Heat Exchange Network Design For Cryogenic CO2 Capture Units

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic CO2 Capture Technology Background and Objectives

Carbon dioxide (CO2) capture and storage has emerged as a critical technology in the global effort to mitigate climate change. Among various capture technologies, cryogenic CO2 capture represents a promising approach that utilizes low-temperature processes to separate CO2 from flue gases or industrial emissions. The development of this technology dates back to the 1980s, but significant advancements have occurred in the past two decades as climate concerns have intensified.

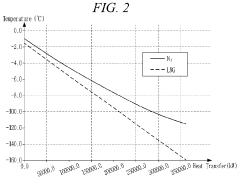

Cryogenic CO2 capture operates on the principle of phase change separation, exploiting the different condensation and desublimation temperatures of gases. At atmospheric pressure, CO2 transitions directly from gas to solid at approximately -78.5°C, while other components like nitrogen remain gaseous at much lower temperatures. This physical property difference enables effective separation with potentially high purity and recovery rates.

The evolution of cryogenic capture technology has been marked by progressive improvements in energy efficiency and process integration. Early systems suffered from prohibitively high energy requirements, primarily due to the cooling demands. However, recent technological innovations have focused on heat integration strategies and novel refrigeration cycles to reduce the energy penalty associated with the cryogenic process.

The primary objective of heat exchange network design for cryogenic CO2 capture units is to optimize energy recovery within the system, thereby improving overall efficiency and economic viability. This involves developing sophisticated heat exchanger configurations that maximize heat recovery between cold and warm process streams, minimizing external utility requirements, and ensuring operational stability under varying conditions.

Current research aims to address several key challenges, including the prevention of frost formation in heat exchangers, reduction of pressure drops, management of impurities that may affect phase behavior, and development of materials suitable for extreme temperature conditions. Additionally, there is significant focus on process intensification to reduce equipment footprint and capital costs.

The technology trajectory indicates a shift toward hybrid systems that combine cryogenic separation with other capture methods to leverage complementary strengths. For instance, integrating membrane pre-separation with cryogenic processes can reduce the cooling load and enhance overall system performance. Similarly, combining cryogenic capture with waste heat utilization from industrial processes presents opportunities for improved energy efficiency.

As global decarbonization efforts accelerate, cryogenic CO2 capture technology is positioned to play an increasingly important role, particularly in applications where high-purity CO2 is required or where integration with liquefied natural gas (LNG) facilities can provide synergistic benefits. The continued advancement of heat exchange network design represents a critical pathway to unlocking the full potential of this technology for industrial-scale carbon capture applications.

Cryogenic CO2 capture operates on the principle of phase change separation, exploiting the different condensation and desublimation temperatures of gases. At atmospheric pressure, CO2 transitions directly from gas to solid at approximately -78.5°C, while other components like nitrogen remain gaseous at much lower temperatures. This physical property difference enables effective separation with potentially high purity and recovery rates.

The evolution of cryogenic capture technology has been marked by progressive improvements in energy efficiency and process integration. Early systems suffered from prohibitively high energy requirements, primarily due to the cooling demands. However, recent technological innovations have focused on heat integration strategies and novel refrigeration cycles to reduce the energy penalty associated with the cryogenic process.

The primary objective of heat exchange network design for cryogenic CO2 capture units is to optimize energy recovery within the system, thereby improving overall efficiency and economic viability. This involves developing sophisticated heat exchanger configurations that maximize heat recovery between cold and warm process streams, minimizing external utility requirements, and ensuring operational stability under varying conditions.

Current research aims to address several key challenges, including the prevention of frost formation in heat exchangers, reduction of pressure drops, management of impurities that may affect phase behavior, and development of materials suitable for extreme temperature conditions. Additionally, there is significant focus on process intensification to reduce equipment footprint and capital costs.

