Modeling CO2 Deposition Kinetics Under Flue Gas Compositions

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CO2 Deposition Background and Objectives

Carbon dioxide deposition, also known as CO2 desublimation or frost formation, represents a critical process in various industrial applications, particularly in carbon capture and storage (CCS) technologies. The phenomenon involves the direct phase transition of gaseous CO2 to solid state without passing through the liquid phase, occurring under specific temperature and pressure conditions. This process has gained significant attention over the past decades as global efforts to mitigate climate change have intensified.

The historical development of CO2 deposition research dates back to the early 20th century with fundamental thermodynamic studies. However, it wasn't until the 1970s and 1980s that serious industrial applications began to emerge, primarily in cryogenic separation processes. The 1990s marked a turning point with the Kyoto Protocol highlighting the urgency of greenhouse gas reduction, which catalyzed research into carbon capture technologies including deposition-based approaches.

Recent technological advancements have significantly expanded our understanding of CO2 deposition kinetics, particularly in complex gas mixtures that simulate real-world flue gas compositions. These mixtures typically contain varying concentrations of nitrogen, oxygen, water vapor, sulfur oxides, and nitrogen oxides, all of which can substantially influence deposition behavior and efficiency.

The primary objective of modeling CO2 deposition kinetics under flue gas compositions is to develop accurate predictive frameworks that can optimize industrial-scale carbon capture processes. Specifically, these models aim to predict deposition rates, purity of captured CO2, energy requirements, and overall process efficiency under varying operational conditions and gas compositions.

Current technological trends indicate a shift toward more sophisticated multi-physics modeling approaches that integrate molecular dynamics, computational fluid dynamics, and machine learning techniques. These advanced models seek to address the complex interplay between heat transfer, mass transfer, and surface chemistry that governs the deposition process.

The ultimate goal of this research direction is to enable the design of more efficient, cost-effective carbon capture systems that can be deployed at scale across various industries, particularly power generation, cement production, and steel manufacturing. By accurately modeling CO2 deposition behavior in realistic flue gas environments, researchers and engineers can overcome current technological barriers and develop next-generation carbon capture solutions.

Furthermore, this research aims to establish standardized methodologies for predicting CO2 deposition behavior that can inform regulatory frameworks and industry standards, facilitating broader adoption of these technologies in the global effort to achieve carbon neutrality targets by mid-century.

The historical development of CO2 deposition research dates back to the early 20th century with fundamental thermodynamic studies. However, it wasn't until the 1970s and 1980s that serious industrial applications began to emerge, primarily in cryogenic separation processes. The 1990s marked a turning point with the Kyoto Protocol highlighting the urgency of greenhouse gas reduction, which catalyzed research into carbon capture technologies including deposition-based approaches.

Recent technological advancements have significantly expanded our understanding of CO2 deposition kinetics, particularly in complex gas mixtures that simulate real-world flue gas compositions. These mixtures typically contain varying concentrations of nitrogen, oxygen, water vapor, sulfur oxides, and nitrogen oxides, all of which can substantially influence deposition behavior and efficiency.

The primary objective of modeling CO2 deposition kinetics under flue gas compositions is to develop accurate predictive frameworks that can optimize industrial-scale carbon capture processes. Specifically, these models aim to predict deposition rates, purity of captured CO2, energy requirements, and overall process efficiency under varying operational conditions and gas compositions.

Current technological trends indicate a shift toward more sophisticated multi-physics modeling approaches that integrate molecular dynamics, computational fluid dynamics, and machine learning techniques. These advanced models seek to address the complex interplay between heat transfer, mass transfer, and surface chemistry that governs the deposition process.

The ultimate goal of this research direction is to enable the design of more efficient, cost-effective carbon capture systems that can be deployed at scale across various industries, particularly power generation, cement production, and steel manufacturing. By accurately modeling CO2 deposition behavior in realistic flue gas environments, researchers and engineers can overcome current technological barriers and develop next-generation carbon capture solutions.

Furthermore, this research aims to establish standardized methodologies for predicting CO2 deposition behavior that can inform regulatory frameworks and industry standards, facilitating broader adoption of these technologies in the global effort to achieve carbon neutrality targets by mid-century.

