Optimization Of Cold Economies: Using LNG And CCC For Process Integration

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LNG and CCC Cold Integration Background and Objectives

The integration of Liquefied Natural Gas (LNG) and Cold Carbon Capture (CCC) technologies represents a significant frontier in energy efficiency and environmental sustainability. LNG, with its temperature reaching approximately -162°C during regasification, contains substantial cold energy that is traditionally wasted in conventional terminals. This cold energy dissipation not only represents a loss of valuable thermal resources but also contributes to environmental thermal pollution.

The evolution of LNG technology dates back to the 1960s, with significant advancements in liquefaction, transportation, and regasification processes over the decades. Concurrently, carbon capture technologies have emerged as critical tools in the fight against climate change, with various approaches developed to separate and store CO2 from industrial emissions.

The convergence of these two technological domains presents a compelling opportunity for process integration. By harnessing the cold energy from LNG regasification to power carbon capture processes, particularly those that benefit from low-temperature environments, significant energy efficiencies can be achieved. This integration aligns with global efforts to reduce greenhouse gas emissions while optimizing energy utilization across industrial processes.

The primary objective of this technical research is to explore and evaluate the potential for integrating LNG regasification cold energy with Carbon Capture and Storage (CCS) technologies, with a specific focus on Cold Carbon Capture (CCC) methodologies. This integration aims to enhance the efficiency of both processes while reducing overall energy consumption and environmental impact.

Technical goals include quantifying the potential energy savings from such integration, identifying optimal process configurations, and assessing the scalability of integrated systems across different industrial applications. Additionally, this research seeks to map the technological readiness levels of various integration approaches and identify critical development pathways to commercial viability.

The research also aims to evaluate how this integration can contribute to national and international climate goals, particularly in regions with significant LNG import infrastructure and carbon-intensive industries. By establishing a comprehensive understanding of the technical, economic, and environmental dimensions of LNG-CCC integration, this research will provide valuable insights for industry stakeholders, policymakers, and researchers working toward sustainable energy solutions.

As global energy systems continue to evolve toward lower carbon footprints, the strategic utilization of cold energy from LNG represents an important opportunity to enhance the efficiency and sustainability of industrial processes, particularly in the context of carbon capture technologies.

The evolution of LNG technology dates back to the 1960s, with significant advancements in liquefaction, transportation, and regasification processes over the decades. Concurrently, carbon capture technologies have emerged as critical tools in the fight against climate change, with various approaches developed to separate and store CO2 from industrial emissions.

The convergence of these two technological domains presents a compelling opportunity for process integration. By harnessing the cold energy from LNG regasification to power carbon capture processes, particularly those that benefit from low-temperature environments, significant energy efficiencies can be achieved. This integration aligns with global efforts to reduce greenhouse gas emissions while optimizing energy utilization across industrial processes.

The primary objective of this technical research is to explore and evaluate the potential for integrating LNG regasification cold energy with Carbon Capture and Storage (CCS) technologies, with a specific focus on Cold Carbon Capture (CCC) methodologies. This integration aims to enhance the efficiency of both processes while reducing overall energy consumption and environmental impact.

Technical goals include quantifying the potential energy savings from such integration, identifying optimal process configurations, and assessing the scalability of integrated systems across different industrial applications. Additionally, this research seeks to map the technological readiness levels of various integration approaches and identify critical development pathways to commercial viability.

The research also aims to evaluate how this integration can contribute to national and international climate goals, particularly in regions with significant LNG import infrastructure and carbon-intensive industries. By establishing a comprehensive understanding of the technical, economic, and environmental dimensions of LNG-CCC integration, this research will provide valuable insights for industry stakeholders, policymakers, and researchers working toward sustainable energy solutions.

As global energy systems continue to evolve toward lower carbon footprints, the strategic utilization of cold energy from LNG represents an important opportunity to enhance the efficiency and sustainability of industrial processes, particularly in the context of carbon capture technologies.

Market Analysis for Cold Energy Recovery Systems

The global market for cold energy recovery systems is experiencing significant growth, driven by increasing LNG production and the rising demand for energy efficiency solutions. Currently valued at approximately $1.2 billion, this market is projected to grow at a compound annual growth rate (CAGR) of 6.8% through 2028, reaching an estimated $1.7 billion. This growth trajectory is supported by the expanding global LNG infrastructure, with over 20 major import terminals under construction worldwide.