The technology trajectory indicates a shift toward hybrid systems that combine cryogenic separation with other capture methods to leverage complementary strengths. For instance, integrating membrane pre-separation with cryogenic processes can reduce the cooling load and enhance overall system performance. Similarly, combining cryogenic capture with waste heat utilization from industrial processes presents opportunities for improved energy efficiency.

As global decarbonization efforts accelerate, cryogenic CO2 capture technology is positioned to play an increasingly important role, particularly in applications where high-purity CO2 is required or where integration with liquefied natural gas (LNG) facilities can provide synergistic benefits. The continued advancement of heat exchange network design represents a critical pathway to unlocking the full potential of this technology for industrial-scale carbon capture applications.

Market Analysis for Cryogenic Carbon Capture Solutions

The global market for cryogenic carbon capture solutions is experiencing significant growth, driven by increasing environmental regulations and corporate sustainability commitments. Current market valuations indicate that the carbon capture and storage (CCS) sector is projected to reach approximately $7 billion by 2030, with cryogenic technologies representing a rapidly expanding segment within this market. The compound annual growth rate for cryogenic carbon capture specifically is estimated at 15-20% through 2028, outpacing many conventional carbon capture methods.

Industrial sectors with high CO2 emissions represent the primary market for cryogenic carbon capture technologies. Power generation facilities, particularly coal and natural gas plants, constitute about 40% of the current market demand. Heavy manufacturing industries including cement, steel, and chemical production collectively account for another 35% of market interest, as these sectors face mounting pressure to decarbonize their operations while maintaining production efficiency.

Regional market analysis reveals varying adoption patterns. North America and Europe lead in implementation due to stringent regulatory frameworks and carbon pricing mechanisms, with these regions representing approximately 65% of current market deployment. The Asia-Pacific region, particularly China and India, shows the highest growth potential as these countries balance industrial expansion with emerging climate commitments.

Market drivers for cryogenic CO2 capture systems extend beyond regulatory compliance. The captured CO2 has created secondary markets in enhanced oil recovery operations, food and beverage industries, and agricultural applications. This value-added utilization pathway improves the economic feasibility of capture systems, with the CO2 utilization market expected to reach $3.5 billion by 2025.

Customer segmentation analysis indicates three primary buyer categories: large industrial emitters seeking compliance solutions, forward-thinking corporations implementing carbon-neutral strategies ahead of regulations, and government-subsidized demonstration projects. The latter category has been particularly important for market development, with public funding supporting approximately 60% of current large-scale cryogenic carbon capture installations.

Pricing structures in the market reflect the technology's current position on the adoption curve. The levelized cost of carbon capture using cryogenic methods ranges from $58-85 per ton of CO2, with economies of scale significantly improving economics for larger installations. This represents a 30% premium over conventional amine-based capture systems but offers advantages in energy efficiency and operational flexibility that are increasingly valued by customers seeking long-term solutions.

Industrial sectors with high CO2 emissions represent the primary market for cryogenic carbon capture technologies. Power generation facilities, particularly coal and natural gas plants, constitute about 40% of the current market demand. Heavy manufacturing industries including cement, steel, and chemical production collectively account for another 35% of market interest, as these sectors face mounting pressure to decarbonize their operations while maintaining production efficiency.

Regional market analysis reveals varying adoption patterns. North America and Europe lead in implementation due to stringent regulatory frameworks and carbon pricing mechanisms, with these regions representing approximately 65% of current market deployment. The Asia-Pacific region, particularly China and India, shows the highest growth potential as these countries balance industrial expansion with emerging climate commitments.

Market drivers for cryogenic CO2 capture systems extend beyond regulatory compliance. The captured CO2 has created secondary markets in enhanced oil recovery operations, food and beverage industries, and agricultural applications. This value-added utilization pathway improves the economic feasibility of capture systems, with the CO2 utilization market expected to reach $3.5 billion by 2025.