Market Analysis for Carbon Capture Technologies

The carbon capture and storage (CCS) market has experienced significant growth in recent years, driven by increasing global focus on climate change mitigation and stringent carbon emission regulations. The global carbon capture market was valued at approximately $2.9 billion in 2022 and is projected to reach $7.0 billion by 2030, growing at a CAGR of 11.8% during the forecast period. This growth trajectory is primarily fueled by government initiatives, corporate sustainability commitments, and technological advancements in CO2 capture methodologies.

The market for technologies specifically addressing CO2 deposition kinetics under flue gas compositions is positioned within the larger post-combustion capture segment, which currently dominates the CCS market with over 60% market share. This dominance stems from the relative maturity of post-combustion technologies and their applicability to existing industrial infrastructure without requiring fundamental process redesigns.

Regional analysis reveals that North America and Europe lead the carbon capture market, collectively accounting for approximately 70% of global installations. However, Asia-Pacific, particularly China and India, represents the fastest-growing region with projected growth rates exceeding 15% annually through 2030, driven by rapid industrialization coupled with emerging climate policies.

Industry-wise, power generation remains the largest application sector, representing approximately 45% of the total market. However, cement, steel, and chemical manufacturing sectors are showing accelerated adoption rates due to their carbon-intensive processes and limited alternative decarbonization options. These hard-to-abate sectors are expected to be key growth drivers for advanced CO2 deposition modeling technologies.

The economic viability of carbon capture technologies continues to improve, with capture costs decreasing from $80-120 per ton of CO2 in 2010 to $40-80 per ton in recent implementations. Technologies specifically optimizing CO2 deposition kinetics under varying flue gas compositions have demonstrated potential to further reduce these costs by 15-25% through improved efficiency and reduced energy penalties.

Market barriers include high capital expenditure requirements, uncertain regulatory frameworks in many regions, and technical challenges related to varying flue gas compositions across different industrial applications. Despite these challenges, the increasing adoption of carbon pricing mechanisms globally and corporate net-zero commitments are creating strong market pull for advanced modeling solutions that can optimize carbon capture performance across diverse operational conditions.

The market for technologies specifically addressing CO2 deposition kinetics under flue gas compositions is positioned within the larger post-combustion capture segment, which currently dominates the CCS market with over 60% market share. This dominance stems from the relative maturity of post-combustion technologies and their applicability to existing industrial infrastructure without requiring fundamental process redesigns.

Regional analysis reveals that North America and Europe lead the carbon capture market, collectively accounting for approximately 70% of global installations. However, Asia-Pacific, particularly China and India, represents the fastest-growing region with projected growth rates exceeding 15% annually through 2030, driven by rapid industrialization coupled with emerging climate policies.

Industry-wise, power generation remains the largest application sector, representing approximately 45% of the total market. However, cement, steel, and chemical manufacturing sectors are showing accelerated adoption rates due to their carbon-intensive processes and limited alternative decarbonization options. These hard-to-abate sectors are expected to be key growth drivers for advanced CO2 deposition modeling technologies.

The economic viability of carbon capture technologies continues to improve, with capture costs decreasing from $80-120 per ton of CO2 in 2010 to $40-80 per ton in recent implementations. Technologies specifically optimizing CO2 deposition kinetics under varying flue gas compositions have demonstrated potential to further reduce these costs by 15-25% through improved efficiency and reduced energy penalties.

Market barriers include high capital expenditure requirements, uncertain regulatory frameworks in many regions, and technical challenges related to varying flue gas compositions across different industrial applications. Despite these challenges, the increasing adoption of carbon pricing mechanisms globally and corporate net-zero commitments are creating strong market pull for advanced modeling solutions that can optimize carbon capture performance across diverse operational conditions.

Current Challenges in CO2 Deposition Modeling

Despite significant advancements in carbon capture technologies, modeling CO2 deposition kinetics under flue gas compositions presents several persistent challenges that impede the development of efficient carbon capture systems. The complexity of flue gas compositions, which vary significantly across different industrial processes, creates a fundamental obstacle in developing universally applicable models. These compositions can include varying concentrations of CO2, SOx, NOx, water vapor, particulate matter, and trace elements, each affecting deposition behavior differently.

Temperature and pressure fluctuations in industrial settings further complicate modeling efforts. Current models often struggle to account for the non-linear relationships between these parameters and deposition rates, particularly at the extreme conditions found in many industrial processes. This limitation reduces the predictive accuracy of existing models when applied to real-world scenarios.

