Cryogenic Capture And Direct Air Capture: When Is Each Appropriate?

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon Capture Technology Background and Objectives

Carbon capture technologies have evolved significantly over the past decades as a response to growing concerns about climate change and greenhouse gas emissions. The journey began with conventional post-combustion capture methods in industrial settings, primarily focusing on high-concentration CO2 sources. As global carbon reduction targets became more ambitious, the technological landscape expanded to include more innovative approaches like Cryogenic Capture and Direct Air Capture (DAC).

Cryogenic Capture represents a thermodynamic approach to carbon separation, utilizing extremely low temperatures to freeze and separate CO2 from gas mixtures. This technology has roots in industrial gas separation dating back to the mid-20th century but has been adapted specifically for carbon capture applications in the last two decades. The fundamental principle leverages the different freezing points of gases, allowing CO2 to be solidified while other gases remain in gaseous form.

Direct Air Capture, conversely, emerged as a more recent innovation, gaining significant attention since the early 2000s. Unlike traditional capture methods that target point sources, DAC systems extract CO2 directly from ambient air, addressing the challenge of capturing emissions from distributed sources like transportation and agriculture. This technology represents a paradigm shift in carbon management strategy, offering potential for negative emissions when combined with permanent storage solutions.

The technological evolution of both approaches has been driven by the increasing urgency of climate action and the recognition that point-source capture alone may be insufficient to meet global climate goals. The Paris Agreement's emphasis on limiting global warming to well below 2°C has accelerated research and development in these fields, pushing for more efficient and cost-effective solutions.

The primary objective of current carbon capture technology development is threefold: reducing energy requirements, lowering operational costs, and increasing capture efficiency. For Cryogenic Capture, this means optimizing refrigeration cycles and heat integration to minimize the substantial energy demands of cooling. For DAC, the focus lies on developing sorbent materials with higher CO2 selectivity and lower regeneration energy.

Both technologies aim to achieve economic viability at scale, with target costs below $100 per ton of CO2 captured—a benchmark considered necessary for widespread commercial adoption. Additionally, these technologies seek to integrate seamlessly with existing industrial processes and energy systems, minimizing disruption while maximizing carbon reduction potential.

As we advance toward a carbon-constrained future, understanding the appropriate applications for each technology becomes crucial for strategic deployment of limited resources and achieving optimal climate impact across diverse sectors and geographies.

Cryogenic Capture represents a thermodynamic approach to carbon separation, utilizing extremely low temperatures to freeze and separate CO2 from gas mixtures. This technology has roots in industrial gas separation dating back to the mid-20th century but has been adapted specifically for carbon capture applications in the last two decades. The fundamental principle leverages the different freezing points of gases, allowing CO2 to be solidified while other gases remain in gaseous form.

Direct Air Capture, conversely, emerged as a more recent innovation, gaining significant attention since the early 2000s. Unlike traditional capture methods that target point sources, DAC systems extract CO2 directly from ambient air, addressing the challenge of capturing emissions from distributed sources like transportation and agriculture. This technology represents a paradigm shift in carbon management strategy, offering potential for negative emissions when combined with permanent storage solutions.

The technological evolution of both approaches has been driven by the increasing urgency of climate action and the recognition that point-source capture alone may be insufficient to meet global climate goals. The Paris Agreement's emphasis on limiting global warming to well below 2°C has accelerated research and development in these fields, pushing for more efficient and cost-effective solutions.

The primary objective of current carbon capture technology development is threefold: reducing energy requirements, lowering operational costs, and increasing capture efficiency. For Cryogenic Capture, this means optimizing refrigeration cycles and heat integration to minimize the substantial energy demands of cooling. For DAC, the focus lies on developing sorbent materials with higher CO2 selectivity and lower regeneration energy.

