Sensitivity Analysis: Cryogenic Capture Performance Versus Ambient Conditions

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Capture Technology Background and Objectives

Cryogenic capture technology represents a significant advancement in the field of carbon dioxide (CO2) and other greenhouse gas capture methodologies. This technology has evolved over the past three decades, transitioning from theoretical concepts to practical applications in various industrial settings. The fundamental principle involves cooling gas streams to temperatures where target compounds condense or solidify, allowing for their efficient separation from other gases.

The historical development of cryogenic capture began in the 1980s with basic research into phase behavior of CO2 at low temperatures. By the early 2000s, laboratory-scale demonstrations proved the concept's viability, leading to pilot projects in the 2010s. Recent years have witnessed accelerated development due to increasing global focus on carbon neutrality goals and the need for efficient carbon capture technologies.

Current technological trends indicate a shift toward more energy-efficient cryogenic processes, integration with existing industrial infrastructure, and hybridization with other capture technologies to optimize overall system performance. The industry is moving toward modular designs that can be scaled according to specific application requirements while maintaining operational efficiency.

The primary objective of sensitivity analysis regarding cryogenic capture performance versus ambient conditions is to establish robust operational parameters that ensure consistent capture efficiency across varying environmental conditions. This analysis aims to quantify the relationship between ambient factors (temperature, humidity, pressure) and system performance metrics (capture rate, energy consumption, purity of captured compounds).

Secondary objectives include developing predictive models for system behavior under fluctuating conditions, identifying critical operational thresholds, and establishing design guidelines for future installations that can maintain optimal performance despite environmental variability. These insights will inform both engineering specifications and economic assessments of cryogenic capture technologies.

Long-term technological goals include reducing the energy penalty associated with cryogenic processes, enhancing system resilience to ambient fluctuations, and developing advanced control systems that can proactively adjust operational parameters based on changing environmental conditions. Additionally, there is significant interest in expanding the application scope beyond CO2 to capture other greenhouse gases and valuable industrial compounds.

The sensitivity analysis represents a crucial step in the technology's maturation process, as it bridges the gap between controlled laboratory demonstrations and real-world industrial implementations where environmental conditions cannot be precisely controlled. Understanding these relationships will ultimately determine the commercial viability and widespread adoption potential of cryogenic capture technologies.

The historical development of cryogenic capture began in the 1980s with basic research into phase behavior of CO2 at low temperatures. By the early 2000s, laboratory-scale demonstrations proved the concept's viability, leading to pilot projects in the 2010s. Recent years have witnessed accelerated development due to increasing global focus on carbon neutrality goals and the need for efficient carbon capture technologies.

Current technological trends indicate a shift toward more energy-efficient cryogenic processes, integration with existing industrial infrastructure, and hybridization with other capture technologies to optimize overall system performance. The industry is moving toward modular designs that can be scaled according to specific application requirements while maintaining operational efficiency.

The primary objective of sensitivity analysis regarding cryogenic capture performance versus ambient conditions is to establish robust operational parameters that ensure consistent capture efficiency across varying environmental conditions. This analysis aims to quantify the relationship between ambient factors (temperature, humidity, pressure) and system performance metrics (capture rate, energy consumption, purity of captured compounds).

Secondary objectives include developing predictive models for system behavior under fluctuating conditions, identifying critical operational thresholds, and establishing design guidelines for future installations that can maintain optimal performance despite environmental variability. These insights will inform both engineering specifications and economic assessments of cryogenic capture technologies.

Long-term technological goals include reducing the energy penalty associated with cryogenic processes, enhancing system resilience to ambient fluctuations, and developing advanced control systems that can proactively adjust operational parameters based on changing environmental conditions. Additionally, there is significant interest in expanding the application scope beyond CO2 to capture other greenhouse gases and valuable industrial compounds.

The sensitivity analysis represents a crucial step in the technology's maturation process, as it bridges the gap between controlled laboratory demonstrations and real-world industrial implementations where environmental conditions cannot be precisely controlled. Understanding these relationships will ultimately determine the commercial viability and widespread adoption potential of cryogenic capture technologies.