The multiphase nature of CO2 deposition processes introduces additional complexity. Interactions between gas, liquid, and solid phases during deposition create intricate thermodynamic and kinetic relationships that are difficult to capture in computational models. Current approaches often oversimplify these interactions, leading to significant discrepancies between predicted and observed deposition behaviors.

Surface chemistry and material interactions represent another critical challenge. The chemical and physical properties of deposition surfaces significantly influence CO2 deposition kinetics, yet many models inadequately account for these effects. Surface roughness, chemical composition, and catalytic properties can dramatically alter deposition patterns and rates, creating scenarios where seemingly identical conditions produce vastly different outcomes.

Computational limitations also constrain current modeling approaches. High-fidelity models that incorporate detailed chemical kinetics, fluid dynamics, and heat transfer require substantial computational resources, making them impractical for real-time applications or extensive parametric studies. This forces researchers to make compromises between model accuracy and computational efficiency.

The lack of comprehensive experimental validation data presents perhaps the most significant barrier to advancement. Laboratory studies often fail to replicate the complex conditions found in industrial settings, while field measurements are frequently limited by accessibility and measurement challenges. This data gap makes it difficult to validate and refine existing models, particularly for novel carbon capture technologies or unconventional flue gas compositions.

Scaling issues further complicate the application of laboratory-derived models to industrial-scale processes. Phenomena that are negligible at laboratory scale may become dominant at industrial scale, creating unexpected deposition patterns that current models fail to predict.

Temperature and pressure fluctuations in industrial settings further complicate modeling efforts. Current models often struggle to account for the non-linear relationships between these parameters and deposition rates, particularly at the extreme conditions found in many industrial processes. This limitation reduces the predictive accuracy of existing models when applied to real-world scenarios.

The multiphase nature of CO2 deposition processes introduces additional complexity. Interactions between gas, liquid, and solid phases during deposition create intricate thermodynamic and kinetic relationships that are difficult to capture in computational models. Current approaches often oversimplify these interactions, leading to significant discrepancies between predicted and observed deposition behaviors.

Surface chemistry and material interactions represent another critical challenge. The chemical and physical properties of deposition surfaces significantly influence CO2 deposition kinetics, yet many models inadequately account for these effects. Surface roughness, chemical composition, and catalytic properties can dramatically alter deposition patterns and rates, creating scenarios where seemingly identical conditions produce vastly different outcomes.

Computational limitations also constrain current modeling approaches. High-fidelity models that incorporate detailed chemical kinetics, fluid dynamics, and heat transfer require substantial computational resources, making them impractical for real-time applications or extensive parametric studies. This forces researchers to make compromises between model accuracy and computational efficiency.

The lack of comprehensive experimental validation data presents perhaps the most significant barrier to advancement. Laboratory studies often fail to replicate the complex conditions found in industrial settings, while field measurements are frequently limited by accessibility and measurement challenges. This data gap makes it difficult to validate and refine existing models, particularly for novel carbon capture technologies or unconventional flue gas compositions.

Scaling issues further complicate the application of laboratory-derived models to industrial-scale processes. Phenomena that are negligible at laboratory scale may become dominant at industrial scale, creating unexpected deposition patterns that current models fail to predict.

Existing CO2 Deposition Kinetic Models

01 CO2 deposition kinetics in carbon capture systems

The kinetics of CO2 deposition in carbon capture systems involves the study of reaction rates and mechanisms by which carbon dioxide is captured and deposited. These systems typically employ various sorbents or catalysts to enhance the capture efficiency. The deposition process is influenced by factors such as temperature, pressure, and the presence of other gases. Understanding these kinetics is crucial for designing efficient carbon capture technologies that can help mitigate greenhouse gas emissions.- CO2 capture and deposition mechanisms: Various mechanisms for capturing and depositing carbon dioxide are explored, including chemical absorption, adsorption, and membrane separation technologies. These processes involve the study of reaction kinetics between CO2 and different sorbents or catalysts, optimizing the rate of CO2 capture and deposition under various temperature and pressure conditions. Understanding these mechanisms is crucial for developing efficient carbon capture systems with improved deposition rates and capacity.

- Monitoring and analysis of CO2 deposition kinetics: Advanced analytical techniques and monitoring systems are employed to study CO2 deposition kinetics in real-time. These include spectroscopic methods, chromatography, and specialized sensors that can track the rate of CO2 deposition, reaction intermediates, and product formation. Such monitoring systems enable researchers to optimize process parameters, identify rate-limiting steps, and develop mathematical models that accurately describe the kinetics of CO2 deposition under various conditions.

