Cryogenic Capture For Refineries: Retrofit Case Studies And Lessons Learned

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Capture Technology Evolution and Objectives

Cryogenic carbon capture technology has evolved significantly over the past several decades, transforming from theoretical concepts to practical applications in industrial settings. The foundational principles of cryogenic separation were established in the early 20th century, but specific applications for carbon capture emerged in the 1970s alongside growing environmental concerns. Initial implementations focused primarily on natural gas processing, where cryogenic techniques were employed to separate CO2 from methane.

The 1990s marked a pivotal shift as researchers began exploring cryogenic methods specifically for post-combustion carbon capture in power plants and industrial facilities. This period saw the development of fundamental process designs that would later be adapted for refinery applications. By the early 2000s, laboratory-scale demonstrations confirmed the theoretical efficiency advantages of cryogenic capture over conventional amine-based systems, particularly for high-concentration CO2 streams.

The technology underwent significant refinement between 2005 and 2015, with innovations in heat exchanger design, phase separation techniques, and energy recovery systems substantially improving overall efficiency. These advancements reduced the energy penalty associated with cryogenic capture, making retrofit applications increasingly economically viable for refineries and similar industrial facilities.

Recent developments have focused on modular system designs that facilitate integration with existing refinery infrastructure, addressing one of the primary challenges in retrofit scenarios. Process intensification techniques have further enhanced performance, with novel refrigeration cycles and advanced materials science contributing to more compact and efficient capture units.

The primary technical objectives for cryogenic capture in refinery applications center on achieving high capture rates (>90%) while minimizing both capital expenditure and operational costs. Energy efficiency remains paramount, with current research targeting systems that can operate below 1.5 GJ/tonne CO2 captured. Additional objectives include reducing physical footprint requirements to accommodate space constraints in existing facilities and developing flexible operations capability to handle fluctuating flue gas compositions typical in refinery environments.

Integration objectives focus on minimizing disruption to existing operations during installation and commissioning, with particular emphasis on safety considerations given the low-temperature processes involved. Long-term reliability under continuous operation represents another critical goal, with systems designed to maintain performance despite the challenging conditions present in refinery environments, including potential contaminants in flue gas streams that could affect cryogenic processes.

The 1990s marked a pivotal shift as researchers began exploring cryogenic methods specifically for post-combustion carbon capture in power plants and industrial facilities. This period saw the development of fundamental process designs that would later be adapted for refinery applications. By the early 2000s, laboratory-scale demonstrations confirmed the theoretical efficiency advantages of cryogenic capture over conventional amine-based systems, particularly for high-concentration CO2 streams.

The technology underwent significant refinement between 2005 and 2015, with innovations in heat exchanger design, phase separation techniques, and energy recovery systems substantially improving overall efficiency. These advancements reduced the energy penalty associated with cryogenic capture, making retrofit applications increasingly economically viable for refineries and similar industrial facilities.

Recent developments have focused on modular system designs that facilitate integration with existing refinery infrastructure, addressing one of the primary challenges in retrofit scenarios. Process intensification techniques have further enhanced performance, with novel refrigeration cycles and advanced materials science contributing to more compact and efficient capture units.

The primary technical objectives for cryogenic capture in refinery applications center on achieving high capture rates (>90%) while minimizing both capital expenditure and operational costs. Energy efficiency remains paramount, with current research targeting systems that can operate below 1.5 GJ/tonne CO2 captured. Additional objectives include reducing physical footprint requirements to accommodate space constraints in existing facilities and developing flexible operations capability to handle fluctuating flue gas compositions typical in refinery environments.

Integration objectives focus on minimizing disruption to existing operations during installation and commissioning, with particular emphasis on safety considerations given the low-temperature processes involved. Long-term reliability under continuous operation represents another critical goal, with systems designed to maintain performance despite the challenging conditions present in refinery environments, including potential contaminants in flue gas streams that could affect cryogenic processes.

Market Demand Analysis for Refinery Emission Control Solutions

The global market for refinery emission control solutions has witnessed significant growth in recent years, driven primarily by stringent environmental regulations and increasing public awareness about air quality. The demand for cryogenic capture technologies specifically has been accelerating as refineries face mounting pressure to reduce their carbon footprint while maintaining operational efficiency.

