling cycles and heat recovery systems tailored to the unique constraints of these environments.

Another critical goal is enhancing system resilience against environmental challenges specific to offshore operations, including salt spray corrosion, platform movement, and space limitations. This requires innovative approaches to equipment design, material selection, and system integration.

Looking forward, the technology aims to achieve greater automation and predictive maintenance capabilities through advanced instrumentation and artificial intelligence integration. This would enable early detection of potential failures and optimization of operational parameters based on changing environmental conditions, ultimately reducing operational costs and increasing capture efficiency in these challenging settings.

The evolution of cryogenic capture technology has been marked by several key milestones. In the 1980s, the introduction of more efficient heat exchangers significantly reduced energy requirements. The 1990s saw the development of specialized materials capable of withstanding extreme temperature cycling, enhancing system durability. By the early 2000s, integration with automated control systems enabled more precise operation and monitoring, critical for remote applications.

Recent technological advancements have focused on miniaturization and modularization, making cryogenic systems more adaptable to space-constrained environments such as offshore platforms. Innovations in insulation materials have dramatically improved thermal efficiency, reducing operational costs and expanding the feasibility of deployment in challenging locations.

The primary objective of instrumenting cryogenic capture for remote and offshore operations is to develop robust, autonomous systems capable of functioning reliably in harsh environments with minimal human intervention. This includes creating sensor networks that can withstand extreme temperature gradients while providing accurate, real-time data on system performance and captured material composition.

Secondary objectives include reducing the energy footprint of cryogenic capture processes, as energy availability is often limited in remote and offshore settings. This necessitates the development of more efficient cooling cycles and heat recovery systems tailored to the unique constraints of these environments.

Another critical goal is enhancing system resilience against environmental challenges specific to offshore operations, including salt spray corrosion, platform movement, and space limitations. This requires innovative approaches to equipment design, material selection, and system integration.

Looking forward, the technology aims to achieve greater automation and predictive maintenance capabilities through advanced instrumentation and artificial intelligence integration. This would enable early detection of potential failures and optimization of operational parameters based on changing environmental conditions, ultimately reducing operational costs and increasing capture efficiency in these challenging settings.

Market Analysis for Remote Cryogenic Capture Systems

The global market for remote cryogenic capture systems is experiencing significant growth, driven by increasing demand for efficient carbon capture solutions in offshore and remote operations. Current market valuations indicate that the carbon capture and storage (CCS) market is projected to reach approximately $7 billion by 2026, with cryogenic capture technologies representing a growing segment within this space. The compound annual growth rate (CAGR) for specialized cryogenic instrumentation in remote applications is estimated at 12-15% through 2030.

Key market drivers include stringent environmental regulations, particularly in regions like the European Union where carbon pricing mechanisms are becoming more robust. The EU Emissions Trading System (ETS) has seen carbon prices rise to over €80 per ton in recent periods, creating strong economic incentives for industrial emitters to adopt capture technologies. Similarly, tax credits such as the 45Q in the United States, which offers up to $85 per ton for captured and sequestered carbon, are stimulating market growth.

The offshore oil and gas sector represents the largest current market segment, accounting for approximately 40% of the total addressable market. These operations face unique challenges in implementing carbon capture technologies due to space constraints, harsh environmental conditions, and remote locations. The shipping industry is emerging as another significant market, with International Maritime Organization (IMO) regulations targeting 50% reduction in greenhouse gas emissions by 2050 driving adoption.

Geographically, the North Sea region leads in offshore cryogenic capture implementation, with significant projects underway by companies like Equinor and Shell. The Gulf of Mexico and Southeast Asian offshore fields are rapidly growing markets, with projected investment increases of 25% and 30% respectively over the next five years.

Customer pain points in this market include high capital expenditure requirements, with typical installation costs for offshore cryogenic systems ranging from $30-50 million depending on capacity and location. Operational reliability in remote environments remains a critical concern, with customers reporting that system downtime can cost up to $100,000 per day in lost production and compliance penalties.