- Temperature and pressure effects on CO2 deposition: The influence of temperature and pressure on CO2 deposition kinetics is extensively studied to determine optimal operating conditions. Research shows that temperature affects reaction rates according to the Arrhenius equation, while pressure impacts the equilibrium and mass transfer of CO2. By manipulating these parameters, researchers can enhance deposition efficiency, control reaction pathways, and improve the overall performance of carbon capture and utilization systems.

- Catalyst development for enhanced CO2 deposition: Novel catalysts are being developed to accelerate CO2 deposition reactions and improve conversion efficiency. These include metal-based catalysts, nanostructured materials, and composite systems that can lower activation energy barriers and promote selective reaction pathways. Research focuses on understanding catalyst surface interactions with CO2, reaction mechanisms, and deactivation processes to design more stable and efficient catalytic systems for carbon capture and utilization applications.

- Biological approaches to CO2 deposition: Biological systems and biomimetic approaches are being explored for CO2 capture and deposition. These include engineered microorganisms, enzymes, and biologically-inspired materials that can efficiently convert CO2 into valuable products or stable forms for sequestration. The kinetics of these biological processes are studied to understand factors affecting reaction rates, substrate specificity, and product formation, leading to the development of more efficient and sustainable carbon capture technologies.

02 Modeling and simulation of CO2 deposition processes

Computational modeling and simulation techniques are employed to understand and predict CO2 deposition kinetics. These models incorporate various parameters such as reaction rates, mass transfer coefficients, and thermodynamic properties to simulate the deposition process under different conditions. Advanced simulation tools help in optimizing process conditions and designing more efficient systems for CO2 capture and utilization. These approaches reduce the need for extensive experimental work and accelerate the development of new technologies.Expand Specific Solutions03 Measurement techniques for CO2 deposition kinetics

Various analytical and measurement techniques are used to study CO2 deposition kinetics. These include spectroscopic methods, calorimetry, gravimetric analysis, and in-situ monitoring systems that can track the deposition process in real-time. Advanced sensors and monitoring equipment allow researchers to measure reaction rates, determine activation energies, and characterize the deposition mechanisms under different conditions. These measurements are essential for validating theoretical models and optimizing process parameters.Expand Specific Solutions04 Novel materials for enhanced CO2 deposition

Research on novel materials focuses on developing substrates, catalysts, and sorbents that can enhance CO2 deposition kinetics. These materials include metal-organic frameworks, functionalized polymers, modified zeolites, and nanostructured materials with high surface areas. The design of these materials aims to increase CO2 adsorption capacity, improve selectivity, and enhance the kinetics of the deposition process. Material properties such as porosity, surface chemistry, and thermal stability play crucial roles in determining their effectiveness for CO2 capture.Expand Specific Solutions05 Biological approaches to CO2 deposition kinetics

Biological systems offer alternative approaches to studying and enhancing CO2 deposition kinetics. These include enzyme-catalyzed reactions, microbial processes, and biomimetic systems that replicate natural carbon fixation mechanisms. Biological approaches often operate under mild conditions and can achieve high selectivity. Research in this area focuses on understanding the kinetics of biological CO2 fixation and developing bioinspired materials and processes for carbon capture and utilization. These approaches may offer sustainable alternatives to conventional chemical processes.Expand Specific Solutions

Leading Organizations in CO2 Capture Research

CO2 deposition kinetics under flue gas compositions is currently in an early growth phase, with the market expanding rapidly due to increasing carbon capture initiatives. The global market size is projected to reach significant scale as industries seek to reduce emissions. Technologically, the field is advancing from experimental to commercial applications, with varying maturity levels across players. Air Liquide and ExxonMobil Technology & Engineering lead with established carbon capture technologies, while companies like CarbonQuest and TDA Research are developing innovative approaches. Chinese entities including PetroChina, Sinopec, and research institutions like Beijing University of Technology are making substantial investments in this space, particularly for coal-fired power applications. Collaboration between academic institutions and industry players is accelerating technological development.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed advanced modeling approaches for CO2 deposition kinetics under various flue gas compositions, focusing on carbon capture and storage (CCS) technologies. Their proprietary Controlled Freeze Zone™ (CFZ) technology represents a significant advancement in CO2 separation from flue gases. This process involves controlled freezing of CO2 from gas streams, allowing for precise modeling of deposition kinetics under different temperature and pressure conditions. ExxonMobil's models incorporate comprehensive thermodynamic parameters and reaction kinetics to predict CO2 phase behavior during deposition processes. Their approach includes detailed computational fluid dynamics (CFD) simulations that account for heat and mass transfer phenomena during CO2 solidification. The company has also developed predictive models that consider the effects of various flue gas contaminants (SOx, NOx, water vapor) on CO2 deposition rates and deposit characteristics, enabling optimization of capture processes for different industrial applications.