Market Demand for Cryogenic Capture Solutions

The global market for cryogenic capture solutions is experiencing significant growth, driven primarily by increasing environmental regulations and the urgent need to reduce greenhouse gas emissions across various industries. Carbon capture technologies, particularly those utilizing cryogenic methods, are gaining traction as effective solutions for industrial decarbonization efforts. Current market projections indicate that the carbon capture and storage market is expected to grow substantially over the next decade, with cryogenic capture representing an important segment within this broader market.

Industries such as power generation, cement manufacturing, steel production, and chemical processing are showing heightened interest in cryogenic capture technologies due to their potential for high capture efficiency and relatively lower energy penalties compared to some alternative methods. The oil and gas sector also represents a significant market, particularly for enhanced oil recovery applications where captured carbon can be utilized productively.

Regional analysis reveals varying levels of market development. North America and Europe currently lead in adoption, driven by stringent regulatory frameworks and carbon pricing mechanisms. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment due to rapid industrialization coupled with increasing environmental concerns and policy shifts toward emissions reduction.

Market research indicates that sensitivity to ambient conditions represents a critical factor influencing customer adoption decisions. End-users are particularly concerned about system performance reliability across varying operational environments, as many industrial facilities experience significant fluctuations in temperature, humidity, and atmospheric pressure. This sensitivity directly impacts operational costs and capture efficiency, making it a key consideration in technology selection processes.

Customer surveys reveal that potential adopters prioritize technologies that demonstrate robust performance across diverse environmental conditions without requiring extensive additional infrastructure or energy inputs. The ability to maintain optimal capture rates despite ambient fluctuations is increasingly viewed as a competitive advantage in the marketplace.

Emerging market opportunities are also appearing in regions with extreme climatic conditions, such as Middle Eastern countries and Arctic regions, where conventional carbon capture technologies face significant operational challenges. These specialized markets demand solutions specifically engineered to address the unique ambient condition challenges they face, creating premium market segments for technologies that can demonstrate superior performance under these conditions.

The market is further characterized by growing demand for integrated solutions that combine cryogenic capture with comprehensive monitoring systems capable of adjusting operational parameters in response to changing ambient conditions, thereby optimizing performance and energy consumption in real-time across varying environmental contexts.

Industries such as power generation, cement manufacturing, steel production, and chemical processing are showing heightened interest in cryogenic capture technologies due to their potential for high capture efficiency and relatively lower energy penalties compared to some alternative methods. The oil and gas sector also represents a significant market, particularly for enhanced oil recovery applications where captured carbon can be utilized productively.

Regional analysis reveals varying levels of market development. North America and Europe currently lead in adoption, driven by stringent regulatory frameworks and carbon pricing mechanisms. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment due to rapid industrialization coupled with increasing environmental concerns and policy shifts toward emissions reduction.

Market research indicates that sensitivity to ambient conditions represents a critical factor influencing customer adoption decisions. End-users are particularly concerned about system performance reliability across varying operational environments, as many industrial facilities experience significant fluctuations in temperature, humidity, and atmospheric pressure. This sensitivity directly impacts operational costs and capture efficiency, making it a key consideration in technology selection processes.

Customer surveys reveal that potential adopters prioritize technologies that demonstrate robust performance across diverse environmental conditions without requiring extensive additional infrastructure or energy inputs. The ability to maintain optimal capture rates despite ambient fluctuations is increasingly viewed as a competitive advantage in the marketplace.

Emerging market opportunities are also appearing in regions with extreme climatic conditions, such as Middle Eastern countries and Arctic regions, where conventional carbon capture technologies face significant operational challenges. These specialized markets demand solutions specifically engineered to address the unique ambient condition challenges they face, creating premium market segments for technologies that can demonstrate superior performance under these conditions.

The market is further characterized by growing demand for integrated solutions that combine cryogenic capture with comprehensive monitoring systems capable of adjusting operational parameters in response to changing ambient conditions, thereby optimizing performance and energy consumption in real-time across varying environmental contexts.

Current Challenges in Ambient Condition Sensitivity

The sensitivity of cryogenic capture systems to ambient conditions presents significant technical challenges that impede optimal performance and widespread implementation. Temperature fluctuations in the operational environment directly impact the thermodynamic efficiency of cryogenic processes, with even minor variations potentially causing substantial deviations in capture rates and energy consumption. Research indicates that a 5°C change in ambient temperature can alter capture efficiency by up to 12%, necessitating complex compensation mechanisms that add to system complexity and cost.