Market research indicates that customers prioritize three key factors when selecting remote cryogenic capture systems: reliability in harsh environments (cited by 87% of surveyed operators), energy efficiency (76%), and integration capabilities with existing infrastructure (68%). These priorities are shaping product development roadmaps across the industry, with increasing focus on modular designs that can be easily deployed and maintained in remote locations.

Key market drivers include stringent environmental regulations, particularly in regions like the European Union where carbon pricing mechanisms are becoming more robust. The EU Emissions Trading System (ETS) has seen carbon prices rise to over €80 per ton in recent periods, creating strong economic incentives for industrial emitters to adopt capture technologies. Similarly, tax credits such as the 45Q in the United States, which offers up to $85 per ton for captured and sequestered carbon, are stimulating market growth.

The offshore oil and gas sector represents the largest current market segment, accounting for approximately 40% of the total addressable market. These operations face unique challenges in implementing carbon capture technologies due to space constraints, harsh environmental conditions, and remote locations. The shipping industry is emerging as another significant market, with International Maritime Organization (IMO) regulations targeting 50% reduction in greenhouse gas emissions by 2050 driving adoption.

Geographically, the North Sea region leads in offshore cryogenic capture implementation, with significant projects underway by companies like Equinor and Shell. The Gulf of Mexico and Southeast Asian offshore fields are rapidly growing markets, with projected investment increases of 25% and 30% respectively over the next five years.

Customer pain points in this market include high capital expenditure requirements, with typical installation costs for offshore cryogenic systems ranging from $30-50 million depending on capacity and location. Operational reliability in remote environments remains a critical concern, with customers reporting that system downtime can cost up to $100,000 per day in lost production and compliance penalties.

Market research indicates that customers prioritize three key factors when selecting remote cryogenic capture systems: reliability in harsh environments (cited by 87% of surveyed operators), energy efficiency (76%), and integration capabilities with existing infrastructure (68%). These priorities are shaping product development roadmaps across the industry, with increasing focus on modular designs that can be easily deployed and maintained in remote locations.

Current Challenges in Offshore Cryogenic Instrumentation

The offshore environment presents unique and severe challenges for cryogenic instrumentation systems. Extreme weather conditions, including high winds, heavy precipitation, and temperature fluctuations, significantly impact the reliability and performance of cryogenic equipment. Salt spray and high humidity levels accelerate corrosion of sensitive components, while the constant motion from waves and platform vibrations introduces mechanical stresses that conventional land-based systems are not designed to withstand.

Remote offshore locations face substantial logistical hurdles in maintaining cryogenic instrumentation. Limited accessibility restricts regular maintenance schedules, with some platforms only receiving technical support during scheduled maintenance windows or emergencies. This isolation necessitates robust, self-diagnostic systems capable of extended operation without human intervention, a requirement that current technology struggles to fulfill consistently.

Power management represents another critical challenge. Offshore facilities often operate with constrained power resources, making energy-efficient cryogenic systems essential. The high power consumption of cooling systems must be balanced against available energy supplies, particularly on platforms utilizing isolated power generation. Additionally, power fluctuations and outages can cause catastrophic failures in cryogenic systems if backup systems are inadequate.

Communication infrastructure limitations further complicate remote monitoring capabilities. Data transmission from offshore platforms frequently suffers from bandwidth constraints, latency issues, and intermittent connectivity. These limitations hamper real-time monitoring and control of cryogenic processes, delaying critical decision-making during operational anomalies.

Safety considerations are paramount in offshore environments where cryogenic failures can have severe consequences. The confined space of offshore platforms magnifies risks associated with cryogenic leaks or system failures. Current safety systems must evolve to provide more comprehensive protection while maintaining operational efficiency.

Regulatory compliance adds another layer of complexity. Offshore operations must navigate diverse international maritime regulations alongside industry-specific standards for cryogenic handling. These regulations often vary by jurisdiction, creating compliance challenges for global operations and necessitating adaptable instrumentation designs.