Customer segmentation analysis indicates three primary buyer categories: large industrial emitters seeking compliance solutions, forward-thinking corporations implementing carbon-neutral strategies ahead of regulations, and government-subsidized demonstration projects. The latter category has been particularly important for market development, with public funding supporting approximately 60% of current large-scale cryogenic carbon capture installations.

Pricing structures in the market reflect the technology's current position on the adoption curve. The levelized cost of carbon capture using cryogenic methods ranges from $58-85 per ton of CO2, with economies of scale significantly improving economics for larger installations. This represents a 30% premium over conventional amine-based capture systems but offers advantages in energy efficiency and operational flexibility that are increasingly valued by customers seeking long-term solutions.

Current Challenges in Heat Exchange Network Design

Heat exchange network design for cryogenic CO2 capture units faces significant technical challenges that impede optimal performance and efficiency. The extreme temperature conditions inherent in cryogenic processes create unique heat transfer problems that conventional design approaches struggle to address effectively. Temperature differences between process streams can exceed 200°C, leading to substantial thermodynamic inefficiencies when not properly managed.

Material selection presents another critical challenge, as materials must maintain structural integrity and thermal performance at temperatures approaching -150°C. Conventional heat exchanger materials experience embrittlement and thermal contraction issues at these extreme conditions, necessitating specialized alloys that significantly increase capital costs. The trade-off between thermal performance and material cost represents a major design constraint.

Process integration complexity further complicates heat exchanger network design. Cryogenic CO2 capture involves multiple phase changes and varying fluid properties across wide temperature ranges. Engineers must account for the dramatic changes in heat capacity, thermal conductivity, and viscosity that occur during phase transitions, particularly during CO2 solidification at approximately -78.5°C. These phase changes create non-linear heat transfer profiles that are difficult to model accurately.

Energy efficiency optimization remains perhaps the most significant challenge. Cryogenic processes are inherently energy-intensive, with refrigeration systems consuming substantial power. Current heat exchanger networks typically achieve only 60-70% of theoretical maximum energy recovery, leaving considerable room for improvement. The complex trade-offs between capital expenditure and operational energy costs create difficult optimization problems that lack standardized solutions.

Fouling and operational stability issues also plague cryogenic heat exchanger networks. CO2 solidification can lead to flow blockages and reduced heat transfer efficiency over time. Current designs struggle to incorporate effective self-cleaning mechanisms or fouling prevention strategies without compromising thermal performance or increasing pressure drop.

Modeling and simulation limitations further hinder optimal design. Existing simulation tools often fail to accurately capture the complex thermodynamic behaviors at cryogenic temperatures, particularly for multi-component mixtures with phase changes. This leads to significant discrepancies between design predictions and actual operational performance, necessitating conservative design approaches that sacrifice efficiency for reliability.

Lastly, the integration of heat exchanger networks with the broader CO2 capture process presents system-level challenges. Fluctuations in feed composition, flow rates, and ambient conditions can dramatically impact heat exchanger performance, yet current designs typically lack the flexibility to adapt to these variations without compromising efficiency or operational stability.

Material selection presents another critical challenge, as materials must maintain structural integrity and thermal performance at temperatures approaching -150°C. Conventional heat exchanger materials experience embrittlement and thermal contraction issues at these extreme conditions, necessitating specialized alloys that significantly increase capital costs. The trade-off between thermal performance and material cost represents a major design constraint.

Process integration complexity further complicates heat exchanger network design. Cryogenic CO2 capture involves multiple phase changes and varying fluid properties across wide temperature ranges. Engineers must account for the dramatic changes in heat capacity, thermal conductivity, and viscosity that occur during phase transitions, particularly during CO2 solidification at approximately -78.5°C. These phase changes create non-linear heat transfer profiles that are difficult to model accurately.

