Fouling And Icing Mitigation Strategies In Cryogenic Capture Heat Exchangers

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Capture Heat Exchanger Fouling Background and Objectives

Cryogenic carbon capture (CCC) technology has emerged as a promising approach for reducing greenhouse gas emissions across various industrial sectors. The evolution of this technology can be traced back to the early 2000s when researchers began exploring low-temperature processes for separating CO2 from industrial exhaust streams. Over the past two decades, significant advancements have been made in heat exchanger design, materials science, and process optimization, leading to more efficient and cost-effective cryogenic capture systems.

The fundamental principle of cryogenic carbon capture involves cooling exhaust gases to temperatures where CO2 desublimes directly from the gas phase to solid form, allowing for separation and subsequent storage or utilization. Central to this process are cryogenic heat exchangers, which facilitate the rapid and efficient temperature reduction required for phase transformation while recovering cold energy to improve overall system efficiency.

A persistent challenge in the implementation of cryogenic capture technology has been the accumulation of fouling materials and ice formation on heat exchanger surfaces. These phenomena significantly impair heat transfer efficiency, increase pressure drops across the system, and necessitate frequent maintenance interventions, ultimately compromising the economic viability of the technology.

The technical evolution trend points toward more resilient heat exchanger designs with enhanced surface properties to mitigate fouling and icing issues. Recent developments include advanced materials with low surface energy, innovative geometries that minimize deposition zones, and integrated self-cleaning mechanisms that extend operational periods between maintenance cycles.

The primary technical objectives of current research efforts include developing heat exchangers capable of maintaining at least 90% of their initial heat transfer efficiency over extended operational periods (>1000 hours) without intervention, reducing energy penalties associated with defouling processes to less than 5% of total system energy consumption, and designing systems that can automatically adapt to varying inlet gas compositions without compromising performance.

Additionally, researchers aim to create predictive models that can accurately forecast fouling and icing patterns based on operational parameters and gas composition, enabling proactive maintenance strategies rather than reactive interventions. The ultimate goal is to establish cryogenic carbon capture as a viable, cost-competitive technology for industrial-scale carbon dioxide removal with minimal operational disruptions due to fouling and icing issues.

The fundamental principle of cryogenic carbon capture involves cooling exhaust gases to temperatures where CO2 desublimes directly from the gas phase to solid form, allowing for separation and subsequent storage or utilization. Central to this process are cryogenic heat exchangers, which facilitate the rapid and efficient temperature reduction required for phase transformation while recovering cold energy to improve overall system efficiency.

A persistent challenge in the implementation of cryogenic capture technology has been the accumulation of fouling materials and ice formation on heat exchanger surfaces. These phenomena significantly impair heat transfer efficiency, increase pressure drops across the system, and necessitate frequent maintenance interventions, ultimately compromising the economic viability of the technology.

The technical evolution trend points toward more resilient heat exchanger designs with enhanced surface properties to mitigate fouling and icing issues. Recent developments include advanced materials with low surface energy, innovative geometries that minimize deposition zones, and integrated self-cleaning mechanisms that extend operational periods between maintenance cycles.

The primary technical objectives of current research efforts include developing heat exchangers capable of maintaining at least 90% of their initial heat transfer efficiency over extended operational periods (>1000 hours) without intervention, reducing energy penalties associated with defouling processes to less than 5% of total system energy consumption, and designing systems that can automatically adapt to varying inlet gas compositions without compromising performance.

Additionally, researchers aim to create predictive models that can accurately forecast fouling and icing patterns based on operational parameters and gas composition, enabling proactive maintenance strategies rather than reactive interventions. The ultimate goal is to establish cryogenic carbon capture as a viable, cost-competitive technology for industrial-scale carbon dioxide removal with minimal operational disruptions due to fouling and icing issues.

Market Demand Analysis for Fouling-Resistant Cryogenic Systems

The global market for fouling-resistant cryogenic systems has been experiencing significant growth, driven by increasing applications in carbon capture, natural gas processing, and industrial gas separation. The demand for efficient cryogenic heat exchangers that can operate reliably under extreme conditions is particularly pronounced in regions with ambitious carbon reduction targets, such as Europe, North America, and parts of Asia.