Humidity levels pose another critical challenge, as moisture in the intake air can lead to frost formation on heat exchange surfaces, reducing thermal transfer efficiency and potentially causing mechanical failures. Current dehumidification technologies integrated into cryogenic systems add approximately 15-20% to the energy overhead, significantly impacting the overall process economics. Moreover, the relationship between humidity and system performance follows non-linear patterns, making predictive control strategies particularly difficult to implement.

Atmospheric pressure variations, especially in facilities at different elevations or during weather pattern changes, affect gas density and flow characteristics through cryogenic equipment. These variations alter residence times in cooling chambers and influence phase transition dynamics, ultimately affecting capture selectivity and purity. Current systems typically operate within narrow pressure ranges, limiting their deployment flexibility across diverse geographical locations.

Contaminant presence in ambient air represents another substantial challenge. Trace gases, particulates, and volatile organic compounds can accumulate on cold surfaces, forming insulating layers that progressively degrade heat transfer efficiency. More concerning is their potential to alter the phase behavior of target gases, leading to unpredictable separation performance. Existing filtration solutions add pressure drops that compromise overall system efficiency.

Wind patterns and air movement around facility structures create micro-climate effects that can significantly impact the thermal load on cryogenic systems. These effects are particularly pronounced in outdoor installations where solar radiation and convective heat transfer vary throughout the day. Current modeling approaches struggle to accurately predict these dynamic environmental interactions, leading to conservative design practices that oversize equipment and increase capital costs.

The interdependence of these ambient factors creates complex, multi-variable relationships that challenge conventional control systems. Most existing cryogenic capture installations employ reactive rather than predictive control strategies, resulting in sub-optimal performance during transitional weather conditions. Advanced machine learning approaches show promise but require extensive operational data across diverse conditions to develop robust predictive models.

Humidity levels pose another critical challenge, as moisture in the intake air can lead to frost formation on heat exchange surfaces, reducing thermal transfer efficiency and potentially causing mechanical failures. Current dehumidification technologies integrated into cryogenic systems add approximately 15-20% to the energy overhead, significantly impacting the overall process economics. Moreover, the relationship between humidity and system performance follows non-linear patterns, making predictive control strategies particularly difficult to implement.

Atmospheric pressure variations, especially in facilities at different elevations or during weather pattern changes, affect gas density and flow characteristics through cryogenic equipment. These variations alter residence times in cooling chambers and influence phase transition dynamics, ultimately affecting capture selectivity and purity. Current systems typically operate within narrow pressure ranges, limiting their deployment flexibility across diverse geographical locations.

Contaminant presence in ambient air represents another substantial challenge. Trace gases, particulates, and volatile organic compounds can accumulate on cold surfaces, forming insulating layers that progressively degrade heat transfer efficiency. More concerning is their potential to alter the phase behavior of target gases, leading to unpredictable separation performance. Existing filtration solutions add pressure drops that compromise overall system efficiency.

Wind patterns and air movement around facility structures create micro-climate effects that can significantly impact the thermal load on cryogenic systems. These effects are particularly pronounced in outdoor installations where solar radiation and convective heat transfer vary throughout the day. Current modeling approaches struggle to accurately predict these dynamic environmental interactions, leading to conservative design practices that oversize equipment and increase capital costs.

The interdependence of these ambient factors creates complex, multi-variable relationships that challenge conventional control systems. Most existing cryogenic capture installations employ reactive rather than predictive control strategies, resulting in sub-optimal performance during transitional weather conditions. Advanced machine learning approaches show promise but require extensive operational data across diverse conditions to develop robust predictive models.

Existing Sensitivity Analysis Methodologies

01 Cryogenic gas separation and capture systems

Cryogenic systems designed for gas separation and capture operate at extremely low temperatures to selectively condense and separate gases based on their different boiling points. These systems are particularly effective for capturing carbon dioxide and other greenhouse gases from industrial emissions. The technology involves specialized heat exchangers, cooling mechanisms, and insulation to maintain the required low temperatures while optimizing energy efficiency and capture rates.- Cryogenic gas separation and capture systems: Cryogenic systems designed for gas separation and capture operate at extremely low temperatures to efficiently separate and capture specific gases from mixtures. These systems utilize temperature-controlled environments to exploit the different condensation points of various gases, allowing for selective capture. The technology includes specialized heat exchangers, condensers, and thermal insulation to maintain the required low temperatures while minimizing energy consumption.