Energy efficiency optimization remains perhaps the most significant challenge. Cryogenic processes are inherently energy-intensive, with refrigeration systems consuming substantial power. Current heat exchanger networks typically achieve only 60-70% of theoretical maximum energy recovery, leaving considerable room for improvement. The complex trade-offs between capital expenditure and operational energy costs create difficult optimization problems that lack standardized solutions.

Fouling and operational stability issues also plague cryogenic heat exchanger networks. CO2 solidification can lead to flow blockages and reduced heat transfer efficiency over time. Current designs struggle to incorporate effective self-cleaning mechanisms or fouling prevention strategies without compromising thermal performance or increasing pressure drop.

Modeling and simulation limitations further hinder optimal design. Existing simulation tools often fail to accurately capture the complex thermodynamic behaviors at cryogenic temperatures, particularly for multi-component mixtures with phase changes. This leads to significant discrepancies between design predictions and actual operational performance, necessitating conservative design approaches that sacrifice efficiency for reliability.

Lastly, the integration of heat exchanger networks with the broader CO2 capture process presents system-level challenges. Fluctuations in feed composition, flow rates, and ambient conditions can dramatically impact heat exchanger performance, yet current designs typically lack the flexibility to adapt to these variations without compromising efficiency or operational stability.

State-of-the-Art Heat Exchange Network Solutions

01 Optimization algorithms for heat exchange network design

Various optimization algorithms are employed to enhance the efficiency of heat exchange network design. These algorithms help in minimizing energy consumption, reducing capital costs, and improving overall system performance. Advanced mathematical models and computational methods are used to determine the optimal configuration of heat exchangers, flow rates, and temperature profiles within the network, leading to more efficient heat transfer and energy utilization.- Optimization algorithms for heat exchange network design: Various optimization algorithms are employed to enhance the efficiency of heat exchange network design. These algorithms help in minimizing energy consumption, reducing capital costs, and improving overall system performance. Advanced mathematical models and computational methods are used to determine the optimal configuration of heat exchangers, flow rates, and temperature profiles within the network.

- Integration of renewable energy sources in heat exchange networks: Heat exchange networks can be designed to efficiently integrate renewable energy sources, such as solar, geothermal, or waste heat recovery systems. This integration helps in reducing the dependency on conventional energy sources and decreases the carbon footprint. The design focuses on managing the intermittent nature of renewable sources while maintaining stable thermal performance across the network.

- Advanced heat exchanger configurations and materials: Innovative heat exchanger configurations and advanced materials are utilized to improve heat transfer efficiency. These include compact heat exchangers, micro-channel designs, and the use of high thermal conductivity materials. Such advancements allow for better heat transfer rates, reduced fouling, and improved durability, contributing to the overall efficiency of the heat exchange network.

- Process integration and pinch analysis techniques: Process integration methodologies and pinch analysis techniques are applied to optimize heat exchange network design. These approaches identify opportunities for energy recovery within industrial processes by analyzing the temperature-enthalpy profiles of hot and cold streams. By determining the minimum energy requirements and optimal heat recovery potential, these techniques lead to more efficient network designs with reduced utility consumption.

- Smart control systems and real-time optimization: Implementation of smart control systems and real-time optimization strategies enhances the operational efficiency of heat exchange networks. These systems utilize sensors, data analytics, and machine learning algorithms to continuously monitor and adjust network parameters based on changing process conditions. Dynamic optimization allows for adaptive operation, ensuring optimal performance under varying loads and environmental conditions.