Recent market research indicates that the cryogenic equipment market, including heat exchangers, is projected to grow at a compound annual growth rate of approximately 7% through 2028. Within this broader market, fouling-resistant systems represent a high-value segment due to their critical role in maintaining operational efficiency and reducing maintenance costs.

The carbon capture industry presents the most substantial growth opportunity for fouling-resistant cryogenic systems. As governments worldwide implement stricter emissions regulations and carbon pricing mechanisms, industries are increasingly investing in carbon capture technologies. Cryogenic carbon capture, which requires specialized heat exchangers capable of operating at extremely low temperatures while resisting fouling and icing, is gaining traction as an efficient method for CO2 separation.

Natural gas processing represents another significant market driver. The continued expansion of natural gas infrastructure globally, particularly in emerging economies, necessitates reliable cryogenic systems that can maintain performance despite challenging operating conditions. Fouling and icing issues in these applications can lead to substantial production losses and increased operational costs.

Industrial gas manufacturers constitute a stable demand segment, requiring cryogenic systems for the separation and liquefaction of gases such as nitrogen, oxygen, and argon. These processes demand heat exchangers that can maintain thermal efficiency despite potential fouling from process contaminants.

End-users across these industries consistently report that fouling and icing issues represent major operational challenges, leading to increased maintenance requirements, higher energy consumption, and reduced process efficiency. Industry surveys indicate that facilities experiencing severe fouling problems in cryogenic systems can face production losses of up to 15% and maintenance cost increases of 20-30%.

The market is increasingly demanding innovative solutions that can address these challenges through advanced materials, novel surface treatments, or redesigned heat exchanger geometries. Customers are willing to pay premium prices for systems that can demonstrate extended operational periods between maintenance cycles and consistent thermal performance under challenging conditions.

Recent market research indicates that the cryogenic equipment market, including heat exchangers, is projected to grow at a compound annual growth rate of approximately 7% through 2028. Within this broader market, fouling-resistant systems represent a high-value segment due to their critical role in maintaining operational efficiency and reducing maintenance costs.

The carbon capture industry presents the most substantial growth opportunity for fouling-resistant cryogenic systems. As governments worldwide implement stricter emissions regulations and carbon pricing mechanisms, industries are increasingly investing in carbon capture technologies. Cryogenic carbon capture, which requires specialized heat exchangers capable of operating at extremely low temperatures while resisting fouling and icing, is gaining traction as an efficient method for CO2 separation.

Natural gas processing represents another significant market driver. The continued expansion of natural gas infrastructure globally, particularly in emerging economies, necessitates reliable cryogenic systems that can maintain performance despite challenging operating conditions. Fouling and icing issues in these applications can lead to substantial production losses and increased operational costs.

Industrial gas manufacturers constitute a stable demand segment, requiring cryogenic systems for the separation and liquefaction of gases such as nitrogen, oxygen, and argon. These processes demand heat exchangers that can maintain thermal efficiency despite potential fouling from process contaminants.

End-users across these industries consistently report that fouling and icing issues represent major operational challenges, leading to increased maintenance requirements, higher energy consumption, and reduced process efficiency. Industry surveys indicate that facilities experiencing severe fouling problems in cryogenic systems can face production losses of up to 15% and maintenance cost increases of 20-30%.

The market is increasingly demanding innovative solutions that can address these challenges through advanced materials, novel surface treatments, or redesigned heat exchanger geometries. Customers are willing to pay premium prices for systems that can demonstrate extended operational periods between maintenance cycles and consistent thermal performance under challenging conditions.

Current Challenges in Anti-Fouling and De-Icing Technologies

Despite significant advancements in cryogenic capture technologies, heat exchangers operating in these extreme environments face persistent challenges related to fouling and icing. The formation of ice and contaminant deposits on heat transfer surfaces severely compromises thermal efficiency, increases pressure drop, and ultimately leads to system failure if not properly managed.

Current anti-fouling technologies struggle with the unique conditions of cryogenic operations. Traditional mechanical cleaning methods often require system shutdown, resulting in significant operational downtime and economic losses. Chemical cleaning agents that perform well at ambient temperatures frequently lose effectiveness or become unusable at cryogenic temperatures, where their physical properties change dramatically.