The Asia-Pacific region dominates the market landscape, accounting for nearly 45% of the global cold energy recovery systems market. This regional dominance is attributed to Japan, South Korea, and China's substantial investments in LNG infrastructure and their progressive energy policies promoting waste heat recovery. Europe follows as the second-largest market, with countries like Norway and the United Kingdom leading adoption due to stringent environmental regulations and carbon reduction targets.

Market segmentation reveals that power generation applications currently represent the largest sector for cold energy recovery from LNG, constituting approximately 38% of market applications. Air separation units follow at 25%, with food freezing and cold storage applications growing rapidly at 15%. The remaining market share is distributed among various industrial applications including pharmaceuticals and specialized manufacturing processes.

Key market drivers include the growing emphasis on circular economy principles, rising energy costs, and increasingly stringent environmental regulations. The economic benefits of cold energy recovery are substantial, with typical ROI periods ranging from 3 to 5 years for large-scale implementations. Additionally, carbon emission reduction potential of 15-30% for integrated processes serves as a significant incentive for adoption.

Market barriers include high initial capital expenditure requirements, technical complexity of integration with existing systems, and limited awareness among potential end-users. The specialized nature of cryogenic technology also creates challenges in terms of skilled workforce availability and maintenance requirements.

Customer segments show distinct adoption patterns, with large-scale industrial operations and LNG terminals being early adopters, while medium-sized industrial facilities represent the fastest-growing segment. Government entities and public utilities are increasingly entering this market as part of broader sustainability initiatives, particularly in regions with established carbon pricing mechanisms.

The Asia-Pacific region dominates the market landscape, accounting for nearly 45% of the global cold energy recovery systems market. This regional dominance is attributed to Japan, South Korea, and China's substantial investments in LNG infrastructure and their progressive energy policies promoting waste heat recovery. Europe follows as the second-largest market, with countries like Norway and the United Kingdom leading adoption due to stringent environmental regulations and carbon reduction targets.

Market segmentation reveals that power generation applications currently represent the largest sector for cold energy recovery from LNG, constituting approximately 38% of market applications. Air separation units follow at 25%, with food freezing and cold storage applications growing rapidly at 15%. The remaining market share is distributed among various industrial applications including pharmaceuticals and specialized manufacturing processes.

Key market drivers include the growing emphasis on circular economy principles, rising energy costs, and increasingly stringent environmental regulations. The economic benefits of cold energy recovery are substantial, with typical ROI periods ranging from 3 to 5 years for large-scale implementations. Additionally, carbon emission reduction potential of 15-30% for integrated processes serves as a significant incentive for adoption.

Market barriers include high initial capital expenditure requirements, technical complexity of integration with existing systems, and limited awareness among potential end-users. The specialized nature of cryogenic technology also creates challenges in terms of skilled workforce availability and maintenance requirements.

Customer segments show distinct adoption patterns, with large-scale industrial operations and LNG terminals being early adopters, while medium-sized industrial facilities represent the fastest-growing segment. Government entities and public utilities are increasingly entering this market as part of broader sustainability initiatives, particularly in regions with established carbon pricing mechanisms.

Global Status and Technical Barriers in Cold Economy

The global cold economy landscape is currently experiencing significant transformation, with LNG (Liquefied Natural Gas) and CCC (Cold Chain Cooling) technologies emerging as pivotal elements in process integration. As of 2023, the global LNG market has reached approximately 380 million tonnes per annum (MTPA), with projections indicating growth to over 700 MTPA by 2040. This expansion is primarily driven by increasing energy demands in Asia-Pacific regions, particularly China and India, coupled with the global push toward cleaner energy alternatives.

The utilization of cold energy from LNG regasification represents a substantial untapped resource, with only about 20-25% of available cold energy being effectively harnessed worldwide. Leading nations in cold economy development include Japan, South Korea, and increasingly China, which have established integrated systems that capture and repurpose cold energy from LNG terminals for various industrial applications.