Integration with existing offshore infrastructure presents significant engineering challenges. Retrofitting cryogenic capture systems onto platforms not originally designed for such technology requires innovative approaches to space utilization, structural reinforcement, and system integration. The weight and footprint constraints of offshore platforms limit the scalability of conventional cryogenic instrumentation, driving the need for more compact, lightweight solutions.

Remote offshore locations face substantial logistical hurdles in maintaining cryogenic instrumentation. Limited accessibility restricts regular maintenance schedules, with some platforms only receiving technical support during scheduled maintenance windows or emergencies. This isolation necessitates robust, self-diagnostic systems capable of extended operation without human intervention, a requirement that current technology struggles to fulfill consistently.

Power management represents another critical challenge. Offshore facilities often operate with constrained power resources, making energy-efficient cryogenic systems essential. The high power consumption of cooling systems must be balanced against available energy supplies, particularly on platforms utilizing isolated power generation. Additionally, power fluctuations and outages can cause catastrophic failures in cryogenic systems if backup systems are inadequate.

Communication infrastructure limitations further complicate remote monitoring capabilities. Data transmission from offshore platforms frequently suffers from bandwidth constraints, latency issues, and intermittent connectivity. These limitations hamper real-time monitoring and control of cryogenic processes, delaying critical decision-making during operational anomalies.

Safety considerations are paramount in offshore environments where cryogenic failures can have severe consequences. The confined space of offshore platforms magnifies risks associated with cryogenic leaks or system failures. Current safety systems must evolve to provide more comprehensive protection while maintaining operational efficiency.

Regulatory compliance adds another layer of complexity. Offshore operations must navigate diverse international maritime regulations alongside industry-specific standards for cryogenic handling. These regulations often vary by jurisdiction, creating compliance challenges for global operations and necessitating adaptable instrumentation designs.

Integration with existing offshore infrastructure presents significant engineering challenges. Retrofitting cryogenic capture systems onto platforms not originally designed for such technology requires innovative approaches to space utilization, structural reinforcement, and system integration. The weight and footprint constraints of offshore platforms limit the scalability of conventional cryogenic instrumentation, driving the need for more compact, lightweight solutions.

Existing Instrumentation Solutions for Remote Operations

01 Cryogenic capture system design for enhanced efficiency

Cryogenic capture systems can be designed with specific components to enhance capture efficiency. These systems typically include specialized cooling mechanisms, temperature control units, and capture chambers that maintain optimal cryogenic conditions. The design focuses on maximizing contact between the target substance and the cold surfaces, ensuring rapid freezing and efficient capture of particles or gases. Advanced insulation materials and precise temperature gradients further improve the overall capture efficiency of these systems.- Cryogenic capture system design for enhanced efficiency: Cryogenic capture systems can be designed with specific components to enhance capture efficiency. These designs include specialized cooling mechanisms, thermal insulation, and flow control systems that optimize the capture of target substances at extremely low temperatures. The systems may incorporate staged cooling processes and precise temperature control to maximize capture rates while minimizing energy consumption.

- Instrumentation for monitoring cryogenic capture performance: Advanced instrumentation is crucial for monitoring and optimizing cryogenic capture efficiency. These instruments include temperature sensors, pressure gauges, flow meters, and composition analyzers that provide real-time data on capture conditions. Integrated monitoring systems allow for continuous assessment of capture efficiency and enable automatic adjustments to maintain optimal performance under varying conditions.

- Image capture technologies in cryogenic environments: Specialized image capture technologies have been developed for use in cryogenic environments. These technologies include cameras and optical systems designed to operate at extremely low temperatures without performance degradation. The systems incorporate thermal isolation, specialized materials, and protective housings to ensure reliable image capture while maintaining the integrity of the cryogenic environment.

- Efficiency enhancement through material selection and surface treatments: The efficiency of cryogenic capture systems can be significantly improved through careful selection of materials and surface treatments. Materials with specific thermal properties, adsorption characteristics, and durability at low temperatures can enhance capture rates. Surface modifications, coatings, and nano-structured materials can increase the effective surface area and binding sites for target substances, thereby improving overall capture efficiency.