Both technologies aim to achieve economic viability at scale, with target costs below $100 per ton of CO2 captured—a benchmark considered necessary for widespread commercial adoption. Additionally, these technologies seek to integrate seamlessly with existing industrial processes and energy systems, minimizing disruption while maximizing carbon reduction potential.

As we advance toward a carbon-constrained future, understanding the appropriate applications for each technology becomes crucial for strategic deployment of limited resources and achieving optimal climate impact across diverse sectors and geographies.

Market Analysis for Carbon Capture Solutions

The carbon capture market is experiencing significant growth driven by increasing global focus on climate change mitigation and net-zero emissions targets. Currently valued at approximately $2 billion, the market is projected to reach $7 billion by 2028, representing a compound annual growth rate of 19.2%. This growth trajectory is supported by substantial government investments, with the US Inflation Reduction Act allocating $369 billion for climate and clean energy initiatives, including carbon capture technologies.

The market for carbon capture solutions can be segmented based on technology types, with Cryogenic Capture and Direct Air Capture (DAC) representing two distinct approaches with different market applications. Cryogenic capture, which freezes CO2 at extremely low temperatures, currently holds a smaller market share of about 8% but is growing at 15% annually due to its high capture efficiency in industrial settings.

Direct Air Capture, while more nascent with approximately 5% market share, is experiencing the fastest growth rate at 25% annually. This acceleration is fueled by over $3.5 billion in recent investments from major corporations seeking to offset emissions and meet sustainability goals. Notable market entrants include Climeworks, Carbon Engineering, and Global Thermostat, who have collectively secured over $800 million in funding since 2020.

From an end-user perspective, the market divides into distinct segments with different technology preferences. Heavy industrial sectors (steel, cement, chemicals) that produce concentrated CO2 streams predominantly favor cryogenic capture solutions due to their cost-effectiveness in high-concentration environments. These sectors represent approximately 45% of the total carbon capture market.

Conversely, technology companies, consumer goods manufacturers, and financial institutions with distributed or indirect emissions are increasingly investing in DAC technologies. This segment represents about 30% of current market demand but is growing at twice the rate of traditional industrial applications.

Geographically, North America leads the carbon capture market with 40% share, followed by Europe (30%) and Asia-Pacific (20%). However, the fastest growth is occurring in emerging economies, particularly in the Middle East and parts of Asia, where industrial expansion coincides with new climate commitments.

Market analysts identify several key drivers that will shape technology adoption patterns: regulatory frameworks including carbon pricing mechanisms, technology cost curves, energy requirements, and integration capabilities with existing infrastructure. The most significant market barrier remains the high cost per ton of captured carbon, currently ranging from $250-600 for DAC and $50-150 for cryogenic capture in optimal conditions.

The market for carbon capture solutions can be segmented based on technology types, with Cryogenic Capture and Direct Air Capture (DAC) representing two distinct approaches with different market applications. Cryogenic capture, which freezes CO2 at extremely low temperatures, currently holds a smaller market share of about 8% but is growing at 15% annually due to its high capture efficiency in industrial settings.

Direct Air Capture, while more nascent with approximately 5% market share, is experiencing the fastest growth rate at 25% annually. This acceleration is fueled by over $3.5 billion in recent investments from major corporations seeking to offset emissions and meet sustainability goals. Notable market entrants include Climeworks, Carbon Engineering, and Global Thermostat, who have collectively secured over $800 million in funding since 2020.

From an end-user perspective, the market divides into distinct segments with different technology preferences. Heavy industrial sectors (steel, cement, chemicals) that produce concentrated CO2 streams predominantly favor cryogenic capture solutions due to their cost-effectiveness in high-concentration environments. These sectors represent approximately 45% of the total carbon capture market.

Conversely, technology companies, consumer goods manufacturers, and financial institutions with distributed or indirect emissions are increasingly investing in DAC technologies. This segment represents about 30% of current market demand but is growing at twice the rate of traditional industrial applications.