Analysis of market data reveals that the global refinery emission control market was valued at approximately $12 billion in 2022, with projections indicating growth at a compound annual rate of 5.7% through 2030. Cryogenic capture technologies, though representing a smaller segment currently at about $1.8 billion, are experiencing faster growth at nearly 8.3% annually, highlighting their emerging importance in the emission control landscape.

Regional analysis shows varied adoption patterns, with North America and Europe leading implementation due to stringent regulatory frameworks. The European Union's Emission Trading System and the U.S. EPA's increasingly strict standards have created strong market pull for advanced capture technologies. Meanwhile, Asia-Pacific represents the fastest-growing market, particularly in China and India, where rapid industrialization coincides with new environmental policies.

Customer segmentation within the refinery sector indicates that large-scale operations with outputs exceeding 250,000 barrels per day constitute the primary adopters of cryogenic capture technologies, accounting for 63% of installations. Medium-sized refineries are increasingly exploring retrofit options as cost structures become more favorable and technology matures.

The economic drivers for adoption extend beyond regulatory compliance. Return on investment analyses from recent implementations show that despite high initial capital expenditure ranging from $30-75 million depending on refinery size, operational benefits including reduced emission penalties, potential carbon credit generation, and improved energy efficiency can yield payback periods of 4-7 years.

Market research indicates that refineries are particularly interested in solutions offering minimal production disruption during installation. This explains the growing demand for modular cryogenic systems that can be integrated during scheduled maintenance periods, reducing costly downtime. Survey data from refinery operators shows that 78% rank "implementation without extended shutdown" as a critical decision factor.

Future market growth is expected to be influenced by carbon pricing mechanisms, with markets having established carbon taxes showing adoption rates three times higher than those without such economic instruments. Additionally, the potential for captured carbon utilization in enhanced oil recovery or other industrial applications is creating secondary market opportunities estimated at $3.2 billion by 2028.

Analysis of market data reveals that the global refinery emission control market was valued at approximately $12 billion in 2022, with projections indicating growth at a compound annual rate of 5.7% through 2030. Cryogenic capture technologies, though representing a smaller segment currently at about $1.8 billion, are experiencing faster growth at nearly 8.3% annually, highlighting their emerging importance in the emission control landscape.

Regional analysis shows varied adoption patterns, with North America and Europe leading implementation due to stringent regulatory frameworks. The European Union's Emission Trading System and the U.S. EPA's increasingly strict standards have created strong market pull for advanced capture technologies. Meanwhile, Asia-Pacific represents the fastest-growing market, particularly in China and India, where rapid industrialization coincides with new environmental policies.

Customer segmentation within the refinery sector indicates that large-scale operations with outputs exceeding 250,000 barrels per day constitute the primary adopters of cryogenic capture technologies, accounting for 63% of installations. Medium-sized refineries are increasingly exploring retrofit options as cost structures become more favorable and technology matures.

The economic drivers for adoption extend beyond regulatory compliance. Return on investment analyses from recent implementations show that despite high initial capital expenditure ranging from $30-75 million depending on refinery size, operational benefits including reduced emission penalties, potential carbon credit generation, and improved energy efficiency can yield payback periods of 4-7 years.

Market research indicates that refineries are particularly interested in solutions offering minimal production disruption during installation. This explains the growing demand for modular cryogenic systems that can be integrated during scheduled maintenance periods, reducing costly downtime. Survey data from refinery operators shows that 78% rank "implementation without extended shutdown" as a critical decision factor.

Future market growth is expected to be influenced by carbon pricing mechanisms, with markets having established carbon taxes showing adoption rates three times higher than those without such economic instruments. Additionally, the potential for captured carbon utilization in enhanced oil recovery or other industrial applications is creating secondary market opportunities estimated at $3.2 billion by 2028.

Current State and Challenges in Cryogenic Capture Implementation

Cryogenic carbon capture (CCC) technology has emerged as a promising solution for CO2 emissions reduction in refineries, with significant advancements over the past decade. Currently, several pilot and demonstration projects are operational globally, showcasing the technical feasibility of this approach. The technology has demonstrated capture efficiencies exceeding 90% in controlled environments, positioning it as a competitive alternative to conventional amine-based systems. Recent implementations in European and North American refineries have validated the scalability of cryogenic systems, though primarily in new construction rather than retrofit scenarios.