- Control systems for optimizing cryogenic capture processes: Advanced control systems play a vital role in maximizing cryogenic capture efficiency. These systems incorporate artificial intelligence, machine learning algorithms, and predictive modeling to optimize operational parameters in real-time. Automated control mechanisms can adjust temperature gradients, flow rates, and pressure conditions to maintain peak efficiency despite variations in input composition or environmental conditions. These intelligent systems can significantly reduce energy consumption while improving capture rates.

02 Sensor integration for monitoring capture performance

Integration of advanced sensors in cryogenic capture instrumentation allows for real-time monitoring of capture performance and efficiency. These sensors can measure parameters such as temperature distribution, pressure variations, flow rates, and concentration of captured substances. The data collected enables automatic adjustments to optimize capture conditions and provides valuable feedback for system improvements. Sensor networks can also detect potential issues before they affect capture efficiency, ensuring consistent performance during operation.Expand Specific Solutions03 Image processing techniques for capture analysis

Advanced image processing techniques are employed in cryogenic capture systems to analyze and quantify capture efficiency. These techniques involve high-resolution imaging of captured particles or substances, followed by computational analysis to determine size distribution, concentration, and spatial arrangement. Machine learning algorithms can be applied to image data to identify patterns and optimize capture parameters. Real-time image analysis allows for immediate feedback on capture performance and enables adjustments to improve efficiency during operation.Expand Specific Solutions04 Flow dynamics optimization for improved capture

Optimizing flow dynamics within cryogenic capture systems significantly enhances capture efficiency. This involves careful design of flow channels, baffles, and capture surfaces to create ideal conditions for particle or gas interception. Computational fluid dynamics simulations help identify optimal flow patterns that maximize contact between the target substance and cryogenic surfaces. Turbulence control mechanisms and precise flow rate management ensure that capture efficiency remains high across varying operational conditions, while minimizing energy consumption and preventing bypass of target substances.Expand Specific Solutions05 Material selection for cryogenic capture surfaces

The selection of appropriate materials for cryogenic capture surfaces plays a crucial role in determining capture efficiency. Materials with high thermal conductivity ensure rapid cooling and freezing of target substances, while specific surface treatments can enhance adhesion properties. Nano-structured surfaces can increase the effective capture area and improve retention of captured particles. Corrosion-resistant and low-temperature tolerant materials extend the operational life of capture systems while maintaining consistent performance. Advanced composite materials may combine multiple beneficial properties to optimize capture efficiency across various target substances.Expand Specific Solutions

Leading Companies in Cryogenic Instrumentation Industry

The cryogenic capture technology for remote and offshore operations is in an early growth phase, characterized by increasing adoption but still evolving technical standards. The market is expanding rapidly, driven by stringent environmental regulations and the oil and gas industry's decarbonization efforts. Leading players include established energy giants like ExxonMobil Upstream Research and Equinor Energy, alongside specialized technology providers such as Quantinuum and Mustang Sampling. Research institutions including Zhejiang University, Fraunhofer-Gesellschaft, and Northwestern Polytechnical University are advancing fundamental technologies. Industrial gas specialists Air Liquide and Schlumberger are developing application-specific solutions. The competitive landscape reflects a mix of proprietary technologies from energy majors and innovative approaches from specialized firms, with increasing collaboration between industry and academic institutions to overcome technical challenges in harsh environments.

Exxonmobil Upstream Research Co.

Technical Solution: ExxonMobil has developed advanced cryogenic capture systems specifically designed for offshore oil and gas operations. Their technology utilizes specialized cryogenic processes to capture and separate CO2 and other greenhouse gases from production streams. The system employs a multi-stage cooling process that gradually reduces gas temperature to cryogenic levels (-150°C to -180°C), causing target compounds to condense or solidify for efficient separation. ExxonMobil's instrumentation includes high-precision temperature and pressure sensors that can withstand extreme marine conditions, with redundant monitoring systems to ensure operational reliability. Their remote monitoring capabilities allow for real-time data transmission via satellite communications, enabling operators to make adjustments from onshore facilities. The system incorporates automated safety protocols that can detect anomalies and initiate shutdown procedures without human intervention when necessary.