Material-based solutions present another significant challenge. While hydrophobic and icephobic coatings show promise in laboratory settings, they demonstrate limited durability in industrial cryogenic applications. The extreme temperature gradients cause differential thermal expansion, leading to coating delamination and cracking. Additionally, many advanced coatings contain compounds that degrade or become brittle at extremely low temperatures, rendering them ineffective for long-term deployment.

Energy-based de-icing systems face efficiency barriers in cryogenic environments. Electrical heating elements require substantial power input, which contradicts the energy efficiency goals of modern carbon capture systems. Ultrasonic and vibration-based methods show inconsistent performance across different fouling types and often fail to address ice formation in hard-to-reach areas of complex heat exchanger geometries.

Monitoring and prediction systems represent another critical challenge. Current sensor technologies struggle to maintain accuracy and reliability at cryogenic temperatures. This limitation hampers the development of predictive maintenance protocols and real-time fouling detection systems, forcing operators to rely on conservative maintenance schedules that may not align with actual system conditions.

Biological fouling presents unique challenges in certain applications where microorganisms can survive even at very low temperatures. Traditional biocides become ineffective in cryogenic conditions, and the metabolic byproducts of cold-adapted microorganisms can accelerate corrosion processes in heat exchanger materials.

The integration of multiple anti-fouling and de-icing technologies into cohesive, automated systems remains underdeveloped. Current solutions typically address either fouling or icing individually, rather than tackling these interconnected phenomena holistically. This fragmented approach results in suboptimal system performance and increased operational complexity.

Current anti-fouling technologies struggle with the unique conditions of cryogenic operations. Traditional mechanical cleaning methods often require system shutdown, resulting in significant operational downtime and economic losses. Chemical cleaning agents that perform well at ambient temperatures frequently lose effectiveness or become unusable at cryogenic temperatures, where their physical properties change dramatically.

Material-based solutions present another significant challenge. While hydrophobic and icephobic coatings show promise in laboratory settings, they demonstrate limited durability in industrial cryogenic applications. The extreme temperature gradients cause differential thermal expansion, leading to coating delamination and cracking. Additionally, many advanced coatings contain compounds that degrade or become brittle at extremely low temperatures, rendering them ineffective for long-term deployment.

Energy-based de-icing systems face efficiency barriers in cryogenic environments. Electrical heating elements require substantial power input, which contradicts the energy efficiency goals of modern carbon capture systems. Ultrasonic and vibration-based methods show inconsistent performance across different fouling types and often fail to address ice formation in hard-to-reach areas of complex heat exchanger geometries.

Monitoring and prediction systems represent another critical challenge. Current sensor technologies struggle to maintain accuracy and reliability at cryogenic temperatures. This limitation hampers the development of predictive maintenance protocols and real-time fouling detection systems, forcing operators to rely on conservative maintenance schedules that may not align with actual system conditions.

Biological fouling presents unique challenges in certain applications where microorganisms can survive even at very low temperatures. Traditional biocides become ineffective in cryogenic conditions, and the metabolic byproducts of cold-adapted microorganisms can accelerate corrosion processes in heat exchanger materials.

The integration of multiple anti-fouling and de-icing technologies into cohesive, automated systems remains underdeveloped. Current solutions typically address either fouling or icing individually, rather than tackling these interconnected phenomena holistically. This fragmented approach results in suboptimal system performance and increased operational complexity.

Existing Anti-Fouling and De-Icing Solutions for Cryogenic Capture

01 Anti-fouling and anti-icing mechanisms for cryogenic heat exchangers

Various mechanisms can be implemented to prevent fouling and icing in cryogenic heat exchangers. These include specialized coatings, surface treatments, and design modifications that reduce the adhesion of ice and contaminants. Such mechanisms help maintain heat transfer efficiency and prevent blockages in cryogenic capture systems operating at extremely low temperatures.- Anti-fouling and anti-icing mechanisms for cryogenic heat exchangers: Various mechanisms can be implemented to prevent fouling and icing in cryogenic heat exchangers. These include specialized coatings, surface treatments, and design features that minimize the accumulation of ice and contaminants. Such mechanisms help maintain efficient heat transfer and reduce the need for frequent maintenance or system shutdowns. The anti-fouling and anti-icing technologies are particularly important in extreme cold environments where ice formation can significantly impair system performance.