Geographically, North America leads the carbon capture market with 40% share, followed by Europe (30%) and Asia-Pacific (20%). However, the fastest growth is occurring in emerging economies, particularly in the Middle East and parts of Asia, where industrial expansion coincides with new climate commitments.

Market analysts identify several key drivers that will shape technology adoption patterns: regulatory frameworks including carbon pricing mechanisms, technology cost curves, energy requirements, and integration capabilities with existing infrastructure. The most significant market barrier remains the high cost per ton of captured carbon, currently ranging from $250-600 for DAC and $50-150 for cryogenic capture in optimal conditions.

Current State and Challenges in Carbon Capture

Carbon capture technologies have evolved significantly over the past decades, with various approaches being developed to address the growing concern of atmospheric CO2 levels. Currently, the carbon capture landscape is dominated by two major technological pathways: post-combustion capture from point sources and direct air capture (DAC) from ambient air. Within these categories, cryogenic capture and various DAC methodologies represent distinct technological approaches with their own sets of challenges and applications.

The global carbon capture capacity stands at approximately 40 million tonnes per annum, which remains insufficient compared to the scale of emissions reduction required to meet climate goals. Most operational facilities are concentrated in North America and Europe, with emerging projects in Asia and the Middle East. This geographical distribution reflects both technological capabilities and policy environments supportive of carbon management strategies.

Cryogenic capture technology, which involves cooling flue gases to temperatures where CO2 freezes and can be separated, faces significant energy efficiency challenges. The process requires substantial cooling energy, often making it economically viable only in specific industrial contexts where waste cold energy can be utilized. Current cryogenic systems demonstrate capture efficiencies of 90-95% but at energy penalties of 15-30% depending on integration strategies.

Direct air capture technologies, meanwhile, confront the fundamental challenge of CO2 dilution in ambient air (approximately 412 ppm compared to 10-15% in flue gases). This dilution necessitates processing enormous volumes of air, resulting in high energy requirements and substantial capital costs. Current DAC technologies require 1.5-3.5 GJ of energy per tonne of CO2 captured, with costs ranging from $250-600 per tonne.

Material limitations present significant barriers for both technologies. Cryogenic systems require specialized materials capable of withstanding extreme temperature cycling without degradation, while DAC systems need sorbents with high CO2 selectivity, capacity, and durability under ambient conditions. Current sorbent materials typically degrade after 100-1000 cycles, necessitating frequent replacement and increasing operational costs.

Scale-up challenges remain paramount for both technologies. Cryogenic systems face heat exchange efficiency losses at larger scales, while DAC installations require substantial land area and air handling infrastructure. The largest DAC facility currently operational captures only about 4,000 tonnes of CO2 annually, far below the megaton scale needed for climate impact.

Regulatory frameworks and carbon pricing mechanisms remain inconsistent globally, creating market uncertainty that hampers investment in these capital-intensive technologies. Without stable policy environments that value carbon removal appropriately, the economic case for widespread deployment remains challenging despite technological progress.

The global carbon capture capacity stands at approximately 40 million tonnes per annum, which remains insufficient compared to the scale of emissions reduction required to meet climate goals. Most operational facilities are concentrated in North America and Europe, with emerging projects in Asia and the Middle East. This geographical distribution reflects both technological capabilities and policy environments supportive of carbon management strategies.

Cryogenic capture technology, which involves cooling flue gases to temperatures where CO2 freezes and can be separated, faces significant energy efficiency challenges. The process requires substantial cooling energy, often making it economically viable only in specific industrial contexts where waste cold energy can be utilized. Current cryogenic systems demonstrate capture efficiencies of 90-95% but at energy penalties of 15-30% depending on integration strategies.

Direct air capture technologies, meanwhile, confront the fundamental challenge of CO2 dilution in ambient air (approximately 412 ppm compared to 10-15% in flue gases). This dilution necessitates processing enormous volumes of air, resulting in high energy requirements and substantial capital costs. Current DAC technologies require 1.5-3.5 GJ of energy per tonne of CO2 captured, with costs ranging from $250-600 per tonne.