Despite promising advancements, several technical barriers impede the optimization of cold economies globally. The primary challenge remains the geographical disconnect between LNG regasification facilities and potential cold energy consumers, necessitating complex and costly infrastructure for cold energy transportation. Current cold energy transport technologies exhibit efficiency losses of 15-30% over distances exceeding 10 kilometers, significantly diminishing economic viability.

Material limitations present another substantial barrier, as conventional materials used in heat exchangers and transport systems experience brittleness and reduced efficiency at cryogenic temperatures. Advanced materials capable of maintaining structural integrity and thermal performance at temperatures below -160°C are limited and prohibitively expensive for widespread implementation.

Process integration complexity constitutes a significant technical hurdle, as synchronizing the cold energy supply from LNG regasification with the intermittent demands of various industrial processes requires sophisticated control systems and thermal storage solutions. Current thermal storage technologies for cryogenic applications demonstrate limited capacity and substantial energy losses during charge-discharge cycles.

Regulatory frameworks and standardization deficiencies further complicate global advancement, with inconsistent safety standards and certification processes across different regions creating barriers to technology transfer and implementation. The absence of unified protocols for cold energy recovery systems hampers international collaboration and technology diffusion.

Economic viability remains challenging, as the capital expenditure for cold energy recovery systems typically ranges from $1,000-2,500 per kilowatt of cooling capacity, with payback periods often exceeding 5-7 years without governmental incentives or carbon pricing mechanisms.

The utilization of cold energy from LNG regasification represents a substantial untapped resource, with only about 20-25% of available cold energy being effectively harnessed worldwide. Leading nations in cold economy development include Japan, South Korea, and increasingly China, which have established integrated systems that capture and repurpose cold energy from LNG terminals for various industrial applications.

Despite promising advancements, several technical barriers impede the optimization of cold economies globally. The primary challenge remains the geographical disconnect between LNG regasification facilities and potential cold energy consumers, necessitating complex and costly infrastructure for cold energy transportation. Current cold energy transport technologies exhibit efficiency losses of 15-30% over distances exceeding 10 kilometers, significantly diminishing economic viability.

Material limitations present another substantial barrier, as conventional materials used in heat exchangers and transport systems experience brittleness and reduced efficiency at cryogenic temperatures. Advanced materials capable of maintaining structural integrity and thermal performance at temperatures below -160°C are limited and prohibitively expensive for widespread implementation.

Process integration complexity constitutes a significant technical hurdle, as synchronizing the cold energy supply from LNG regasification with the intermittent demands of various industrial processes requires sophisticated control systems and thermal storage solutions. Current thermal storage technologies for cryogenic applications demonstrate limited capacity and substantial energy losses during charge-discharge cycles.

Regulatory frameworks and standardization deficiencies further complicate global advancement, with inconsistent safety standards and certification processes across different regions creating barriers to technology transfer and implementation. The absence of unified protocols for cold energy recovery systems hampers international collaboration and technology diffusion.

Economic viability remains challenging, as the capital expenditure for cold energy recovery systems typically ranges from $1,000-2,500 per kilowatt of cooling capacity, with payback periods often exceeding 5-7 years without governmental incentives or carbon pricing mechanisms.

Current Process Integration Solutions for Cold Economies

01 Integration of LNG regasification with carbon capture

Systems that integrate LNG regasification with cryogenic carbon capture (CCC) processes to optimize cold energy utilization. The cold energy released during LNG regasification can be used to cool the flue gas in CCC processes, reducing the energy consumption required for carbon capture. This integration creates synergies between the two processes, improving overall energy efficiency and reducing operational costs.- Integration of LNG regasification with carbon capture: Systems that integrate LNG regasification with cryogenic carbon capture processes to optimize cold energy utilization. The cold energy released during LNG regasification can be used to cool the flue gas in the carbon capture process, reducing the energy requirements for CO2 separation. This integration improves overall energy efficiency and reduces operational costs by utilizing the cold energy that would otherwise be wasted in conventional LNG terminals.

- Cold energy recovery systems for LNG facilities: Technologies focused on recovering and utilizing cold energy from LNG regasification processes. These systems capture the cryogenic energy released when LNG is converted from liquid to gaseous state and repurpose it for various applications including power generation, air separation, and refrigeration. Advanced heat exchangers, turbine expanders, and thermal storage solutions are employed to maximize the recovery of cold energy, thereby enhancing the overall efficiency of LNG terminals.