Despite these advances, cryogenic capture implementation faces substantial technical challenges. Energy intensity remains a primary concern, with current systems requiring 0.8-1.2 MWh per ton of CO2 captured, creating significant operational cost barriers. Retrofit applications present particular difficulties due to space constraints in existing facilities, often necessitating complex integration solutions that increase capital expenditure by 15-30% compared to greenfield implementations.

Material compatibility issues persist at cryogenic temperatures, with specialized alloys and insulation systems required to maintain structural integrity and prevent thermal losses. Several retrofit projects have reported premature equipment degradation, particularly in heat exchanger components exposed to temperature cycling. Process integration challenges are equally significant, as existing refinery operations must remain uninterrupted during installation and commissioning phases.

The geographical distribution of cryogenic capture technology development shows concentration in North America, Western Europe, and East Asia, with limited penetration in developing economies despite their growing refinery sectors. This disparity reflects both technological access barriers and varying regulatory pressures across regions. Current implementation costs range from $60-120 per ton of CO2 captured, significantly higher than the carbon pricing in most jurisdictions, creating economic feasibility challenges without substantial incentives.

Technical standardization remains underdeveloped, with competing proprietary systems utilizing different cooling cycles, separation techniques, and control methodologies. This fragmentation complicates knowledge transfer between projects and limits economies of scale in equipment manufacturing. Recent case studies from Gulf Coast refineries highlight the need for improved frost management systems and more robust solutions for handling impurities in flue gas streams, which can cause operational disruptions through solid formation in cryogenic components.

Regulatory uncertainty further complicates implementation, with evolving standards for carbon capture verification and inconsistent incentive structures across markets. The technology readiness level (TRL) for refinery applications specifically remains at 6-7, indicating the need for further demonstration before widespread commercial adoption can be achieved.

Despite these advances, cryogenic capture implementation faces substantial technical challenges. Energy intensity remains a primary concern, with current systems requiring 0.8-1.2 MWh per ton of CO2 captured, creating significant operational cost barriers. Retrofit applications present particular difficulties due to space constraints in existing facilities, often necessitating complex integration solutions that increase capital expenditure by 15-30% compared to greenfield implementations.

Material compatibility issues persist at cryogenic temperatures, with specialized alloys and insulation systems required to maintain structural integrity and prevent thermal losses. Several retrofit projects have reported premature equipment degradation, particularly in heat exchanger components exposed to temperature cycling. Process integration challenges are equally significant, as existing refinery operations must remain uninterrupted during installation and commissioning phases.

The geographical distribution of cryogenic capture technology development shows concentration in North America, Western Europe, and East Asia, with limited penetration in developing economies despite their growing refinery sectors. This disparity reflects both technological access barriers and varying regulatory pressures across regions. Current implementation costs range from $60-120 per ton of CO2 captured, significantly higher than the carbon pricing in most jurisdictions, creating economic feasibility challenges without substantial incentives.

Technical standardization remains underdeveloped, with competing proprietary systems utilizing different cooling cycles, separation techniques, and control methodologies. This fragmentation complicates knowledge transfer between projects and limits economies of scale in equipment manufacturing. Recent case studies from Gulf Coast refineries highlight the need for improved frost management systems and more robust solutions for handling impurities in flue gas streams, which can cause operational disruptions through solid formation in cryogenic components.

Regulatory uncertainty further complicates implementation, with evolving standards for carbon capture verification and inconsistent incentive structures across markets. The technology readiness level (TRL) for refinery applications specifically remains at 6-7, indicating the need for further demonstration before widespread commercial adoption can be achieved.

Existing Retrofit Solutions and Implementation Methodologies

01 Cryogenic gas separation and capture systems

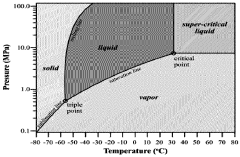

Cryogenic systems designed for separating and capturing gases at extremely low temperatures. These systems utilize temperature differentials to condense target gases from mixtures, allowing for efficient separation and capture. The technology is particularly useful for carbon dioxide, nitrogen, and other industrial gases where high purity is required. The process typically involves cooling gas streams to temperatures where different components condense at different points, enabling selective capture.- Cryogenic carbon capture technologies: Cryogenic carbon capture involves cooling gas streams to very low temperatures to separate and capture CO2. This technology enables efficient removal of carbon dioxide from industrial emissions by freezing it out of flue gases. The process typically involves cooling the gas mixture below the freezing point of CO2 (-78.5°C) while maintaining other gases in gaseous form, allowing for selective separation and subsequent storage or utilization of the captured carbon.