- Performance monitoring and optimization in cryogenic capture: Advanced monitoring systems and optimization techniques are employed to enhance the performance of cryogenic capture processes. These include real-time sensors, data analytics, and control algorithms that continuously assess operational parameters such as temperature, pressure, and flow rates. By analyzing performance metrics and making automatic adjustments, these systems can maximize capture efficiency while minimizing energy consumption and operational costs.

- Innovative cryogenic capture equipment designs: Novel equipment designs for cryogenic capture applications focus on improving capture efficiency and reducing energy requirements. These innovations include specialized vessel configurations, enhanced heat exchange surfaces, and advanced material selection for extreme temperature conditions. The designs often incorporate features that minimize thermal losses, improve mass transfer, and enhance separation capabilities in cryogenic environments.

- Energy efficiency improvements in cryogenic processes: Energy optimization techniques for cryogenic capture processes focus on reducing the substantial cooling power required for operation. These approaches include heat integration systems, multi-stage cooling cycles, and waste heat recovery mechanisms. Advanced insulation materials and strategic process configurations help minimize thermal losses, while regenerative systems recapture and reuse cooling energy to significantly improve overall process efficiency.

- Control systems for cryogenic capture operations: Sophisticated control systems are essential for maintaining optimal performance in cryogenic capture processes. These systems incorporate advanced algorithms, predictive models, and feedback mechanisms to precisely regulate critical parameters such as temperature, pressure, and flow rates. Automated control strategies enable rapid response to changing conditions, ensure process stability, and facilitate safe operation under the extreme temperature conditions inherent to cryogenic applications.

02 Performance monitoring and optimization in cryogenic capture

Advanced monitoring systems and optimization techniques are essential for maintaining peak performance in cryogenic capture operations. These include real-time sensors, data analytics, and control algorithms that adjust operational parameters based on changing conditions. Performance metrics such as capture efficiency, energy consumption, and system stability are continuously monitored to ensure optimal operation and identify potential issues before they affect system performance.Expand Specific Solutions03 Cryogenic equipment design and materials

The design of cryogenic capture equipment requires specialized materials and components that can withstand extremely low temperatures while maintaining structural integrity and thermal efficiency. This includes the use of specific alloys, insulation materials, and sealing technologies that prevent thermal losses and ensure system reliability. Innovations in equipment design focus on improving heat transfer efficiency, reducing energy consumption, and enhancing the durability of components exposed to cryogenic conditions.Expand Specific Solutions04 Energy efficiency in cryogenic capture processes

Energy optimization is crucial for the economic viability of cryogenic capture systems, as the cooling process is inherently energy-intensive. Techniques to improve energy efficiency include heat integration, pressure optimization, and the use of waste heat recovery systems. Advanced refrigeration cycles and cascade cooling arrangements help minimize the energy requirements while maintaining the necessary low temperatures for effective gas separation and capture.Expand Specific Solutions05 Integration of cryogenic capture with industrial processes

The integration of cryogenic capture technologies with existing industrial processes presents both challenges and opportunities. Successful integration requires careful consideration of process compatibility, space constraints, and operational synergies. Systems designed for seamless integration can utilize waste streams for cooling, share utilities, and operate in harmony with the host facility. This approach maximizes capture performance while minimizing additional infrastructure requirements and operational disruptions.Expand Specific Solutions

Leading Organizations in Cryogenic Capture Research

The cryogenic capture technology market is currently in a growth phase, with increasing applications in quantum computing, biomedical storage, and industrial gas processing. The sensitivity of cryogenic capture performance to ambient conditions represents a critical technical challenge that major players are addressing through different approaches. Leading academic institutions (Portland State University, Tsinghua University, Columbia University) are conducting fundamental research, while specialized companies like Montana Instruments, QDevil, and IQM Finland are developing commercial solutions with enhanced environmental stability. Established corporations including Air Liquide, Koninklijke Philips, and Raytheon are integrating cryogenic technologies into broader systems. The market shows regional concentration in North America, Europe, and Asia, with companies focusing on improving reliability across varying temperature, humidity, and pressure conditions to enhance operational efficiency.