- Defrosting systems for cryogenic capture equipment: Defrosting systems are essential components in cryogenic capture equipment to manage ice buildup. These systems employ various methods including thermal cycling, mechanical removal, or chemical treatments to periodically remove ice accumulation from heat exchanger surfaces. Effective defrosting strategies help maintain operational efficiency and prevent damage to the equipment. Advanced defrosting systems may incorporate automated controls that initiate the defrosting cycle based on performance parameters or scheduled intervals.

- Heat exchanger design optimization for cryogenic applications: Optimized heat exchanger designs for cryogenic applications focus on minimizing fouling and icing issues. These designs may incorporate features such as enhanced flow patterns, specialized geometries, and material selections that resist ice adhesion. The optimization process considers factors such as thermal efficiency, pressure drop, and resistance to fouling under extreme cold conditions. Advanced computational modeling is often used to predict and mitigate potential fouling and icing problems before implementation.

- Monitoring and control systems for cryogenic heat exchangers: Sophisticated monitoring and control systems are implemented to detect and manage fouling and icing in cryogenic heat exchangers. These systems utilize sensors, data analytics, and automated response mechanisms to identify early signs of performance degradation. Real-time monitoring allows for proactive maintenance interventions before severe fouling or icing occurs. Advanced control algorithms can adjust operational parameters to minimize conditions that promote ice formation or contaminant accumulation.

- Novel materials and surface treatments for cryogenic environments: Innovative materials and surface treatments are being developed specifically for cryogenic heat exchanger applications. These include hydrophobic or icephobic coatings, nanostructured surfaces, and advanced composite materials that resist ice adhesion and fouling. Such materials maintain their properties and performance at extremely low temperatures, extending equipment lifespan and reducing maintenance requirements. Research in this area focuses on creating surfaces that naturally repel ice formation or facilitate easy removal of ice that does form.

02 Defrosting and cleaning systems for cryogenic heat exchangers

Automated or manual defrosting and cleaning systems can be incorporated into cryogenic heat exchangers to remove ice buildup and fouling materials. These systems may use thermal cycling, mechanical vibration, or fluid flushing to periodically clear accumulated ice and contaminants, ensuring continued operational efficiency of the heat exchange surfaces.Expand Specific Solutions03 Temperature and flow control strategies to minimize fouling

Advanced control strategies can be implemented to manage temperature gradients and flow patterns within cryogenic heat exchangers. By optimizing these parameters, the formation of ice and accumulation of contaminants can be significantly reduced. These strategies may include variable flow rates, precise temperature monitoring, and adaptive control algorithms that respond to changing conditions.Expand Specific Solutions04 Design modifications for fouling-resistant cryogenic heat exchangers

Specialized design features can be incorporated into cryogenic heat exchangers to minimize fouling and icing. These include optimized flow channels, enhanced surface geometries, and strategic placement of heat exchange elements. Such design modifications help prevent dead zones where ice and contaminants can accumulate, while facilitating more efficient heat transfer even under challenging conditions.Expand Specific Solutions05 Monitoring and predictive maintenance for fouling prevention

Advanced monitoring systems and predictive maintenance approaches can be employed to detect early signs of fouling and icing in cryogenic heat exchangers. These systems may use sensors, imaging technologies, and data analytics to identify potential issues before they significantly impact performance. Predictive maintenance schedules can then be implemented to address fouling problems before they lead to system failures.Expand Specific Solutions