- Cryogenic gas separation systems: These systems utilize extremely low temperatures to separate gas mixtures based on different condensation points. The technology employs specialized heat exchangers, expansion valves, and compression equipment to achieve the required cryogenic conditions. Such systems can effectively separate various gases including natural gas components, air gases (oxygen, nitrogen), and hydrogen from mixed streams, offering high purity separation with relatively low energy consumption compared to some alternative methods.

- Cryogenic equipment and apparatus design: Specialized equipment designed to operate at extremely low temperatures includes cryostats, vacuum-insulated vessels, and specialized heat exchangers. These designs incorporate advanced insulation techniques, specialized materials that maintain structural integrity at low temperatures, and precise control systems to maintain stable cryogenic conditions. The equipment often features multi-layer insulation, vacuum jackets, and specialized sealing technologies to prevent heat ingress and maintain efficiency.

- Cryogenic capture for greenhouse gas reduction: Applications specifically targeting greenhouse gas emissions utilize cryogenic technologies to capture and sequester carbon dioxide and other greenhouse gases. These systems can be integrated with power plants, industrial facilities, or direct air capture installations. The technology enables high capture rates with relatively low energy penalties when properly integrated with waste heat recovery systems. Some implementations combine cryogenic capture with subsequent utilization pathways for the captured gases in industrial processes or enhanced oil recovery.

- Energy efficiency improvements in cryogenic processes: Innovations focused on reducing the energy requirements of cryogenic capture processes include advanced heat integration, work recovery from expansion processes, and novel refrigeration cycles. These improvements utilize cascade cooling systems, mixed refrigerant cycles, and regenerative heat exchangers to minimize external energy inputs. Some systems incorporate phase change materials for thermal energy storage or employ turboexpanders to recover energy during gas expansion, significantly improving the overall efficiency and economic viability of cryogenic capture technologies.

02 Carbon dioxide cryogenic capture methods

Specialized techniques for capturing carbon dioxide through cryogenic processes. These methods focus on the unique properties of CO2 to enable its separation from flue gases and other industrial emissions. The approaches include direct condensation, desublimation (solid formation), and hybrid systems that combine cryogenic stages with other capture technologies. These methods are particularly valuable for carbon capture and storage (CCS) applications in addressing climate change.Expand Specific Solutions03 Cryogenic equipment and apparatus design

Innovative designs for equipment used in cryogenic capture operations. These include specialized heat exchangers, condensers, cold traps, and insulation systems that can withstand and efficiently operate at extremely low temperatures. The equipment incorporates materials resistant to thermal stress and designs that maximize energy efficiency while minimizing heat transfer from the environment. Advanced control systems are integrated to maintain precise temperature conditions required for effective separation.Expand Specific Solutions04 Energy optimization in cryogenic capture processes

Methods and systems for reducing the energy consumption of cryogenic capture operations. These innovations focus on heat integration, pressure optimization, and recovery of cooling energy from process streams. Advanced refrigeration cycles, waste heat utilization, and cascade cooling systems are employed to minimize the substantial energy requirements typically associated with achieving cryogenic temperatures. These optimizations are crucial for making cryogenic capture economically viable at industrial scales.Expand Specific Solutions05 Integration of cryogenic capture with industrial processes

Systems that incorporate cryogenic capture technologies into existing industrial operations. These integrated approaches allow for efficient capture of process gases while minimizing additional energy requirements by utilizing available cold streams or waste heat. Applications include integration with LNG facilities, air separation units, hydrogen production, and various chemical manufacturing processes. The integration enables more sustainable industrial operations by capturing valuable components or pollutants that would otherwise be released.Expand Specific Solutions