Strengths: Proprietary CFZ technology provides unique insights into CO2 freezing behavior; extensive industrial-scale testing capabilities; models incorporate real-world operational variables from petroleum and power generation facilities. Weaknesses: Models may be optimized primarily for natural gas processing rather than diverse industrial flue gas compositions; proprietary nature limits academic validation and broader application.

IFP Energies Nouvelles

Technical Solution: IFP Energies Nouvelles has developed sophisticated multi-scale modeling approaches for CO2 deposition kinetics, particularly focusing on cryogenic carbon capture processes. Their models integrate molecular-level simulations with process-scale modeling to accurately predict CO2 deposition behavior under varying flue gas compositions. IFP's approach incorporates detailed reaction mechanisms that account for the influence of common flue gas components (SOx, NOx, O2, H2O) on CO2 crystallization and deposition rates. Their models utilize advanced computational methods to simulate heat and mass transfer during CO2 phase transitions, enabling precise prediction of deposition patterns and rates. IFP has also developed specialized kinetic models that consider the effects of pressure, temperature, and gas velocity on CO2 deposition efficiency. These models have been validated through extensive laboratory experiments and pilot-scale testing, allowing for accurate scaling to industrial applications. Additionally, IFP's research includes the development of novel anti-agglomeration techniques to prevent operational issues during CO2 deposition processes in carbon capture systems.

Strengths: Comprehensive multi-scale modeling approach bridges molecular and process engineering perspectives; strong focus on practical industrial applications; extensive validation through experimental work. Weaknesses: Models may require significant computational resources; some aspects of the technology remain proprietary, limiting broader scientific validation and implementation.

Key Scientific Advances in Flue Gas Interactions

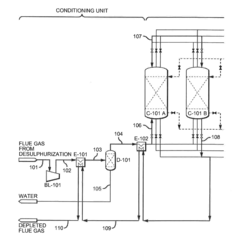

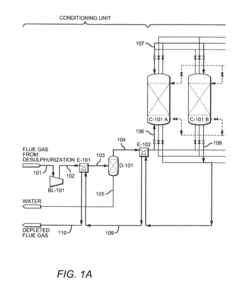

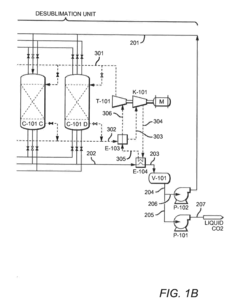

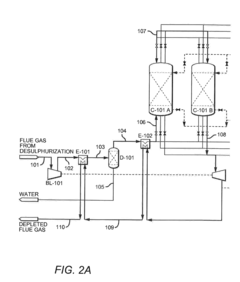

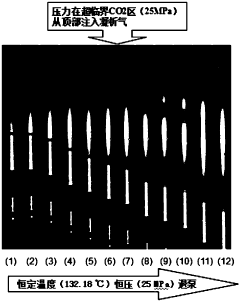

Configurations and methods of co2 capture from FLUE gas by cryogenic desublimation

PatentActiveUS20160327337A1

Innovation

- A CO2 capture system utilizing a plurality of desublimators fluidly coupled via valves and a control unit, operating in desublimation, regeneration, and deep-cooling modes, with recycled refrigeration content to enhance energy efficiency, and a flue gas conditioning unit that cools flue gas using CO2-depleted gas, allowing for efficient CO2 separation and recovery as a solid at low pressure.

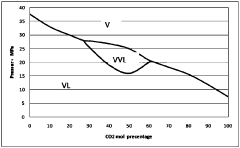

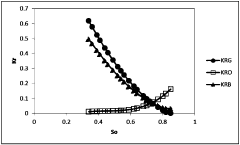

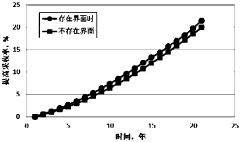

Interface-phase-considered supercritical CO2-condensate gas multiphase seepage simulation method

PatentActiveCN110298048A

Innovation

- A supercritical CO2-condensate gas multiphase seepage simulation method considering the interface phase is proposed. By determining the basic parameters of the CO2-condensate gas system, a multiphase seepage model is established, and long core experiments and numerical simulations are used to introduce CO2 injection at the injection end. The volume and condensate oil and gas production data at the production end are used to calculate the saturation and pressure parameters of each phase and simulate the CO2 displacement process.