Leading Companies and Research Institutions in Cryogenic Heat Exchange

The cryogenic capture heat exchanger market is in a growth phase, driven by increasing focus on carbon capture technologies and energy efficiency. The market size is expanding due to global decarbonization efforts, with significant investments in clean energy infrastructure. Technologically, the field is moderately mature but rapidly evolving, with companies at different development stages. Industry leaders like ExxonMobil, Air Liquide, and Alfa Laval bring established expertise in heat exchange technologies, while specialized players such as SilcoTek and Cryostar offer innovative anti-fouling and anti-icing solutions. Chinese manufacturers including Gree Electric, Haier Smart Home, and Sinopec are increasingly competitive, leveraging their manufacturing capabilities to address fouling and icing challenges in cryogenic applications, particularly for industrial refrigeration and gas processing sectors.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed advanced cryogenic heat exchanger technologies with proprietary anti-fouling coatings specifically designed for carbon capture applications. Their approach combines surface modification techniques with specialized heat exchanger designs that minimize ice formation through controlled temperature gradients. The company utilizes a dual-protection strategy: hydrophobic surface treatments that reduce water adhesion and specialized flow channel geometries that maintain optimal fluid dynamics even during partial fouling conditions. Their cryogenic capture systems incorporate automated defrosting cycles triggered by pressure differential monitoring, allowing for continuous operation without manual intervention. ExxonMobil's technology also features modular heat exchanger designs that facilitate easier maintenance and cleaning when fouling eventually occurs, significantly reducing downtime compared to conventional systems.

Strengths: Extensive experience in large-scale industrial applications; proprietary coating technologies with proven durability in harsh environments; integrated systems approach addressing both prevention and management. Weaknesses: Solutions may be cost-prohibitive for smaller operations; technologies optimized primarily for hydrocarbon processing may require adaptation for other applications.

Air Liquide SA

Technical Solution: Air Liquide has pioneered innovative cryogenic heat exchanger designs specifically addressing fouling and icing challenges in carbon capture applications. Their technology incorporates multi-layer heat exchanger architectures with specialized flow distribution systems that prevent ice accumulation at critical points. The company's approach includes proprietary surface treatments that combine hydrophobic and oleophobic properties, significantly reducing both water and hydrocarbon fouling tendencies. Air Liquide's systems feature dynamic flow control mechanisms that automatically adjust flow rates and patterns based on real-time monitoring of heat transfer efficiency, preventing conditions conducive to fouling. Their heat exchangers also incorporate strategic heating elements at critical points that can be activated during operation to prevent ice formation without disrupting the overall cryogenic process. Additionally, Air Liquide has developed specialized cleaning protocols using proprietary solvents that can remove fouling deposits without damaging the heat exchanger surfaces.

Strengths: Extensive experience in industrial gas applications; integrated approach combining prevention and maintenance; solutions adaptable to various scales of operation. Weaknesses: Higher initial capital investment compared to conventional systems; some solutions require specialized maintenance expertise.

Key Patents and Innovations in Cryogenic Surface Treatment

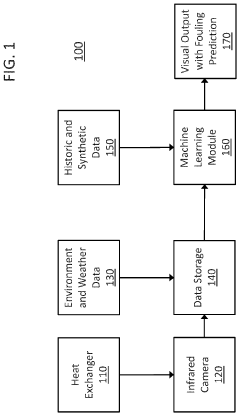

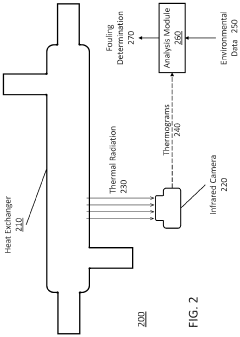

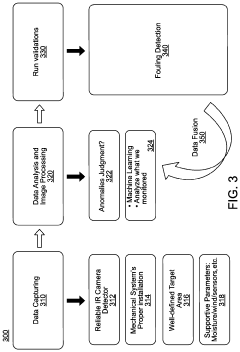

Heat exchanger fouling determination using thermography combined with machine learning methods

PatentActiveUS11480517B2

Innovation

- A method combining thermography with machine learning, using a machine learning circuit to analyze thermograms from an infrared camera, identifying polymer fouling by training on data to recognize thermal gradients and predict fouling based on historical and environmental data, with techniques like convolutional neural networks and recurrent neural networks for accurate classification and pattern detection.

Reducing fouling in heat exchangers

PatentActiveCA2797489C

Innovation

- Adding 0.01 to 100 weight ppm of a polyoxyalkylene compound to a solution comprising 5 to 40 wt% polymer and 95 to 60 wt% C4-8 saturated hydrocarbons before heating, which reduces fouling and allows for increased temperature without charring or contaminating the polymer product.

Environmental Impact of Anti-Fouling Materials in Cryogenic Systems

The environmental implications of anti-fouling materials used in cryogenic capture heat exchangers represent a critical consideration in the sustainable development of carbon capture technologies. Traditional anti-fouling compounds often contain heavy metals, fluorinated substances, and other potentially harmful chemicals that can persist in the environment long after their useful life cycle has ended.