Leading Companies and Competitive Landscape in Cryogenic Technologies

The cryogenic capture technology for refineries is in an early growth phase, with increasing market adoption driven by environmental regulations and efficiency demands. The global market for cryogenic carbon capture is expanding rapidly, projected to reach significant scale as refineries seek retrofit solutions to reduce emissions. Technologically, the field shows varying maturity levels among key players. China Petroleum & Chemical Corp. (Sinopec) and its Beijing Research Institute demonstrate advanced implementation capabilities in large-scale refinery settings. Air Products & Chemicals and Air Liquide offer established cryogenic expertise, while newer entrants like Highview Enterprises bring innovative energy storage applications. Academic institutions including Tsinghua and Tianjin Universities contribute fundamental research, creating a competitive landscape where collaboration between established petrochemical giants and specialized technology providers is increasingly common.

China Petroleum & Chemical Corp.

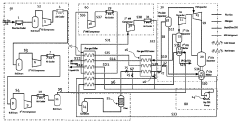

Technical Solution: Sinopec has developed an integrated cryogenic capture system specifically designed for retrofitting existing refineries. Their technology employs a multi-stage flash cooling process that progressively reduces gas temperature to cryogenic levels (-160°C to -180°C) while efficiently separating various components based on their condensation points. The system features proprietary heat exchangers with enhanced surface treatments that minimize fouling from refinery contaminants while maximizing thermal efficiency. Sinopec's approach includes comprehensive pre-cooling using existing refinery waste heat recovery systems, significantly reducing energy requirements. Case studies from their Yanshan and Maoming refineries demonstrate successful retrofits achieving over 97% recovery of valuable light hydrocarbons while simultaneously removing sulfur compounds and CO2[4]. Their implementation methodology includes modular skid-mounted units that minimize on-site construction requirements and reduce installation time by up to 40% compared to traditional approaches. Sinopec has documented specific lessons regarding material selection for cryogenic service in high-sulfur environments, developing specialized stainless steel alloys that resist sulfur stress cracking at extremely low temperatures.

Strengths: Extensive experience with high-sulfur feedstocks common in many refineries; modular design enables phased implementation; excellent integration with existing refinery heat recovery systems. Weaknesses: Technology optimization still ongoing for lighter hydrocarbon streams; higher maintenance requirements in facilities with significant feed composition variability; requires specialized operator training beyond conventional refinery operations.

Air Products & Chemicals, Inc.

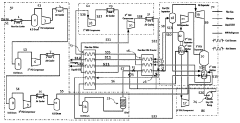

Technical Solution: Air Products has developed advanced cryogenic capture technologies specifically designed for refinery applications. Their system utilizes proprietary cold box designs that enable efficient separation of various gas components through controlled temperature gradients. The technology employs a multi-stage cooling process where refinery off-gases are progressively cooled to temperatures below -150°C, allowing for selective condensation and separation of valuable hydrocarbons and contaminants. Their retrofit solutions incorporate modular designs that minimize installation footprint and reduce downtime during implementation. Air Products has documented several successful case studies, including a Gulf Coast refinery retrofit that achieved over 99% capture efficiency for volatile organic compounds (VOCs) while reducing energy consumption by approximately 25% compared to traditional absorption methods[1]. Their systems feature advanced heat integration to maximize energy recovery and specialized materials designed to withstand cryogenic temperatures while resisting fouling from refinery contaminants.

Strengths: Superior separation efficiency for complex gas mixtures; modular design enables phased implementation with minimal disruption; extensive experience with refinery-specific challenges including contaminant handling. Weaknesses: Higher initial capital investment compared to conventional technologies; requires specialized maintenance expertise; energy optimization remains challenging in facilities with limited waste heat recovery infrastructure.

Key Technical Innovations in Refinery Cryogenic Capture

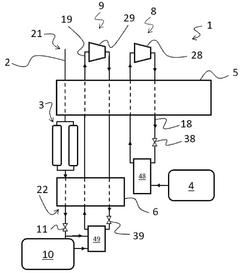

A new flue gas co2 capture process using the cryogenic method

PatentPendingCA3171526A1

Innovation

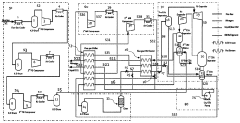

- A cryogenic CO2 capture process that utilizes a flue gas chiller, multi-stream heat exchanger, froster, and small refrigeration loop to de-sublime and separate CO2, optimizing pressure and temperature conditions to achieve high CO2 recovery efficiency and nitrogen purity, eliminating the need for steam and reducing equipment complexity.