Material limitations present significant barriers for both technologies. Cryogenic systems require specialized materials capable of withstanding extreme temperature cycling without degradation, while DAC systems need sorbents with high CO2 selectivity, capacity, and durability under ambient conditions. Current sorbent materials typically degrade after 100-1000 cycles, necessitating frequent replacement and increasing operational costs.

Scale-up challenges remain paramount for both technologies. Cryogenic systems face heat exchange efficiency losses at larger scales, while DAC installations require substantial land area and air handling infrastructure. The largest DAC facility currently operational captures only about 4,000 tonnes of CO2 annually, far below the megaton scale needed for climate impact.

Regulatory frameworks and carbon pricing mechanisms remain inconsistent globally, creating market uncertainty that hampers investment in these capital-intensive technologies. Without stable policy environments that value carbon removal appropriately, the economic case for widespread deployment remains challenging despite technological progress.

Comparative Analysis of Cryogenic and DAC Methods

01 Cryogenic carbon capture technologies

Cryogenic carbon capture involves cooling flue gases to very low temperatures to freeze out CO2 as dry ice. This technology is particularly suitable for high-concentration CO2 sources and can achieve high capture rates (>90%). The process typically involves multiple cooling stages and heat exchangers to improve energy efficiency. Cryogenic methods offer advantages including high purity of captured CO2 and the ability to operate in various industrial settings where high-concentration CO2 streams are available.- Cryogenic carbon capture technology advancements: Cryogenic carbon capture involves cooling flue gases to very low temperatures to freeze out CO2. Recent advancements have improved energy efficiency and operational costs of these systems. The technology is particularly suitable for high-concentration CO2 sources and can achieve capture rates exceeding 90%. Innovations include improved heat exchangers, novel refrigeration cycles, and integration with existing power plants to utilize waste cold energy.

- Direct air capture (DAC) system innovations: Direct air capture technologies extract CO2 directly from ambient air using sorbents or solvents. Recent innovations focus on reducing energy requirements and improving sorbent materials. These systems are suitable for distributed deployment and can address emissions from mobile or diffuse sources. Advancements include modular designs, renewable energy integration, and novel materials with higher CO2 selectivity and lower regeneration energy.

- Hybrid and integrated carbon capture approaches: Hybrid systems combining multiple carbon capture technologies offer improved efficiency and flexibility. These integrated approaches can leverage the strengths of different methods while mitigating their individual limitations. Examples include combining membrane separation with cryogenic processes or integrating direct air capture with conventional post-combustion systems. These hybrid approaches are particularly suitable for industrial applications with varying CO2 concentrations and operational conditions.

- Environmental and economic suitability factors: The appropriateness of carbon capture technologies depends on various environmental and economic factors. Considerations include energy requirements, water usage, land footprint, and lifecycle emissions. Economic viability is influenced by capital costs, operational expenses, and potential revenue streams from captured CO2. Site-specific factors such as available infrastructure, energy sources, and proximity to storage or utilization facilities significantly impact technology selection.

- Application-specific carbon capture solutions: Different carbon capture technologies are suited to specific applications based on CO2 concentration, volume, and operational requirements. Cryogenic capture is particularly effective for high-purity applications like natural gas processing and hydrogen production. Direct air capture is suitable for offsetting distributed emissions and achieving negative emissions. Technological adaptations for specific industries include customized sorbents, specialized process integration, and tailored heat management strategies.