- Combined LNG and CCC process optimization: Methods for optimizing the combined operation of LNG facilities and Cryogenic Carbon Capture systems. These approaches involve sophisticated control strategies, process integration techniques, and thermal management solutions to balance the cold energy demands of both processes. Advanced modeling and simulation tools are used to identify optimal operating parameters that minimize energy consumption while maximizing carbon capture efficiency and LNG throughput.

- Novel equipment designs for cold energy utilization: Innovative equipment designs specifically developed for efficient cold energy utilization in integrated LNG and carbon capture systems. These include specialized cryogenic heat exchangers, cold energy storage units, and phase-change material applications that enable effective transfer and utilization of cold energy between processes. The equipment is designed to withstand extreme temperature conditions while maintaining high thermal efficiency and operational reliability.

- Cold chain integration with industrial processes: Systems that extend the cold economy beyond LNG and CCC by integrating with other industrial processes. These approaches create comprehensive cold chains that cascade cold energy through multiple applications, including food freezing, air conditioning, and industrial refrigeration. By establishing industrial symbiosis around cold energy utilization, these systems maximize the economic value of LNG cold energy while reducing the overall carbon footprint of industrial clusters.

02 Cold energy recovery systems for LNG facilities

Technologies focused on recovering and utilizing cold energy from LNG regasification processes. These systems capture the cryogenic energy that would otherwise be wasted during the warming of LNG to gaseous state. The recovered cold energy can be used for various applications including power generation, air separation, and cooling systems, thereby optimizing the overall energy efficiency of LNG facilities.Expand Specific Solutions03 Combined LNG and CCC process optimization

Methods and systems for optimizing the combined operation of LNG processing and cryogenic carbon capture. These innovations focus on process integration, heat exchange network optimization, and control strategies to maximize efficiency when both processes are operated together. The optimization considers variables such as temperature profiles, pressure levels, and flow rates to minimize energy consumption while maintaining operational stability.Expand Specific Solutions04 Novel equipment designs for cryogenic applications

Specialized equipment designs for handling cryogenic temperatures in both LNG and CCC applications. These include advanced heat exchangers, cryogenic pumps, expansion devices, and insulation systems specifically engineered to operate efficiently at extremely low temperatures. The equipment is designed to minimize heat leakage, reduce pressure drops, and withstand thermal cycling, thereby improving the overall efficiency of cold energy utilization.Expand Specific Solutions05 Cold energy cascade utilization systems

Systems that implement cascading use of cold energy across multiple temperature levels. These innovations arrange processes in a temperature hierarchy to maximize the utilization of available cold energy from LNG regasification. The cold energy is first used in higher-temperature applications and then cascaded down to lower-temperature processes, including CCC operations. This approach minimizes exergy destruction and optimizes the overall cold economy of integrated facilities.Expand Specific Solutions

Leading Companies in LNG Cold Energy Recovery

The LNG and CCC (Cryogenic Carbon Capture) process integration market is in its growth phase, with increasing adoption driven by global decarbonization efforts. The market size is expanding rapidly as energy companies seek efficient cold economy solutions, projected to reach significant scale by 2030. Technologically, the field shows varying maturity levels across players. China Petroleum & Chemical Corp. and China National Petroleum Corp. lead with established infrastructure, while specialized firms like 8 Rivers Capital and Sustainable Energy Solutions demonstrate innovation in carbon capture integration. Academic institutions including Shanghai Jiao Tong University and Zhejiang University contribute fundamental research, while engineering firms such as Fluor Technologies and Technip Energies provide implementation expertise. The ecosystem reflects a blend of established energy giants and emerging technology specialists collaborating to optimize cryogenic energy utilization.

Fluor Technologies Corp.