Environmental Impact Assessment

The environmental implications of CO2 deposition processes under varying flue gas compositions extend far beyond the immediate technical considerations. When evaluating carbon capture technologies, their overall environmental footprint must be thoroughly assessed to ensure that solutions do not create secondary environmental problems while addressing carbon emissions.

The modeling of CO2 deposition kinetics directly influences the efficiency of carbon capture systems, which in turn affects their environmental impact. More efficient deposition processes require less energy input per ton of CO2 captured, resulting in lower auxiliary emissions from power generation. Research indicates that optimized kinetic models can potentially reduce the energy penalty of carbon capture by 15-20%, significantly decreasing the overall carbon footprint of these technologies.

Water consumption represents another critical environmental consideration. CO2 deposition processes utilizing certain solvents or requiring cooling systems can consume substantial quantities of water. Models that accurately predict deposition behavior under various flue gas compositions can help optimize water usage, potentially reducing consumption by up to 30% compared to non-optimized systems. This is particularly significant in water-stressed regions where carbon capture facilities might operate.

Chemical emissions from CO2 capture processes present additional environmental concerns. Depending on the specific technology employed, various chemical compounds may be released, including amine degradation products, ammonia, or other potentially harmful substances. Accurate modeling of deposition kinetics enables better prediction and mitigation of these secondary emissions, ensuring that solving one environmental problem doesn't exacerbate others.

Land use impacts must also be considered, as carbon capture facilities require significant space. The efficiency of deposition processes directly influences the physical footprint of these installations. More efficient kinetic models can lead to more compact designs, reducing land disturbance and habitat fragmentation. Current research suggests that advanced modeling approaches could reduce facility footprints by up to 25% compared to conventional designs.

Lifecycle assessment studies indicate that the environmental benefits of carbon capture technologies heavily depend on the efficiency of the deposition process. When properly optimized through accurate kinetic modeling, the net environmental benefit can be substantial, with greenhouse gas reductions of 80-90% compared to unabated emissions. However, poorly designed systems may achieve only 50-60% reductions while generating significant secondary environmental impacts.

The long-term fate of captured CO2 also warrants consideration. Whether utilized in enhanced oil recovery, converted to useful products, or permanently sequestered, the environmental implications vary considerably. Kinetic models that account for impurities in flue gas can better predict long-term storage stability and potential environmental risks associated with CO2 storage.

The modeling of CO2 deposition kinetics directly influences the efficiency of carbon capture systems, which in turn affects their environmental impact. More efficient deposition processes require less energy input per ton of CO2 captured, resulting in lower auxiliary emissions from power generation. Research indicates that optimized kinetic models can potentially reduce the energy penalty of carbon capture by 15-20%, significantly decreasing the overall carbon footprint of these technologies.

Water consumption represents another critical environmental consideration. CO2 deposition processes utilizing certain solvents or requiring cooling systems can consume substantial quantities of water. Models that accurately predict deposition behavior under various flue gas compositions can help optimize water usage, potentially reducing consumption by up to 30% compared to non-optimized systems. This is particularly significant in water-stressed regions where carbon capture facilities might operate.

Chemical emissions from CO2 capture processes present additional environmental concerns. Depending on the specific technology employed, various chemical compounds may be released, including amine degradation products, ammonia, or other potentially harmful substances. Accurate modeling of deposition kinetics enables better prediction and mitigation of these secondary emissions, ensuring that solving one environmental problem doesn't exacerbate others.

Land use impacts must also be considered, as carbon capture facilities require significant space. The efficiency of deposition processes directly influences the physical footprint of these installations. More efficient kinetic models can lead to more compact designs, reducing land disturbance and habitat fragmentation. Current research suggests that advanced modeling approaches could reduce facility footprints by up to 25% compared to conventional designs.