Strengths: Superior engineering for harsh offshore environments with robust corrosion resistance and stability during vessel movement. Advanced integration with existing production infrastructure minimizes retrofitting costs. Weaknesses: Higher initial capital investment compared to conventional capture technologies. System requires significant energy for cryogenic cooling, potentially reducing overall process efficiency in remote locations with limited power resources.

Services Petroliers Schlumberger SA

Technical Solution: Schlumberger has pioneered a comprehensive cryogenic capture instrumentation system for offshore operations that combines advanced sensing technology with robust remote monitoring capabilities. Their solution utilizes distributed temperature sensing (DTS) fiber optic technology that can continuously monitor temperatures along the entire cryogenic process chain with accuracy to 0.1°C even at extremely low temperatures. The system incorporates specialized pressure transducers designed to function reliably at cryogenic conditions, with materials selected specifically to maintain calibration despite thermal cycling. Schlumberger's instrumentation package includes proprietary algorithms that analyze real-time data to predict potential system failures before they occur, allowing for preventative maintenance. For remote operations, they've developed satellite and cellular communication systems with multiple redundancies to ensure continuous data transmission even in adverse weather conditions. The control systems feature automated response protocols that can adjust operational parameters based on changing environmental or process conditions without human intervention.

Strengths: Exceptional data analytics capabilities that transform raw sensor data into actionable insights, reducing the need for specialist interpretation. Highly modular design allows for customization to specific operational requirements and easy upgrades. Weaknesses: Complex system architecture requires specialized training for maintenance personnel. Higher initial implementation costs compared to conventional monitoring systems, though potentially offset by reduced operational failures.

Key Patents in Offshore Cryogenic Capture Technology

Patent

Innovation

- Integration of real-time monitoring systems with cryogenic carbon capture technology for remote and offshore operations, enabling continuous data collection and analysis in harsh environments.

- Implementation of automated control mechanisms that adjust cryogenic capture parameters based on real-time environmental and operational data, optimizing carbon capture efficiency in variable offshore conditions.

- Design of modular, scalable cryogenic capture units specifically engineered for space-constrained offshore platforms, with reduced footprint while maintaining capture efficiency.

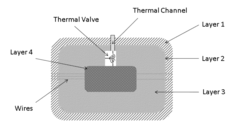

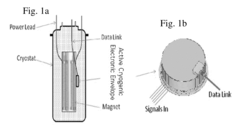

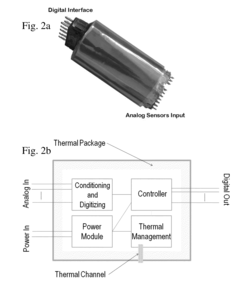

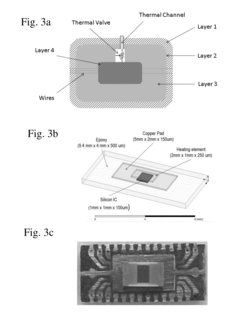

Active Cryogenic Electronic Envelope

PatentActiveUS20160061538A1

Innovation

- A data acquisition module capable of operating at cryogenic temperatures, which resides inside a cryostat and maintains electronic components within a controlled thermal envelope, allowing conventional electronics to function effectively at temperatures as low as 0° K, thereby reducing thermal noise and simplifying the feedthrough interface.

Environmental Impact Assessment of Offshore Cryogenic Operations

The implementation of cryogenic capture systems in offshore environments necessitates comprehensive environmental impact assessment due to the sensitive nature of marine ecosystems. These operations, while offering significant benefits for carbon capture and natural gas processing, introduce potential environmental risks that must be carefully evaluated and mitigated. The primary environmental concerns include thermal impacts on marine life, potential refrigerant leakage, and energy consumption implications.