02 Integration of renewable energy sources in heat exchange networks

Heat exchange networks can be designed to efficiently integrate renewable energy sources, such as solar, geothermal, or waste heat recovery systems. This approach reduces dependency on conventional energy sources and decreases carbon emissions. The design focuses on accommodating the variable nature of renewable energy inputs while maintaining stable thermal performance across the network, thereby improving overall energy efficiency and sustainability.Expand Specific Solutions03 Advanced materials and construction techniques for heat exchangers

The use of advanced materials and innovative construction techniques significantly improves the efficiency of heat exchange networks. High thermal conductivity materials, corrosion-resistant alloys, and specialized surface treatments enhance heat transfer rates and extend equipment lifespan. Novel fabrication methods, such as additive manufacturing and micro-channel designs, allow for more compact and efficient heat exchanger units that can operate under extreme conditions with minimal maintenance requirements.Expand Specific Solutions04 Process integration and pinch analysis techniques

Process integration methodologies and pinch analysis techniques are fundamental approaches for optimizing heat exchange network design. These methods identify the minimum energy requirements and optimal heat recovery opportunities within industrial processes. By analyzing temperature-enthalpy profiles and establishing energy targets, engineers can design networks that maximize heat recovery between hot and cold streams, minimize utility consumption, and reduce operational costs while maintaining process requirements.Expand Specific Solutions05 Dynamic control systems and real-time optimization

Implementation of dynamic control systems and real-time optimization strategies enhances the operational efficiency of heat exchange networks. Advanced sensors, monitoring equipment, and automated control algorithms allow for continuous adjustment of operating parameters in response to changing process conditions. These systems can detect performance degradation, predict maintenance needs, and automatically optimize flow distribution and temperature profiles to maintain peak efficiency under varying load conditions.Expand Specific Solutions

Leading Companies in Cryogenic Carbon Capture Industry

The cryogenic CO2 capture technology market is in a growth phase, with increasing focus on carbon reduction driving demand. The market is expanding rapidly due to global climate initiatives, with significant investments in research and development. Technologically, the field shows varying maturity levels across players. Leading companies like Air Liquide, Saudi Aramco, and Huaneng Clean Energy Research Institute have established strong positions through commercial-scale implementations. Academic institutions including Tianjin University and Harbin Institute of Technology contribute significant research advancements. Specialized firms like 8 Rivers Capital and Carboncapture are developing innovative solutions, while industrial players such as DENSO and Sanhua Holding Group bring manufacturing expertise to heat exchange network optimization for cryogenic applications.

Huaneng Clean Energy Research Institute

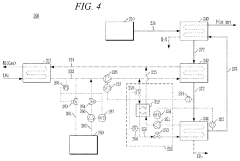

Technical Solution: Huaneng Clean Energy Research Institute has developed an innovative cryogenic CO2 capture system with an advanced heat exchange network specifically designed for coal-fired power plants. Their approach utilizes a multi-stage flash separation process combined with an optimized heat integration strategy. The heat exchange network incorporates both shell-and-tube and plate heat exchangers arranged in a pinch-optimized configuration that minimizes external utility requirements. A distinctive feature is their dual-pressure refrigeration cycle that provides cooling at two temperature levels, matching the thermodynamic requirements of different process stages. The institute has implemented specialized heat exchangers with enhanced tube geometries that increase heat transfer coefficients by approximately 30% compared to conventional designs. Their system achieves a minimum approach temperature of 3°C in the main cryogenic heat exchangers while maintaining reasonable pressure drops. The heat exchange network recovers approximately 75% of the available cold energy from the CO2 liquefaction process, significantly reducing the overall energy penalty of the capture system. The institute has demonstrated this technology at pilot scale at several Huaneng power plants in China.

Strengths: Specifically optimized for integration with existing coal-fired power plants with demonstrated performance at pilot scale. Their system achieves lower energy penalties compared to conventional amine-based systems when integrated with power plant waste heat. Weaknesses: Higher complexity in control systems and operational challenges during load variations. The system requires significant modifications to existing plant infrastructure for optimal integration.