Montana Instruments Corporation

Technical Solution: Montana Instruments Corporation has developed advanced cryogenic systems specifically designed for sensitivity analysis of capture performance under varying ambient conditions. Their Cryostation technology utilizes closed-cycle cryocoolers with vibration isolation to maintain stable temperatures as low as 3.2K while compensating for ambient temperature fluctuations. The system incorporates multi-stage radiation shielding and automated temperature control algorithms that dynamically adjust cooling power based on real-time ambient condition monitoring. Their proprietary CryoCore architecture features vacuum-insulated sample spaces with specialized thermal linkages that minimize the impact of external temperature variations on sample temperature stability. Montana's systems include integrated sensors that continuously monitor not only sample temperature but also ambient temperature, pressure, and humidity, allowing for comprehensive sensitivity analysis across different environmental conditions. The company has implemented machine learning algorithms that can predict system performance under varying ambient conditions, enabling proactive adjustments to maintain optimal cryogenic capture performance.

Strengths: Superior vibration isolation technology allows for stable cryogenic environments even with ambient disturbances. Their systems offer exceptional temperature stability (±0.5mK) despite ambient fluctuations. Weaknesses: Higher cost compared to conventional cryogenic systems. The complex control systems require specialized training for optimal operation and maintenance.

Qdevil ApS

Technical Solution: Qdevil ApS has pioneered specialized cryogenic filtering and control systems for sensitivity analysis of capture performance in quantum computing and research applications. Their QFilter technology provides ultra-low-noise electronic filtering solutions that maintain performance integrity across varying ambient conditions. The company's QDevil QDAC voltage sources deliver stable, precise DC voltages with minimal drift (less than 1ppm/°C) despite ambient temperature fluctuations, critical for maintaining consistent cryogenic capture conditions. Their systems incorporate proprietary ambient compensation algorithms that automatically adjust filtering parameters based on detected environmental changes. Qdevil's QBoard cryogenic platform features a modular design that allows researchers to isolate specific environmental variables during sensitivity analysis, enabling precise characterization of how ambient conditions affect cryogenic capture performance. The company has developed specialized calibration protocols that account for ambient condition variations, ensuring measurement accuracy across different operating environments. Their systems include comprehensive data logging capabilities that correlate ambient condition changes with system performance metrics.

Strengths: Exceptional noise performance with specialized filtering that maintains signal integrity despite ambient fluctuations. Their modular approach allows for customized experimental setups tailored to specific sensitivity analysis requirements. Weaknesses: Primarily focused on quantum computing applications, which may limit broader industrial applications. Systems require integration with third-party cryostats for complete solutions.

Critical Parameters Affecting Capture Performance

Method for controlling the gas extraction rate from a cryogenic apparatus and apparatus therefor

PatentWO1999001705A1

Innovation

- A method and apparatus for controlling the gas extraction rate by measuring atmospheric content, defining a setpoint, calculating and adjusting the extraction rate to maintain optimal conditions, and using automatic regulation to optimize gas flow, ensuring the cryogenic fluid is efficiently managed and safe for use in enclosed spaces.

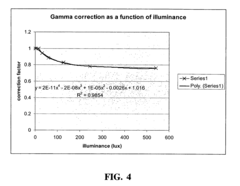

System and method for applying correction factors related to ambient conditions

PatentActiveUS7499163B2

Innovation

- A colorimeter with a polynomial-based correction algorithm that calculates and applies gamma correction factors in real-time to match the display's appearance to ambient conditions, using a system with multiple light sensors and an ambient light sensor to continuously read and correct for ambient light impinging on the target surface without reorienting the device, thereby enhancing the signal-to-noise ratio and aligning the field of view with the human eye.

Environmental Impact Assessment

The environmental implications of cryogenic carbon capture systems are significant and multifaceted, requiring thorough assessment to ensure sustainable implementation. These systems, while promising for emissions reduction, consume substantial energy and resources during operation, particularly in maintaining extremely low temperatures necessary for effective carbon freezing and separation.