02 Direct air capture (DAC) systems and suitability

Direct air capture technologies extract CO2 directly from ambient air, making them suitable for addressing distributed emissions sources. These systems typically use sorbents or solvents that selectively bind with CO2. DAC is appropriate for carbon-neutral or negative emission goals but faces challenges including high energy requirements due to the low concentration of CO2 in ambient air (about 0.04%). Recent innovations focus on improving sorbent materials and reducing the energy penalty associated with the regeneration phase.Expand Specific Solutions03 Energy efficiency and integration considerations

The appropriateness of carbon capture technologies largely depends on their energy efficiency and integration capabilities with existing infrastructure. Systems that utilize waste heat from industrial processes or renewable energy sources significantly improve overall efficiency. Hybrid approaches combining multiple capture methods can optimize performance across varying conditions. Energy consumption remains a critical factor in determining the economic viability and environmental benefits of both cryogenic and direct air capture technologies.Expand Specific Solutions04 Environmental impact and sustainability factors

The environmental suitability of carbon capture technologies extends beyond capture efficiency to include considerations of water usage, land requirements, and potential ecological impacts. Cryogenic systems typically have smaller physical footprints but higher energy demands, while some DAC approaches require significant land area but may use less energy per ton of CO2 captured. Life cycle assessments indicate that the source of energy used to power these systems significantly influences their net environmental benefit. Technologies incorporating biodegradable materials or closed-loop resource cycles demonstrate enhanced sustainability profiles.Expand Specific Solutions05 Economic viability and scalability considerations

The appropriateness of carbon capture technologies is heavily influenced by their economic viability and scalability potential. Cryogenic capture typically shows better economics at large scales and with high-concentration CO2 sources, while DAC systems offer more flexibility in deployment location but at higher cost per ton of CO2 captured. Modular designs that allow for incremental capacity expansion improve the adaptability of these technologies to various market conditions. Recent innovations focus on reducing capital costs and improving operational efficiency to enhance commercial feasibility.Expand Specific Solutions

Major Industry Players in Carbon Capture

The direct air capture (DAC) technology market is currently in its early growth phase, with cryogenic capture and traditional DAC technologies competing for dominance. The global carbon capture market is projected to reach $7-10 billion by 2030, though technology maturity varies significantly. Companies like Climeworks AG and Mission Zero Technologies lead in traditional DAC solutions, while Aspiradac, Capture6, and Terrafixing are pioneering cryogenic capture approaches. Research institutions including Portland State University, Arizona State University, and China's Huaneng Clean Energy Research Institute are advancing both technologies. Major corporations such as IBM, Microsoft, and ExxonMobil are investing in these solutions, with cryogenic capture generally preferred for large-scale industrial applications where cooling infrastructure exists, while traditional DAC offers more flexibility for distributed deployment scenarios.

Climeworks AG

Technical Solution: Climeworks has pioneered commercial Direct Air Capture (DAC) technology using solid sorbent filters that selectively capture CO2 when air passes through them. Their modular collectors use a two-step process where CO2 is first captured on the filter surface under ambient conditions, then released through heating to 80-100°C, producing high-purity CO2. Their Orca plant in Iceland, launched in 2021, captures 4,000 tons of CO2 annually and permanently stores it underground through mineralization in basaltic rock formations. Climeworks is scaling up with their Mammoth plant, designed to capture 36,000 tons of CO2 annually. Their approach is particularly suitable for regions with renewable energy access and geological storage capabilities, as demonstrated by their strategic placement in Iceland where geothermal energy powers the process.

Strengths: Modular design allows for scalable implementation; integration with renewable energy sources; proven commercial deployment; permanent storage solution through mineralization. Weaknesses: Relatively high cost per ton of CO2 captured (currently $600-$800); energy-intensive regeneration process; requires specific geological conditions for optimal permanent storage.

Terrafixing, Inc.