Thermal discharge from cryogenic operations can create localized temperature gradients in surrounding waters, potentially disrupting marine habitats and affecting species distribution patterns. Studies indicate that even small temperature variations of 2-3°C can significantly alter marine ecosystem dynamics, particularly in sensitive areas such as coral reefs or spawning grounds. Continuous monitoring systems with temperature sensors distributed at various distances from operations are essential for tracking these thermal footprints.

Refrigerant management presents another critical environmental consideration. Modern cryogenic systems utilize various refrigerants, some of which have significant global warming potential (GWP) or ozone depletion potential (ODP). Accidental releases in offshore environments can have far-reaching consequences, necessitating robust containment systems and leak detection technologies. Industry best practices now include triple-containment designs and real-time monitoring systems capable of detecting leaks at parts-per-billion levels.

Energy consumption represents a substantial environmental factor, as cryogenic processes are inherently energy-intensive. The carbon footprint of powering these systems must be evaluated against the environmental benefits they provide. Recent innovations in energy recovery systems have demonstrated potential efficiency improvements of 15-25%, significantly reducing the net environmental impact of these operations. Integration with renewable energy sources, particularly offshore wind, offers promising pathways for further reducing environmental footprints.

Noise pollution from compressors and other equipment can disrupt marine mammal communication and navigation systems. Acoustic modeling studies suggest that underwater noise from cryogenic operations can propagate over several kilometers, potentially affecting migration patterns and feeding behaviors. Advanced acoustic insulation technologies and operational scheduling around sensitive biological periods represent important mitigation strategies.

Regulatory frameworks for offshore cryogenic operations vary significantly across jurisdictions, creating challenges for standardized environmental assessment. The International Maritime Organization (IMO) and regional bodies like OSPAR Commission have begun developing specific guidelines, though significant gaps remain. Companies implementing these technologies must often exceed minimum requirements to ensure comprehensive environmental protection and maintain social license to operate in increasingly scrutinized offshore environments.

Thermal discharge from cryogenic operations can create localized temperature gradients in surrounding waters, potentially disrupting marine habitats and affecting species distribution patterns. Studies indicate that even small temperature variations of 2-3°C can significantly alter marine ecosystem dynamics, particularly in sensitive areas such as coral reefs or spawning grounds. Continuous monitoring systems with temperature sensors distributed at various distances from operations are essential for tracking these thermal footprints.

Refrigerant management presents another critical environmental consideration. Modern cryogenic systems utilize various refrigerants, some of which have significant global warming potential (GWP) or ozone depletion potential (ODP). Accidental releases in offshore environments can have far-reaching consequences, necessitating robust containment systems and leak detection technologies. Industry best practices now include triple-containment designs and real-time monitoring systems capable of detecting leaks at parts-per-billion levels.

Energy consumption represents a substantial environmental factor, as cryogenic processes are inherently energy-intensive. The carbon footprint of powering these systems must be evaluated against the environmental benefits they provide. Recent innovations in energy recovery systems have demonstrated potential efficiency improvements of 15-25%, significantly reducing the net environmental impact of these operations. Integration with renewable energy sources, particularly offshore wind, offers promising pathways for further reducing environmental footprints.

Noise pollution from compressors and other equipment can disrupt marine mammal communication and navigation systems. Acoustic modeling studies suggest that underwater noise from cryogenic operations can propagate over several kilometers, potentially affecting migration patterns and feeding behaviors. Advanced acoustic insulation technologies and operational scheduling around sensitive biological periods represent important mitigation strategies.

Regulatory frameworks for offshore cryogenic operations vary significantly across jurisdictions, creating challenges for standardized environmental assessment. The International Maritime Organization (IMO) and regional bodies like OSPAR Commission have begun developing specific guidelines, though significant gaps remain. Companies implementing these technologies must often exceed minimum requirements to ensure comprehensive environmental protection and maintain social license to operate in increasingly scrutinized offshore environments.