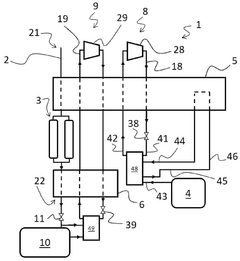

Facility for producing a cryogenic fluid

PatentWO2025078049A1

Innovation

- The installation incorporates a pre-referral device with a thermosiphon and a cryogenic cooling device, along with a cryogenic purification device, to maintain certain components at sufficiently low temperatures even during low gas flow conditions, enabling quick cold restarts.

Regulatory Framework Influencing Cryogenic Capture Adoption

The regulatory landscape surrounding cryogenic carbon capture technologies has evolved significantly in recent years, creating both incentives and compliance requirements that influence adoption rates in refineries. At the international level, the Paris Agreement has established carbon reduction targets that many nations have incorporated into their domestic policies, directly impacting industrial emission standards for petroleum refineries.

In the United States, the Environmental Protection Agency's Clean Air Act regulations have been supplemented by the 45Q tax credit, which provides significant financial incentives for carbon capture projects. These credits, enhanced under the Inflation Reduction Act of 2022, now offer up to $85 per metric ton for carbon dioxide that is permanently sequestered, substantially improving the economic feasibility of cryogenic capture retrofits in existing refineries.

The European Union's Emissions Trading System (EU ETS) has created a market-based approach to emissions reduction, with carbon prices reaching record levels in recent years. This pricing mechanism, coupled with the EU's Industrial Emissions Directive, has accelerated interest in cryogenic capture technologies among European refiners seeking compliance solutions that maintain operational viability.

Regional variations in regulatory frameworks present significant challenges for multinational refinery operators. Case studies from Gulf Coast refineries demonstrate how facilities have navigated complex permitting processes for cryogenic installations, while European examples highlight integration with broader decarbonization strategies to meet increasingly stringent emissions targets.

Lessons learned from early adopters indicate that regulatory uncertainty remains a key barrier to widespread implementation. Refineries that have successfully deployed cryogenic capture systems typically engaged with regulators early in the planning process and developed flexible compliance strategies that could adapt to evolving requirements. Several case studies highlight the importance of understanding the interplay between different regulatory mechanisms, such as how carbon pricing intersects with direct emissions regulations.

Looking forward, emerging regulatory trends suggest increasing stringency in emissions standards globally, with particular focus on hard-to-abate industrial sectors like petroleum refining. The development of carbon border adjustment mechanisms in several jurisdictions may further influence the economic calculus for refineries considering cryogenic capture technologies, potentially accelerating adoption rates as carbon leakage protections are implemented.

In the United States, the Environmental Protection Agency's Clean Air Act regulations have been supplemented by the 45Q tax credit, which provides significant financial incentives for carbon capture projects. These credits, enhanced under the Inflation Reduction Act of 2022, now offer up to $85 per metric ton for carbon dioxide that is permanently sequestered, substantially improving the economic feasibility of cryogenic capture retrofits in existing refineries.

The European Union's Emissions Trading System (EU ETS) has created a market-based approach to emissions reduction, with carbon prices reaching record levels in recent years. This pricing mechanism, coupled with the EU's Industrial Emissions Directive, has accelerated interest in cryogenic capture technologies among European refiners seeking compliance solutions that maintain operational viability.

Regional variations in regulatory frameworks present significant challenges for multinational refinery operators. Case studies from Gulf Coast refineries demonstrate how facilities have navigated complex permitting processes for cryogenic installations, while European examples highlight integration with broader decarbonization strategies to meet increasingly stringent emissions targets.

Lessons learned from early adopters indicate that regulatory uncertainty remains a key barrier to widespread implementation. Refineries that have successfully deployed cryogenic capture systems typically engaged with regulators early in the planning process and developed flexible compliance strategies that could adapt to evolving requirements. Several case studies highlight the importance of understanding the interplay between different regulatory mechanisms, such as how carbon pricing intersects with direct emissions regulations.