Technical Solution: Terrafixing has developed a hybrid approach combining elements of both cryogenic capture and direct air capture technologies. Their system utilizes a preliminary cooling phase to enhance the efficiency of subsequent chemical absorption processes. The technology employs a multi-stage temperature gradient system where ambient air is first cooled to approximately -20°C to reduce moisture content and increase CO2 concentration, followed by a proprietary chemical absorption process optimized for these conditions. This approach reduces the energy requirements typically associated with pure cryogenic systems (which operate at much lower temperatures around -140°C) while improving capture efficiency compared to standard DAC systems. Terrafixing's pilot facilities have demonstrated capture rates of approximately 1,500 tons CO2/year with energy requirements approximately 20% lower than conventional DAC systems.

Strengths: Lower energy consumption than pure cryogenic systems; higher efficiency than standard DAC; modular design allows for deployment in various settings; potentially lower operational costs. Weaknesses: Still requires significant cooling energy; technology remains at early commercial scale; requires specialized equipment and expertise for operation; optimal performance depends on ambient conditions.

Technical Deep Dive into Capture Mechanisms

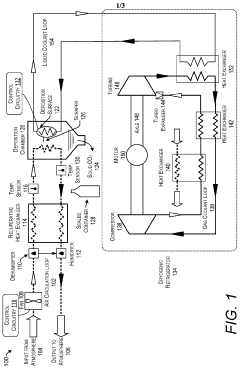

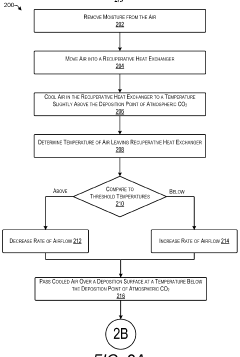

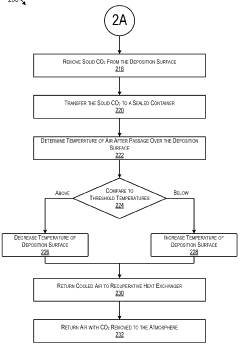

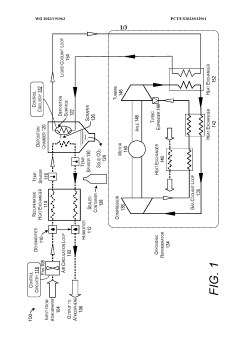

Cryogenic removal of carbon dioxide from the atmosphere

PatentWO2023191963A1

Innovation

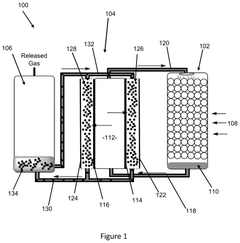

- The cryogenic CO2 direct air capture system, known as CryoDAC, freezes CO2 out of air without liquifying other components, using a recuperative heat exchanger and deposition chamber to pre-cool and deposit CO2 as solid dry ice, which is then collected and sequestered, with energy efficiency enhanced by recycling cooling air through the system.

Method of capturing a target species from a gas

PatentActiveUS12115498B2

Innovation

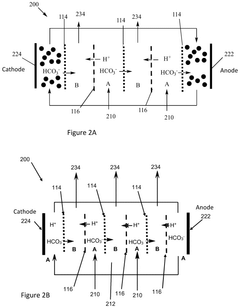

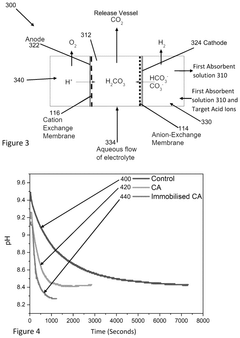

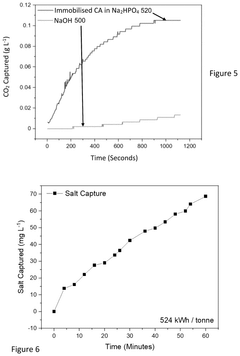

- A method involving a gas capture process that uses a first absorbent solution with a capture species, where the target species is dissolved and electrochemically separated through ion-exchange membranes into a second absorbent solution, preventing the capture species from passing through, allowing for recirculation and reducing the need for energy-intensive heat decomposition steps.