Safety Standards and Risk Management for Remote Cryogenic Systems

The implementation of cryogenic capture systems in remote and offshore environments necessitates adherence to stringent safety standards and comprehensive risk management protocols. International standards such as ISO 16903 (Installation and equipment for liquefied natural gas) and IEC 60079 (Explosive atmospheres) provide foundational guidelines for cryogenic operations in hazardous environments. These standards establish minimum requirements for equipment design, material selection, and operational procedures to ensure system integrity under extreme temperature conditions.

Risk assessment methodologies specific to remote cryogenic systems must incorporate both conventional hazards and unique challenges posed by geographical isolation. The HAZOP (Hazard and Operability Study) and LOPA (Layer of Protection Analysis) frameworks have been adapted for cryogenic applications, with particular emphasis on thermal stress management, material embrittlement prevention, and emergency response capabilities in low-accessibility scenarios.

Automated monitoring systems represent a critical component of safety infrastructure for remote cryogenic operations. Real-time telemetry of temperature, pressure, and structural integrity parameters enables early detection of potential failure modes. Industry best practices now mandate redundant sensor arrays with self-diagnostic capabilities to ensure continuous monitoring despite harsh environmental conditions. These systems typically incorporate AI-driven predictive maintenance algorithms that can identify degradation patterns before critical failures occur.

Emergency response planning for remote cryogenic systems presents unique challenges that conventional protocols cannot adequately address. The industry has developed specialized contingency frameworks that account for extended response times and limited resource availability. These frameworks emphasize robust containment systems, automated shutdown procedures, and remote intervention capabilities that can be activated without physical presence.

Personnel safety considerations extend beyond standard cryogenic handling procedures when operating in remote locations. Enhanced training requirements include scenario-based simulations of isolation-specific emergencies and proficiency with remote diagnostic tools. Certification programs such as the International Cryogenic Safety Association's Remote Operations Specialist designation have emerged to standardize competency requirements for technicians working with these systems.

Regulatory compliance across international boundaries presents additional complexity for offshore cryogenic operations. Maritime regulations (SOLAS, MARPOL) intersect with industrial safety standards, creating a multifaceted compliance landscape. Leading operators have developed integrated compliance management systems that harmonize these requirements while maintaining operational flexibility in diverse jurisdictional environments.

Risk assessment methodologies specific to remote cryogenic systems must incorporate both conventional hazards and unique challenges posed by geographical isolation. The HAZOP (Hazard and Operability Study) and LOPA (Layer of Protection Analysis) frameworks have been adapted for cryogenic applications, with particular emphasis on thermal stress management, material embrittlement prevention, and emergency response capabilities in low-accessibility scenarios.

Automated monitoring systems represent a critical component of safety infrastructure for remote cryogenic operations. Real-time telemetry of temperature, pressure, and structural integrity parameters enables early detection of potential failure modes. Industry best practices now mandate redundant sensor arrays with self-diagnostic capabilities to ensure continuous monitoring despite harsh environmental conditions. These systems typically incorporate AI-driven predictive maintenance algorithms that can identify degradation patterns before critical failures occur.

Emergency response planning for remote cryogenic systems presents unique challenges that conventional protocols cannot adequately address. The industry has developed specialized contingency frameworks that account for extended response times and limited resource availability. These frameworks emphasize robust containment systems, automated shutdown procedures, and remote intervention capabilities that can be activated without physical presence.

Personnel safety considerations extend beyond standard cryogenic handling procedures when operating in remote locations. Enhanced training requirements include scenario-based simulations of isolation-specific emergencies and proficiency with remote diagnostic tools. Certification programs such as the International Cryogenic Safety Association's Remote Operations Specialist designation have emerged to standardize competency requirements for technicians working with these systems.

Regulatory compliance across international boundaries presents additional complexity for offshore cryogenic operations. Maritime regulations (SOLAS, MARPOL) intersect with industrial safety standards, creating a multifaceted compliance landscape. Leading operators have developed integrated compliance management systems that harmonize these requirements while maintaining operational flexibility in diverse jurisdictional environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!