Air Liquide SA

Technical Solution: Air Liquide has developed advanced cryogenic CO2 capture technologies utilizing optimized heat exchange network designs. Their approach incorporates multi-stream plate-fin heat exchangers that maximize thermal efficiency in cryogenic separation processes. The company's Cryocap™ technology specifically addresses CO2 capture from industrial processes using an integrated heat exchange network that recovers cold energy from the CO2 liquefaction process and reuses it within the system. Their design incorporates specialized aluminum brazed plate-fin heat exchangers with enhanced surface geometries that minimize pressure drop while maximizing heat transfer coefficients. Air Liquide's systems typically achieve temperature approaches of less than 2°C between streams, significantly reducing the overall energy requirement for CO2 separation. The company has implemented spiral-wound heat exchangers for handling high-pressure CO2 streams, which provide better resistance to thermal cycling and pressure fluctuations compared to conventional shell-and-tube designs.

Strengths: Industry-leading expertise in cryogenic processes with proprietary heat exchanger designs that achieve exceptional thermal efficiency. Their integrated approach reduces overall energy consumption by 15-25% compared to conventional systems. Weaknesses: Higher capital costs for specialized heat exchanger equipment and complexity in system integration requiring advanced control systems.

Key Patents and Innovations in Cryogenic Heat Exchange

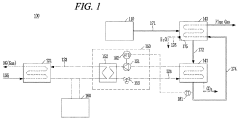

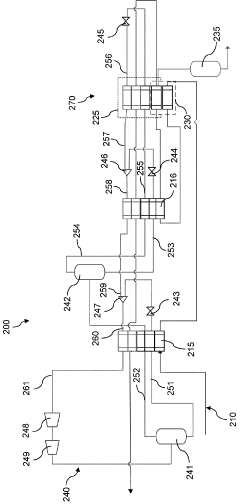

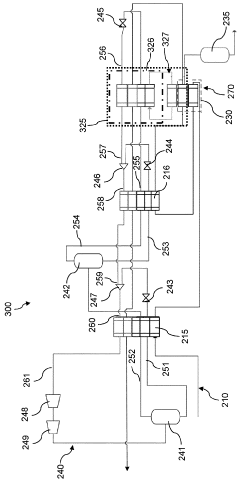

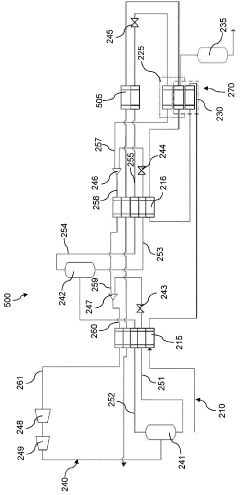

Carbon dioxide capturing apparatus using cold heat of liquefied natural gas and power generation system using same

PatentActiveUS11071938B2

Innovation

- A carbon dioxide capturing apparatus utilizing the cold heat of liquefied natural gas (LNG) to cool a primary coolant, which is then used to capture CO2 from flue gas through a series of heat exchangers and chillers, achieving cryogenic temperatures to convert CO2 into dry ice, thereby reducing emissions and improving safety.

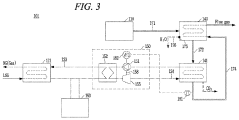

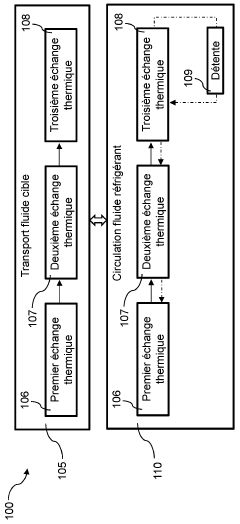

Device and method for cryogenic capture of carbon dioxide contained in a target fluid stream

PatentWO2024003285A1

Innovation

- A device and method for cryogenic capture of carbon dioxide using a closed circuit with multiple heat exchangers and a refrigerant fluid mixture of hydrocarbons (methane, ethane, propane, isobutane, and n-butane) that allows for pre-cooling and anti-sublimation without liquid condensation, optimizing heat exchanges and reducing energy costs.