Energy Efficiency and Cost Considerations

Energy efficiency and cost considerations represent critical factors in determining the appropriate application scenarios for Cryogenic Capture (CC) and Direct Air Capture (DAC) technologies. The energy requirements for both technologies differ significantly, with cryogenic capture typically demanding substantial cooling energy to reach the ultra-low temperatures necessary for CO₂ solidification, generally between -78°C and -140°C depending on the specific process configuration.

When examining energy efficiency metrics, cryogenic capture demonstrates advantages in high-concentration CO₂ streams (>10%), where the energy penalty per ton of captured carbon can be 30-40% lower than comparable DAC systems. This efficiency advantage stems from the thermodynamic principles governing gas separation, where working with concentrated streams requires less energy than extracting CO₂ from ambient air with concentrations of approximately 420 ppm.

Direct Air Capture, conversely, faces inherent thermodynamic challenges due to the dilute nature of atmospheric CO₂. Current DAC technologies require between 5-10 GJ of energy per ton of CO₂ captured, significantly higher than cryogenic systems operating on concentrated sources. However, DAC systems benefit from location flexibility, allowing placement near renewable energy sources or waste heat facilities, potentially offsetting some efficiency disadvantages.

From a capital expenditure perspective, cryogenic capture systems typically require higher initial investment due to specialized cryogenic equipment, insulation requirements, and materials capable of withstanding extreme temperature cycling. Current estimates place cryogenic capture CAPEX at $600-1,200 per ton of annual CO₂ capture capacity, compared to $400-1,000 for leading DAC technologies.

Operational costs present a more complex picture. While cryogenic systems have higher energy demands for cooling, they often achieve lower sorbent replacement costs and maintenance requirements. DAC systems frequently require regular replacement of sorbent materials and face challenges with moisture management and contaminant handling that increase operational expenses over time.

Scaling economics favor cryogenic capture for large, point-source applications where economies of scale can be realized. The cost per ton of CO₂ captured decreases more rapidly with scale for cryogenic systems than for DAC installations. Analysis of recent industrial deployments indicates that cryogenic capture costs can decrease by 25-30% when scaling from pilot to commercial size, while DAC systems typically achieve 15-20% cost reductions at similar scaling factors.

When examining energy efficiency metrics, cryogenic capture demonstrates advantages in high-concentration CO₂ streams (>10%), where the energy penalty per ton of captured carbon can be 30-40% lower than comparable DAC systems. This efficiency advantage stems from the thermodynamic principles governing gas separation, where working with concentrated streams requires less energy than extracting CO₂ from ambient air with concentrations of approximately 420 ppm.

Direct Air Capture, conversely, faces inherent thermodynamic challenges due to the dilute nature of atmospheric CO₂. Current DAC technologies require between 5-10 GJ of energy per ton of CO₂ captured, significantly higher than cryogenic systems operating on concentrated sources. However, DAC systems benefit from location flexibility, allowing placement near renewable energy sources or waste heat facilities, potentially offsetting some efficiency disadvantages.

From a capital expenditure perspective, cryogenic capture systems typically require higher initial investment due to specialized cryogenic equipment, insulation requirements, and materials capable of withstanding extreme temperature cycling. Current estimates place cryogenic capture CAPEX at $600-1,200 per ton of annual CO₂ capture capacity, compared to $400-1,000 for leading DAC technologies.

Operational costs present a more complex picture. While cryogenic systems have higher energy demands for cooling, they often achieve lower sorbent replacement costs and maintenance requirements. DAC systems frequently require regular replacement of sorbent materials and face challenges with moisture management and contaminant handling that increase operational expenses over time.

Scaling economics favor cryogenic capture for large, point-source applications where economies of scale can be realized. The cost per ton of CO₂ captured decreases more rapidly with scale for cryogenic systems than for DAC installations. Analysis of recent industrial deployments indicates that cryogenic capture costs can decrease by 25-30% when scaling from pilot to commercial size, while DAC systems typically achieve 15-20% cost reductions at similar scaling factors.