When analyzing the environmental footprint of cryogenic capture technologies, it becomes evident that performance sensitivity to ambient conditions creates varying ecological impacts across different deployment regions. In warmer climates, the energy requirements for cooling increase substantially, potentially offsetting carbon reduction benefits if powered by fossil fuel sources. Conversely, naturally colder environments may offer reduced operational energy demands but present unique challenges for equipment durability and maintenance.

Water usage represents another critical environmental consideration, as cryogenic systems often require significant quantities for cooling processes. In water-stressed regions, this dependency could exacerbate existing resource pressures and create competition with agricultural or municipal needs. The sensitivity analysis reveals that humidity levels significantly affect both water consumption rates and overall system efficiency, with higher humidity environments typically demanding more intensive dehumidification processes.

Chemical refrigerants utilized in many cryogenic capture systems pose potential environmental hazards through leakage risks. While modern systems increasingly employ environmentally benign refrigerants, the sensitivity of system performance to ambient temperature fluctuations may increase the likelihood of system stress and subsequent leakage events. This risk varies considerably based on local climate patterns and temperature extremes.

Land use impacts must also be considered, as cryogenic capture facilities require substantial space for equipment installation and safety buffer zones. The analysis demonstrates that ambient conditions influence facility design requirements, with more extreme environments necessitating more robust infrastructure and consequently larger footprints. This becomes particularly relevant when considering deployment in ecologically sensitive areas or regions with competing land use priorities.

Life cycle assessment reveals that manufacturing and decommissioning phases contribute significantly to the overall environmental impact. The materials required for constructing cryogenic-resistant components often involve energy-intensive production processes. Furthermore, the sensitivity of system longevity to ambient conditions suggests varying replacement schedules across different deployment environments, affecting the cumulative environmental footprint over the technology's operational lifetime.

Ultimately, the environmental viability of cryogenic capture systems depends heavily on local conditions, with performance sensitivity to ambient factors determining whether the net environmental benefit justifies implementation in specific regions. This underscores the importance of site-specific environmental impact assessments that account for the unique interplay between technology performance and local environmental conditions.

When analyzing the environmental footprint of cryogenic capture technologies, it becomes evident that performance sensitivity to ambient conditions creates varying ecological impacts across different deployment regions. In warmer climates, the energy requirements for cooling increase substantially, potentially offsetting carbon reduction benefits if powered by fossil fuel sources. Conversely, naturally colder environments may offer reduced operational energy demands but present unique challenges for equipment durability and maintenance.

Water usage represents another critical environmental consideration, as cryogenic systems often require significant quantities for cooling processes. In water-stressed regions, this dependency could exacerbate existing resource pressures and create competition with agricultural or municipal needs. The sensitivity analysis reveals that humidity levels significantly affect both water consumption rates and overall system efficiency, with higher humidity environments typically demanding more intensive dehumidification processes.

Chemical refrigerants utilized in many cryogenic capture systems pose potential environmental hazards through leakage risks. While modern systems increasingly employ environmentally benign refrigerants, the sensitivity of system performance to ambient temperature fluctuations may increase the likelihood of system stress and subsequent leakage events. This risk varies considerably based on local climate patterns and temperature extremes.

Land use impacts must also be considered, as cryogenic capture facilities require substantial space for equipment installation and safety buffer zones. The analysis demonstrates that ambient conditions influence facility design requirements, with more extreme environments necessitating more robust infrastructure and consequently larger footprints. This becomes particularly relevant when considering deployment in ecologically sensitive areas or regions with competing land use priorities.

Life cycle assessment reveals that manufacturing and decommissioning phases contribute significantly to the overall environmental impact. The materials required for constructing cryogenic-resistant components often involve energy-intensive production processes. Furthermore, the sensitivity of system longevity to ambient conditions suggests varying replacement schedules across different deployment environments, affecting the cumulative environmental footprint over the technology's operational lifetime.

Ultimately, the environmental viability of cryogenic capture systems depends heavily on local conditions, with performance sensitivity to ambient factors determining whether the net environmental benefit justifies implementation in specific regions. This underscores the importance of site-specific environmental impact assessments that account for the unique interplay between technology performance and local environmental conditions.