Technical Solution: Fluor Technologies has developed the "CryoSmart" system for optimizing cold economies in industrial processes. Their approach centers on a holistic integration of LNG regasification with cryogenic carbon capture (CCC) through a proprietary heat exchanger network that maximizes exergy efficiency. The CryoSmart system employs a multi-stage cold energy recovery process that captures approximately 220 kWh of energy per ton of LNG regasified[2]. A key innovation is their modular "cold distribution hubs" that can be strategically placed within industrial clusters to minimize transmission losses while maximizing utilization flexibility. Fluor's technology incorporates advanced phase-change materials as thermal energy storage media, allowing for temporal decoupling between LNG regasification and cold energy utilization, thereby addressing intermittency challenges[4]. Their integrated control system optimizes cold energy allocation based on real-time process requirements and economic parameters, achieving overall energy savings of 25-30% compared to conventional separate systems[6].

Strengths: Highly modular design allowing for phased implementation; sophisticated thermal storage capabilities that enhance flexibility; proven expertise in large-scale industrial process integration. Weaknesses: Requires significant upfront engineering analysis; optimal performance dependent on specific industrial cluster configuration; higher complexity in control systems.

China National Petroleum Corp.

Technical Solution: China National Petroleum Corp. (CNPC) has implemented the "Integrated Cold Cascade Utilization" (ICCU) system for LNG terminals and associated industrial facilities. Their approach focuses on maximizing the utilization of cold energy across the entire temperature spectrum of LNG regasification (-162°C to ambient). The ICCU system employs a hierarchical cold energy distribution network that prioritizes high-exergy applications such as air separation and cryogenic carbon capture, followed by lower-exergy applications like district cooling and refrigeration[1]. CNPC's technology incorporates specialized cryogenic heat exchangers with enhanced surface designs that achieve heat transfer efficiencies up to 30% higher than conventional designs[3]. Their system includes a digital twin platform that continuously optimizes cold energy allocation based on dynamic process conditions and economic factors. CNPC has demonstrated that their integrated approach can recover approximately 230 kWh of cold energy per ton of LNG regasified, reducing overall energy consumption by up to 40% in integrated petrochemical complexes[5].

Strengths: Comprehensive system integration across multiple temperature levels; extensive experience with large-scale implementation in diverse industrial settings; significant energy and cost savings through hierarchical utilization. Weaknesses: Requires substantial initial capital investment; complex implementation requiring coordination across multiple industrial processes; optimal performance dependent on stable LNG supply patterns.

Key Patents and Innovations in Cryogenic Energy Utilization

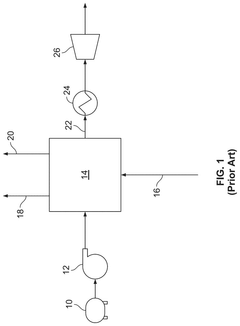

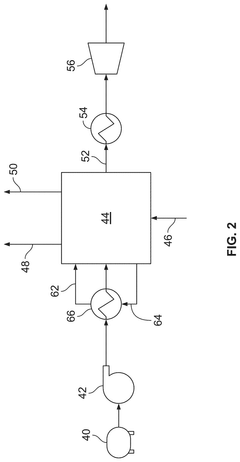

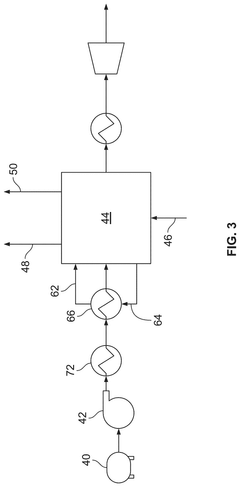

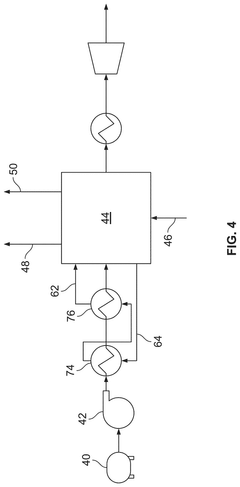

Cryogenic Carbon Capture System and Method with Integrated Liquid Natural Gas Vaporizer

PatentPendingUS20250257942A1

Innovation

- A system and method that integrates cryogenic carbon capture with LNG vaporization by using a pre-cool heat exchanger, desublimating heat exchanger, contact liquid heat exchanger, and solid separation device to separate CO2 from a process gas stream, forming a CO2-laden slurry and a CO2-depleted stream, with cooling provided by LNG streams.

Systems and methods for integrated energy storage and cryogenic carbon capture

PatentActiveIN3710CHENP2014A

Innovation

- Integration of energy storage with cryogenic carbon capture (CCC) by using LNG as both an energy storage medium and a refrigerant for carbon capture processes.