When examining the ecological footprint of these materials, it becomes evident that many conventional anti-fouling solutions release toxic compounds during their degradation process. For instance, copper-based anti-fouling agents, while effective at preventing biological growth, can accumulate in marine sediments and impact aquatic ecosystems when improperly disposed of after decommissioning cryogenic equipment.

Fluoropolymer coatings, commonly employed for their excellent anti-icing properties in cryogenic applications, present particular environmental concerns due to their persistence. These materials contain per- and polyfluoroalkyl substances (PFAS), which are known as "forever chemicals" because they do not naturally degrade in the environment. Their bioaccumulative potential in wildlife and humans raises significant long-term health and ecological concerns.

The manufacturing processes for specialized anti-fouling materials also contribute substantially to their environmental impact. Production often involves energy-intensive procedures and hazardous chemical precursors, resulting in significant carbon emissions and potential pollution risks if not properly managed. Life cycle assessments indicate that the environmental cost of producing certain high-performance coatings may partially offset the efficiency gains they provide in cryogenic systems.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns. The European Union's REACH regulation and similar initiatives in other regions have begun restricting certain anti-fouling compounds, forcing industry to develop more environmentally benign alternatives. This regulatory pressure has accelerated research into bio-based and biodegradable anti-fouling solutions specifically designed for extreme temperature applications.

Promising developments in environmentally friendly alternatives include silica-based nanocoatings that provide anti-fouling properties without toxic components, and biomimetic surfaces inspired by natural anti-icing mechanisms found in certain plant and animal species. These innovations aim to maintain or improve performance while dramatically reducing environmental impact throughout the material's lifecycle.

The waste management challenges associated with decommissioning and replacing anti-fouling materials in cryogenic systems also merit consideration. Current practices often lack standardized protocols for the safe disposal or recycling of these specialized materials, potentially leading to improper handling and environmental contamination. Developing closed-loop systems for these materials represents an important frontier in improving the sustainability profile of cryogenic capture technologies.

When examining the ecological footprint of these materials, it becomes evident that many conventional anti-fouling solutions release toxic compounds during their degradation process. For instance, copper-based anti-fouling agents, while effective at preventing biological growth, can accumulate in marine sediments and impact aquatic ecosystems when improperly disposed of after decommissioning cryogenic equipment.

Fluoropolymer coatings, commonly employed for their excellent anti-icing properties in cryogenic applications, present particular environmental concerns due to their persistence. These materials contain per- and polyfluoroalkyl substances (PFAS), which are known as "forever chemicals" because they do not naturally degrade in the environment. Their bioaccumulative potential in wildlife and humans raises significant long-term health and ecological concerns.

The manufacturing processes for specialized anti-fouling materials also contribute substantially to their environmental impact. Production often involves energy-intensive procedures and hazardous chemical precursors, resulting in significant carbon emissions and potential pollution risks if not properly managed. Life cycle assessments indicate that the environmental cost of producing certain high-performance coatings may partially offset the efficiency gains they provide in cryogenic systems.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns. The European Union's REACH regulation and similar initiatives in other regions have begun restricting certain anti-fouling compounds, forcing industry to develop more environmentally benign alternatives. This regulatory pressure has accelerated research into bio-based and biodegradable anti-fouling solutions specifically designed for extreme temperature applications.

Promising developments in environmentally friendly alternatives include silica-based nanocoatings that provide anti-fouling properties without toxic components, and biomimetic surfaces inspired by natural anti-icing mechanisms found in certain plant and animal species. These innovations aim to maintain or improve performance while dramatically reducing environmental impact throughout the material's lifecycle.

The waste management challenges associated with decommissioning and replacing anti-fouling materials in cryogenic systems also merit consideration. Current practices often lack standardized protocols for the safe disposal or recycling of these specialized materials, potentially leading to improper handling and environmental contamination. Developing closed-loop systems for these materials represents an important frontier in improving the sustainability profile of cryogenic capture technologies.