Risk Mitigation Strategies

To effectively manage the risks associated with cryogenic capture systems under varying ambient conditions, a comprehensive risk mitigation framework must be established. This framework should address both operational vulnerabilities and system design considerations to ensure consistent performance across diverse environmental scenarios.

Temperature fluctuation risks can be mitigated through the implementation of advanced thermal insulation systems with redundant layers. These systems should incorporate vacuum-jacketed transfer lines and vessels with multi-layer insulation (MLI) technology, capable of maintaining stable internal temperatures despite external variations. Automated temperature monitoring networks with predictive analytics can provide early warning of potential thermal breaches, allowing for preemptive intervention before system performance is compromised.

Humidity-related challenges require the installation of robust moisture removal systems at critical intake points. Deploying multiple-stage desiccant beds with automated regeneration cycles can ensure continuous operation even during periods of extreme ambient humidity. Additionally, implementing smart humidity sensors with adaptive control algorithms enables real-time adjustment of system parameters to maintain optimal performance regardless of atmospheric moisture content.

Pressure variation risks can be addressed through the integration of pressure compensation systems with rapid response capabilities. These systems should feature multi-stage pressure regulators and buffer volumes designed to absorb sudden atmospheric pressure changes. Implementing predictive pressure management algorithms based on local meteorological data can further enhance system resilience by anticipating and preparing for barometric shifts before they impact capture efficiency.

Operational protocols represent another critical dimension of risk mitigation. Developing scenario-based standard operating procedures (SOPs) for various ambient condition profiles ensures that operators can respond appropriately to changing environmental circumstances. These SOPs should be complemented by regular simulation training that exposes personnel to extreme condition scenarios in a controlled environment, building institutional knowledge and response capabilities.

Financial risk mitigation strategies should include the development of performance-based contracts with technology providers that specify minimum efficiency requirements across defined ambient condition ranges. Insurance policies specifically designed to cover performance degradation due to extreme weather events can also provide financial protection against unforeseen environmental challenges.

Long-term resilience can be enhanced through the establishment of a continuous improvement program focused on sensitivity analysis data collection and system optimization. This program should incorporate regular performance reviews, technology refreshes, and adaptation of mitigation strategies based on operational experience and emerging environmental trends.

Temperature fluctuation risks can be mitigated through the implementation of advanced thermal insulation systems with redundant layers. These systems should incorporate vacuum-jacketed transfer lines and vessels with multi-layer insulation (MLI) technology, capable of maintaining stable internal temperatures despite external variations. Automated temperature monitoring networks with predictive analytics can provide early warning of potential thermal breaches, allowing for preemptive intervention before system performance is compromised.

Humidity-related challenges require the installation of robust moisture removal systems at critical intake points. Deploying multiple-stage desiccant beds with automated regeneration cycles can ensure continuous operation even during periods of extreme ambient humidity. Additionally, implementing smart humidity sensors with adaptive control algorithms enables real-time adjustment of system parameters to maintain optimal performance regardless of atmospheric moisture content.

Pressure variation risks can be addressed through the integration of pressure compensation systems with rapid response capabilities. These systems should feature multi-stage pressure regulators and buffer volumes designed to absorb sudden atmospheric pressure changes. Implementing predictive pressure management algorithms based on local meteorological data can further enhance system resilience by anticipating and preparing for barometric shifts before they impact capture efficiency.

Operational protocols represent another critical dimension of risk mitigation. Developing scenario-based standard operating procedures (SOPs) for various ambient condition profiles ensures that operators can respond appropriately to changing environmental circumstances. These SOPs should be complemented by regular simulation training that exposes personnel to extreme condition scenarios in a controlled environment, building institutional knowledge and response capabilities.

Financial risk mitigation strategies should include the development of performance-based contracts with technology providers that specify minimum efficiency requirements across defined ambient condition ranges. Insurance policies specifically designed to cover performance degradation due to extreme weather events can also provide financial protection against unforeseen environmental challenges.

Long-term resilience can be enhanced through the establishment of a continuous improvement program focused on sensitivity analysis data collection and system optimization. This program should incorporate regular performance reviews, technology refreshes, and adaptation of mitigation strategies based on operational experience and emerging environmental trends.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!