Lifecycle assessment studies indicate that the environmental benefits of carbon capture technologies heavily depend on the efficiency of the deposition process. When properly optimized through accurate kinetic modeling, the net environmental benefit can be substantial, with greenhouse gas reductions of 80-90% compared to unabated emissions. However, poorly designed systems may achieve only 50-60% reductions while generating significant secondary environmental impacts.

The long-term fate of captured CO2 also warrants consideration. Whether utilized in enhanced oil recovery, converted to useful products, or permanently sequestered, the environmental implications vary considerably. Kinetic models that account for impurities in flue gas can better predict long-term storage stability and potential environmental risks associated with CO2 storage.

Policy Frameworks for Carbon Capture Implementation

The global policy landscape for carbon capture technologies has evolved significantly in recent years, reflecting growing recognition of their importance in climate change mitigation strategies. Carbon pricing mechanisms have emerged as primary policy instruments, with over 40 jurisdictions worldwide implementing either carbon taxes or emissions trading systems that create economic incentives for CO2 capture implementation. These mechanisms establish a cost for carbon emissions, thereby improving the financial viability of carbon capture projects.

Tax incentives represent another crucial policy approach, exemplified by the United States' 45Q tax credit which provides up to $50 per metric ton of CO2 permanently sequestered. Similar frameworks have been adopted in Canada, Norway, and the UK, creating substantial financial support for carbon capture initiatives. These incentives directly address the economic barriers that have historically limited widespread adoption of carbon capture technologies.

Regulatory frameworks have also evolved to accommodate carbon capture implementation. The EU's Carbon Capture and Storage Directive provides comprehensive guidelines for CO2 storage site selection, permitting procedures, and long-term liability considerations. Similarly, Australia's Offshore Petroleum and Greenhouse Gas Storage Act establishes legal frameworks for CO2 storage activities, demonstrating how policy can create the necessary legal infrastructure.

Public funding programs represent a significant policy tool, with governments worldwide allocating substantial resources to carbon capture research, development, and demonstration projects. The EU Innovation Fund, UK's CCS Infrastructure Fund, and similar programs in Japan and Australia have collectively mobilized billions in public investment, accelerating technology development and commercial deployment.

International cooperation frameworks further enhance policy effectiveness. The Clean Energy Ministerial's CCUS Initiative and Mission Innovation facilitate knowledge sharing and collaborative research efforts across borders. These frameworks enable coordinated policy approaches and technology transfer, particularly important for developing economies seeking to implement carbon capture solutions.

Future policy directions indicate a shift toward more integrated approaches that combine multiple instruments. Performance standards, procurement policies, and carbon border adjustment mechanisms are emerging as complementary tools to existing frameworks. Additionally, policies increasingly recognize the importance of addressing both technological and social aspects of carbon capture implementation, including public acceptance and just transition considerations for affected communities and industries.

Tax incentives represent another crucial policy approach, exemplified by the United States' 45Q tax credit which provides up to $50 per metric ton of CO2 permanently sequestered. Similar frameworks have been adopted in Canada, Norway, and the UK, creating substantial financial support for carbon capture initiatives. These incentives directly address the economic barriers that have historically limited widespread adoption of carbon capture technologies.

Regulatory frameworks have also evolved to accommodate carbon capture implementation. The EU's Carbon Capture and Storage Directive provides comprehensive guidelines for CO2 storage site selection, permitting procedures, and long-term liability considerations. Similarly, Australia's Offshore Petroleum and Greenhouse Gas Storage Act establishes legal frameworks for CO2 storage activities, demonstrating how policy can create the necessary legal infrastructure.

Public funding programs represent a significant policy tool, with governments worldwide allocating substantial resources to carbon capture research, development, and demonstration projects. The EU Innovation Fund, UK's CCS Infrastructure Fund, and similar programs in Japan and Australia have collectively mobilized billions in public investment, accelerating technology development and commercial deployment.

International cooperation frameworks further enhance policy effectiveness. The Clean Energy Ministerial's CCUS Initiative and Mission Innovation facilitate knowledge sharing and collaborative research efforts across borders. These frameworks enable coordinated policy approaches and technology transfer, particularly important for developing economies seeking to implement carbon capture solutions.

Future policy directions indicate a shift toward more integrated approaches that combine multiple instruments. Performance standards, procurement policies, and carbon border adjustment mechanisms are emerging as complementary tools to existing frameworks. Additionally, policies increasingly recognize the importance of addressing both technological and social aspects of carbon capture implementation, including public acceptance and just transition considerations for affected communities and industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!