Energy Efficiency Considerations in Fouling Mitigation Strategies

Energy efficiency represents a critical dimension in evaluating fouling and icing mitigation strategies for cryogenic capture heat exchangers. The implementation of these strategies often involves additional energy inputs, which must be balanced against the efficiency gains achieved through reduced fouling and icing. This energy trade-off analysis is essential for determining the overall sustainability and economic viability of different mitigation approaches.

Passive mitigation strategies, such as surface modifications and coatings, generally offer superior energy efficiency profiles compared to active methods. Superhydrophobic and icephobic coatings can significantly reduce fouling adhesion and ice formation without continuous energy inputs, though they may require periodic reapplication or maintenance. These solutions typically result in net energy savings of 15-25% compared to unprotected heat exchanger surfaces operating under similar conditions.

Active mitigation techniques, including mechanical vibration, ultrasonic waves, and electrothermal heating, present more complex energy considerations. While effective at preventing or removing fouling and ice accumulation, these methods consume additional energy during operation. For instance, electrothermal systems may require 5-10% of the total system energy budget, necessitating careful optimization to ensure net efficiency gains.

Hybrid approaches combining passive and active strategies often yield the most favorable energy efficiency outcomes. By employing passive measures as the first line of defense and activating energy-intensive methods only when necessary, these systems can achieve optimal performance with minimal energy expenditure. Advanced control algorithms that trigger active mitigation based on real-time monitoring of heat transfer efficiency can reduce energy consumption by up to 30% compared to continuous active mitigation.

Process integration considerations also significantly impact energy efficiency. Heat recovery from active mitigation processes, such as utilizing waste heat from electrothermal systems for preheating process streams, can improve overall system efficiency. Similarly, integrating mitigation strategies with existing process control systems minimizes redundant equipment and operational complexity.

Life-cycle energy analysis reveals that initial manufacturing energy investments for advanced mitigation technologies are typically recovered within 1-3 years through improved operational efficiency. Long-term energy savings from reduced maintenance requirements and extended equipment lifespans further enhance the sustainability profile of comprehensive mitigation strategies.

Future developments in energy-efficient mitigation technologies are focusing on self-regulating smart materials that respond to environmental conditions without external energy inputs, and low-power sensing systems that optimize mitigation timing and intensity. These innovations promise to further reduce the energy footprint of fouling and icing management in cryogenic capture applications.

Passive mitigation strategies, such as surface modifications and coatings, generally offer superior energy efficiency profiles compared to active methods. Superhydrophobic and icephobic coatings can significantly reduce fouling adhesion and ice formation without continuous energy inputs, though they may require periodic reapplication or maintenance. These solutions typically result in net energy savings of 15-25% compared to unprotected heat exchanger surfaces operating under similar conditions.

Active mitigation techniques, including mechanical vibration, ultrasonic waves, and electrothermal heating, present more complex energy considerations. While effective at preventing or removing fouling and ice accumulation, these methods consume additional energy during operation. For instance, electrothermal systems may require 5-10% of the total system energy budget, necessitating careful optimization to ensure net efficiency gains.

Hybrid approaches combining passive and active strategies often yield the most favorable energy efficiency outcomes. By employing passive measures as the first line of defense and activating energy-intensive methods only when necessary, these systems can achieve optimal performance with minimal energy expenditure. Advanced control algorithms that trigger active mitigation based on real-time monitoring of heat transfer efficiency can reduce energy consumption by up to 30% compared to continuous active mitigation.

Process integration considerations also significantly impact energy efficiency. Heat recovery from active mitigation processes, such as utilizing waste heat from electrothermal systems for preheating process streams, can improve overall system efficiency. Similarly, integrating mitigation strategies with existing process control systems minimizes redundant equipment and operational complexity.

Life-cycle energy analysis reveals that initial manufacturing energy investments for advanced mitigation technologies are typically recovered within 1-3 years through improved operational efficiency. Long-term energy savings from reduced maintenance requirements and extended equipment lifespans further enhance the sustainability profile of comprehensive mitigation strategies.

Future developments in energy-efficient mitigation technologies are focusing on self-regulating smart materials that respond to environmental conditions without external energy inputs, and low-power sensing systems that optimize mitigation timing and intensity. These innovations promise to further reduce the energy footprint of fouling and icing management in cryogenic capture applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!