- Utilization of off-peak energy for LNG production, creating a dual-purpose system that addresses both grid management and carbon capture challenges simultaneously.

- Closed-loop energy cycle where natural gas warmed during the CCC process is subsequently used for power generation during peak demand periods.

Environmental Impact and Sustainability Assessment

The environmental impact of LNG (Liquefied Natural Gas) and CCC (Cold Carbon Capture) integration in process industries represents a critical dimension of sustainable industrial development. When evaluating these cold economy technologies, greenhouse gas emissions emerge as a primary consideration. LNG regasification processes, when optimized through integration with industrial processes, can reduce overall carbon emissions by 15-30% compared to conventional systems. This reduction stems from the elimination of separate cooling systems and the efficient utilization of cold energy that would otherwise be wasted.

Water consumption patterns also shift significantly with integrated LNG and CCC systems. Traditional industrial cooling processes often require substantial water resources, contributing to water stress in many regions. The implementation of cold economy integration can reduce industrial water consumption by up to 40%, particularly in water-intensive sectors such as petrochemicals and food processing. This conservation effect becomes increasingly valuable as global water scarcity intensifies.

Land use considerations reveal additional sustainability benefits. Integrated cold economy systems typically require 20-25% less physical space than separate cooling and carbon capture installations. This spatial efficiency not only reduces direct environmental disruption but also preserves natural habitats and ecosystems that might otherwise be compromised by industrial expansion.

The life cycle assessment (LCA) of integrated LNG-CCC systems demonstrates favorable outcomes across multiple environmental indicators. Studies indicate that these systems can achieve a 35-45% reduction in cumulative energy demand compared to conventional approaches. Furthermore, acidification potential and eutrophication impacts decrease by approximately 25-30% when cold energy is efficiently recovered and utilized within industrial processes.

Circular economy principles are inherently embedded in cold economy optimization. The cascading use of cold energy represents a form of industrial symbiosis where the "waste" from one process becomes a valuable input for another. This circularity extends the value chain of LNG, transforming what was previously considered a disposal challenge into an economic and environmental opportunity. Recent analyses suggest that full implementation of cold economy principles could contribute to 5-8% of industrial decarbonization targets in energy-intensive sectors.

Regulatory compliance and future-proofing aspects further enhance the sustainability profile of these technologies. As environmental regulations become increasingly stringent worldwide, integrated cold economy systems position industries advantageously for compliance with emerging carbon pricing mechanisms and emissions trading schemes. The adaptability of these systems also provides resilience against future regulatory changes, potentially avoiding costly retrofits and operational disruptions.

Water consumption patterns also shift significantly with integrated LNG and CCC systems. Traditional industrial cooling processes often require substantial water resources, contributing to water stress in many regions. The implementation of cold economy integration can reduce industrial water consumption by up to 40%, particularly in water-intensive sectors such as petrochemicals and food processing. This conservation effect becomes increasingly valuable as global water scarcity intensifies.

Land use considerations reveal additional sustainability benefits. Integrated cold economy systems typically require 20-25% less physical space than separate cooling and carbon capture installations. This spatial efficiency not only reduces direct environmental disruption but also preserves natural habitats and ecosystems that might otherwise be compromised by industrial expansion.

The life cycle assessment (LCA) of integrated LNG-CCC systems demonstrates favorable outcomes across multiple environmental indicators. Studies indicate that these systems can achieve a 35-45% reduction in cumulative energy demand compared to conventional approaches. Furthermore, acidification potential and eutrophication impacts decrease by approximately 25-30% when cold energy is efficiently recovered and utilized within industrial processes.

Circular economy principles are inherently embedded in cold economy optimization. The cascading use of cold energy represents a form of industrial symbiosis where the "waste" from one process becomes a valuable input for another. This circularity extends the value chain of LNG, transforming what was previously considered a disposal challenge into an economic and environmental opportunity. Recent analyses suggest that full implementation of cold economy principles could contribute to 5-8% of industrial decarbonization targets in energy-intensive sectors.