Environmental Impact Assessment

The environmental impact assessment of carbon capture technologies reveals significant differences between Cryogenic Capture and Direct Air Capture (DAC) methods. Cryogenic capture, which operates at extremely low temperatures to freeze and separate CO2, demonstrates higher energy efficiency when implemented at point sources with concentrated CO2 emissions. This approach minimizes the overall carbon footprint when the energy source powering the system is renewable or low-carbon.

When properly integrated with existing industrial facilities, cryogenic systems can achieve capture efficiencies exceeding 90% while generating fewer secondary pollutants compared to chemical solvent-based alternatives. The absence of chemical reagents eliminates concerns about toxic waste streams and reduces water consumption by approximately 40-60% compared to conventional amine-based capture systems.

Direct Air Capture, conversely, presents a more complex environmental profile. While DAC can be deployed anywhere and addresses historical emissions, its operation requires substantially more energy per ton of CO2 captured due to the dilute concentration of atmospheric carbon dioxide (approximately 400 ppm). Current DAC technologies consume between 5-15 GJ of energy per ton of CO2 removed, potentially creating significant indirect emissions unless powered by clean energy sources.

Land use considerations also differ markedly between these technologies. Cryogenic systems typically have a smaller physical footprint when integrated with existing industrial infrastructure, whereas large-scale DAC installations require substantial land area - approximately 0.5-2 hectares per kiloton of annual CO2 removal capacity. This raises concerns about habitat disruption and land use competition in certain deployment scenarios.

Water consumption patterns vary significantly between technologies. Modern cryogenic systems operate with minimal water requirements, while certain DAC approaches, particularly those using liquid solvents, can consume 3-7 tons of water per ton of CO2 captured. In water-stressed regions, this differential becomes a critical factor in technology selection and deployment planning.

Life cycle assessments indicate that the environmental break-even point - where the emissions avoided exceed those generated during construction and operation - occurs more rapidly for cryogenic capture at point sources (typically 1-3 years) compared to DAC systems (often 3-7 years). This temporal difference significantly influences the short-term climate mitigation potential of each approach.

When properly integrated with existing industrial facilities, cryogenic systems can achieve capture efficiencies exceeding 90% while generating fewer secondary pollutants compared to chemical solvent-based alternatives. The absence of chemical reagents eliminates concerns about toxic waste streams and reduces water consumption by approximately 40-60% compared to conventional amine-based capture systems.

Direct Air Capture, conversely, presents a more complex environmental profile. While DAC can be deployed anywhere and addresses historical emissions, its operation requires substantially more energy per ton of CO2 captured due to the dilute concentration of atmospheric carbon dioxide (approximately 400 ppm). Current DAC technologies consume between 5-15 GJ of energy per ton of CO2 removed, potentially creating significant indirect emissions unless powered by clean energy sources.

Land use considerations also differ markedly between these technologies. Cryogenic systems typically have a smaller physical footprint when integrated with existing industrial infrastructure, whereas large-scale DAC installations require substantial land area - approximately 0.5-2 hectares per kiloton of annual CO2 removal capacity. This raises concerns about habitat disruption and land use competition in certain deployment scenarios.

Water consumption patterns vary significantly between technologies. Modern cryogenic systems operate with minimal water requirements, while certain DAC approaches, particularly those using liquid solvents, can consume 3-7 tons of water per ton of CO2 captured. In water-stressed regions, this differential becomes a critical factor in technology selection and deployment planning.

Life cycle assessments indicate that the environmental break-even point - where the emissions avoided exceed those generated during construction and operation - occurs more rapidly for cryogenic capture at point sources (typically 1-3 years) compared to DAC systems (often 3-7 years). This temporal difference significantly influences the short-term climate mitigation potential of each approach.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!