Energy Integration and Process Intensification Strategies

Energy integration and process intensification represent critical strategies for enhancing the efficiency and economic viability of cryogenic CO2 capture units. These approaches focus on minimizing energy consumption while maximizing capture performance through innovative system designs and operational methodologies.

The integration of heat exchange networks within cryogenic CO2 capture processes presents significant opportunities for energy recovery. By strategically positioning heat exchangers to facilitate thermal energy transfer between process streams, facilities can reduce external cooling and heating requirements by 25-40%. Multi-stream heat exchangers, particularly plate-fin and spiral-wound varieties, have demonstrated exceptional performance in cryogenic applications due to their compact design and high thermal efficiency.

Process intensification techniques further enhance system performance through the combination of multiple unit operations into integrated modules. For cryogenic CO2 capture, this includes the development of combined separation-heat exchange units that simultaneously perform phase separation and energy recovery functions. Research indicates that such integrated designs can reduce the physical footprint by up to 30% while improving overall thermodynamic efficiency.

Pinch analysis methodology has emerged as a powerful tool for optimizing heat exchange networks in cryogenic systems. By identifying the minimum energy requirements and optimal temperature approaches, engineers can design networks that achieve maximum energy recovery. Studies show that properly implemented pinch analysis can reduce external refrigeration loads by 15-35% in cryogenic CO2 capture applications.

Advanced exergy analysis techniques complement traditional energy integration approaches by identifying irreversibilities within the system. This analysis reveals opportunities for process modifications that minimize entropy generation, particularly in the critical low-temperature sections of cryogenic capture units where thermodynamic inefficiencies are most costly.

Novel working fluid combinations represent another frontier in process intensification for cryogenic capture. Mixed refrigerant cycles utilizing carefully selected fluid compositions can better match the cooling curve of the CO2 separation process, reducing temperature differences and associated thermodynamic losses. Recent developments in this area have demonstrated potential energy savings of 10-20% compared to conventional single-refrigerant systems.

The implementation of dynamic heat integration strategies allows capture systems to maintain optimal performance across varying operating conditions. Adaptive control systems that adjust flow distributions and temperature approaches in response to changing process parameters ensure consistent energy efficiency despite fluctuations in feed composition or capture requirements.

The integration of heat exchange networks within cryogenic CO2 capture processes presents significant opportunities for energy recovery. By strategically positioning heat exchangers to facilitate thermal energy transfer between process streams, facilities can reduce external cooling and heating requirements by 25-40%. Multi-stream heat exchangers, particularly plate-fin and spiral-wound varieties, have demonstrated exceptional performance in cryogenic applications due to their compact design and high thermal efficiency.

Process intensification techniques further enhance system performance through the combination of multiple unit operations into integrated modules. For cryogenic CO2 capture, this includes the development of combined separation-heat exchange units that simultaneously perform phase separation and energy recovery functions. Research indicates that such integrated designs can reduce the physical footprint by up to 30% while improving overall thermodynamic efficiency.

Pinch analysis methodology has emerged as a powerful tool for optimizing heat exchange networks in cryogenic systems. By identifying the minimum energy requirements and optimal temperature approaches, engineers can design networks that achieve maximum energy recovery. Studies show that properly implemented pinch analysis can reduce external refrigeration loads by 15-35% in cryogenic CO2 capture applications.

Advanced exergy analysis techniques complement traditional energy integration approaches by identifying irreversibilities within the system. This analysis reveals opportunities for process modifications that minimize entropy generation, particularly in the critical low-temperature sections of cryogenic capture units where thermodynamic inefficiencies are most costly.

Novel working fluid combinations represent another frontier in process intensification for cryogenic capture. Mixed refrigerant cycles utilizing carefully selected fluid compositions can better match the cooling curve of the CO2 separation process, reducing temperature differences and associated thermodynamic losses. Recent developments in this area have demonstrated potential energy savings of 10-20% compared to conventional single-refrigerant systems.