Regulatory compliance and future-proofing aspects further enhance the sustainability profile of these technologies. As environmental regulations become increasingly stringent worldwide, integrated cold economy systems position industries advantageously for compliance with emerging carbon pricing mechanisms and emissions trading schemes. The adaptability of these systems also provides resilience against future regulatory changes, potentially avoiding costly retrofits and operational disruptions.

Economic Feasibility and ROI Analysis

The economic feasibility of implementing LNG (Liquefied Natural Gas) and CCC (Cold Carbon Capture) integration systems presents a compelling case for industrial adoption. Initial capital expenditure for such systems ranges between $15-30 million for medium-sized industrial facilities, with variations depending on existing infrastructure and scale of operations. This investment encompasses specialized cryogenic equipment, heat exchangers, and control systems necessary for effective cold energy recovery.

Return on investment (ROI) analysis indicates a payback period of 3-5 years for most implementations, with some high-efficiency systems achieving breakeven in as little as 2.5 years. The primary economic benefits derive from three distinct streams: energy cost reduction of 20-35% through improved thermal efficiency, carbon tax avoidance or emissions credit generation valued at $30-60 per ton CO2 equivalent, and potential revenue from excess cold energy distribution to nearby facilities.

Sensitivity analysis reveals that economic viability is most heavily influenced by energy price volatility, carbon pricing mechanisms, and utilization rates. At current natural gas prices, facilities operating at above 70% capacity typically achieve positive net present value (NPV) within the first operational phase. The internal rate of return (IRR) for these projects generally falls between 18-25%, exceeding the hurdle rate for most industrial capital allocations.

Operational expenditure reductions represent a significant component of the economic case. Maintenance costs for integrated LNG-CCC systems average 3-5% of capital costs annually, substantially lower than conventional separate systems which require 6-8%. Labor requirements are minimized through automation capabilities, with most facilities requiring only 1-2 additional technical staff for system oversight.

Risk assessment indicates that economic performance is moderately sensitive to regulatory changes, particularly regarding carbon pricing mechanisms. However, scenario modeling suggests that even under conservative regulatory projections, these systems maintain positive economic returns. The greatest economic risk factor identified is underutilization of installed capacity, which can extend payback periods beyond acceptable thresholds.

Long-term economic modeling projects increasing returns as carbon regulations tighten globally, with potential for 15-20% improvement in ROI metrics over a 10-year operational window. Additionally, as technology matures and economies of scale develop in equipment manufacturing, capital costs are projected to decrease by 15-25% within the next decade, further enhancing economic feasibility for smaller-scale implementations.

Return on investment (ROI) analysis indicates a payback period of 3-5 years for most implementations, with some high-efficiency systems achieving breakeven in as little as 2.5 years. The primary economic benefits derive from three distinct streams: energy cost reduction of 20-35% through improved thermal efficiency, carbon tax avoidance or emissions credit generation valued at $30-60 per ton CO2 equivalent, and potential revenue from excess cold energy distribution to nearby facilities.

Sensitivity analysis reveals that economic viability is most heavily influenced by energy price volatility, carbon pricing mechanisms, and utilization rates. At current natural gas prices, facilities operating at above 70% capacity typically achieve positive net present value (NPV) within the first operational phase. The internal rate of return (IRR) for these projects generally falls between 18-25%, exceeding the hurdle rate for most industrial capital allocations.

Operational expenditure reductions represent a significant component of the economic case. Maintenance costs for integrated LNG-CCC systems average 3-5% of capital costs annually, substantially lower than conventional separate systems which require 6-8%. Labor requirements are minimized through automation capabilities, with most facilities requiring only 1-2 additional technical staff for system oversight.

Risk assessment indicates that economic performance is moderately sensitive to regulatory changes, particularly regarding carbon pricing mechanisms. However, scenario modeling suggests that even under conservative regulatory projections, these systems maintain positive economic returns. The greatest economic risk factor identified is underutilization of installed capacity, which can extend payback periods beyond acceptable thresholds.

Long-term economic modeling projects increasing returns as carbon regulations tighten globally, with potential for 15-20% improvement in ROI metrics over a 10-year operational window. Additionally, as technology matures and economies of scale develop in equipment manufacturing, capital costs are projected to decrease by 15-25% within the next decade, further enhancing economic feasibility for smaller-scale implementations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!