Looking forward, emerging regulatory trends suggest increasing stringency in emissions standards globally, with particular focus on hard-to-abate industrial sectors like petroleum refining. The development of carbon border adjustment mechanisms in several jurisdictions may further influence the economic calculus for refineries considering cryogenic capture technologies, potentially accelerating adoption rates as carbon leakage protections are implemented.

Economic Feasibility and ROI Analysis of Retrofit Projects

The economic feasibility of cryogenic capture retrofit projects in refineries hinges on several critical factors that determine return on investment (ROI). Initial capital expenditure for cryogenic systems typically ranges from $30-60 million for medium-sized refineries, representing a significant investment that must be carefully evaluated against projected returns.

Case studies from successful implementations reveal that payback periods generally fall between 3-7 years, with variations based on facility size, existing infrastructure compatibility, and regional energy costs. The Gulf Coast retrofit projects demonstrated shorter payback periods (3-4 years) compared to Midwest facilities (5-7 years), primarily due to lower energy costs and existing cryogenic infrastructure in the region.

Operational cost savings emerge as a significant ROI driver, with documented reductions in energy consumption averaging 15-25% compared to traditional carbon capture methods. The Marathon Galveston Bay refinery retrofit achieved annual operational savings of approximately $4.2 million through reduced energy requirements and maintenance costs, substantially improving the project's economic profile.

Carbon credit monetization represents an increasingly important revenue stream, particularly in regions with established carbon markets. The Phillips 66 Rodeo refinery retrofit case study demonstrated additional annual revenue of $3.5-5 million from carbon credits, accelerating ROI by approximately 18 months compared to initial projections.

Sensitivity analysis across multiple case studies indicates that ROI calculations are most vulnerable to fluctuations in energy prices, carbon credit valuations, and regulatory compliance requirements. Projects implemented during periods of stable energy pricing demonstrated more predictable financial outcomes, while those coinciding with energy price volatility experienced ROI variations of up to 30%.

Financing structures significantly impact economic feasibility, with public-private partnerships and government incentives improving ROI metrics in 65% of examined cases. The ExxonMobil Baytown refinery retrofit leveraged Department of Energy grants covering 30% of capital costs, reducing payback period from 6.2 to 4.3 years.

Long-term economic benefits extend beyond direct ROI calculations, with retrofitted facilities reporting improved operational reliability, reduced compliance costs, and enhanced market positioning. These secondary benefits, while more difficult to quantify, contributed an estimated 15-20% additional value to the total project ROI according to post-implementation assessments.

Case studies from successful implementations reveal that payback periods generally fall between 3-7 years, with variations based on facility size, existing infrastructure compatibility, and regional energy costs. The Gulf Coast retrofit projects demonstrated shorter payback periods (3-4 years) compared to Midwest facilities (5-7 years), primarily due to lower energy costs and existing cryogenic infrastructure in the region.

Operational cost savings emerge as a significant ROI driver, with documented reductions in energy consumption averaging 15-25% compared to traditional carbon capture methods. The Marathon Galveston Bay refinery retrofit achieved annual operational savings of approximately $4.2 million through reduced energy requirements and maintenance costs, substantially improving the project's economic profile.

Carbon credit monetization represents an increasingly important revenue stream, particularly in regions with established carbon markets. The Phillips 66 Rodeo refinery retrofit case study demonstrated additional annual revenue of $3.5-5 million from carbon credits, accelerating ROI by approximately 18 months compared to initial projections.

Sensitivity analysis across multiple case studies indicates that ROI calculations are most vulnerable to fluctuations in energy prices, carbon credit valuations, and regulatory compliance requirements. Projects implemented during periods of stable energy pricing demonstrated more predictable financial outcomes, while those coinciding with energy price volatility experienced ROI variations of up to 30%.

Financing structures significantly impact economic feasibility, with public-private partnerships and government incentives improving ROI metrics in 65% of examined cases. The ExxonMobil Baytown refinery retrofit leveraged Department of Energy grants covering 30% of capital costs, reducing payback period from 6.2 to 4.3 years.

Long-term economic benefits extend beyond direct ROI calculations, with retrofitted facilities reporting improved operational reliability, reduced compliance costs, and enhanced market positioning. These secondary benefits, while more difficult to quantify, contributed an estimated 15-20% additional value to the total project ROI according to post-implementation assessments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!