The implementation of dynamic heat integration strategies allows capture systems to maintain optimal performance across varying operating conditions. Adaptive control systems that adjust flow distributions and temperature approaches in response to changing process parameters ensure consistent energy efficiency despite fluctuations in feed composition or capture requirements.

Environmental Impact and Sustainability Assessment

The environmental impact of cryogenic CO2 capture systems extends far beyond their primary function of carbon sequestration. These systems, while designed to mitigate greenhouse gas emissions, themselves carry significant environmental footprints that must be carefully assessed. The intensive energy requirements for cooling processes to cryogenic temperatures (-100°C to -140°C) represent a substantial indirect environmental burden, particularly when powered by fossil fuel sources. This creates a paradoxical situation where carbon capture technology may initially contribute to the very problem it aims to solve.

Life cycle assessment (LCA) studies reveal that cryogenic CO2 capture units demonstrate varying environmental performance metrics depending on their integration with existing power generation facilities. When powered by renewable energy sources, these systems show promising net environmental benefits. However, when dependent on conventional energy grids, their overall carbon reduction efficiency decreases substantially, with some configurations requiring up to 30% additional energy compared to the original emissions-producing process.

Water consumption presents another critical environmental consideration. Cryogenic systems typically require less direct water usage compared to amine-based capture technologies, potentially reducing water stress in arid regions. Nevertheless, the indirect water footprint associated with increased energy production remains significant and must be factored into comprehensive sustainability assessments.

The refrigerants employed in cryogenic processes introduce additional environmental concerns. While modern systems increasingly utilize natural refrigerants with lower global warming potential, the risk of refrigerant leakage and subsequent atmospheric impact necessitates robust monitoring and maintenance protocols. Recent technological innovations have reduced these risks through advanced containment designs and leak detection systems.

From a sustainability perspective, cryogenic CO2 capture presents compelling advantages in terms of chemical usage. Unlike solvent-based approaches that require continuous chemical replenishment and generate hazardous waste streams, cryogenic methods operate primarily through physical phase changes, substantially reducing chemical-related environmental impacts and disposal challenges.

The land use requirements for cryogenic capture facilities must also be evaluated within broader sustainability frameworks. While the physical footprint may be comparable to alternative capture technologies, the additional infrastructure needed for cryogenic cooling and potential CO2 transportation creates cascading land use implications that extend beyond the immediate facility boundaries.

Life cycle assessment (LCA) studies reveal that cryogenic CO2 capture units demonstrate varying environmental performance metrics depending on their integration with existing power generation facilities. When powered by renewable energy sources, these systems show promising net environmental benefits. However, when dependent on conventional energy grids, their overall carbon reduction efficiency decreases substantially, with some configurations requiring up to 30% additional energy compared to the original emissions-producing process.

Water consumption presents another critical environmental consideration. Cryogenic systems typically require less direct water usage compared to amine-based capture technologies, potentially reducing water stress in arid regions. Nevertheless, the indirect water footprint associated with increased energy production remains significant and must be factored into comprehensive sustainability assessments.

The refrigerants employed in cryogenic processes introduce additional environmental concerns. While modern systems increasingly utilize natural refrigerants with lower global warming potential, the risk of refrigerant leakage and subsequent atmospheric impact necessitates robust monitoring and maintenance protocols. Recent technological innovations have reduced these risks through advanced containment designs and leak detection systems.

From a sustainability perspective, cryogenic CO2 capture presents compelling advantages in terms of chemical usage. Unlike solvent-based approaches that require continuous chemical replenishment and generate hazardous waste streams, cryogenic methods operate primarily through physical phase changes, substantially reducing chemical-related environmental impacts and disposal challenges.

The land use requirements for cryogenic capture facilities must also be evaluated within broader sustainability frameworks. While the physical footprint may be comparable to alternative capture technologies, the additional infrastructure needed for cryogenic cooling and potential CO2 transportation creates cascading land use implications that extend beyond the immediate facility boundaries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!